ASSEMBLY

OF

THE

I.F.

CIRCUIT BOARD PC-8

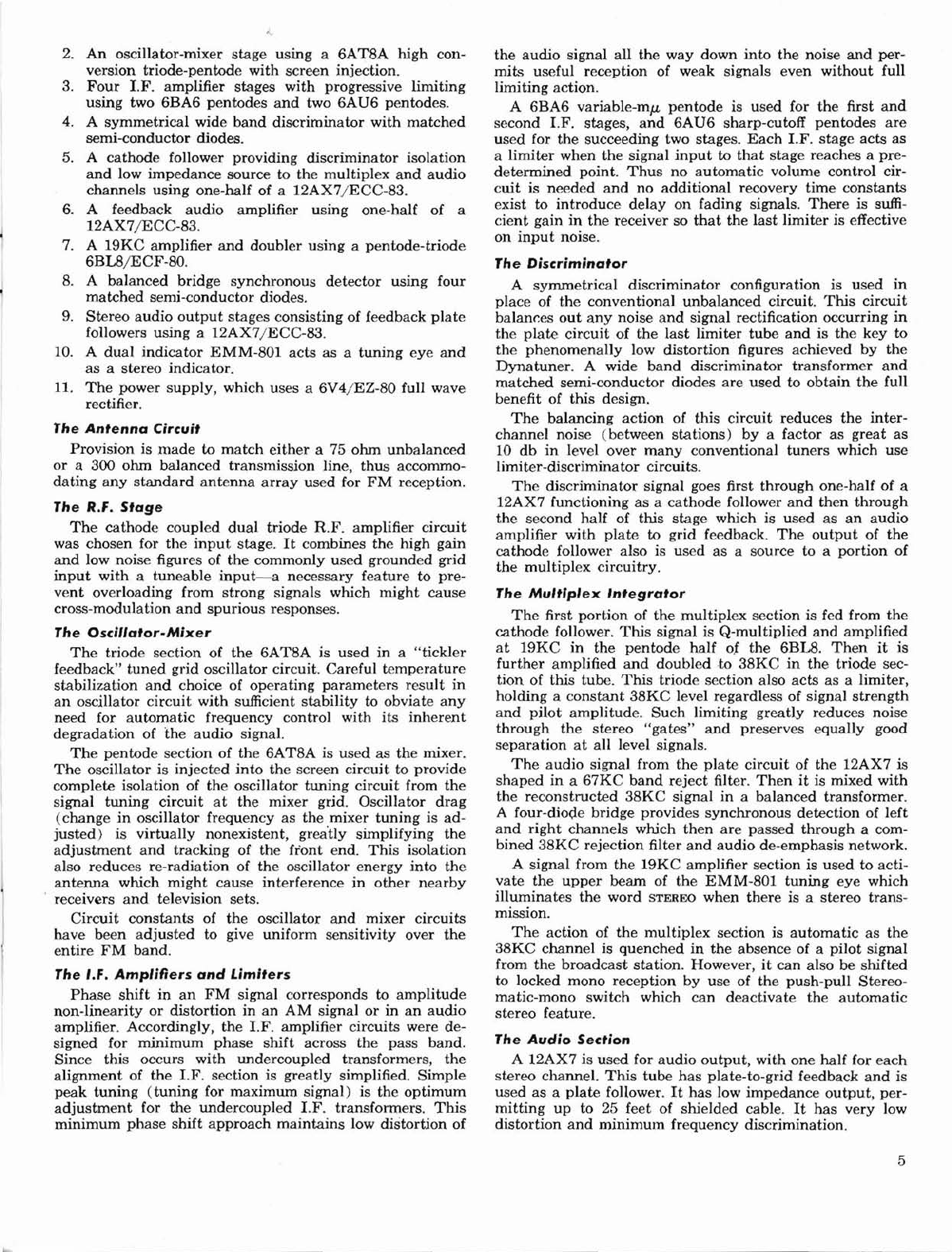

1(

J)

As before,

support

the

board

on

an

open

box

or

between two objects so

that

the

leads

may

project

below the board

as

you

insert

components.

Insert

all

of

the

one-half

watt

resistors,

after

bending

their

leads

as

before.

Be

sure

all

the

resistors

are

seated

firmly

against

the

board.

Tum

the

board

over

and

solder all of

the

leads.

Cut

off

the

excess.

J

2(,j )

Insert

the

one

watt

resistor R22,

the

two

watt

resistors

Rll

and

R13,

and

the four

heater

chokes L6, L7,

L8

and

L9.

Solder

these

in

place

and

trim

off

the

excess leads.

3(

j)

Mount

the

four seven

pin

sockets V3, V4, V5

and

V6.

Note

the

orientation of

the

flat side of

each

socket.

Be

sure each pin penetrates the board

and

does not bend over on top of the board.

Make

sure

that

each socket is

seated

firmly

against

the

board

and

then

solder

all seven pins

and

the

center

ground

pin

of each socket.

4

(/;

Mount

the

nine

pin

socket V7.

Be

sure each pin

penetrates the board

and

does not bend over on top

of

the board.

Seat

it

firmly,

and

solder all nine

pins

and

the

center

ground pin.

5

(J)

Install

capacitors C29

and

C31. Solder all four leads

and

cut

off

the

excess.

6

(J)

Install

all of

the

disc capacitors. As before, the leads

of these capacitors

may

be

bent

slightly to hold

them

in

place,

but

be careful

that

no "bridges"

are

formed

to

adjacent

parts

of the circuit.

Solder

all leads

and

cut

off

the

excess.

7(

I)

Install

PEC

555004, making sure

that

it

is correctly

oriented.

Solder

all three leads

and

cut

off the excess.

8( J)

Insert

the

remaining I.F. transformers

T2,

T3

and

T4

(all

432(01).

Follow

the

location of

the

indi-

cator

at

the top of each transformer

as

shown in

the

pictorial.

Solder

both tabs

and

all

four lugs

on

each

transformer. Avoid excessive solder, which

may

flow

into

the transformer

and

damage it.

The

dis-

criminator transformer

T5

will be

mounted

later.

9(

J)

Note

the orientation of the offset in

the

ground

straps

and

install them

in

each

tube

socket.

Solder

these ground straps.

LO

(

V)

Install

the

pilot light socket. Observe

that

the

con-

necting

tab

from

the

socket

center

contact

goes

into

the

hole

adjoining

eyelet

#20.

Do not install

it

backwards! Solder

both

tabs.

ASSEMBLY

OF

THE

MULTIPLEX BOARD

PC-l

2

1(

J)

Insert

the

one-half

watt

resistors R71

through

R93

in

their

places on

the

board

after

bending

their

leads

as

before. Solder

aU

leads

and

cut

off

the

excess.

2

(J)

Insert

capacitors C71 through C84 in

their

places

on

the

board. Solder all leads

and

cut

off the excess.

NOTE:

It

is

necessary

to

spread

the

leads

of

C76

to

fit

their

hole

spacing.

3 (

J)

Insert

the

two 9-pin sockets V71

and

V72.

Note

the

orientation of

the

flat

side

of

each

socket.

Be

sure

each

pin

penetrates the board

and

does not bend

over

on

top

of

the

board.

Seat

each socket firmly

to

the

board

and

then

solder all

nine

pins

on each

socket. Do not solder the center ground

pin

on

either socket at this time.

4

(rviInstali

the

small wooden wedge

under

the

choke

L71,

and

install L71 so

that

the

thick

part

of

the

wedge is

adjacent

to C81 when

the

choke leads

are

inserted

into

the board.

Solder

both leads

and

cut

off

the

excess.

5(

v)

Mount

the

transformers T71

and

T72

(432003). Be

careful

to

orient

these correctly.

Make

certain that

the indicator

on

top

of the transformer coincides

with

the heavy dash on the board

and

with the pic-

torial.

These

transformers

must

be

seated

firmly

against

the

board,

and

the

two mounting tabs

should

snap

into

place. Solder

both

mounting

tabs

and

all

four lugs

on

each

transforme:.:.

6

(J;

Mount

transformer

T73

(432(04) .

Note

that

this

transformer

can

be

mounted

only one way.

Seat

it

firmly so

that

it

snaps

into

position,

and

make cer-

tain

that

all

5connecting lugs,

as

well

as

the

two

mounting

tabs,

penetrate

the

board.

Do

not solder

lugs

#2

and

#3

as shown

in

the pictorial. Solder

both

mounting

tabs

and

the

other

three lugs.

7(

h

Mount

PEC-l

and

PEC-2

(555001).

Note

that

these identical

units

face in opposite directions.

Solder

all 6leads

and

cut

off

the

excess.

8

(J)

Note

the

orientation of

the

offset

in

the

ground

straps

and

install

them

in

each tube socket. Solder

these ground straps.

9 (

J)

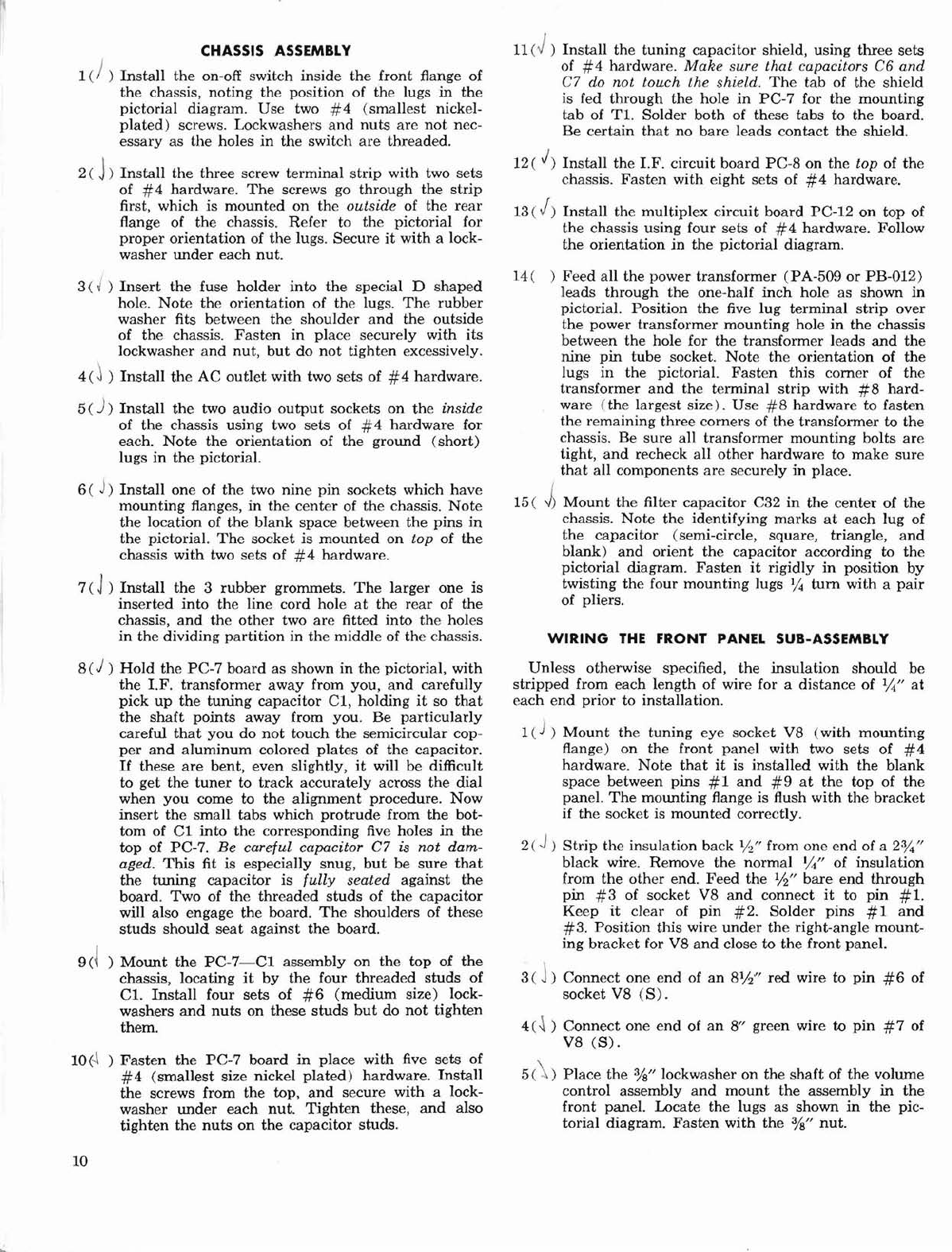

Observing detail

E,

mount

each of

the

four diodes

D71 through D74.

Those

supplied

may

look like

either

of those in

the

illustration,

and

will have

one

end

painted

red, or

marked

with three stripes.

(Disregard

single green dots

or

stripes.)

DIODE

POLARITY

IS

IMPORTANT.

The

arrowheads

on

the

PC-12 board

point

to

the

marked ends of

the

di-

odes. Diodes should be soldered carefully using the

following technique:

The

leads

should

be

bent

up,

and

looped down

in

the

manner

shown to provide a

"heat

sink."

When

soldering them, grasp

the

loop with a

pair

of pliers from

the top of

the

board to absorb

any

excess

heat,

and

solder from

the

bot-

tom of

the

board.

This

technique

prevents damage to

the

relatively

delicate diodes from excessive heat.

DETAIL

E

This

completes

the

assembly of

the

etched

circuit

boards.

Your

FM-3

is now

almost

half completed.

9