Dynabrade Dynangle 14200 User manual

Other Dynabrade Sander manuals

Dynabrade

Dynabrade 51611 Guide

Dynabrade

Dynabrade Dynabug 10278 Guide

Dynabrade

Dynabrade Dynorbital-Spirit 59000 Guide

Dynabrade

Dynabrade 55126 Guide

Dynabrade

Dynabrade 52900 Operating instructions

Dynabrade

Dynabrade Dynorbital 57600 User manual

Dynabrade

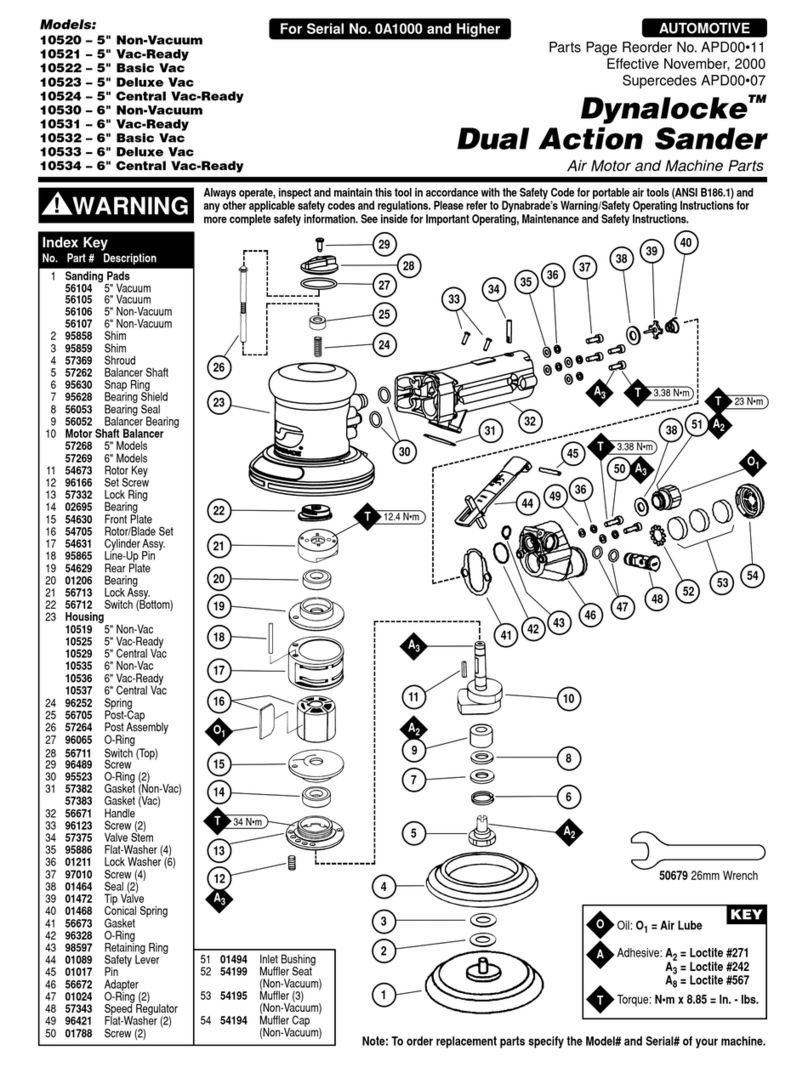

Dynabrade Dynalocke 10520 User manual

Dynabrade

Dynabrade 58441 User manual

Dynabrade

Dynabrade 58040 User manual

Dynabrade

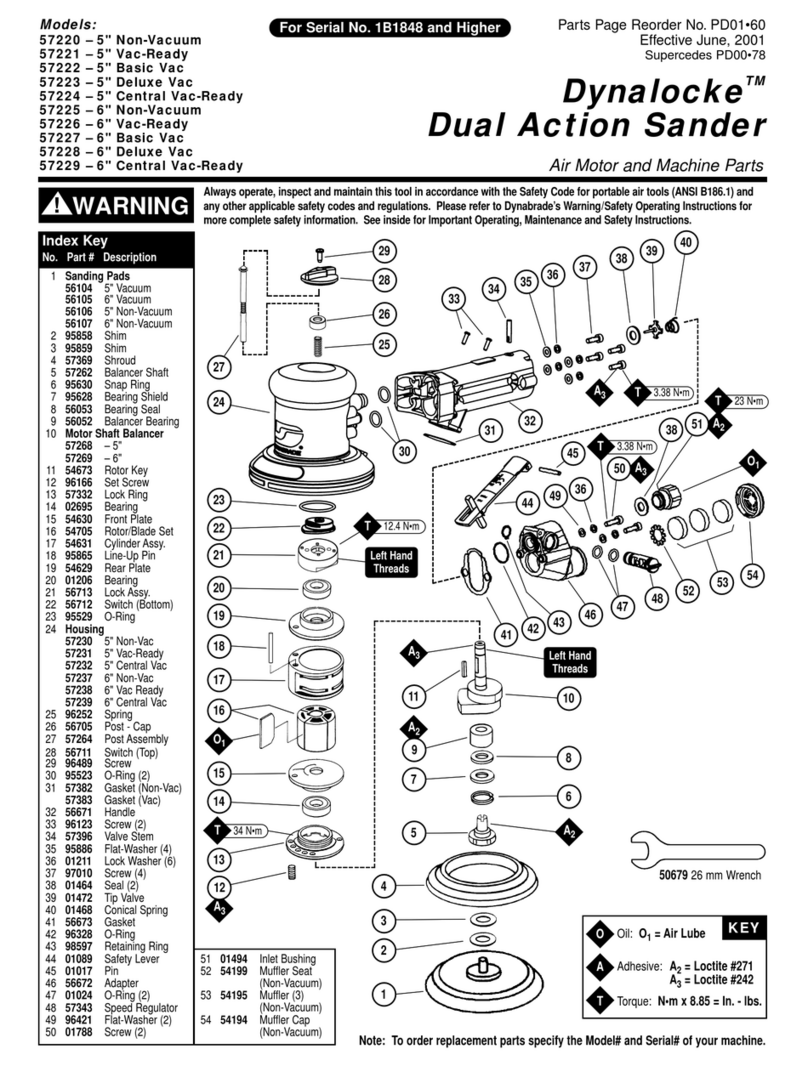

Dynabrade 57220 User guide

Dynabrade

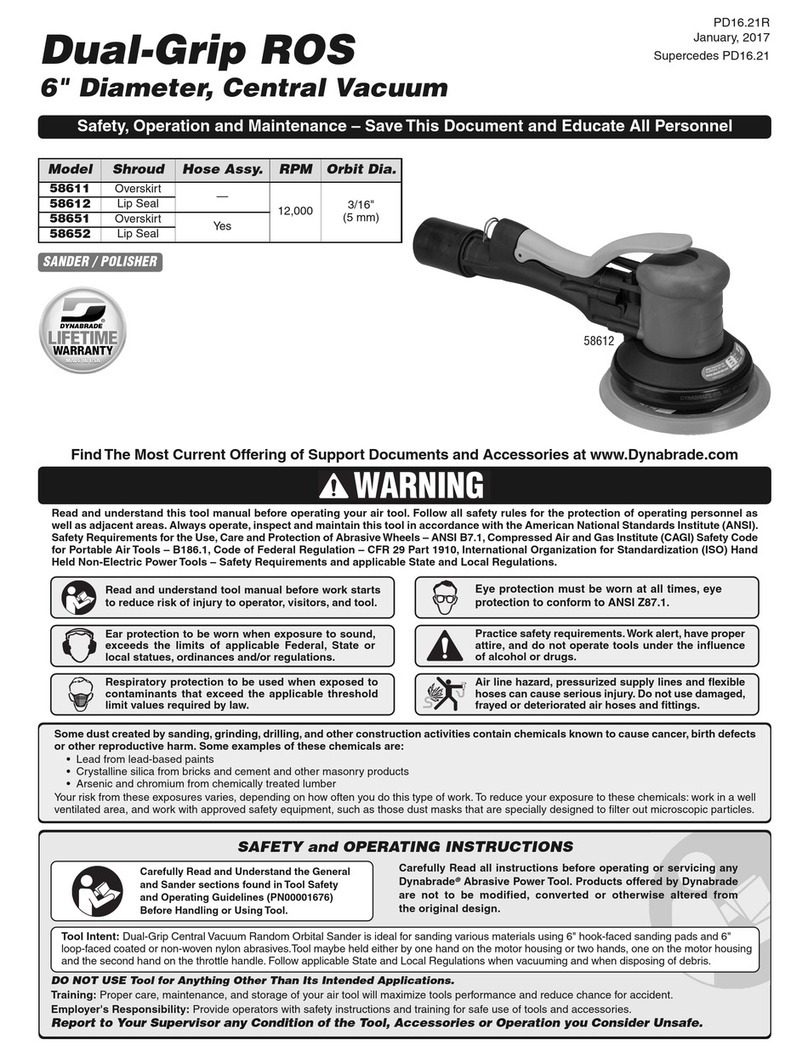

Dynabrade 58611 Guide

Dynabrade

Dynabrade Dynorbital Supreme 56800 Guide

Dynabrade

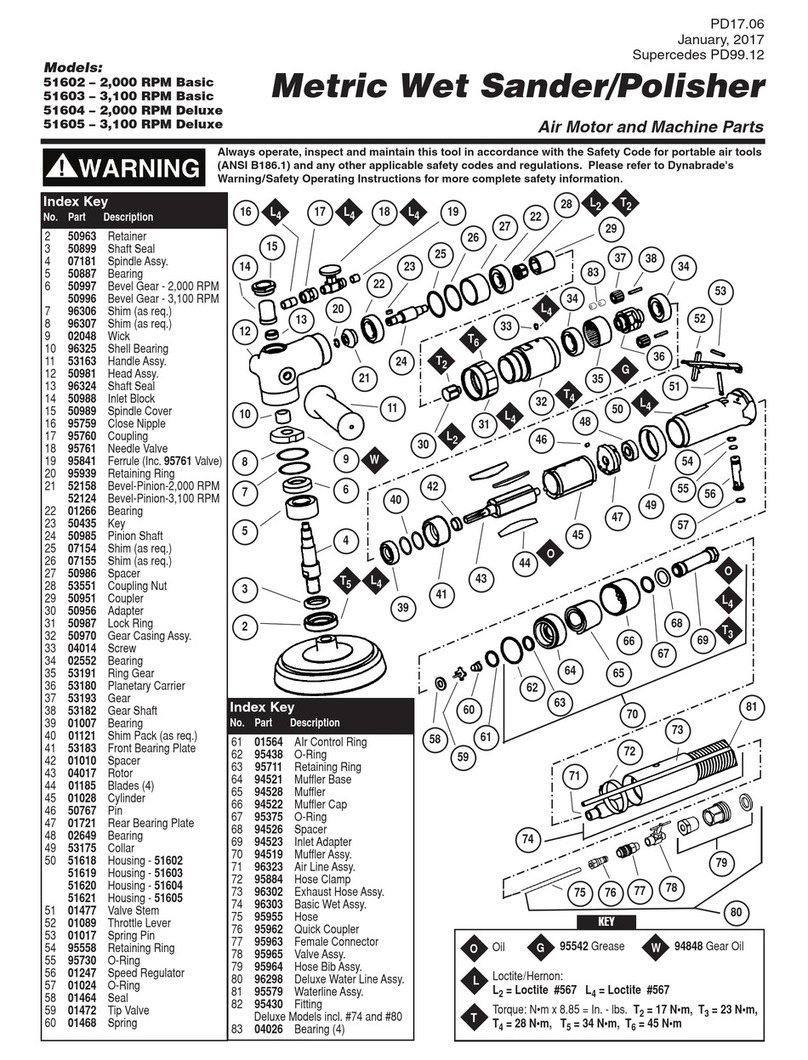

Dynabrade 51602 User manual

Dynabrade

Dynabrade Nitro ROB1 Series Guide

Dynabrade

Dynabrade 57400 User manual

Dynabrade

Dynabrade 51612 Guide

Dynabrade

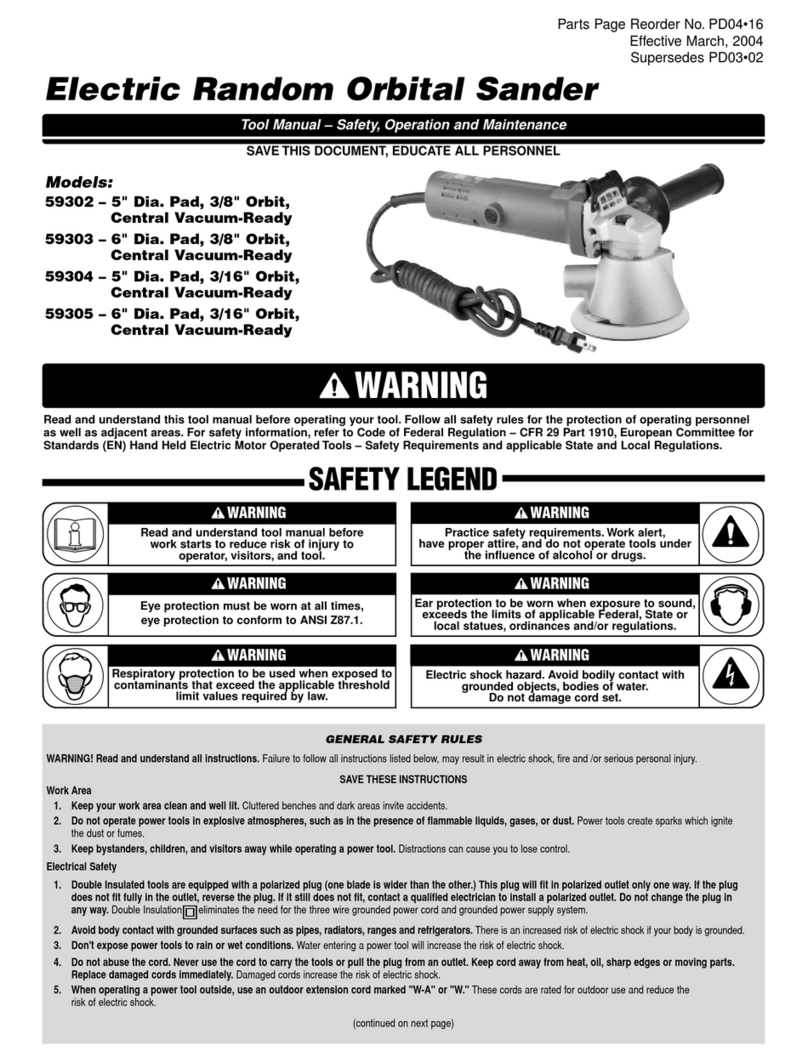

Dynabrade 59302 Operating instructions

Dynabrade

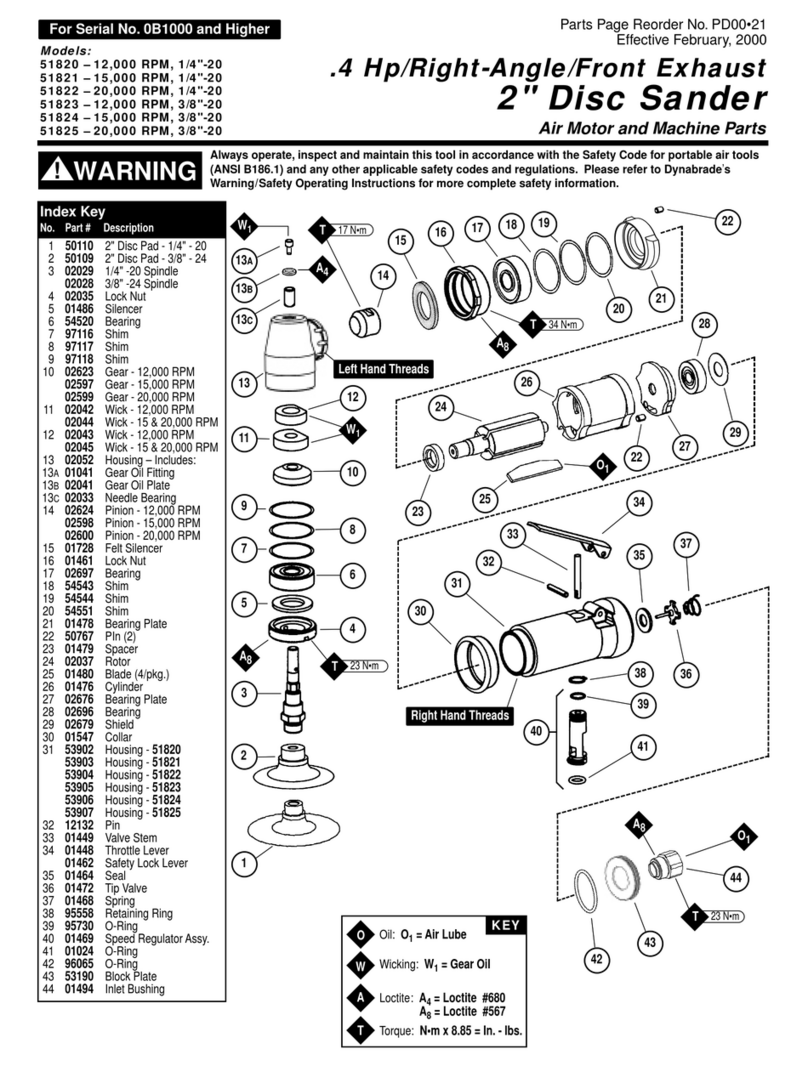

Dynabrade 51479 User manual

Dynabrade

Dynabrade 53251 Guide

Dynabrade

Dynabrade Dynabug 57920 User guide