Page 2 of 21

Table of Contents

Table of Contents ................................................................................................................ 2

Table of Figures .................................................................................................................. 3

Section 1: About This Manual ............................................................................................ 4

Who Should Attempt this Project? ................................................................................. 4

Tools you’ll need ............................................................................................................ 4

Helpful Tools .................................................................................................................. 4

Project Overview ............................................................................................................ 5

Important Safety Notes ................................................................................................... 5

About Components ......................................................................................................... 5

Recommended Solder ..................................................................................................... 5

Warranty ......................................................................................................................... 5

Section 2: Kit Building Hints .............................................................................................. 6

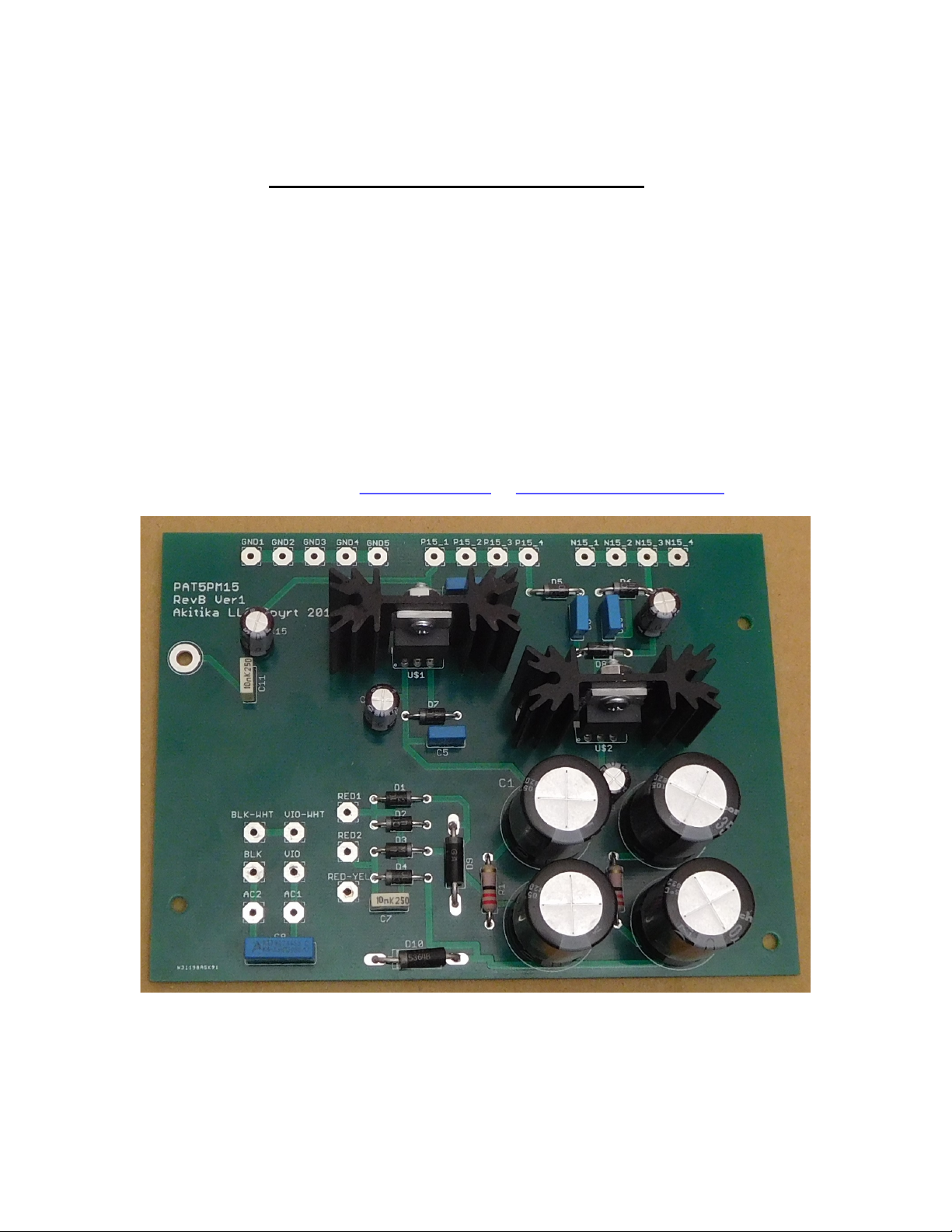

Section 3: Building the Power Supply ................................................................................ 7

Component Order............................................................................................................ 8

Install the diodes ............................................................................................................. 8

Install the Resistors ......................................................................................................... 8

Install the non-polar Capacitors ...................................................................................... 9

Install the Polarized Electrolytic Capacitors ................................................................... 9

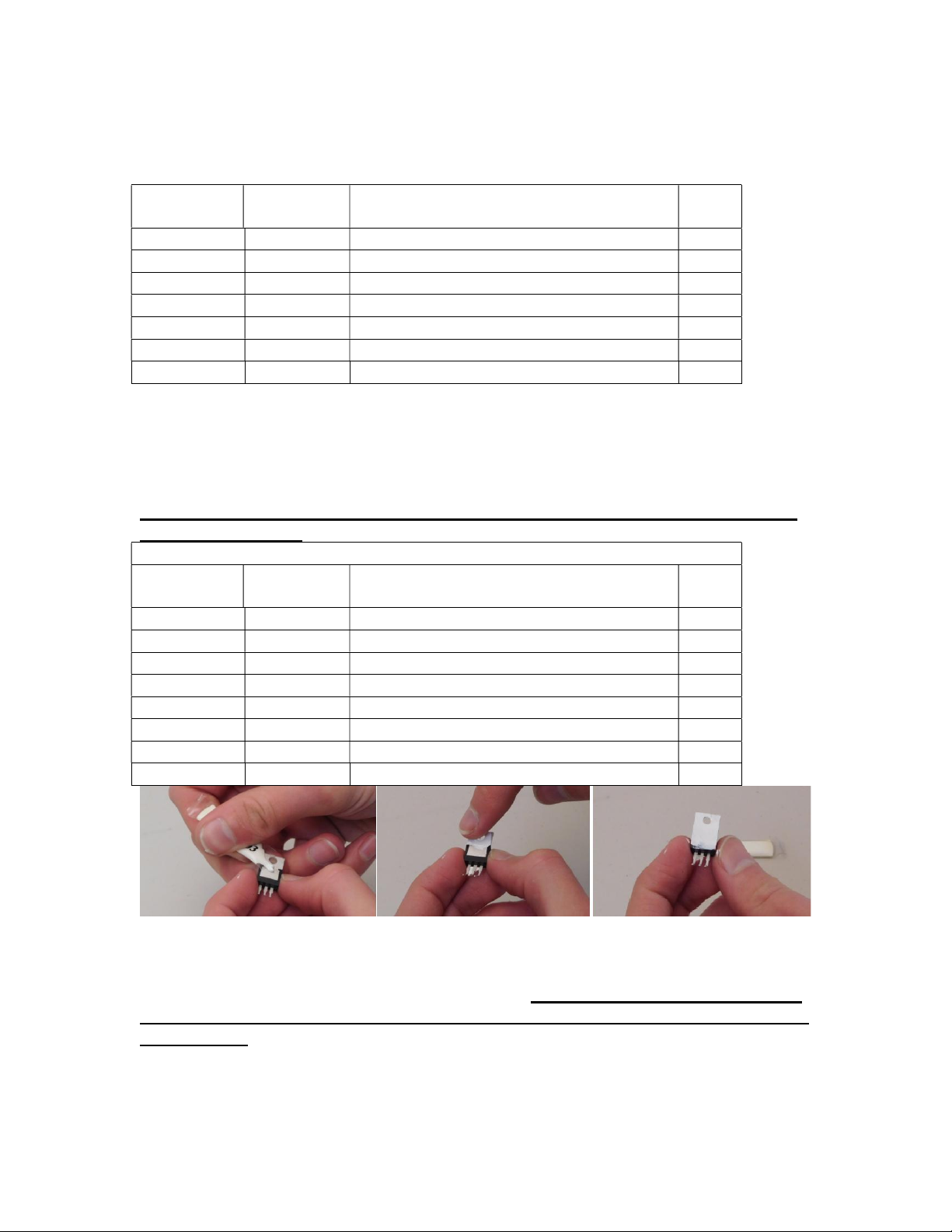

Install the TO-220 Regulators and Heatsinks ................................................................. 9

Check your work ........................................................................................................... 11

Removing the Old Power Supply ..................................................................................... 11

Connect the Transformer .................................................................................................. 13

Connecting the low voltage transformer wires ......................................................... 13

Connecting the AC line-side transformer wires ........................................................ 14

Connecting AC Power to the PCB ............................................................................ 15

What if PAT5PM Is Installed? .................................................................................. 15

Take a break .............................................................................................................. 15

Testing the New Power Supply................................................................................. 16

Installing the New Power Supply ................................................................................. 17

Complete Zig-Zag Wall and back panel re-Installation ............................................ 18

Re-connect Power Supply to Preamp and Phono Sections ....................................... 18

Testing the Power Supply Line-Stage Combination ................................................. 20

Final Re-Assembly.................................................................................................... 20

Schematic ...................................................................................................................... 21