8

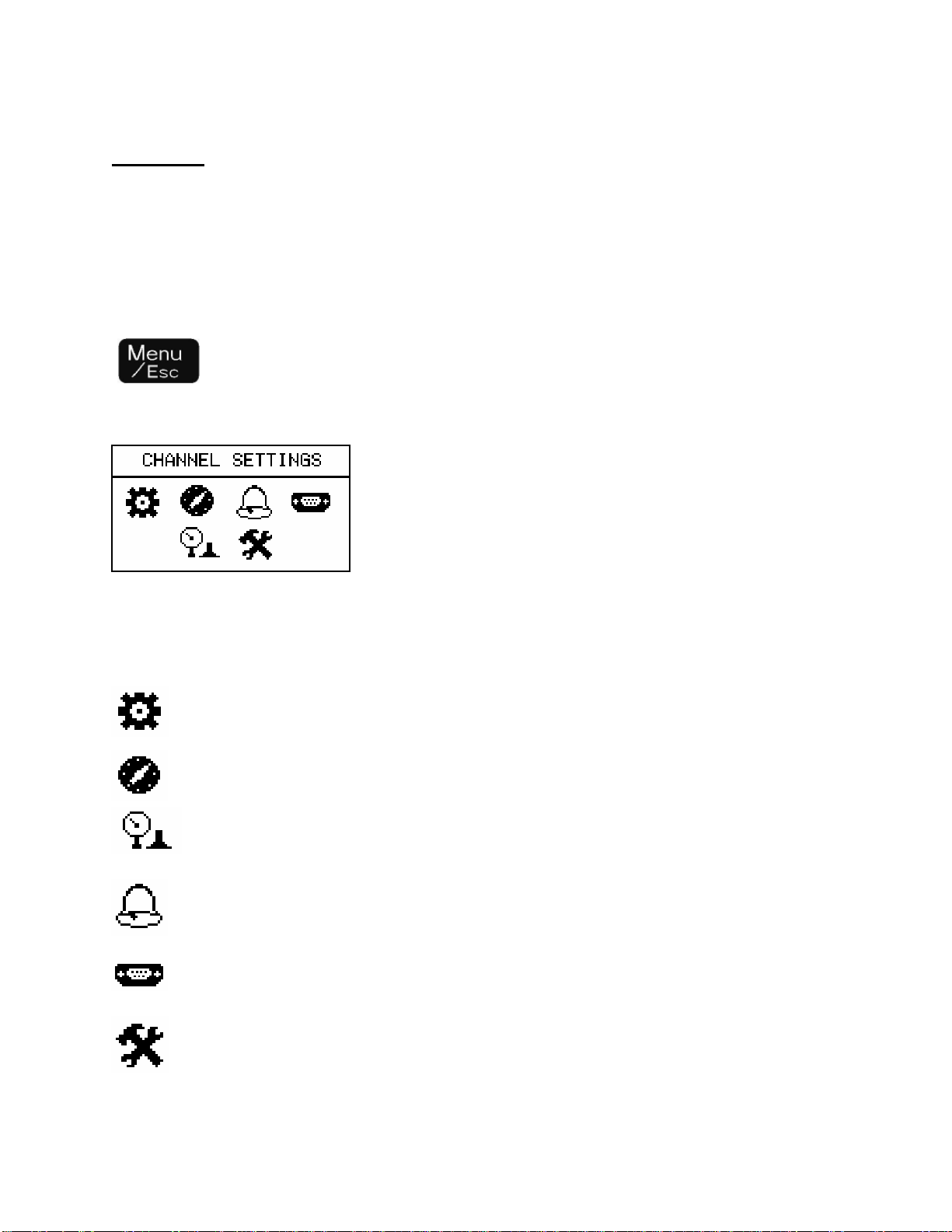

1) Configuration of “Run Signal”

Using the arrows on the keypad, select the “Run Signal” icon.

There are (3) run types available. The definitions are as follows:

None: No run indication required. Monitoring is always active.

RPM: Monitoring is active when signal received from magnetic pickup.

Digital: Monitoring is active when contact closure (connection to ground) is sensed.

To select run signal type, use the up / down arrows to select, then press enter.

If “None” is selected, there is no other action required other than to select “escape.”

After selecting escape, you will be asked to select “yes” to save.

If “RPM” is selected, you will need to set the # gear teeth, RPM threshold and startup

delay. The RPM threshold is the speed above which monitoring will be active. The

startup delay allows you to delay monitoring for as many as 300 seconds (5 minutes) to

allow time for all inputs to be at normal levels. If no delay is required, set to 0 seconds.

If “Digital” is selected, you will only need to set the startup delay (if applicable).

Pressing at any time during configuration will prompt you to save the

changes. Select “Yes” to save any changes made. Selecting “No” will not save

changes.

2) Configuration of each “Channel”

Using the arrows on the keypad, select the “Channel” icon.

Next, select the channel number to configure by pressing the up / down arrows and

pressing enter. The screens allow you to enable each channel and select the following:

Enable Channel Yes / No

Channel Type (0-1 V, 0-5 V, 0-10 V, 4-20 mA, J Type, K Type)

Description (name input with up to 20 characters)

Engineering Units (up to 3 characters for PSI, F, C etc…)

Enable alarms (read only or alarm?)

Alarm Type (latching or non-latching)

Alarm Output (select output #1, output #2 or both)

Alarm Low (select threshold for under-trip)

Alarm High (select threshold for over-trip)

Alarm Reset Points (select either the default reset value or manually set)

Alarm Reset Low (manually set reset hysteresis for low trip)