2DBC410 Installation Manual Rev K.docx

features

Single Phase Supply

Simple supply requirement, 40A single

phase.

4 Switched Outputs

Each 10A output is switched via a high

specification relay with specially treated

contacts which prevent contact fusion when

switching very reactive loads.

4 Control Outputs

Each of the 4 optically isolated outputs can

be configured to be either 1-10V, or DSI

Serial control, covering the latest types of

HF Fluorescent Ballasts. Also compatible

with 1-10V and DSI dimmable electronic

transformers.

MCB Protection

Each mains output is protected by a single

pole magnetic circuit breaker.

Many Control Options

Control of this device can be from a

combination of methods, eg. serial control

port, relay contacts, push button wall

stations, infra red receivers and timeclocks.

Easy high-level interface to other popular AV

control systems and Building Management

Systems (BMS) is also available.

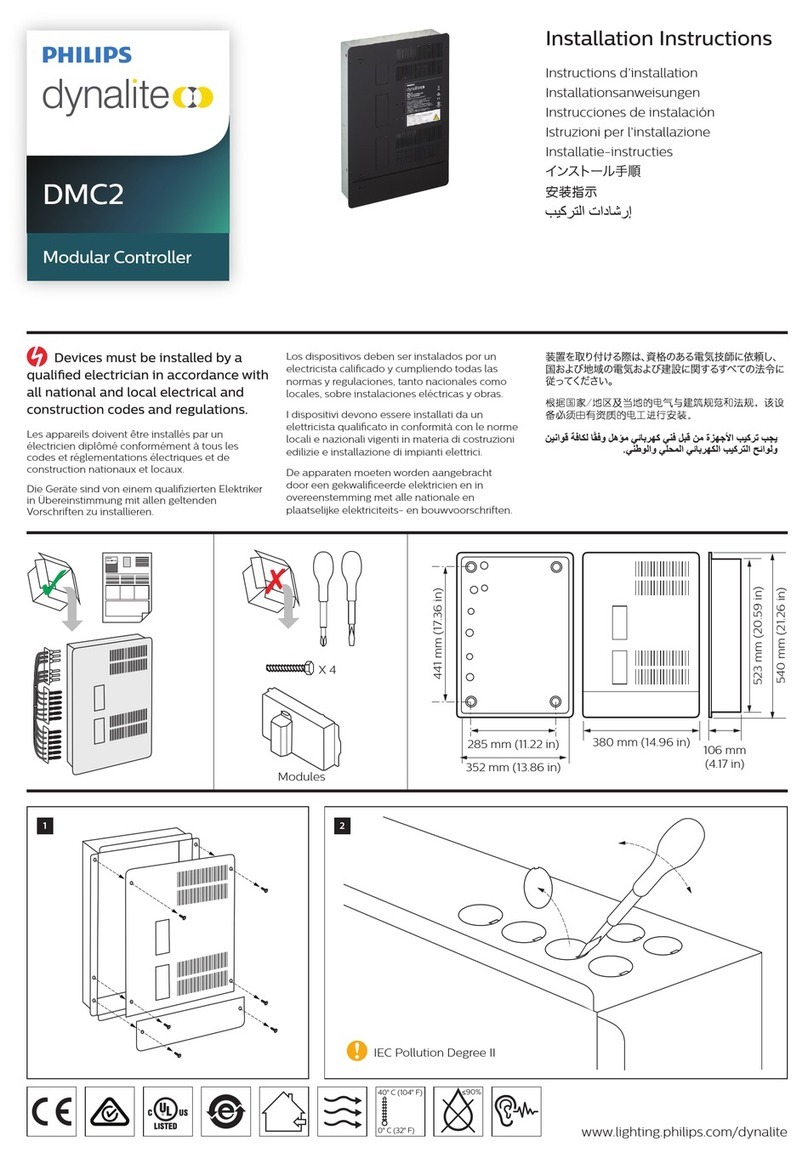

Simple Installation

Wall-mount enclosure with mounting lugs

facilitates installation. Cable knockouts are

provided, at the top of the enclosure for

supply and load cables, with low voltage

(LV) control at the bottom.

important safeguards

Warning –this is a class A product. In a domestic

environment this product may cause radio interference, in

which case the user may be required to take adequate

measures.

Read Instructions –We recommend that you read this

Instruction Manual Prior to commencement of installation.

Retain instructions and give the end user.

Troubleshooting - If problems are encountered, check

the Troubleshooting section on page 8.

Special Programming –Once powered and terminated

correctly this device will only operate in basic mode. A

new Dynalite panel will turn on all lighting channels from

button 1 and turn off from button 4 if network terminations

are correct. Only once the full network is test correct can

commissioning begin. Advanced functions can be

commissioned via Envision software. If commissioning is

required, contact your local distributor for details.

Check Connections –Treat this device as a

switchboard that has been shipped. Tighten all load-

carrying screw connections, as vibrations from transport

can cause MCB and terminal block screws to become

loose.

Power Sources –This device should only be operated

from the type of supply specified on the front panel. This

device must be earthed.

Output Circuits –The load on a circuit should not

exceed the specified capacity of 10A. Loads should be

calculated to ensure that the overall maximum capacity of

40A is not exceeded.

Load Control Circuits –If this device is being used to

control 1-10V or DSI HF Fluorescent Ballasts, a 2 core

mains rated control cable is required to be run to the

loads, in addition to the mains feed.

Load Type –Default settings are for load control outputs

to be 1-10V. Check to see what type of HF Fluorescent

Ballasts are in the luminaries. Do not terminate the

control lines to any DSI loads until the relevant channel

has been programmed as DSI. When connecting 1-10V

load control lines, pay attention that the correct polarity is

maintained.

Megger Testing –Do not megger test any circuitry

connected to the dimming system, as damage to the

electronics may result.

Mounting Location –This device must be mounted right

way up, on a vertical surface (refer to page 4 for

mounting instructions). The specified minimum clearance

of 100mm for all sides must be adhered to. Install in a

dry, well-ventilated location. Controllers may emit some

mechanical noise. Take this into account when deciding

the mounting location.

Data Cable –The recommended cable for connections to

the serial port is screened, stranded RS485 data cable

with three twisted pairs. Part numbers for various

manufacturers are listed on page 6. This cable should be

segregated from mains cables by a minimum distance of

300mm. If anticipated cable runs are over 600 metres for

serial cables, consult your dealer for advice. Do not cut or

terminate live data cables.