features

4 x Feed Thru Outputs –Latching Relays rated at 20A inductive, no

de-rating necessary

Separate Control Supply –1 phase at 0.1A

Manual Overrides for each channel

Powerful Internal PLC –Custom scripts can be written to provide

process control based on conditional logic.

Many Control Options –Control of this device can be via a

combination of methods eg. Serial control port, relay contacts, push

button control panels, infrared receivers and timeclocks.

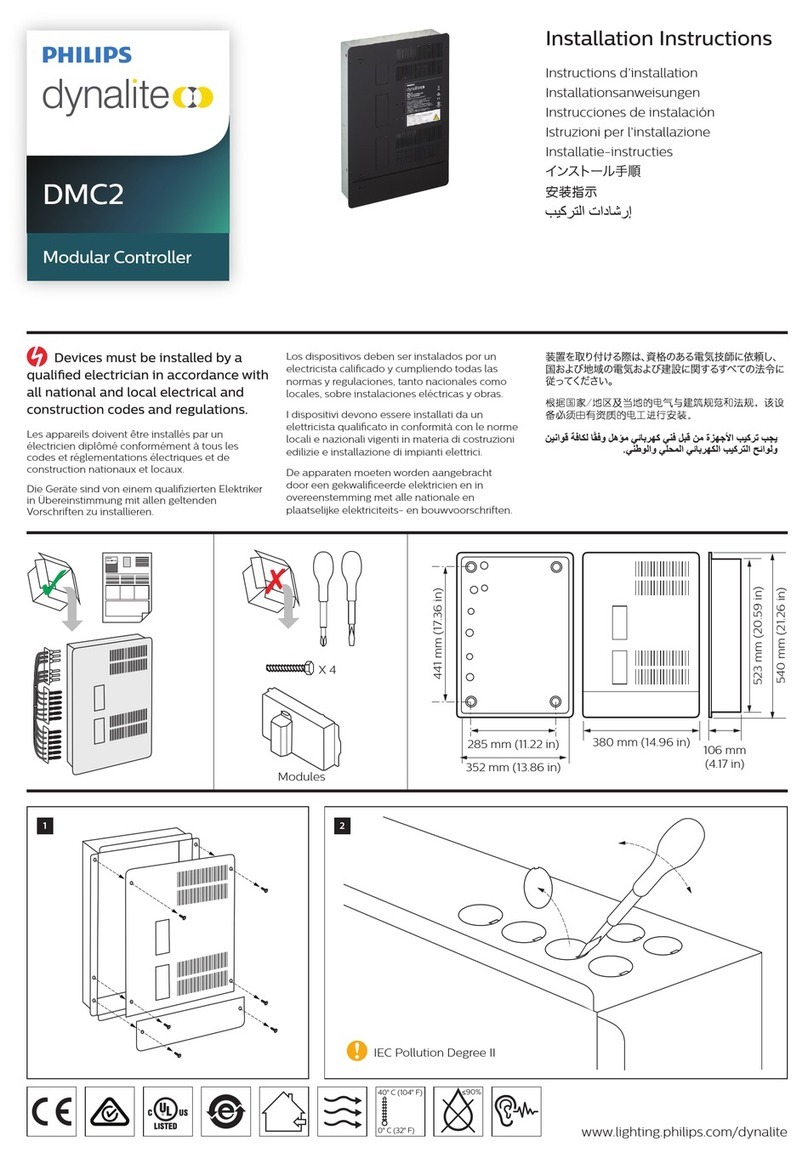

Simple Installation –DIN Rail mount facilitates installation.

All connection terminals accessible without disassembly.

Warning –this device is a class A product. In a domestic environment this

product may cause radio interference, in which case the user may be required

to take adequate measures.

Manual Override Switches –These switches do not provide permanent

isolation. Isolate at the supply before performing work on load circuits.

Special Programming –Once powered and terminated correctly this device

will only operate in basic mode. A new Dynalite panel will turn on all lighting

channels from button 1 and turn off from button 4 if network terminations are

correct. Only once the full network is test correct can commissioning begin.

Advanced functions can be commissioned via Envision software. If

commissioning is required, contact your local distributor for details.

Check Connections –Tighten all load-carrying screw connections, as

vibrations from transport can cause terminal block screws to become loose.

Power Sources –This device should only be operated from the type of supply

specified on the front cover. This device must be earthed.

Output Circuits –The load circuit should not exceed the specified capacity of

20A. Loads should be calculated to ensure that the overall maximum capacity

of 80A is not exceeded. Each channel shall be protected with a HRC fuse or

MCB rated 20A or less. Output circuits are suitable for Single Phase or Three

Phase Star (with Neutral) only, Delta wiring is not supported.

Mounting Location –Install in a dry, well-ventilated location. Controllers may

emit some mechanical noise. Take this into account when deciding the

mounting location.

Data Cable –Use screened, stranded RS485 data cable with three twisted

pairs. Segregate from mains cable by 300mm minimum. Connect devices in a

‘daisy chain’. A data cable connected to an energized device is live. Do not

cut or terminate live data cables.

To reduce the risk of fire or electric shock, do

not expose this device to rain or moisture. Do

not energise unless the front cover is in place.

The device must be earthed. Installation,

programming and maintenance must be carried

out by qualified personnel.