2” and 2” Tandem

Polarized-Media

Air Cleaners

Installation

&

Operation

Manual

All Dynamic Air Cleaners operate with the same basic principles of active-field polarized media. In the 2” Panel

Air Cleaner, the 24 VAC input to the Powerhead is stepped up to 7 kV (DC) at very low current. This voltage is

applied to the center screen inside the replaceable media pad. This creates an electrostatic field between the

center screen and the grounded exterior metal screens. The electrostatic field polarizes both the fibers in the

media and airborne contaminants. These are then attracted to and collected by the media fibers. When the

pads are loaded, they are easily removed and replaced.

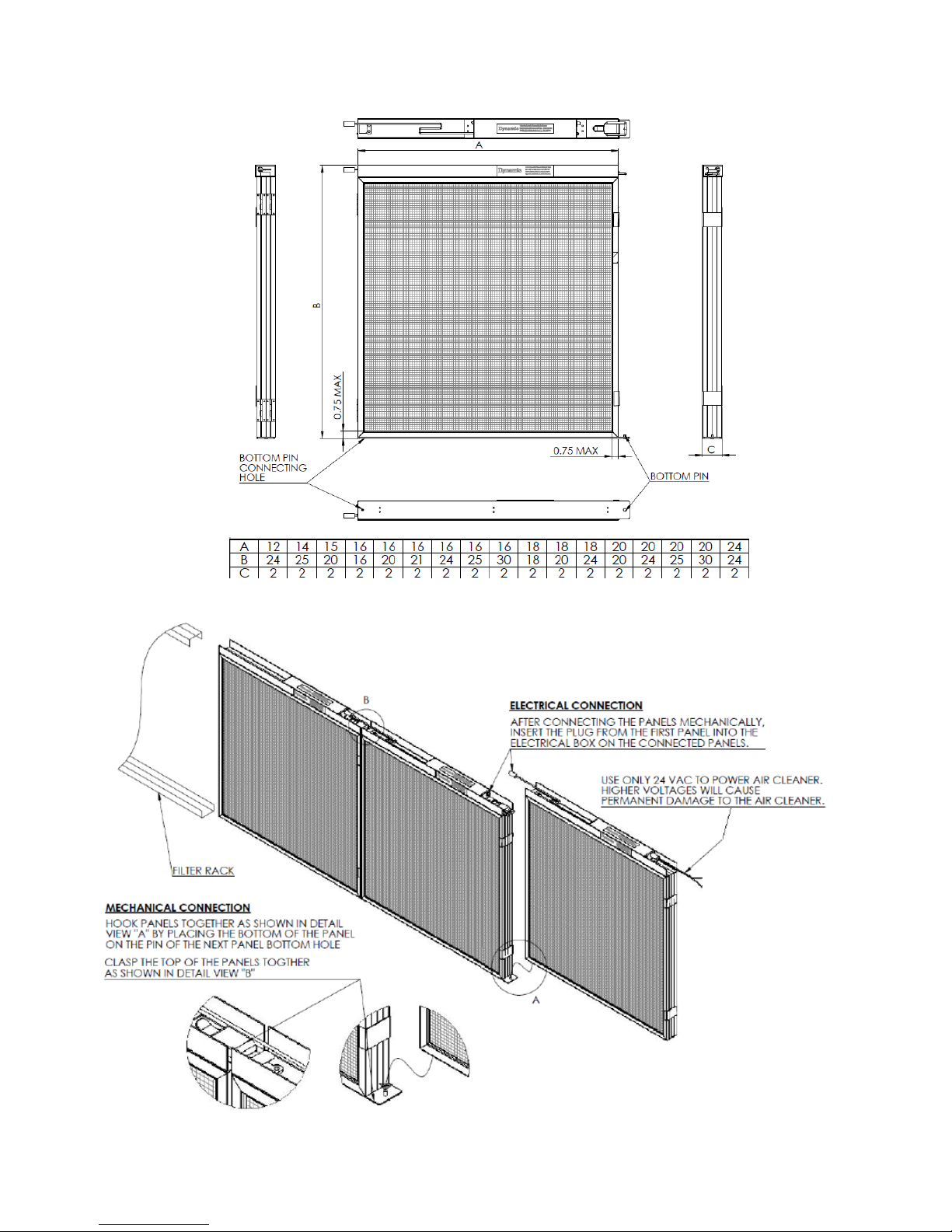

Dynamic 2” Air Cleaners typically slide into the standard 2” racks in the air handler. They are available as

individual Panels or as Tandem Panels. Typically, a Panel Air Cleaner is used when there is only one filter per

row. Each Panel is wired separately. Tandem Panels are used when there are multiple Air Cleaners per row.

They are connected mechanically and electrically to the adjacent Air Cleaner, and there is one electrical

connection per row. The entire row may be pulled out for service. Neoprene foam strips are used on the mating

faces of the Air Cleaners in a row to block the flow of air between Panels.

Section I. Sizing

While Air Cleaner height is consistent with filter rack height, Air Cleaner widths are typically sized to minimize the

number of Air Cleaners in a row and fill the width of the rack in the unit. Keeping the Air Cleaner width consistent

will also standardize replacement media pad size. For example, a rack that has three 24”x24”x2” passive filters

would typically take two 36”x24”x2” Dynamic Tandem Panels. Make sure that there is enough room to slide out

the larger Panel. In the above example, the Powerhead would go on top on the long side. When ordering, the

first dimension is the side with the Powerhead. Therefore, a 36”x24” Tandem is not the same as a 24”x36”

Tandem. Assuming a set of two, the first would give you an assembly that is 72” wide and 24” high and the

second would yield an assembly that is 48” wide and 36” high.

Like passive filters, 2” Panels are undersized from the nominal dimensions. They are undersized ½” on height

(the height of the filter track) and ¼” on width. Whenever possible, and on all retrofit applications, measure the

filter racks rather than relying on the nominal dimensions of the passive filters.

Section II. Installation

Dynamic 2” Panels slide into the existing filter racks. The required 24 VAC may come from an on-board source,

a dedicated transformer, or a Dynamic Control Panel, with optional pressure transmitter gauge. Make certain

that there is sufficient capacity (3 VA) when using an on-board transformer. Follow all applicable local codes.

Make certain the air handler is off when installing the Panels.

In the case of a Panel Air Cleaner, each Panel will require an electrical connection. With Tandem Panels, each

row requires its own input.