ITEM

NO. PCS.

REQ’D DESCRIPTION

2-80000-29

SERIES

PART NO.

4-80000-29

SERIES

PART NO.

6-80000-32

SERIES

PART NO.

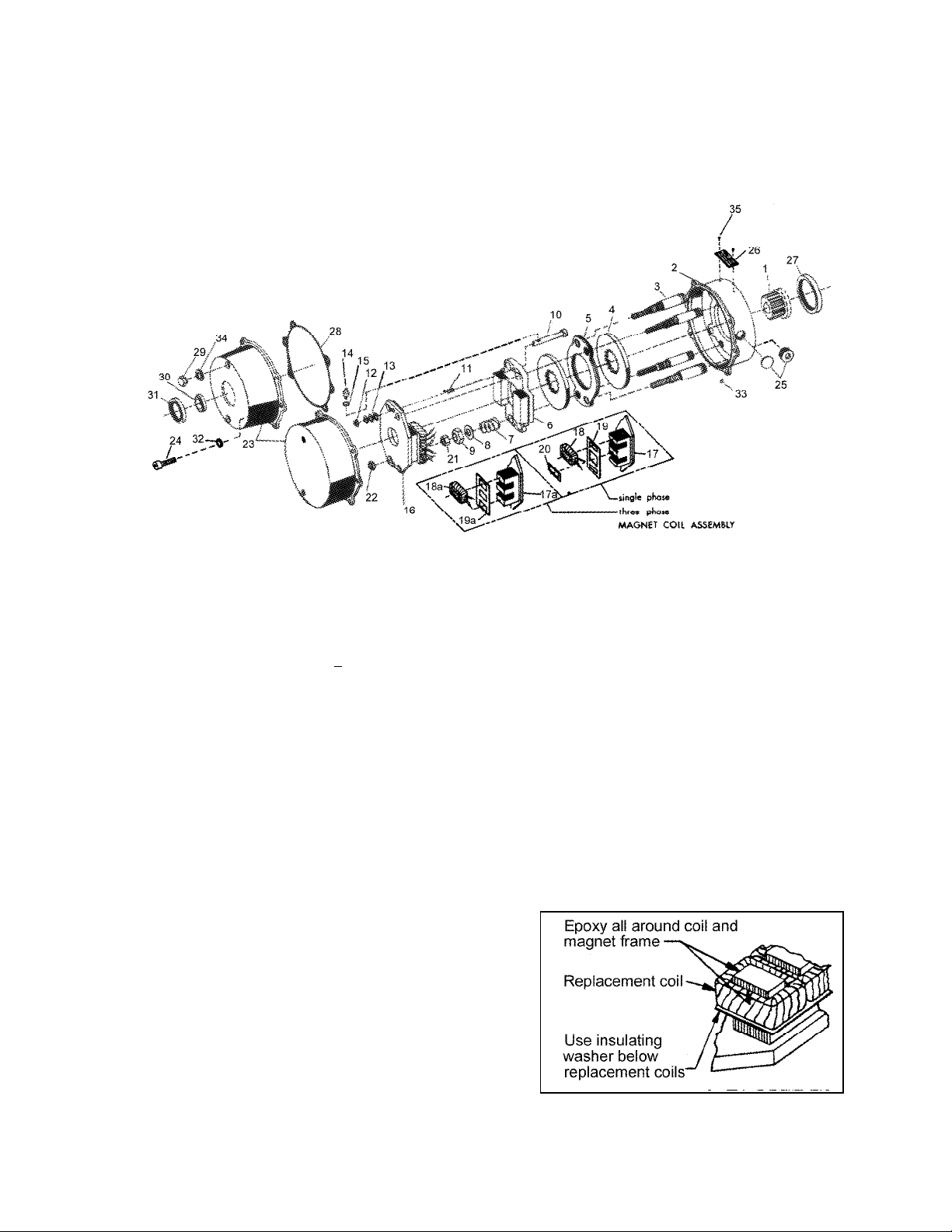

11Hub

21Bracket W/Studs –1Disc H080105-001

21Bracket W/Studs –2 Disc H080105-002

21Bracket W/Studs –3 Disc H080105-003

21Bracket W/Studs –4 Disc H080105-004

21Bracket W/Studs –5 Disc H080105-005

2a 1Bracket W/High Tensile Studs –1 Disc H080105-006

2a 1Bracket W/High Tensile Studs –2 Disc H080105-007

2a 1Bracket W/High Tensile Studs –3 Disc H080105-008

2a 1Bracket W/High Tensile Studs –4 Disc H080105-009

2a 1Bracket W/High Tensile Studs –5 Disc H080105-010

34Stud –1 Disc G070213-001

34Stud –2 Disc G070213-002

34Stud –3 Disc G070213-003

34Stud –4 Disc G070213-004

34Stud –5 Disc G070213-005

3a 4Stud –1 Disc High Tensile G070219-001

3a 4Stud –2 Disc High Tensile G070219-002

3a 4Stud –3 Disc High Tensile G070219-003

3a 4Stud –4 Disc High Tensile G070219-004

3a 4Stud –5 Disc High Tensile G070219-005

4(1) Rotating Friction Disc H080002-002

4a (1) Heavy Duty Rotating Friction Disc (Alt.) H080026-003

5(2) Stationary Disc K080179-001

61Pressure Plate K080072-001

74Torque Spring (25, 50, 75 Lb. Ft.) G070011-001

74Torque Spring (35, 70,105,125,175 Lb. Ft.) G070019-001

84Torque Spring Washer W004004-001

94Torque Adjusting Nut W003001-022

10 2Manual Release Rod G070001-002

11 2Manual Release Spring G060010-001

12 2Manual Release Washer W004004-003

13 As Req’d Manual Release Shim W004004-004

14 2Manual Release Stop Screw G060029-001

15 2Manual Release Lockwasher W004007-007

16 1Magnet Assembly, Single Phase –Complete with Coils K080126 (3)

16 1Magnet Assembly, Three Phase –Complete with Coils K080127 (3)

17 1Magnet Plate w/o Coils, Single Phase K080152-001

17a 1Magnet Plate w/o Coils, Three Phase K080101-001

18 4Magnet Coil –Single Phase K080083 (3)

18a 6Magnet Coil –Three Phase H080062 (3)

19 2Insulating Washer –Single Phase G080148-001

19a 2Insulating Washer –Three Phase G080016-001

20 2Shading Coil, Single Phase Only G080022-001

21 4Gap Adjusting Nut W003003-023

22 4Gap Adjusting Nut W003001-020

23 1Cover, Standard L080067-001 L080056-002

23 1Cover, w/ Thru Shaft L080067 (4) L080056-003

24 6Cover Screw W001013-028A

25 1Conduit Hole Plug W008003-001 W010002-004

26 1Name Plate H050020-001

27 1Hub Seal --- W011001-008 ---

28 1Cover Gasket --- K080143-001

29 2Release Cap --- G060170-002

30 1Thru-Shaft Sleeve --- H080036 (5)

31 1Thru-Shaft Seal --- W011001-007

32 6Lockwasher, 1/4 W004007-009 W004006-006 W004007-009

33 1Drain Hole Plug --- W010002-001

34 2Release Cap Gasket --- G070381-001

35 2Drive Screw W001012-048

(1) Number of rotating discs is shown as second digit of Model No. (3) Basic part number shown –specify model number, voltage,

Example: 2-82050-28 phase and frequency.

(2) Number of stationary discs is one less than the number of rotating discs. (4) Basic part number shown –specify shaft diameter.

(5) Basic part number shown –specify shaft diameter and keyway.