7

Dynaset

O

y

|

Menotie

3,

FI-33470

Ylöjärvi,

Finland

|

tel:

+358

3

3488

200

|

inf

[email protected] |

ww

w

.dynaset.com

HIGH PRESSURE PIPE CLEANING UNITS

GENERAL

1. GENERAL

This manual contains general information about assembly, installation, operation

and maintenance of DYNASET PPL High Pressure Pipe Cleaning Unit.

ATTENTION!

Read this user manual before installation, use or maintenance of the PPL

unit to ensure proper handling, operation and maintenance right from

the beginning. Pay attention to warnings and safety instructions. READ

CHAPTER ”2. SAFETY” for more information.

1.1. PRODUCT INFORMATION

The high pressure pipe cleaning unit is typically used in works such as unclogging

or defrosting pipes and sewers with high pressure water jets and manual high

pressure cleaning with spray gun.

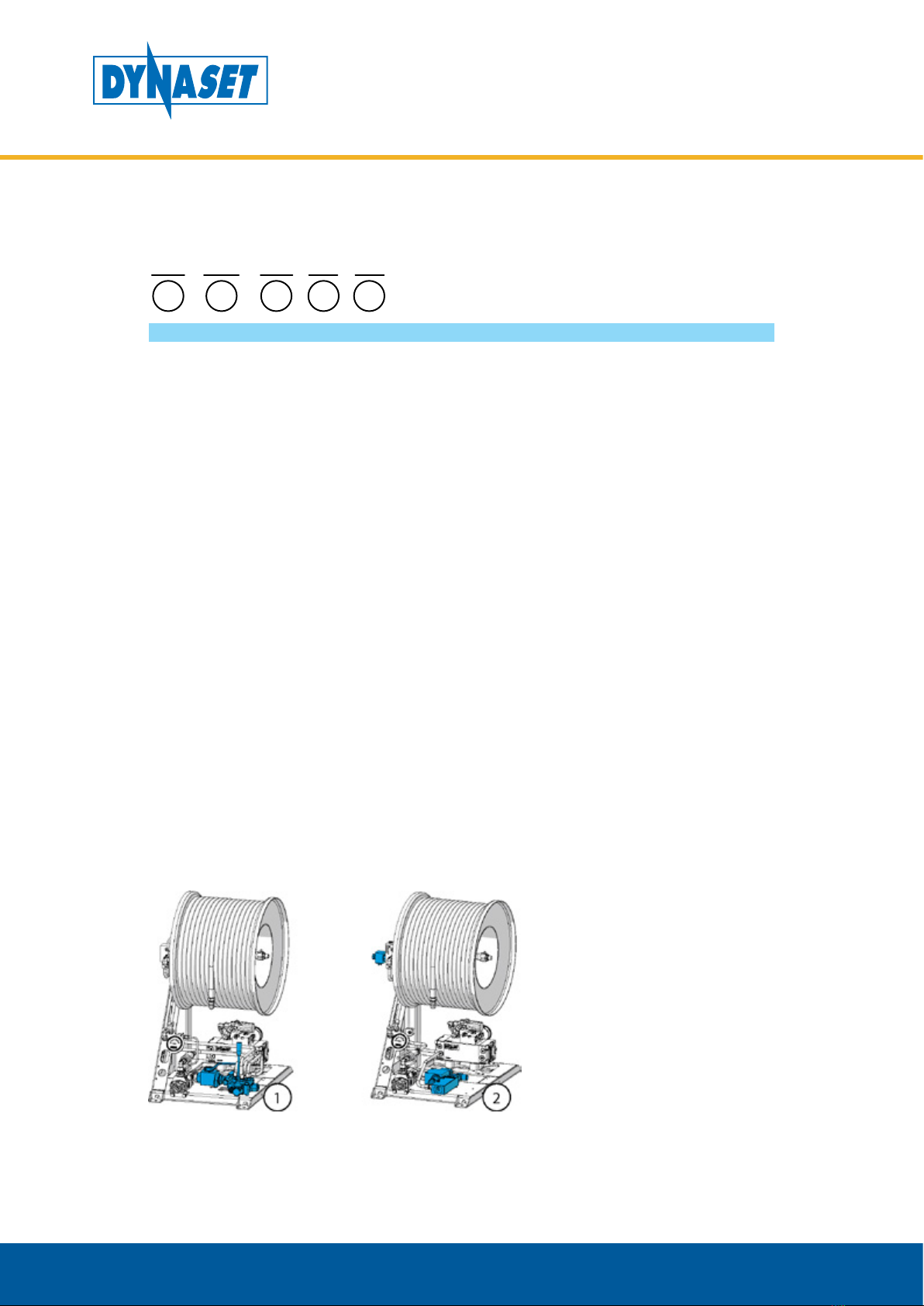

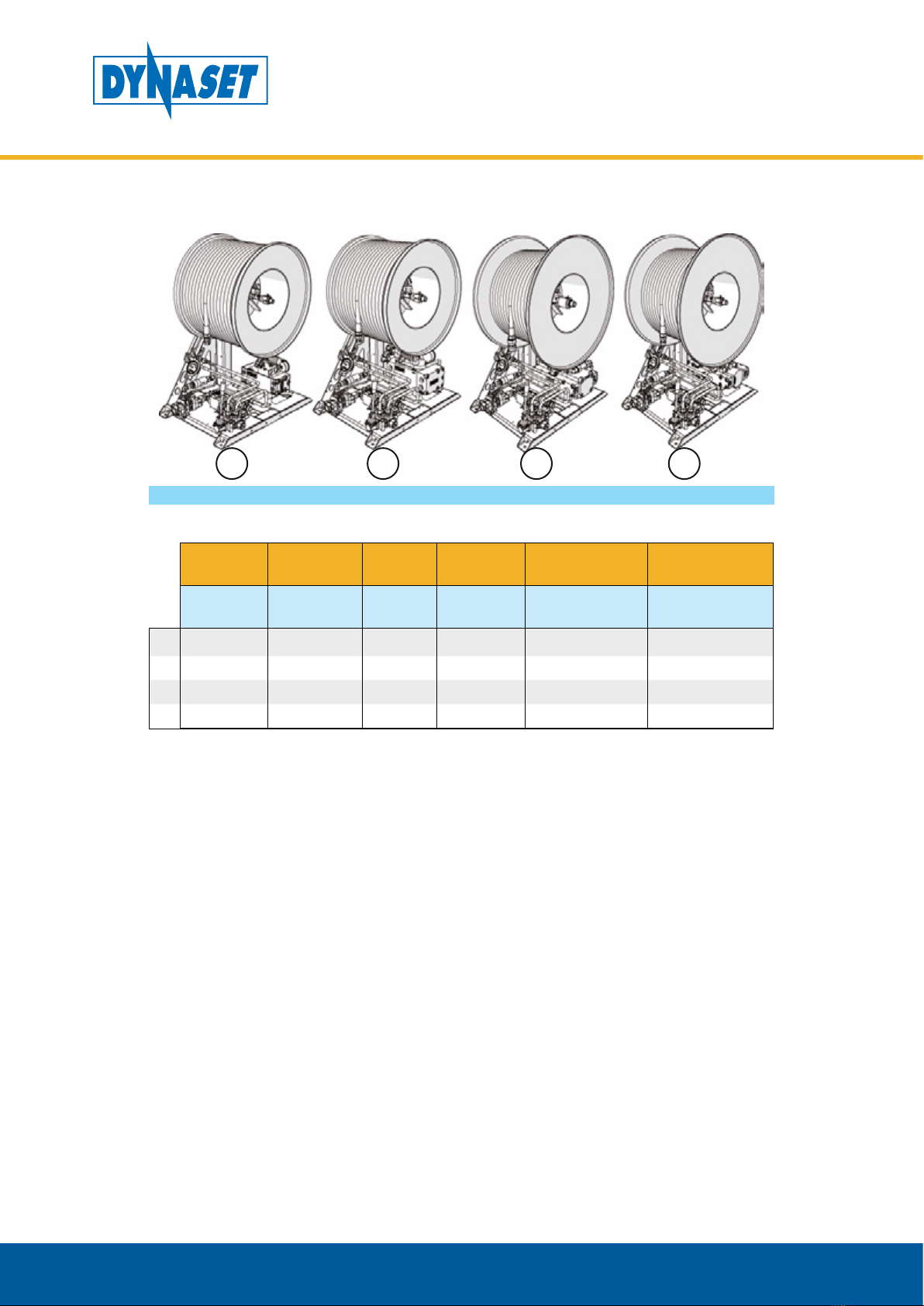

The Dynaset Hydraulic Hose Reel is designed for convenient at-work storage and

quick and safe handling of high pressure hose. Together with Dynaset HPW High

Pressure Water Pump, hose reel integrates core elements of professional pipe

cleaning equipment.

Unreeling the hose is easy due to the free reel rotation. The reel can be locked

hydraulically in any position. The hose reel is controlled with manual or solenoid

valve with positions for locking, reeling, and free rotation.

The rotation speed of the hose reel can be changed by adjusting the hydraulic

flow that rotates the reel motor. Reeling force is preset to 800 N, which equals to

50 bar pressure. The setting can be changed with a pressure limiter valve.

Dynaset also offers a wide range of different nozzles for pipe washing and

defrosting, and other purposes as well.