• For stripping, spot cleaning, blasting, and hard to reach areas use the 15° spray tip. This option is for removing paint,

rust, mildew, marine growth off boats, or grease stains. This option can be used for reaching second story surfaces, or

for the removal of paint, rust, oil stains, tar, gum, and other stubborn substances. Use extreme caution when using this

nozzle.

• For applying pressure washer safe detergent, use the black soap nozzle.

• The angle of the nozzles shown indicates the spray “fan shape” projected from the nozzle when the trigger of the spray

gun is pulled and high pressure water is passing through the nozzle. The pressure and flow will not change significantly

due to the various fan patterns (Nozzles).

OPERATION

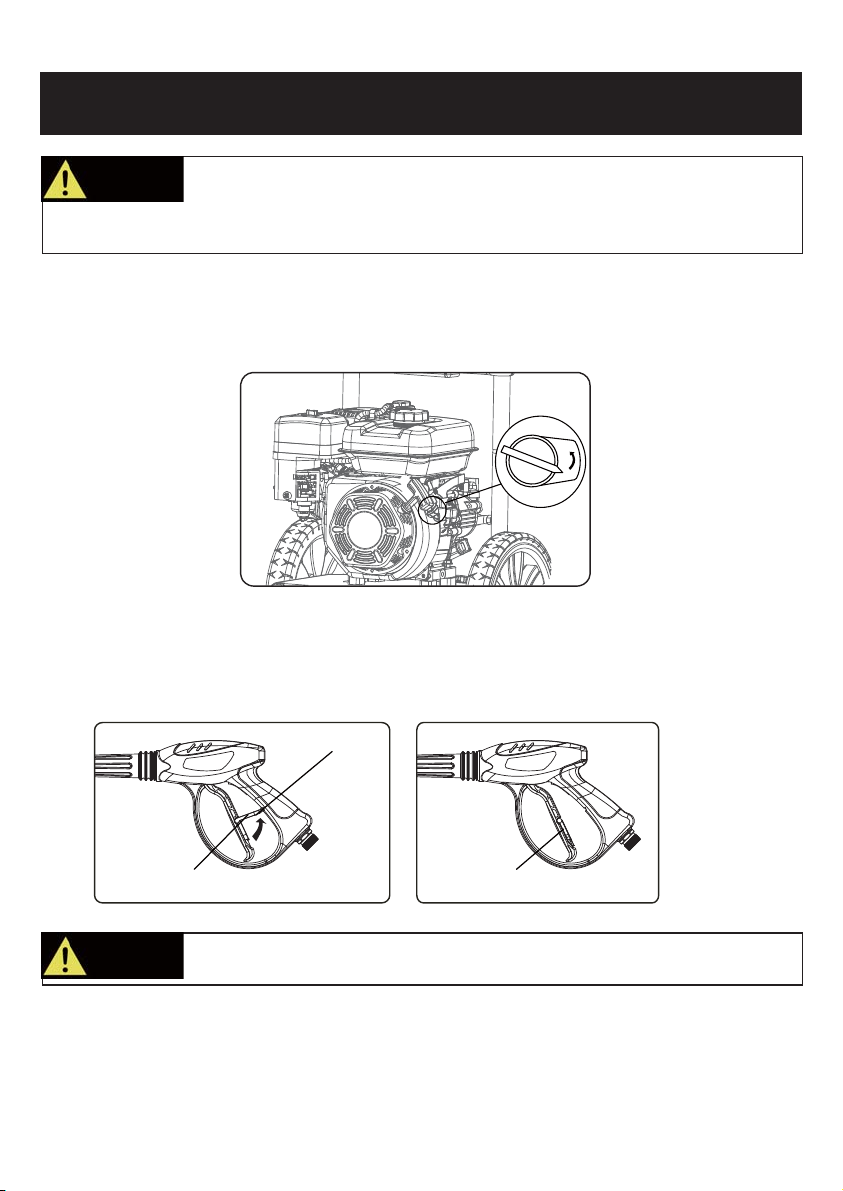

FIG 16 FIG 17

SPRAY

WAND

NOZZLE

“CLICK”

Applying Detergent

• Rinse surface with cool water before applying cleaner.

• Prepare detergent as required by job. For best results follow detergent directions as supplied from manufacturer.

• Remove cap from detergent container and fill.

• Spray detergent on surface. For best results use long, even, and overlapping strokes. Allow detergent to set for about

3 minutes before rinsing, but do not allow detergent to dry on surface or it may cause streaking or cause damage to the

surface. Use good judgment.

•a bucket of clean water to remove detergent.

Only use mild, environmentally friendly detergents intended for use in pressure washers.

Ask at your specialist dealer about these special products. Never use aggressive chemicals

(eg bleach), abrasive detergents or similar to avoid damage to your health, the product and

the environment.

WARNING!

Avoid skin contact with detergents, in particular contact with eyes! If detergents gets in

your eyes flush your eyes with clean water and seek immediate medical attention!

WARNING!

Rinsing with the Pressure Washer

•

• Rinse from top to bottom using long, overlapping strokes.

Test a small area first to avoid surface damage.

Moving the Pressure Washer

• Turn the pressure washer off.

• Tilt unit towards you until it is balanced on its wheels.

• Roll machine to desired location.

0° 15° 25° 40° Soap