Dynaset

O

y

|

Menotie

3,

FI-33470

Ylöjärvi,

Finland

|

tel:

+358

3

3488

200

|

[email protected] |

w

ww.dynaset.c

om

HIGH PRESSURE WATER PUMPS

TABLE OF PICTURES

Picture 1: Identication key for HPW pumps..................................................................................................................... 8

Picture 2: Type plate..........................................................................................................................................................9

Picture 3: HPW pump line-up.......................................................................................................................................... 10

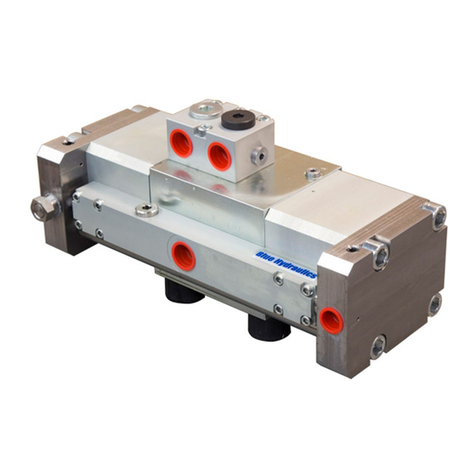

Picture 4: Main components of HPW pump..................................................................................................................... 11

Picture 5: Operating description of HPW pump 1............................................................................................................ 17

Picture 6: Operating description of HPW pump 2............................................................................................................ 18

Picture 7: Relation of pumping uid’s ow rate and pressure.......................................................................................... 19

Picture 8: HPW hydraulic line connection in parallel ....................................................................................................... 19

Picture 9: HPW hydraulic line connection in series .......................................................................................................... 20

Picture 10: Open centre hydraulic system with Load Sensing variable displacement pump ............................................ 22

Picture 11: Connection gure for open centre hydraulic system with Load Sensing variable displacement pump........... 23

Picture 12: Closed centre hydraulic system with Load Sensing variable displacement pump .......................................... 24

Picture 13: Connection gure for closed centre hydraulic system with Load Sensing variable displacement pump......... 25

Picture 14: Hydraulic system with xed displacement pump .......................................................................................... 26

Picture 15: Connection gure for hydraulic system with xed discplacement pump....................................................... 27

Picture 16: Load sensing valve LSV.................................................................................................................................. 28

Picture 17: Priority valve PV-SAE..................................................................................................................................... 28

Picture 18: Placing HPW high pressure water pumps...................................................................................................... 29

Picture 19: Connecting hydraulic hoses........................................................................................................................... 30

Picture 20: Base machine’s pumps .................................................................................................................................. 30

Picture 21: Return line connection .................................................................................................................................. 31

Picture 22: Leakage detecting holes................................................................................................................................ 31

Picture 23: Connection to the pumping uid intake........................................................................................................ 32

Picture 24: Installation into pumping uid line............................................................................................................... 32

Picture 25: Connection to the pumping uid output....................................................................................................... 33

Picture 26: Starting the HPW pump ................................................................................................................................ 35

Picture 27: HPW pump with water pressure unloader valve............................................................................................ 36

Picture 28: HPW pump without water pressure unloader valve.......................................................................................36

Picture 29: Stopping the HPW pump............................................................................................................................... 38

Picture 30: Stopping procedure of the HPW pump.......................................................................................................... 38