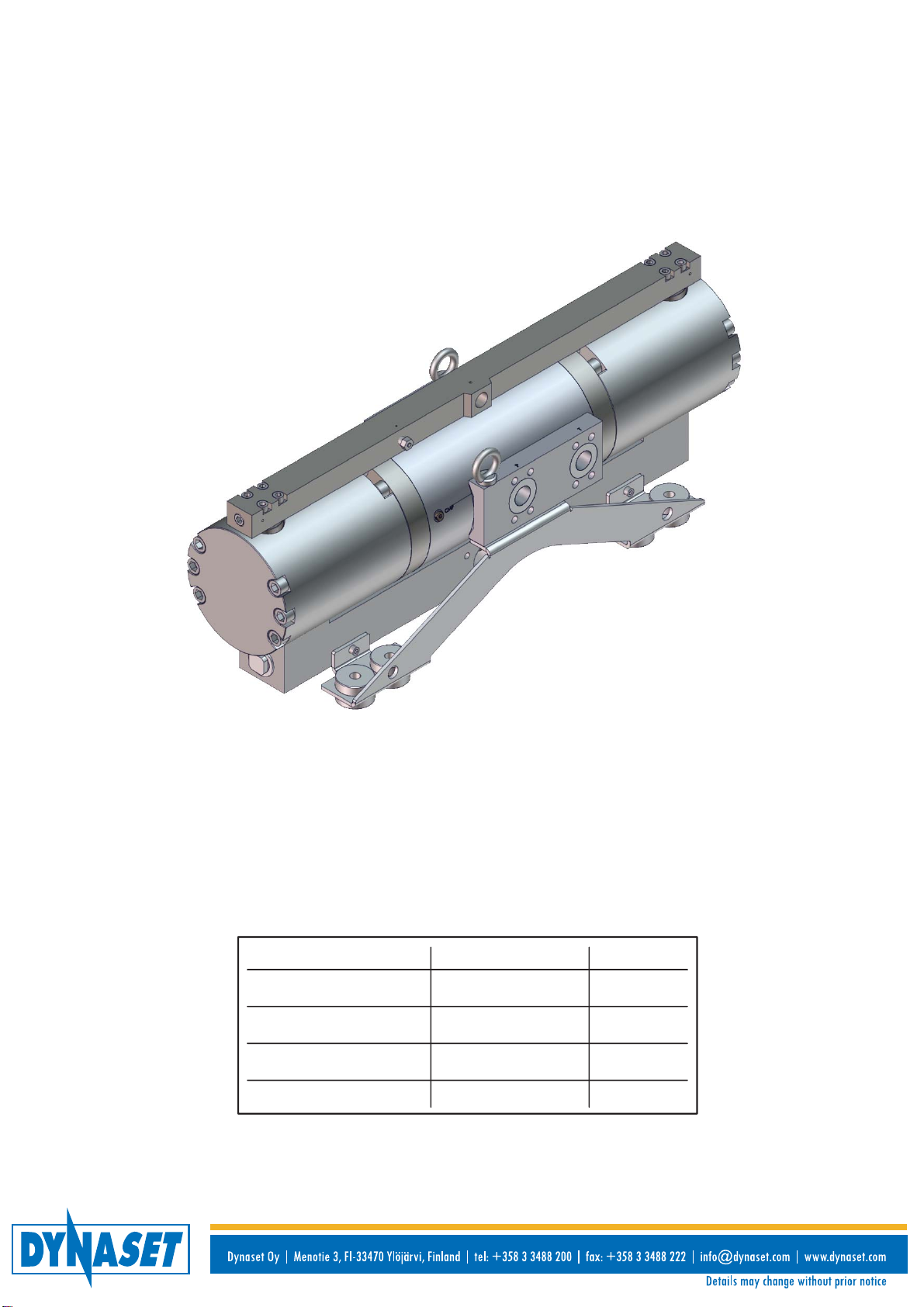

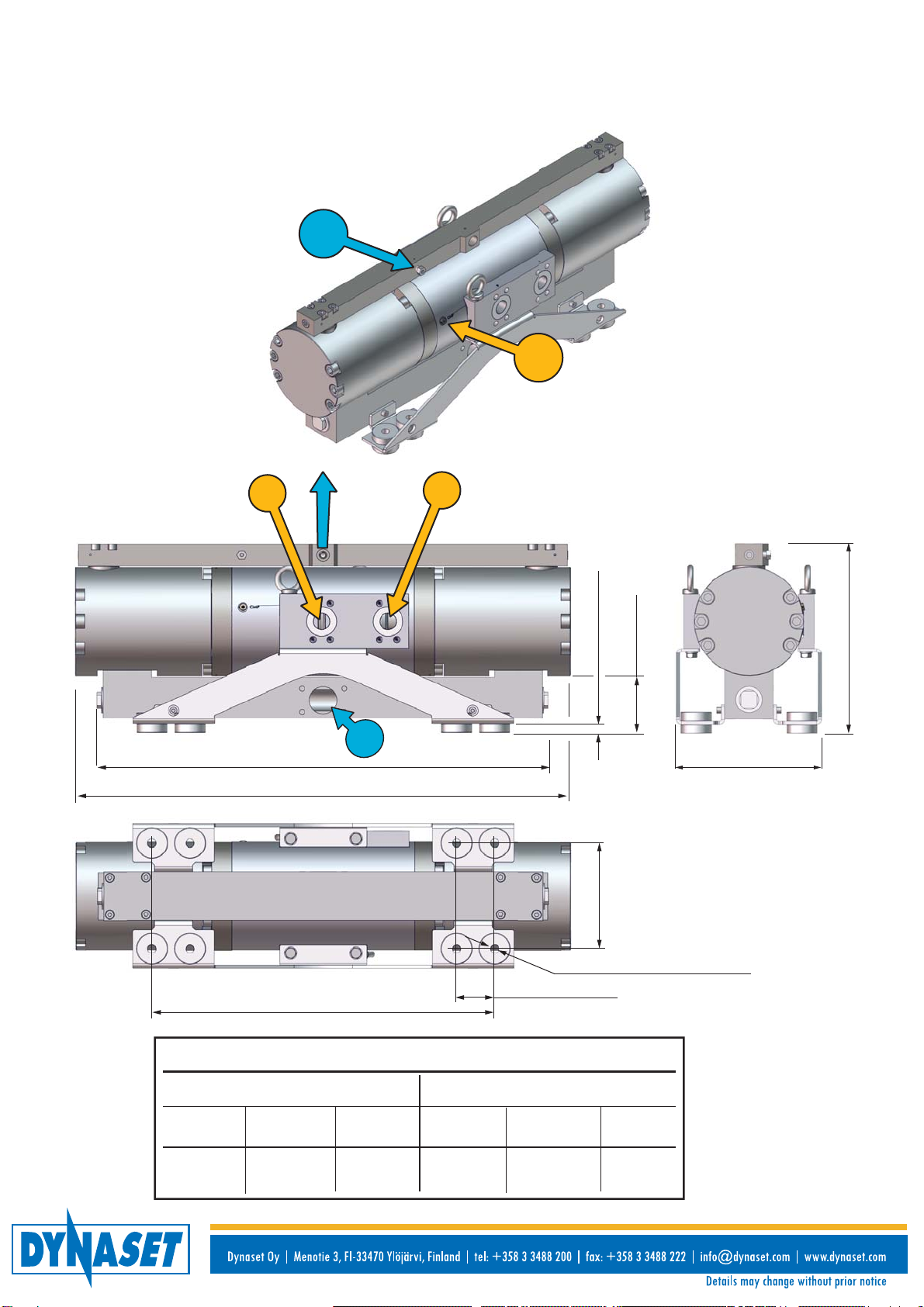

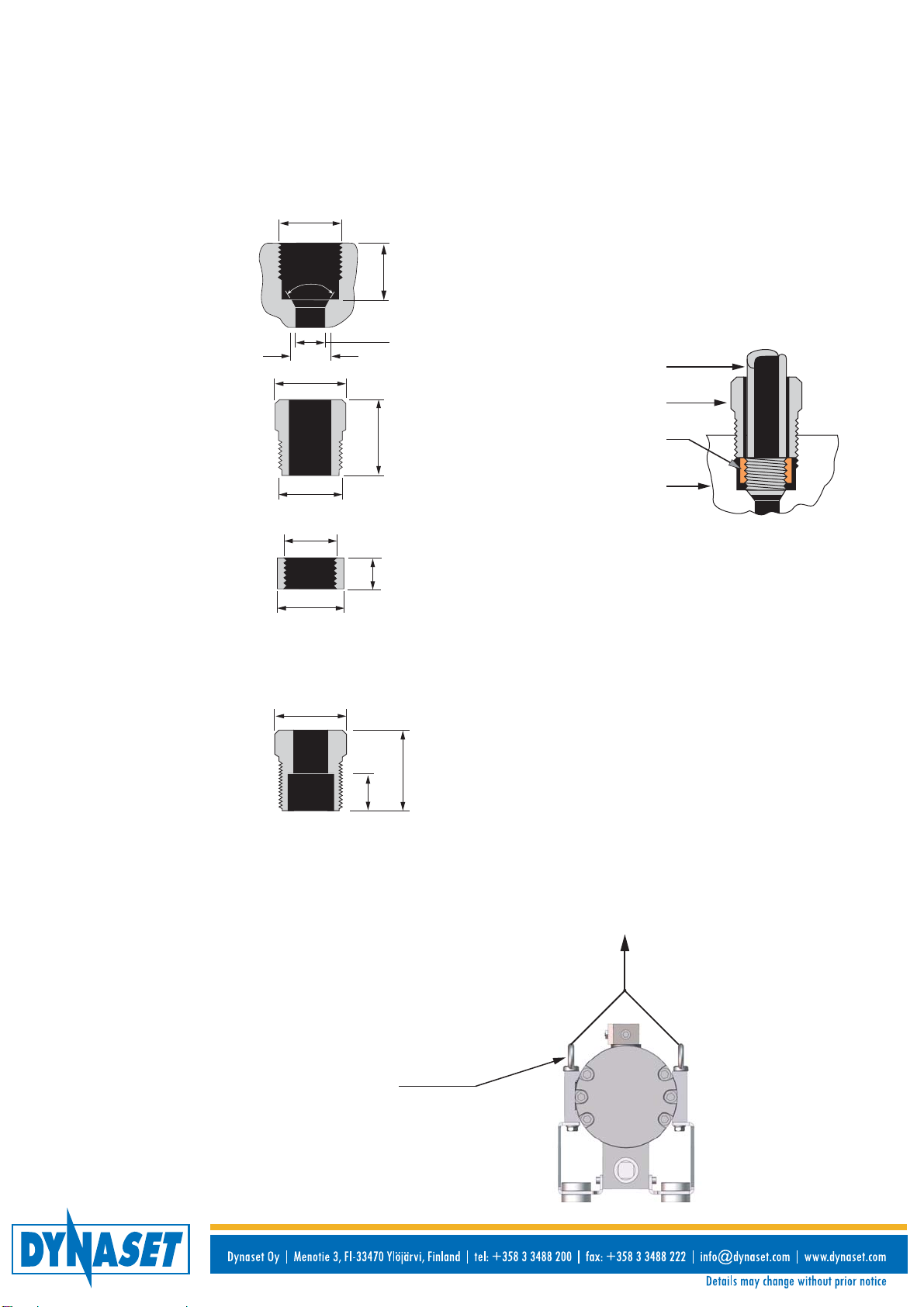

To ensure secure installation use in hydraulic ports SAE 6000 1 1/4” flanges. Use in pressure port MP 3/4“

fitting and in water intake SAE 3000 2” flange.

Recommended bolt torques on assembly.

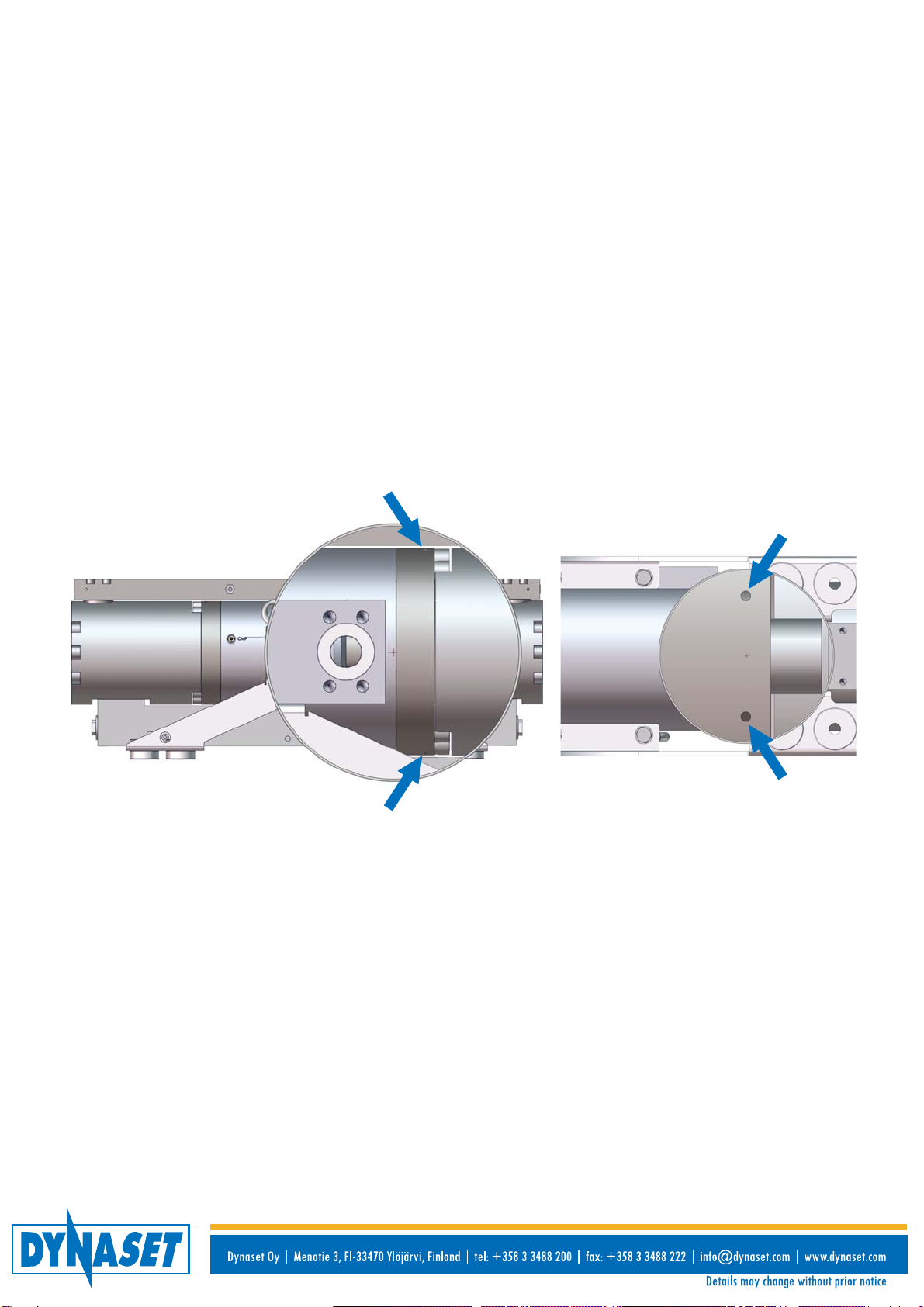

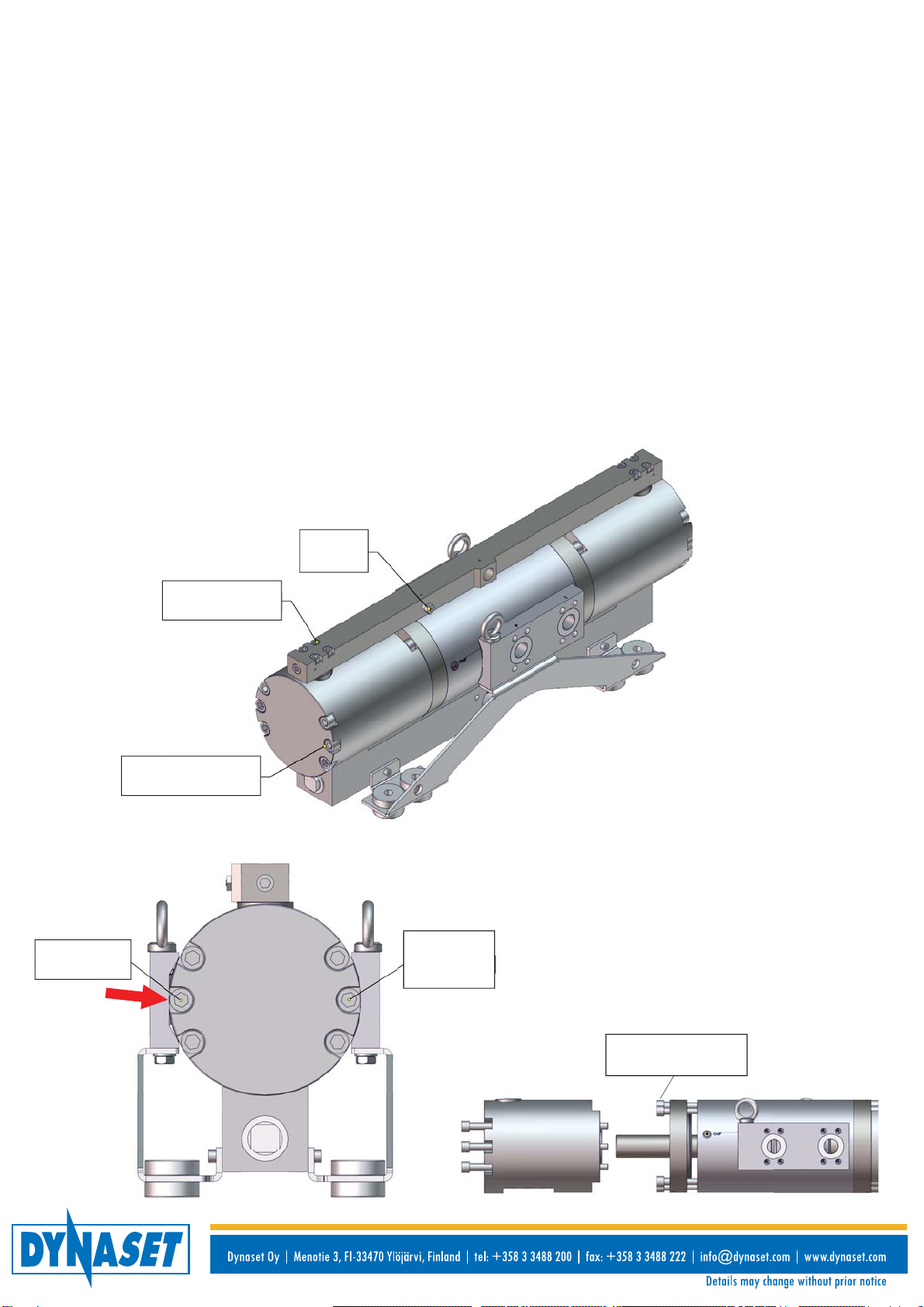

- Water head left six (6) bolts 16x300 mm 300 Nm (221 ft-lb)

- Water head right five (5) bolts 16x300 mm 300 Nm (221 ft-lb), front middle near tank line 1 bolt 16x300 mm

200 Nm (148 ft-lb) red arrow, see next page).

- Seal flange 2 psc. six (6) bolts 16x75 mm 335 Nm (247 ft-lb).

CONNECTIONS

5

1. Pressure and flow in pumping fluid circuit are adjusted by adjusting corresponding parameters in hydraulic

circuit.

2. In circuits based on constant displacement pump closing the water pressure line opens the pressure relief

valve in hydraulic system. PAY ATTENTION THAT HYDRAULIC FLUID CIRCULATION THROUGH

PRESSURE RELIEF VALVE CAUSES HEATING OF HYDRAULIC SYSTEM!

3. In circuits based on variable displacement hydraulic pump closing the water pressure line adjusts pump’s

swash plate at 0° angle when hydraulic pump produces flow only for self-lubrication and self-flushing.

Pressure control must be fast enough to protect HPW-pump from pressure peaks or the hydraulic system

must be provided with pressure peak limiter.

INSTALLATION

HIGH PRESSURE PUMP HPW 1200/100-440

March 2013 JLe

PUMP START-UP

HPW-pump starts immediately after the hydraulic flow has been put on either with control valve (manual or

solenoid) and/or by pulling the trigger of spray gun.

Immediately after opening the water pressure line, air is being vented out from the pumping fluid circuit and

high-pressure washing is about to begin!

DO NOT TRY WITH HAND THE WATER OR AIR COMING OUT FROM HIGH PRESSURE NOZZLE!

The nozzle, attached to a pressure tool, determines the flow rate and pressure of water when operating

parameters of hydraulic circuit meet HPW-pump’s requirements.

In other words, even your HPW-pump fits perfectly to hydraulic system and does well with the job, dimensioning

of the pressure tool should never be underestimated as a very important step for ensuring the optimal water jet

or hydro-demolition power in each application.

ADJUSTING FLOW RATE AND PRESSURE OF PUMPING FLUID

ATTENTION !

Check the ports of your HPW-pump and connect it to hydraulic and pumping fluid circuits according to their

markings !

1. If the hydraulic pressure line will be connected by accident to the return port and return line

correspondingly to the pressure port, it will not cause any harm to HPW-pump, however pump will not

operate.

2. Output power of HPW-pump depends on the pressure difference between pressure and return lines.

The more is the pressure in return line, the less is concerned pressure difference and output power of the

pump. The fact should be taken into account when certain number of machines are intended to be joined-up

in series.

3. Since the piston assembly reverses extremely rapidly (refer to the TECHNICAL SPECIFICATIONS), certain

oscillation can be imposed to the return line because of pressure pulsation. In order to reduce both pressure

pulsation and return line oscillation, the flexible hose with textile fabric cord is recommended to be used in

return line to protect from damage low pressure units, such as oil cooler.

4. Prior to connecting HPW-pump to hydraulic circuit, compatibility of used equipment should be ensured.

Hydraulic pressure and flow rate produced by hydraulic circuit should meet values demanded by your

HPW-pump. Refer to the technical specifications.