3

Table of Contents

1Overview .................................................................................................................4

2Laser Safety............................................................................................................6

2.1 General Information ..........................................................................................6

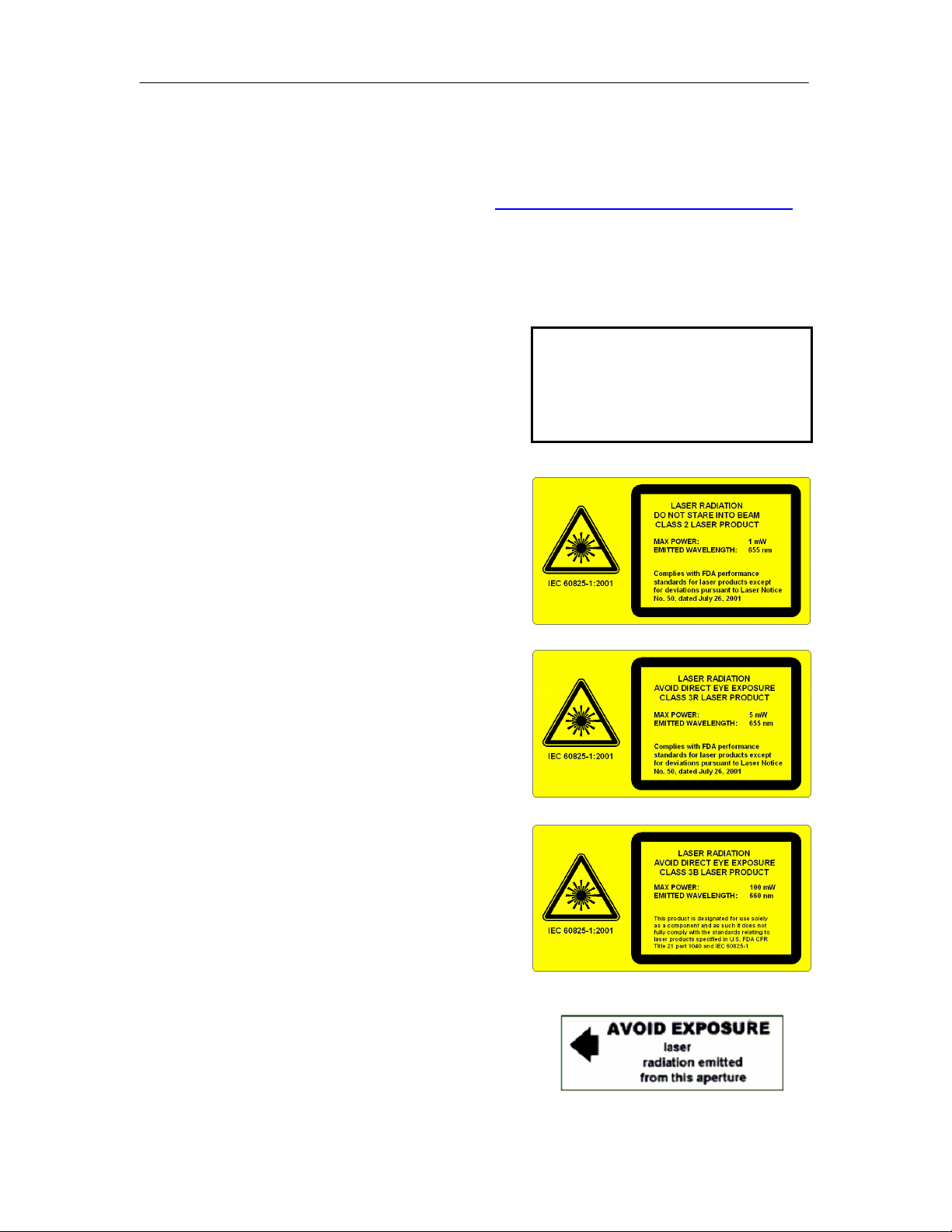

2.2 Laser Classification...........................................................................................7

2.2.1 Laser Classes ..........................................................................................7

2.2.2 User Precautions & OEM Responsibilities................................................8

2.2.3 Class 3B/lllb OEM Responsibilities...........................................................8

2.3 Requirements on laser systems sold or used in the USA ................................10

2.4 B800 laser safety specification........................................................................10

3Sensor Description ..............................................................................................11

3.1 General ...........................................................................................................11

3.2 Performance Specifications.............................................................................11

3.3 Electrical Power Requirements .......................................................................11

3.4 Dimensions .....................................................................................................12

4Maintenance .........................................................................................................13

4.1 Preventative Maintenance Procedures............................................................13

4.2 Welding and the Scanner Frame.....................................................................13

5Connecting the Hardware....................................................................................14

5.1 Connection Overview ......................................................................................14

5.2 Mounting .........................................................................................................15

5.2.1 Sensor Positioning .................................................................................15

5.2.1.1 Relative to the Target...................................................................................... 15

5.2.1.2 Relative to other sensors ................................................................................ 16

5.2.2 Chain Spacing........................................................................................17

5.3 Cabling/Power.................................................................................................19

5.3.1 Connector and Cable Part Numbers.......................................................20

6OEM Design..........................................................................................................21

6.1 Design Requirements......................................................................................21

6.1.1 System Calibration .................................................................................21

6.1.1.1 Determine Laser Alignment Offset/Delay........................................................ 21

6.1.1.2 Determine Range Offset ................................................................................. 21

6.2 Design Recommendations ..............................................................................22

6.2.1 Sensor Mounting....................................................................................22

6.2.2 Baffle Plates...........................................................................................22

6.2.3 Photocells ..............................................................................................23

6.2.4 Scanner Frame ......................................................................................23

7Getting Started .....................................................................................................24

7.1 Powering up....................................................................................................24

7.2 Connecting......................................................................................................25

7.3 Sensor Diagnostics .........................................................................................26

7.4 Application development .................................................................................26

7.5 Ranges ...........................................................................................................27

8Warranty ...............................................................................................................28

8.1 Warranty policies.............................................................................................28

8.2 Return policy...................................................................................................28

9Getting Help..........................................................................................................29