E-Plex 413DWM User manual

Powering systems - Empowering designers

413DWM

Design Specifications

• Shock: Mil Std 202 Method 213 test condition 1.

• Vibration: Tested to Lloyds Register Approval Vibration

Test 2.

• Transient voltage suppression: EN6100-6-1.

• Moisture resistance: IP66.

• PCB characteristics: UL94V-0.

• Power distribution: UL 1077 compliant (except high-

voltage dielectric test).

• Ignition protection: UL 1500 compliant.

• Salt spray: Tested to Lloyds Register Approval Salt Spray

Test.

• Operating Temperature: -40°C to 60°C.

• Storage Temperature: -40°C to 85°C.

• Operating Humidity: 0% to 100% (condensing).

• Weight: 1.34 lb (610g).

Key Features

• 6 channels with outputs capable to 15 amps each (50

amps total).

• 4 channels are diode protected against back feeding.

• 2 channels with PWM dimming capabilities.

• Reverse battery protected.

• Status LED’s for each channel.

• Thermal, short circuit, and programmable overload

protection.

• Local electronic override capabilities.

• Designed for motor loads.

• LEN value 2.

Introduction

The E-Plex®413DWM is a six channel DC power distribution module capable of handling loads of up to 15A

per channel or 50A total. The six channels can be utilized as either inputs, outputs, or a combination of both.

The individual channels may be combined in order to handle larger amperage loads.

With four diode protected channels the module and E-Plex system are protected from being back-fed. This

protection is required in applications where the module is wired in parallel with a system that may be powered

by an additional external source. An example of this includes a bilge pump controlled by a float switch along

with an E-Plex module.

Local electronic override capabilities allow independent operation of the device loads. In addition, the

413DWM design allows for the ability to utilize up to two channels as dimmer circuits, providing a flexible

solution for lighting without requiring additional external dimming hardware.

Hexa Multi Module,

Diode Protected

Powering systems - Empowering designers

413DWM

Electrical Specifications

Mounting Instructions

Screw assembly to a flat mounting surface in 2 places, as shown in the

illustration.

Imperial (English) fasteners: Use #10 size screw, #10 split lock washer, #10

washer. Torque to 20~22 in-lb. Do not exceed this torque as it could cause

damage to the electronics.

Metric fasteners: Use M5 size screw, M5 split lock washer and M5 washer.

Torque to 250~280 N-cm. Do not exceed this torque as it could cause

damage to the electronics.

NOTES:

1. De-rate max current by 0.2 A per °C above ambient, 25°C.

2. Measured at 8.3 ms single half sine wave. (JEDEC Method).

3. Duty cycle at 1 minute on time, 5 minutes off. Trip delay must

be set to maximum rating.

4. Single pulse only.

5. Measured at 10 A load.

6. PWM not recommended for motor loads unless factory

authorized.

7. For load resistance greater than 2 ohms load inductance is

unlimited.

8. Specified as 50 feet of 2 AWG (43 mm²) wires with a 6 inch

diameter spool for both power and ground.

9. For a channel configured as an input this specifies the turn-on/

off threshold impedance @ 50K.

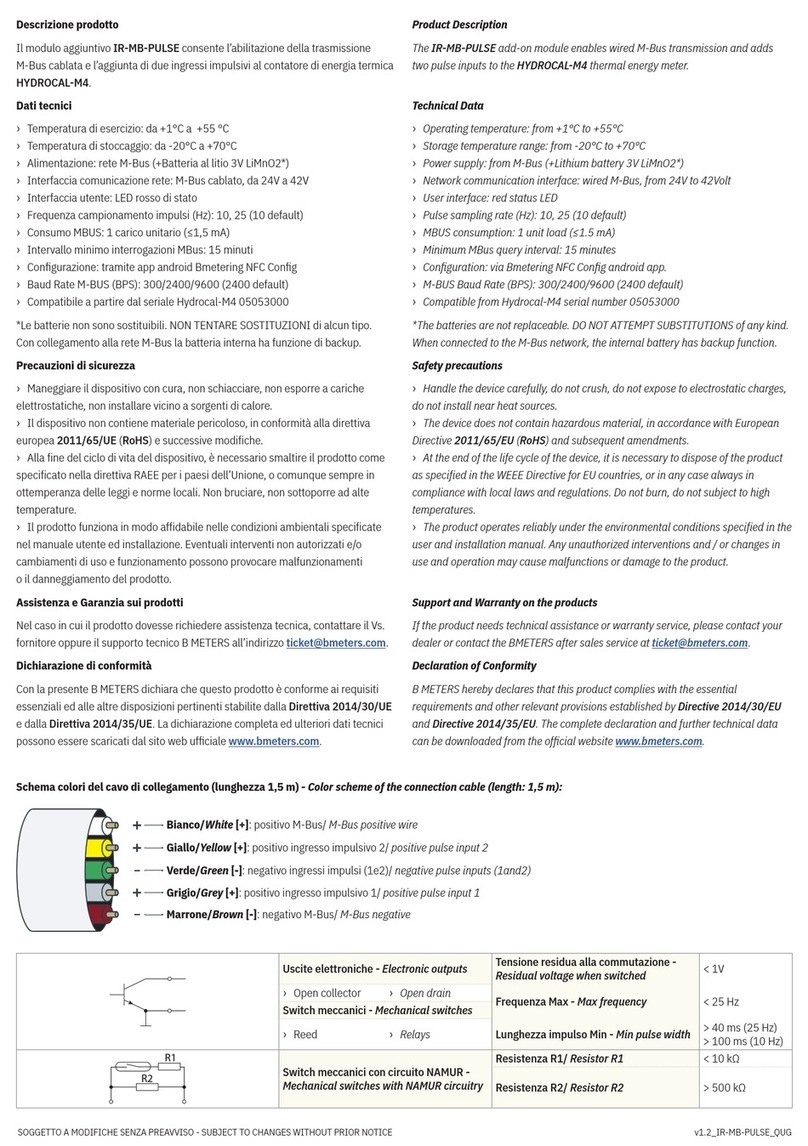

Description Minimum Nominal Maximum Absolute Maximum (Surge)

Voltage 7 VDC 12/24 VDC 32 VDC 45 VDC

Current, Total 0.025 A 30 A 50 A 1160 A 2

Current, per channel continuous 0 12 A 15 A 80 A 4

Current, per channel

intermittent duty 30 – 20 A 80 A 4

Inrush capable per channel – – 80 A 80 A 4

Input low threshold 90 V – 3.5 V –

Input high threshold 94.5 V – 32 V –

Lead inductance 0 – 100 µH 8–

Load Inductance 70 – 20 mH –

PWM Frequency 60 Hz 122 Hz – -

Output Impedance 510 mΩ 12 mΩ 14 mΩ

Diode Protection (Back-Feed) 0 - 20A -

The supply to the module should be protected by a fuse or circuit breaker, 50A maximum

Powering systems - Empowering designers

413DWM

Trip Speed Characteristics

Wiring Specifications

Pin # Pin Description

A1 Solid State Output 3

E1 Output 3 Return

PWM

Capable

B1 Solid State Output 2

F1 Output 2 Return

C1 Solid State Output 1

G1 Output 1 Return

D1 E-Plex Data Bus +

H1 E-Plex Data Bus –

M5-T1 Battery Power

Pin # Pin Description

D2 Solid State Output 4

Diode

Protected

C2 Solid State Output 5

B2 Solid State Output 6

A2 E-Plex Data Bus +

E2 E-Plex Data Bus -

F2 Output 6 Return

G2 Output 5 Return

H2 Output 4 Return

M5-T2 Battery Return

Outputs and Returns: 0 to 15A, 7-32VDC

The first two outputs (C1, B1) are PWM capable and may be used to dim lighting loads. Channels A1 and B2 through D2

incorporate a diode to protect against back-feeding from an external source.

Battery Power (+): 0.025A to 50A, 7-32VDC

Status LEDs:

ON - Channels 1-6 indicates Load ON, E-Plex channel indicates module responding.

OFF - Channels 1-6 indicates Load OFF, E-Plex channel indicates module not responding. 10

BLINKING - Channels 1-6 indicates Load FAULT, E-Plex channel indicates module responding.

Power / Battery Connections: Must be fused at a maximum of 50A. Maximum wire size should be sized based on upstream fuse.

When connecting the power source to the power studs on the module, torque the M5 hex nuts should be torqued to 20~22 in

lb or 250~280 n-m after installing the battery terminals to the studs. Failure to properly torque hex nuts may result in intermittent

operation due to terminals loosening over time. Note: External surge suppression is required when the module battery supply

cable is longer then 50’ (25’ for any 2 outputs that are paralleled).

Reversed Battery Conditions: The loads will turn on, but no damage will occur to the module if disconnected within 1 minute

(Under nominal operating load conditions).

Powering systems - Empowering designers

413DWM

Pin Specifications

Typical Wiring Diagram

NOTES:

10. LED will be off if system is not functioning or present, however, modules in the system may still be responding.

11. Manual override switches are meant to be used as a local electronic manual override for emergency situations only.

12. Load activation function for switches 1 thru 6 are defined in E-Logic as either toggle or momentary operation.

13. Diode is incorporated to protect channel from back-feeding from an external source.

Cable Range AWG (mm2)Female Terminal Terminal Insulation

Range

Seal Insulation

Range Seal P/N

18-16 (1.0-0.75 mm2) 15304716 1.70-2.25 mm 1.20-1.85 mm 15366063

1.85-2.25 mm 15356064

16-12 (2.50-1.50 mm2) 15304717 2.20-3.00 mm 2.09-2.66 mm 15366061

2.70-3.2 mm 15336674

Status LEDs,

Channels 1 - 6

and E-Plex10

Ch. 6

Ch. 5

Ch. 4

Ch. 3

Ch. 2

Ch. 1

E-Plex

Channels 1-6,

Override Switches

11,12

M5 - T2

M5 - T1

+

Battery Return

(Ground)

E-Plex +

E-Plex –

D1

H1 Lamp

C1

B1

A113 Pump

G1

F1

E1

Pump

Motor

E2

A2

H2

G2

F2

D213

C213

B213

E-Plex

+E-Plex

–

Lamp

Motor

12VDC or 24VDC,

Battery power protected by a fuse

or circuit breaker, 50A maximum

Powering systems - Empowering designers

413DWM

Dimensional Diagram

Mechanical Specifications Ordering Information

Description E-Plex Part Number

413DWM Series - Hexa

Multi Module, Diode

Protected

EP-SW-IO-6CH-413DWM

Connectors:

J1 - Brown: Mates to Delphi P/N 15317308

J2 - Blue: Mates to Delphi P/N 15317304

Cavity Plug:

Delphi P/N 12059168

Power Stud Connections:

M5 nickel plated brass

127mm [5.00”]

63.5mm [2.50”]

113.3mm [4.46”]

13.7mm [0.54”]

73.7mm

[2.90”]

92.7mm

[3.65”]

135.6mm

[5.34”]

45.7mm

[1.80”]

Ø0.39 [Ø9.91]

Ø 6.10mm [0.24”] x 2]

Ø 5.08mm

[0.20”]

12.9mm [0.51”]

11.9mm [0.47”]

8.1mm [0.32”]

4.8mm [0.19”]

63.5mm

[1.50”]

52 – 54 Riverside, Sir Thomas Longley Road, Medway City Estate, Rochester, Kent ME2 4DP

tel: +44 (0)1634 711622 fax: +44 (0)1634 290773

email: [email protected]

web: www.e-plex.co

Important Notice: E-Plex Ltd. (E-Plex) reserves the right to make changes to or discontinue any product or service identified in this publication without notice. E-Plex advises its customers to obtain

the latest version of the relevant information to verify, before placing any orders, that the information being relied upon is current. E-Plex assumes no responsibility for infringement of patents or

rights of others based on E-Plex applications assistance or product specifications since E-Plex does not possess full access concerning the use or application of customers’ products. E-Plex also

assumes no responsibility for customers’ product designs.

Powering Systems - Empowering Designers

Table of contents

Other E-Plex Control Unit manuals