E-Plex 805OPM Series User manual

This manual suits for next models

4

Table of contents

Other E-Plex Control Unit manuals

Popular Control Unit manuals by other brands

DMP Electronics

DMP Electronics 734 Installation and programming guide

A.R.I.

A.R.I. Eliptix R-30RM Installation, operation and maintenance

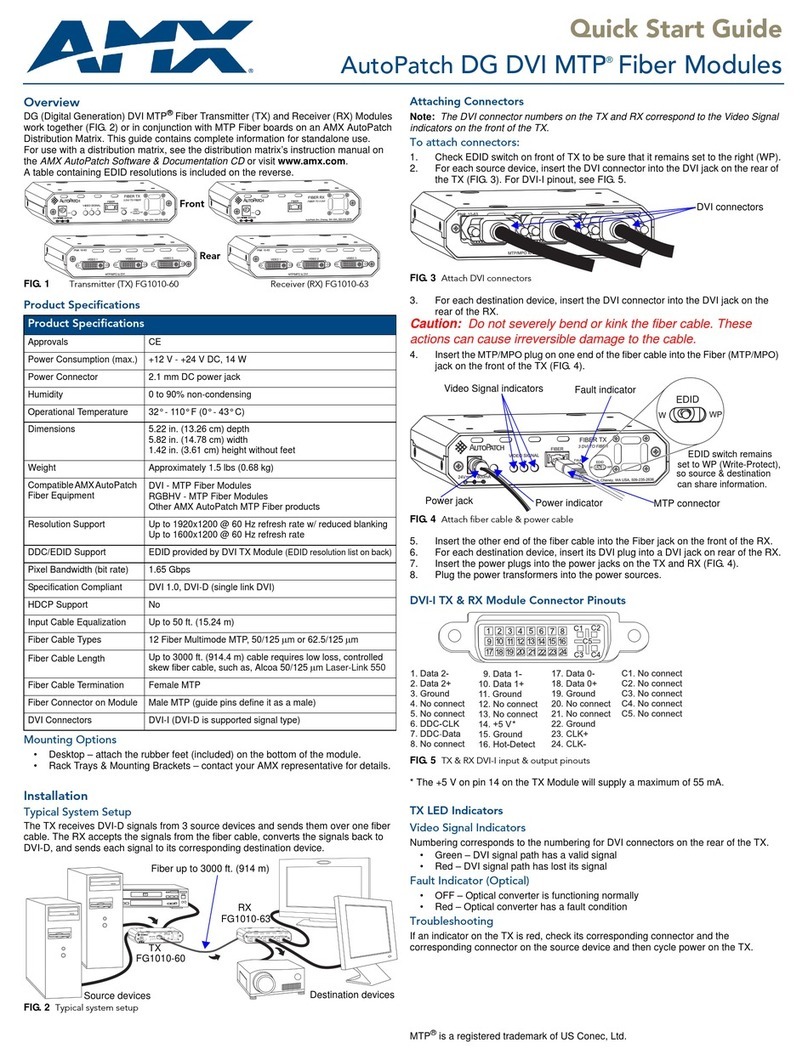

Epson

Epson RX4111CE Applications manual

Ecolab

Ecolab MULTILINE 1000 Short operating instructions

Current

Current GTX PS6 GT1 installation guide

PCB Piezotronics

PCB Piezotronics 070M70 Installation and operating manual

M-system

M-system R7E-DC16A instruction manual

Red Valve

Red Valve Flexgate D series Installation, operation and maintenance manual

G-Tools

G-Tools Smart Box manual

Reliance electric

Reliance electric GV3000 instruction manual

Delta Computer Systems

Delta Computer Systems VMC 186/40 manual

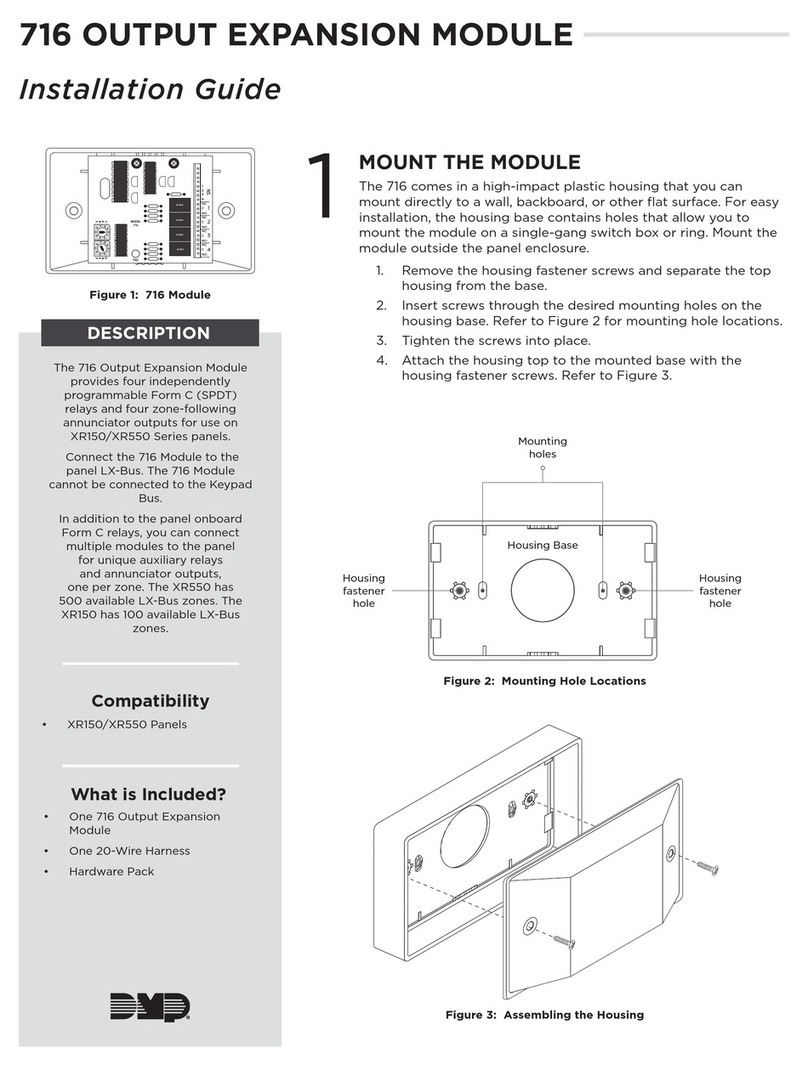

DMP Electronics

DMP Electronics 716 installation guide