E-SCS PBR-15L Guide

22

33

44

55

66

77

22

33

44

66

55

INSTALLATION MANUALINSTALLATION MANUAL

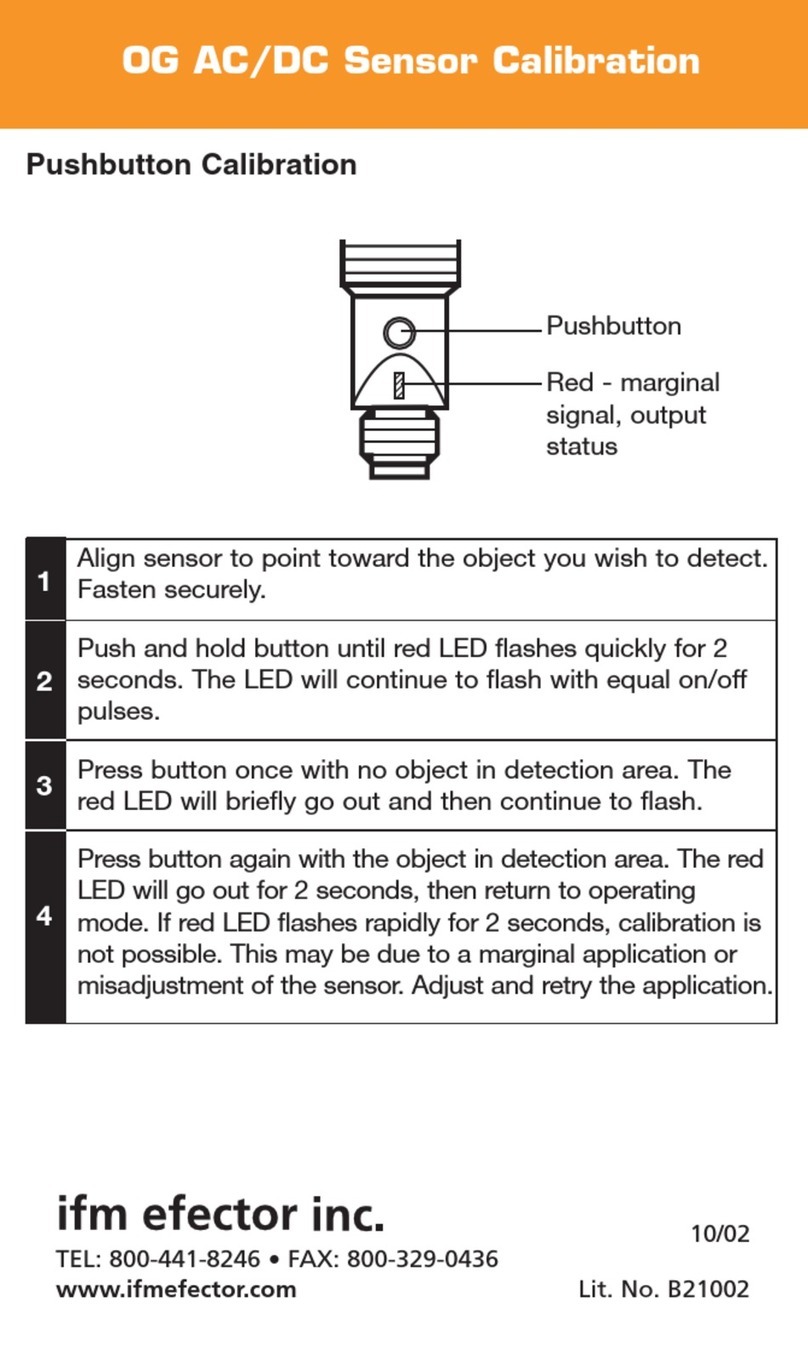

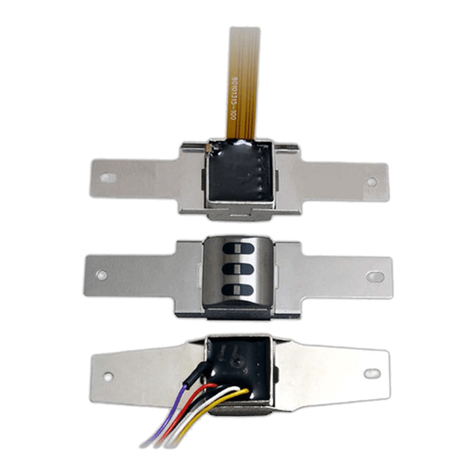

[COVER] [SENSOR] [REFLECTOR]

Terminals

Alarm LED

Voltage

Vertical

adjustment

screw

View finder

Signal LED

Delay time

adjustment

knob

Horizontal

adjustment

Lens

Tapping screw:4

Mounting Plate:2

2.CAUTIONS ON INSTALLATION

Do Not

Remove all abstructions

(trees,clothes,lines,etc.)

between Sensor and

Reflector.

Avoid strong light from the sun,

automobile headlights etc.directly

shining on Sensor/Reflector.

When strong light stays in optical

axis for a long time, it does not

cause malfunction but will affect

the product life.

Do not install the unit on places

where it may be splashed by dirty

water or direct sea spray.

Do not install the unit on

unsteady surfaces.

Expansion of beam

The protection distance(between Sensor

/Reflector)should be placed in the rated range.

Model

PBR-15 15m(49 ft.) 0.6m(2.0 ft.)

Detection distance Spread of beam

Spread of beam

Features: Applications:

Full Range Input VoltageFull Range Input Voltage

Retro-Reflective Photobeam DetectorRetro-Reflective Photobeam Detector

1.PARTS DESCRIPTION

PBR-15L / PBR-15D

Retro-Reflective photobeam detector Gateopener

Full Range input voltage (AC/DC 12~250V) Overhead door

Red infrared led element Swing gate

Long sensing range: 15 meters Sliding door

IP-55 water proof Parking lot

Hood for sensor & reflector pack Window

Triple square shape reflector set Terrace

Pole mounting bracket included. Warehouse

Perimeter protection

Power and beam alignment led indicators included.

Automation control

1

6.RESPONSE TIME

Adjust response time as follows.The unit does not detect the passing object faster than the response time set.

If the response time is set longer, the unit does not detect human beings.

Adjust to a little longer response time in a site where large passing objects, newspaper or carton box may move.

7.TROUBLESHOOTING

Trouble

Sensor LED does not light.

Sensor LED never lights up

when the beam is interrupted.

Incorrectly wired and/or insufficient voltage

a. Insufficient voltage

b. Beam reflected away from receiver

c. Beams not simultaneously interrupted.

Beams interrupted and LED

lights, but no alarm tigger.

Alarm tigger cable may be cut,or the relay

contact stuck due to overloading.

Alarm LED continuously lit. a. Lenses out of alignment.

b. Beam are blocked.

c. Cover is foggy or dirty.

Alarm tigger becomes erratic

in bad weather.

Lenses out of alignment.

Frequent false triggers from

leaves, bird, etc.

a. Too sensitive.

b. Bad location. a. Reduce the response time.

b. Change the sensor and/or location.

Ensure the power supply to the sensor is

10 to 30 VDC.

a. Double-check the voltage.

b. Clean the cover.

c. Check overall installation.

Check the continuity of the wiring between the

sensor and the alarm.

a. Realign the lenses.

b. Remove any obstacles.

c. Clean the cover.

Check overall system installation. If still erratic,

realign the lenses.

Possible Origin(s) Remedy(s)

Model Number Light On: Normally Close Relay Output

Dark On: Normally Open Relay Output

Input Volt. AC/DC 12~250V

Infrared Led Red infrared led element/940 nm

Detection Method

Contact capacity N.O./N.C. Relay Output, 0.5A@120V (min. 1 sec.)

Response time 50~700 msec.

Delay time of relay 1,000 msec

Sensing range 15 meters

Current Drain

Volt. Output

Led indicators for

beam alignment

& Power

Beam Aligned: 90mA / Beam Broken: 70mA

Beam Aligned: 70mA / Beam Broken: 90mA

1~6V

Yellow led Off: Beam aligned / Yellow led On: Beam broken

Yellow led flash: Beam alignment signal weak (Re-align)

Green led On: Power On

Wirign connection Terminal block/Cable gland (IP-66)

Ingress Protection IP-55

Environment/Stroage Temp.

Alignment angle

-13 F ~ 131 F (-25 C ~ 55 C)

Horizontal: 90 / Vertical: 5

8.SPECIFICATIONS 9.EXTERNAL DIMENSIONS

4

Retro-Reflective

Unit: mm

Detection distance

Dimensions

Weight

Sensor: 182(L) 80.4(W) 91(D)mm

Sensor: 0.41 kgs

Reflector with Hood: 182(L) 80.4(W) 91(D)mm

Reflector with Hood: 0.25 kgs

ABC

A

B

CFast running Normal walking Slow walking

PBR-15L

PBR-15L

PBR-15D

PBR-15D

91

91

80.4

80.4

88

182182

Power

Alarm signal

Example connection 2 - In-line Single Channel

Sensor(1)Reflector(1) Reflector(2)Sensor(2)

Example connection 1 - Standard

Power

Alarm signal

Connection

Position of installation

The photoelectric beam lens can be adjusted horizontally

, and vertically . This allows much flexibility in

terms of how the Sensor and Reflector can be mounted.

Install at a distance of 32" to 39"(80 to 100cm)above the

ground for most situations.

Vertical

adjustment

screw

Horizontal

adjustment

3.WIRING

Wiring

Power

AC/DC 12~250V

(non-polarity)

Tamper output N.C.

switch 120V(AC/DC)1A

(When cover detached)

Alarm output

120V(AC/DC)1A

Run a cable from the alarm control panel to the photobeam sensor.

If burying the cable is required, make sure to use electrical conduit.

Shielded cables strongly suggested. See table 1 for maximum cable length.

Running the Cable

Note(1): Max.cable length when two or more sets are connected is the value

show in Table 1 divided by the number of sets.

Note(2): The power line be wired to a distance of up to 3,300 ft.(1,000m)

with AWG22(0.33mm) telephone wire.

2

22

33

44

55

66

77

22

33

44

66

55

22

33

44

55

66

77

22

33

44

66

55

Wall Mount

(1)Loosen the cover locking screw and remove

the cover.Loosen the unit setting screw at

lower part of unit base. Side the mounting

plate downwards and remove it.

(2)Pull wire through on the installation site.

(3)Break grommet on mounting plate and

pull wire through it.Secure the plate with

4mm screws.

Note:Plug opening between grommet

and wire with sealing meterials.

Pull wire through sensor body(back to front)

and attach it to the mounting plate.

(4)When exposed wired break knockouts

(2 positions)on the rear of unit,pull

wire through as the figure and attach

it to the mounting plate.

(5)After wiring is completed,adjust

alignment ,check operation and

attach cover.

Pole Mount

(6)Do the same procedure as (3)-(5)of wall mount.

(2)Insert 2 pcs.of oval countersunk head screws(M4x20)in a pole bracket

with a few rotation.

(3)Fix pole mounting plate to pole with pole bracket.

(1)Use dia 38mm to 45mm pole.

(4)Detach cover,and remove mounting plate from sensor body.

(5)Temporily insert 2 pcs of M4x10 screws in pole mounting plate and fix

sensor,mounting plate on them.

Pole mounting

plate

Pole breaket

Eyeball adjustment

(1)Remove the sensor cover, and look into one of the alignment viewfinders

(one of the four holes located between to two lenses)at a 45 angle.

(2)Adjust the horizontal angle of the lens vertically and horizontally until the

reflector is clearly seen in the viewfinder.

(3)Replace the sensor covers.

NOTE: If you cannot see the opposite unit in the viewfinder, put a

sheet of white paper near the unit to be seen.

Horizontal

adjustment

View

finder

Vertical adjustment

View finder

Voltage output

> 2.8V

2.0~2.7V

1.2~19V

Best

Re-adjust

Good

Alignment quality

Fine Tuning the Receiver

(1)Once the sensor is mounted and aligned,the sensor can

be fine tuned using the voltage output jack.

<1.1V

Fair

(2)Set the range of a volt-ohm meter(VOM)to 0~10VDC.

(3)Measure the voltage.

(4)Adjust the horizontal angle by hand until the VOM

indicates the highest voltage.

(5)Adjust the vertical angle by turning the vertical

adjustment screw until the VOM indicates the highest

voltage.

4.INSTALLATION METHOD

5.ALIGNMENT AND OPERATION

3

Table1:Cable Length

12V 24V

PBR-15

Wire/Volt.

340m

575m

900m

1,090m

3,000m

5,100m

7,920m

10,400m

AWG22

AWG20

AWG18

AWG16

Model No.

Sensor

Reflector

This manual suits for next models

1

Other E-SCS Accessories manuals