E.T. Systems Challenger MKIII User guide

INSTALLER’S MANUAL

REVISED DATE: March 2004

AUTOMATIC GARAGE DOOR OPENER

take control of your world

2

1. WHAT’S IN THE BOX

A list of contents you will receive with this product and

technical specifications

2. WHAT’S NOT IN THE BOX

A list of optional accessories available for this product.

Please contact your E.T supplier for more information.

3. RECOMMENDED TOOLS

A list of tools recommended for the installation of this

product

4. IMPORTANT: BEFORE INSTALLING

What you need to know before installing this product.

PLEASE ENSURE THAT YOU READ AND UNDERSTAND THIS SECTION BEFORE

INSTALLING THE PRODUCT.

This section highlights any special warnings and precautions.

5. INSTALLING THE HARDWARE

6. WIRING & SCHEMATICS

7. PROGRAMMING & COMMISSIONING

8. MAINTENANCE

9. TROUBLESHOOTING

10. WARRANTY

11. NOTES

Documented serial number and date of purchase

INDEX

6

7

9

17

20

23

24

29

5

3

30

3

MOTORHEAD:

· 1 x Motorhead - complete

· 1 x installer’s manual

· 1 x user’s manual

In sealed bag:

· 4 x M6 x 75mm hexagonal bolts

· 4 x 6mm washers

· 1 x M8 Rawl bolt

· 4 x M8 x 40mm coachscrews

· 1 x M8 x 90mm hexagonal bolt

· 7 x M8 Nylock nuts

· 4 x M8 x 16mm hexagonal bolts

· 2 x M8 x 25mm hexagonal bolts

· 1 x wall mount bracket

· 1 x door bracket

· 4 x No.4 3mm x 16mm counter-sunk self-tapping screws (possie-

drive head)

· 1 x emergency manual release cord kit

· short strip double-sided velcro (for fixing TX to wall for wall console)

DRAWBAR:

· 1 x drawbar complete (see technical specifications overleaf for

more details)

· 2.5 lengths perforated angle hanging straps

· 1 x link arm

· 2 x magnets and holders for chain

WHAT’S IN THE BOX

4

TECHNICAL SPECIFICATIONS

Motor - 220v AC 50Hz

- 2 Amp single-phase

- Thermal overload protection

- Intermittent duty cycle

Drive assembly - Worm reduction gearbox

- Sprocket and chain driven

Traveling speed: - 8.6 metres/ minute (approx.)

Operating temperature: - 0°C – 50°C

Control system: - Microprocessor controlled

- On-board 2-channel receiver with

remote holiday lock-out option.

- Revolution counter load sensing.

Required front-end - Sectional overhead doors:

spacing above door: 50mm above highest point of travel

- Trackless one-piece doors (tip-up):

275mm top edge of closed door

Drawbar options: - 2m: Standard door with 7 foot hinge

- 2.5m: Oversize door with 8 or 9 foot hinge

- 3m: Sesco door up to H 2.3

- 3.5m: Sesco door 2.3 - 2.7m

WHAT’S IN THE BOX

5

· 1, 2 or 3 button transmitters (remote controls)

· Escape lock (to use when no side entrance to garage)

· Extendable link arm (to use when motor installation above

door not possible. Please ask for advice before attempting to

fit these)

· Safety infra-red beams or other safety input device

· Multi-memory location receiver for individual coding security

· Assortment of nuts, bolts, wall plugs, Rawl bolts, coachscrews,

pop-rivets, dowels, self-drilling screws or chemical fasteners

needed for fixing of operator to non-wooden doors and

hanging structures.

PLEASE CONTACT YOUR E.T. PRODUCT SUPPLIER FOR MORE

INFORMATION OR TO ORDER THE ABOVE.

WHAT’S NOT IN THE BOX

6

RECOMMENDED TOOLS

· electric hammer-action drill

· 13mm masonry bit

· 5mm wood bit

· 10mm spanner/ wrench

· 2 x 13mm spanners/ wrenches

· 2.5mm blade flat screwdriver

· PH01 star screwdriver

· hacksaw

· hammer

· 6ft/ 2m A-frame self-standing stepladder

· tape measure

· spirit level

In the case of a non-wooden door, always check with the door supplier

as to recommended fixings and types of tools needed for the installa-

tion of a garge door operator on their doors.

7

BEFORE INSTALLING

BEFORE ATTEMPTING TO INSTALL A GARAGE DOOR

OPERATOR, PLEASE BE CERTAIN YOU HAVE READ AND

UNDERSTOOD THE FOLLOWING:

1. CHECK THAT THE GARAGE DOOR IS MECHANICALLY SOUND AS PER

MANUFACTURERS SPECIFICATIONS.

Points to inspect (general to all makes of doors):

· Mechanisms must be secure, sound, lubricated. Door hinging and

balancing mechanisms must be fastened properly to both door and

structure.

· All nuts and bolts must be tightened according to manufacturers

specifications.

· Do not attempt to adjust tensioning systems unless duly

qualified to do so.

· Ensure springs are not over-stretched and are functioning properly.

· Test door for ease of operation with no snags throughout

door’s travel to full opening to full closing positions.

2. ENSURE THAT A SOLID FIXING POINT IS USED ABOVE DOOR for

securing the front-end bracket. A correctly fabricated bracket

extended from a solid structure is to be used in the case of

fascias, false panelling, header panels etc. For installations

in block walls (cinder bricks), you should use a through-bolt

or cross-braced plate.

3. ENSURE THAT THE HANGING BRACKETS USED TO SECURE THE

MOTORHEAD are fixed to a structure that can support the

weight and load of the garage door operator in operation.

(Rhino boarding and ceiling board DO NOT qualify as solid

structures).

8

4. INSPECT THE SPINE (TOP EDGE) OF THE DOOR for weaknesses such as

cracks or wood-knots. Ensure that the point that the door mount

bracket is attached to, will sufficiently support the weight and load

of the door when operated.

If there is any question to the above, replace or brace the spine

(top edge) of the door with stronger material.

5. ENSURE THAT ANY MECHANICAL LOCKS are either removed or se-

curely locked in the UNLOCKED position.

6. ONE CHALLENGER DOOR OPERATOR IS NOT INTENDED TO BE USED TO

OPERATE TWO SINGLE GARAGE DOORS IN TANDEM. i.e. one motor

per installed door.

E.T. Systems will not guarentee any Challenger unit working on

more than one door. However, the Challenger units will be able to

automate one complete double oversized door.

7. PLEASE BE SURE TO MATCH THE DRAWBAR LENGTH to the type of

hinge assembly when automating oversized doors.

8. Please note that the Challenger range of garage door operators

are NOT IP55 weather-proof rated and are thus only intended for

installations in protected garage-type conditions i.e. under a roof

and out of the wind. This is even more critical when the unit is used

near a coastline.

BEFORE INSTALLING

9

INSTALLING THE HARDWARE

Before starting your installation, check that you have the correct

tools required for your type of installation.

Check that your Challenger garage door operator kit is complete.

STEP 1 - ASSEMBLE THE DRAWBAR TO THE MOTORHEAD

If you choose to mount the

motorhead above the drawbar

(for more headroom when using

the Challenger operator on a Tip

Up type Door), you must reverse

the motor’s forward and reverse

wiring and open and close limits.

BROWN

WHITE

RED

BLUE

FINAL WIRING CONFIGURATION FOR REVERSE MOUNTING

Remove magnet assembly and re-attach

the assembly to the chain by turning it

over so that it ends up as shown in this

photograph.

The magnet should be between the

chain and reed switch.

Once you have finished assembling your Challenger garage door operator,

proceed to Step 2 - Mounting the link arm and door mount bracket.

Figure 9.2

Figure 9.1

Figure 9.3

Using the 4 M6 x 75mm hexagonal bolts

and 6mm washers, tighten your

motorhead unit to the drawbar’s

geared and splined back-end, by

means of the 10mm spanner/ wrench.

10

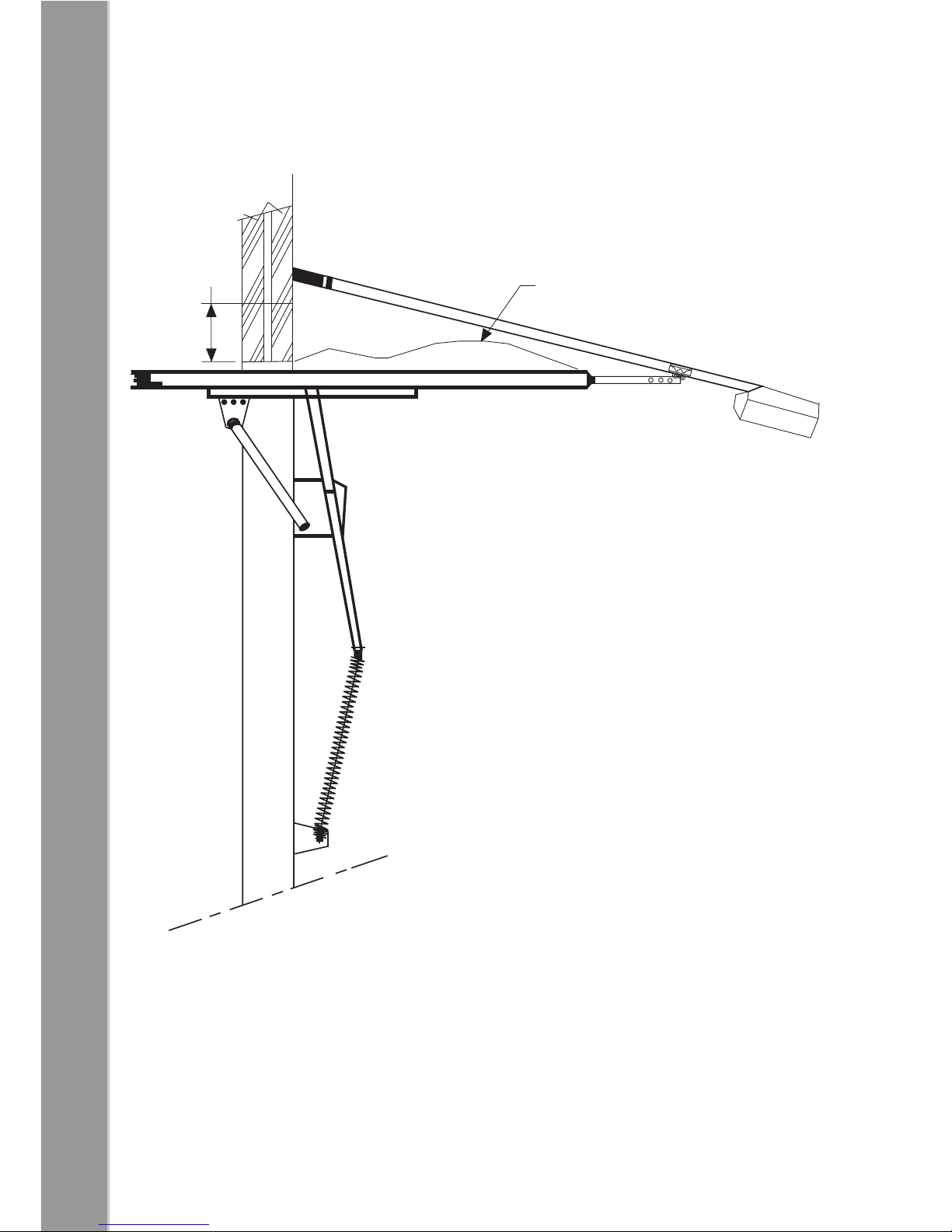

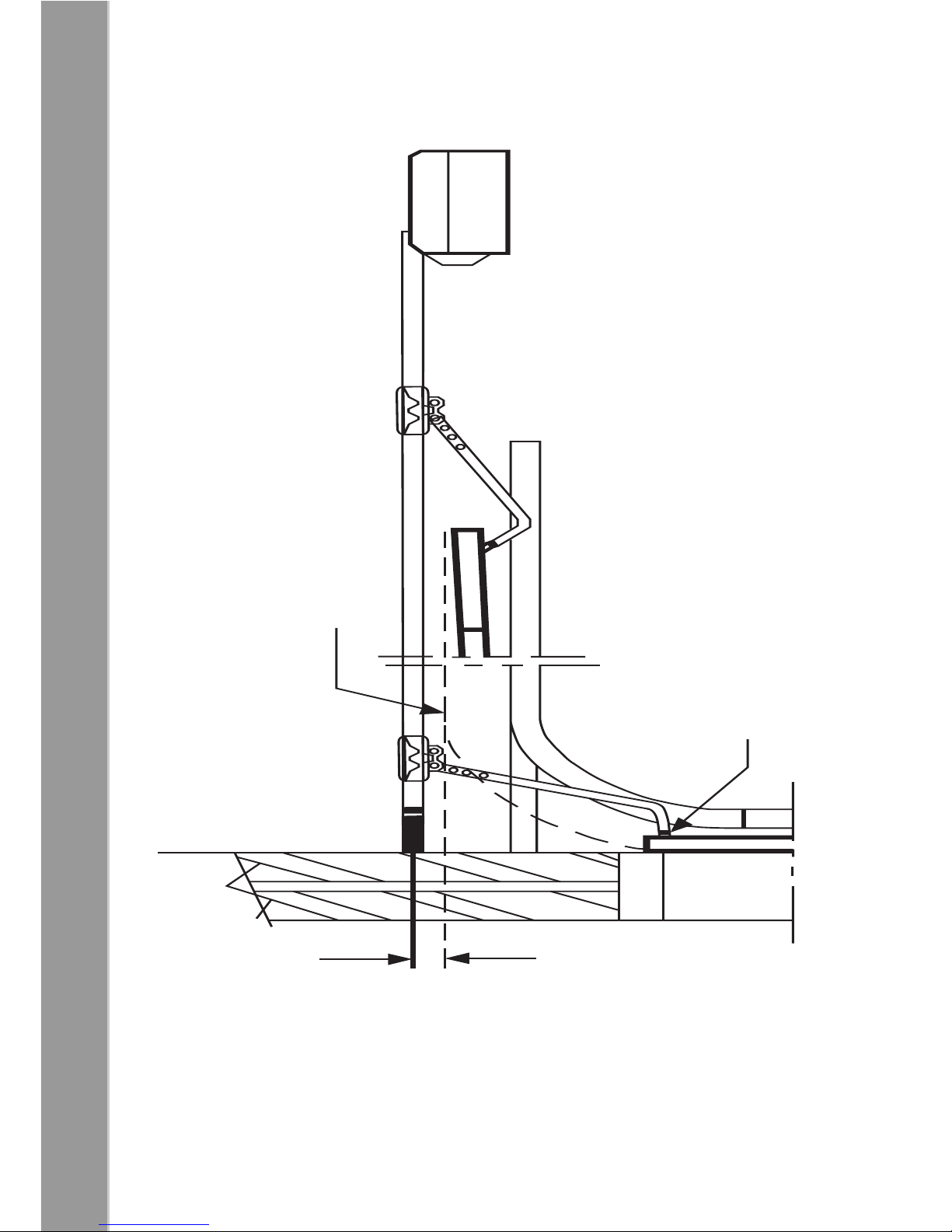

TIP-UP TYPE DOORS

INSTALLING THE HARDWARE

Figure 10.1

275mm

from top of door

when closed

HIGHEST POINT

OF TRAVEL

11

INSTALLING THE HARDWARE

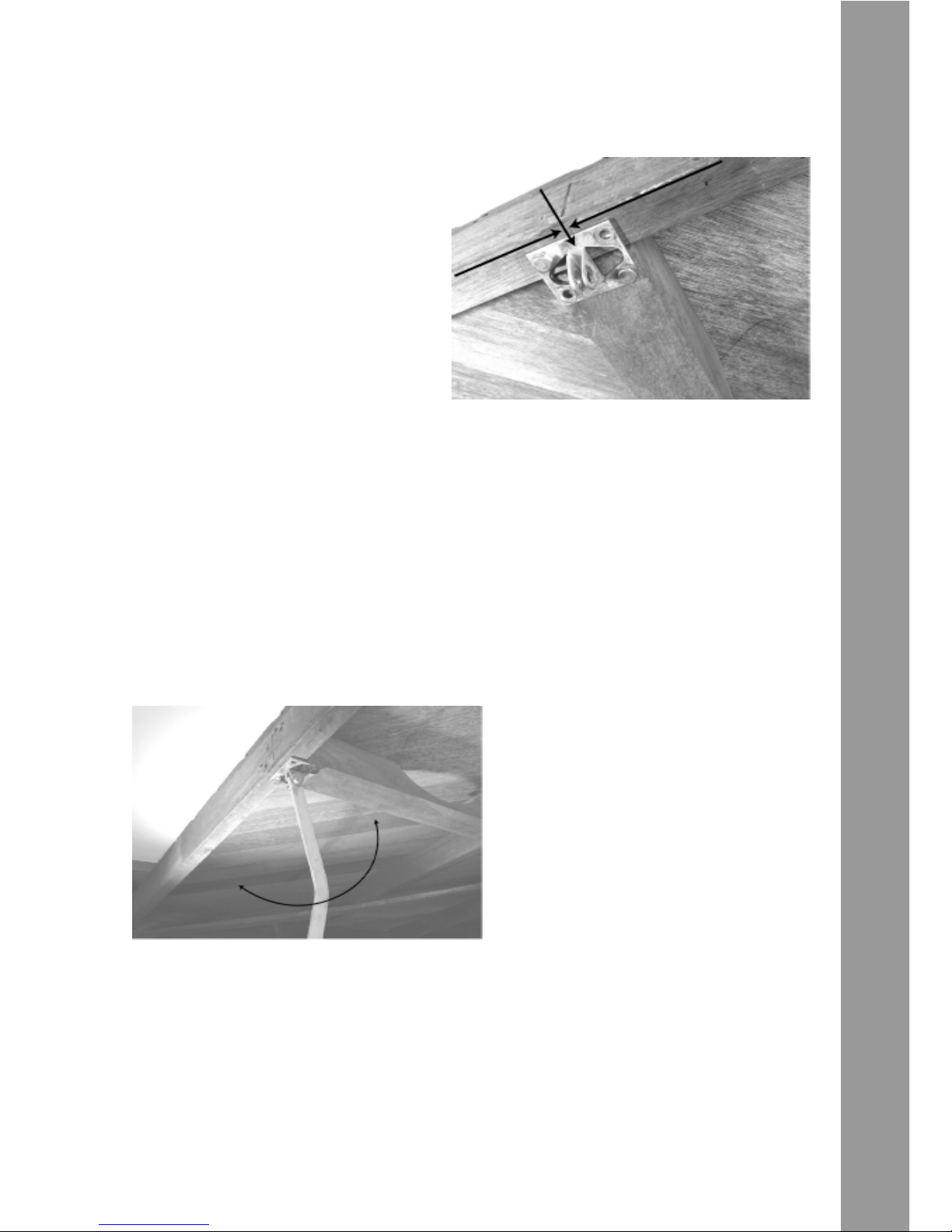

STEP 2 - MOUNTING THE LINK ARM AND DOOR MOUNT BRACKET

TIP UP TYPE DOOR

(refer to diagram on page 10)

Locate and mark the center position

of the spine (top edge) of the door.

Figure 11.1 .

While holding the door mount bracket in place on the centre position, mark

the mounting hole positions.

Using your 5mm wood drill bit, drill pilot holes into the door spine where you

have just marked the door.

Fasten the door mount bracket to

the door, using your 13mm spanners

and/ or wrenches and 2 of the M8 x

40mm coachscrews (for other types of

doors, use recommended fixtures).

Figure 11.2

Fasten the link arm to the door mount bracket, using your 13mm spanners

and/or wrenches and 1 of the M8 x 25mm hexagonal bolts and M8 Nylock

nuts.

Be certain not to over tighten the nut and bolt as the link arm must be able to

swing freely up and down in the door-mount bracket.

When you have completed the above, move on to Step 3 - Determining the

mounting position and mounting of the drawbar front-end.

A=B

AB

12

OVERHEAD SECTIONAL TYPE DOORS

INSTALLING THE HARDWARE

Figure 12.1

HIGHEST POINT

OF DOOR TRAVEL

DOOR BRACKET

LEVEL WITH ROLLER

IN TOP BRACKET

50mm

13

INSTALLING THE HARDWARE

OVERHEAD SECTIONAL TYPE DOOR

(refer to diagram on page 12)

Locate and mark off the

centre position on the inside

fascia on the spine (top edge)

of the top panel of the door, in

line with roller in top bracket.

Figure 13.1

While holding the door mount bracket in place on the centre position

mark the mounting hole positions.

Using your 5mm wood drill bit, drill pilot holes into the door spine where

you have just marked the door.

Fasten the door mount bracket to the door, using your 13mm spanner

or wrench and 2 of the M8 x 40mm coach screws.

Fasten the link arm to the door

mount bracket, using your

13mm spanners and/or

wrenches and 1 of the M8 x

25mm hexagonal bolts and M8

Nylock nuts.

Figure 13.2

Be certain not to over tighten the nut and bolt as the link arm must be

able to swing freely up and down in the door-mount bracket.

When you have completed the above, move on to Step 3 - Determining

the mounting position and mounting of the drawbar front-end.

A=B

A

B

14

INSTALLING THE HARDWARE

STEP 3 - DETERMINING THE MOUNTING POSITION, AND MOUNTING OF THE

DRAWBAR FRONT-END

TIP UP TYPE DOOR (Refer to diagram on page 10)

OVERHEAD SECTIONAL TYPE DOOR (Refer to diagram on page 12)

With the door in the closed position swing the link arm up fully vertical,

in line with the centre mark previously determined in Step 2.

For a TIP UP TYPE DOOR:

Measure strictly 275mm (two

hundred and seventy-five millime-

ters) above the top edge of the

door along the link arm.

Mark the wall at this point.

Figure 14.1

For an OVERHEAD SECTIONAL TYPE DOOR:

Measure strictly 50mm (fifty

millimeters) above the highest

point of travel of the door

along the link arm (use

horizontal tracks for door height

reference).

Mark the wall at this point.

Figure 14.2

FOR BOTH TYPES OF INSTALLATION:

You now use your 13mm masonary drill bit to drill a hole approximately

90mm deep at position marked on wall.

Fasten the wall mount bracket to the wall using the M8 Rawl bolt by

means of your 13mm spanner/ wrench.

When you have completed the above for your type of door, move on

to Step 4 – Determining The mounting position of the motorhead.

275mm on the wall

HIGHEST POINT

OF DOOR TRAVEL

HORIZONTAL TRACK

50mm

15

STEP 4 - DETERMINING MOUNTING POSITION OF MOTORHEAD UNIT

TIP UP TYPE DOOR (Refer to diagram on page 10)

OVERHEAD SECTIONAL TYPE DOOR (Refer to diagram on page 12)

With the door in the closed position, fasten front-end moulding into wall

bracket using the M8 x 90mm hexagonal bolt and a M8 Nylock nut.

Fasten using your 13mm spanners and/ or wrenches.

Lift motor unit out of the way of the door travel, supporting it with a

stepladder 90O to wall.

Release the sledge from the bobbin by pulling the release lever down

90O to drawbar. This will assist in the attaching of the linkarm to the

sledge mounting.

Fasten the link arm to the sledge, using your 13mm spanners and/or

wrenches and 1 of the M8 x 25mm hexagonal bolts and M8 Nylock nuts.

Be certain not to over tighten the nut and bolt as the link arm must be

able to swing freely up and down in the sledge mounting.

For OVERHEAD SECTIONAL TYPE DOOR installation, open door and

support motorhead so that the drawbar is 50mm above the door (level

with your spirit-level).

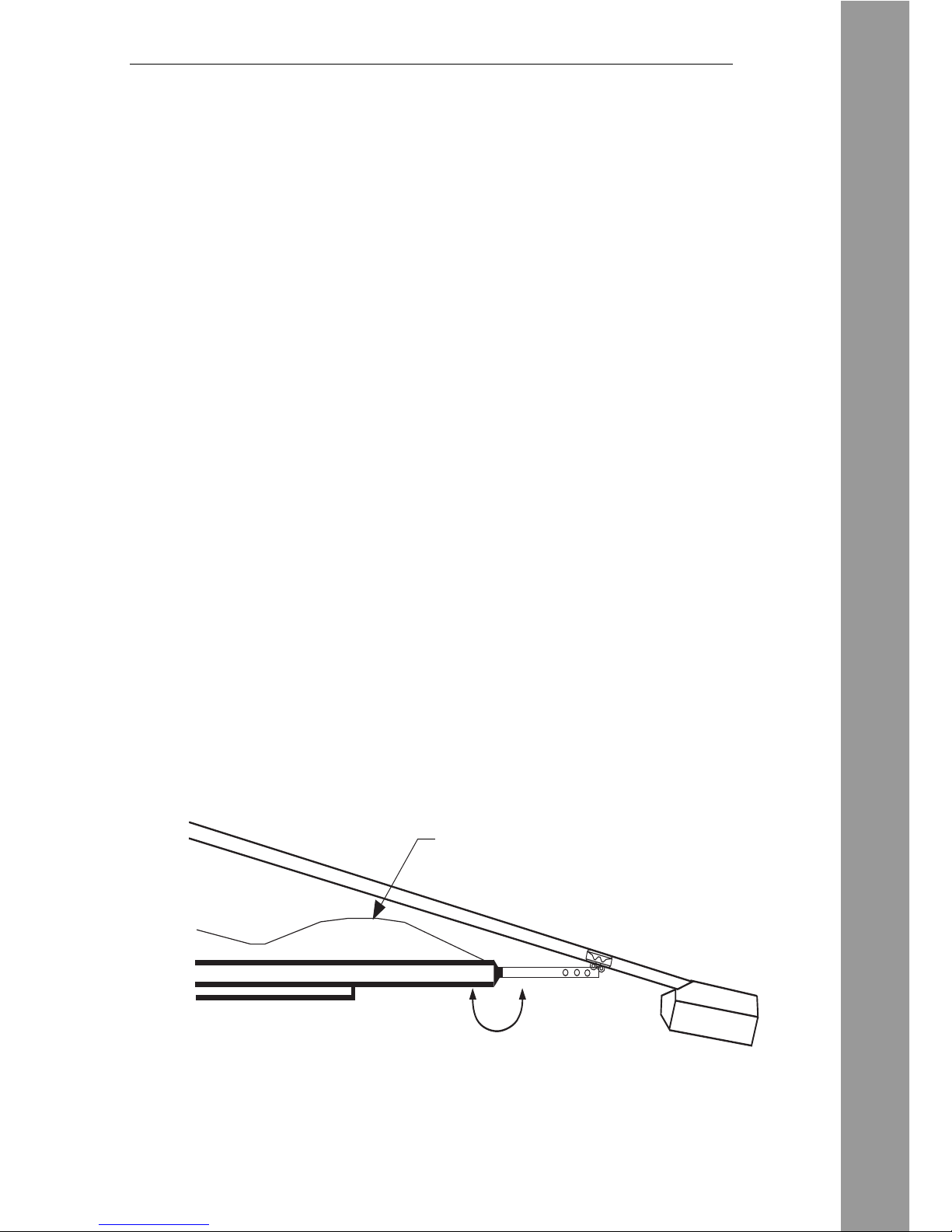

For TIP UP TYPE DOOR:

Open door to check travel clearance.

Ensure link arm is in the horizontal position when door is horizontal.

INSTALLING THE HARDWARE

HIGHEST POINT

OF TRAVEL

180o

Now proceed to Step 5 - Mounting the motorhead unit and

hanging straps.

Figure 15.1

DOOR AND LINK ARM SHOULD BE LEVEL

16

Figure 16.1

Mount the hanging straps to the fixed structure or rafters with 2 of the

M8 x 40mm coachscrews provided.

DO NOT exceed one hanging angle length from fixed structure or

rafters. In the case of double volume roof clearance, manufacture

or extend stable support structure down.

Mount powerhead to hanging straps with 2 of the M8 x 16mm

hexagonal bolts and Nylock nuts provided, using your 13mm

spanners and/ or wrenches.

Use the last 2 of the M8 x 16mm hexagonal bolts and Nylock nuts

with your 13mm spanners and/ or wrenches, to mount cross-

bracing.

Ensure that sufficient cross-bracing is used to disable any sideways

sway of the motorhead when in operation.

You can now commence with the programming and commissioning

schedule.

INSTALLING THE HARDWARE

PERPENDICULAR

RAFTERS

SOLID ROOF

PARALLEL RAFTERS

STEP 5 - MOUNTING MOTORHEAD UNIT AND HANGING STRAPS

Measure, cut and prepare the hanging straps according to the type of

fixed structure or rafter to which the unit is to be mounted.

17

WIRING & SCHEMATICS

EXTERNAL RECEIVER

Figure 17.1

BEAMS

Figure 17.2

To (+) of receiver

(+)

(C)

To (-) and/ or com of receiver

200mA max.

(BT)

From N/O or neg. out of receiver

To (+) of beams

(+)

(C)

To (-) and/ or com of beams

200mA max.

(Bm)

From N/O of beams

18

WIRING & SCHEMATICS

WALL CONSOLE

Figure 18.1

PROGRAMMING

Figure 18.2

(+) RED

(C) BLACK/ BLUE

(L) GREEN

(BT) WHITE

RECEIVER (B) (L)

PROGRAMMING

PRG L.E.D.

PRG JUMPER

PCB BUTTON

19

WIRING & SCHEMATICS

AUTO-CLOSE

Figure 19.1

LOAD POT

Figure 19.2

LOAD POT

AUTO-CLOSE JUMPER

PRG JUMPER

20

PROGRAMMING & COMMISSIONING

Programming a remote transmitter into the onboard receiver (Fig 18.2)

The receiver can learn one code for the garage door control button and

one code for the light control button.

1. Code the transmitter with a unique code as per make and model of

transmitter (refer to supplier for more information).

For the garage door control button:

1. Short the pin B to the middle pin with the jumper supplied

2. Press the desired button on the transmitter

3. The PRG LED will flash to indicate that the code has been memo-

rized.

4. Remove the jumper.

For the light control button:

1. Short the L pin to the middle pin with the jumper supplied

2. Press the desired button on the transmitter

3. The PRG LED will flash to indicate that the code has been memo-

rized.

4. Remove the jumper.

Erasing the codes on the receiver

The onboard receiver uses overwrite procedure.Recode the transmitter to a

new code and follow the process above.

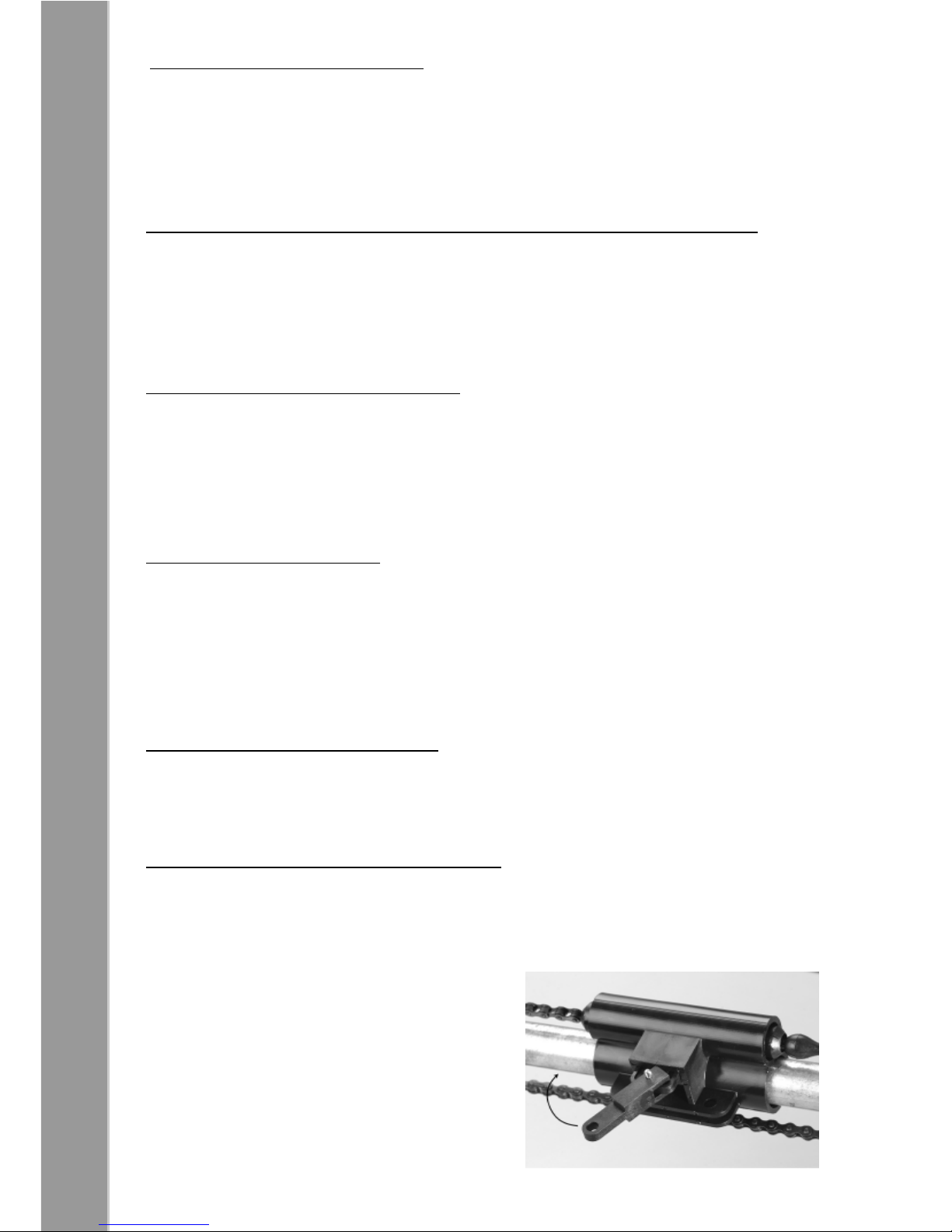

Setting up the open and closed positions

The Challenger MKIII relies on magnetic limits switches for the open and

close positions and uses intelligent profiling of the door’s operation for the

overload (sensitivity) function

1. Clear away any obstacles

2. Move the door so that the

bobbin on the chain slides into the

carriage or sledge.

Make sure the sledge pull clip is

in the engaged position.

Figure 20.1

To begin programming the unit:

Power up by plugging the three-pin plug attached to the Challenger into a 15Amp

plug socket (check with electrician for latest SABS compliancy).

NOTE: The unit should beep 5 times if it has never been programmed before

and once if being reprogrammed.

Table of contents

Other E.T. Systems Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Automatic Technology Australia

Automatic Technology Australia GDO-5-AS installation instructions

CAME

CAME FAST-S24 KIT installation manual

Genie

Genie CHAINMAX 1200 4022 Operation and maintenance manual

SOMFY

SOMFY KEASY L+ manual

Chamberlain

Chamberlain 84505R owner's manual

Ricon

Ricon RDO2700 Series Service manual

Chamberlain

Chamberlain 1280R 1/2 HP owner's manual

Chamberlain

Chamberlain RJO20C manual

moore o matic

moore o matic X125 Installation and operation manual

SAMT

SAMT RGD350 Installation instructions and user guide

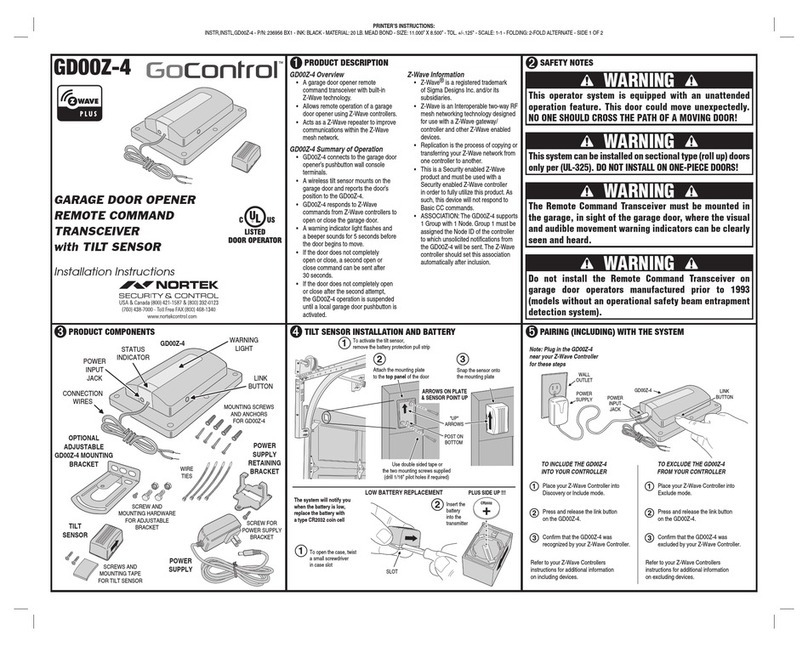

Nortek

Nortek GoControl GD00Z-4 Installation instructions manual

BPA

BPA BPA500 Assembly and operating instructions