E.T. Systems DC BLUE ADVANCED User manual

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

2

www.et.co.za

TABLE OF CONTENTS

Page

Category

Introduction

3

Safety obligations and general warnings.

4

Technical specifications.

5

Component identification and descriptions.

Hardware installation

6

Installing the clutch release mechanism on the sledge/traveller.

7

Sectional overhead door – Installing the wall mount bracket.

7

Sectional overhead door – Installing the drawbar and hanging straps.

8

Sectional overhead door – Installing the door mount bracket.

8

Sectional overhead door – Installing the link arm.

8

Sectional overhead door – Testing the mechanical drive and linkage.

9

Trackless tip-up door – Installing the wall mount bracket.

10

Trackless tip-up door – Installing the door mount bracket.

10

Trackless tip-up door – Installing the link arm and hanging straps.

10

Trackless tip-up door – Testing the mechanical drive and linkage.

11

Both doortypes – Attaching the motor-head to the drawbar.

11

Both doortypes – Attaching the battery to the drawbar.

11

Both doortypes – Supplying household mainspower to themotor-head.

Control card wiring and setup

12

Wiring of optional extra devices to the system.

13

Control panel dashboard and programming menu summary. (How to navigatethe menu)

14

Programming - Open and closed limit setupand door loadprofiling.

15

Programming - Setting the obstructionforce sensing, safety level.

16

Programming - Activating safety beam mode.

17

Programming - Activating and selecting the auto-close time.

18

Programming - Selecting an electric lock mode.

Receiver programming

19

Learning anew transmitterbuttoncode into the receiver memory.

20

Clearing a single transmitterbuttoncode from the receiver memory.

21

Master erasing all transmitter buttoncodes from the receiver memory.

22

Quick method oflearning a transmitter buttoncode into thememory without entering the

programmingmenu.

Operating

23

Basic operating features using the (BT) buttontriggers.

25

Advanced operating features - Party mode.

26

Advanced operating features - Holidaylock-out mode.

27

Advanced operating features - Strike lock mode.

28

Advanced operating features - Magnetic lock mode.

29

Advanced operating features - Auto-close example.

29

Advanced features - Safety beam example.

30

Advanced features - Courtesy light operation.

Troubleshooting

31

Buzzer, courtesy light and displaywarnings.

Warranty

32

Warranty terms and conditions.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

3

www.et.co.za

IMPORTANT WARNINGS TO THE INSTALLER AND GENERAL SAFETY OBLIGATIONS

•Caution! Itisimportantforpersonal safetytofollowalltheinstructionscarefully.Incorrectinstallationormisuse

may cause serious personal harm.

•Keepthe instructionsina safe place forfuturereference.

•This product was designed and manufactured strictlyfor the use indicatedin this documentation.Any other use

not expresslyindicatedinthis documentation,may damage the product and/or be a source of danger.

•Weaccept no responsibilitydue toimproperuse or incorrect installationofthis product.

•Wewillnot accept responsibilityiftheprinciplesofgoodworkmanshipare disregardedby the installer. The

constructionofthedoor mustbe soundand automatable.Itistheresponsibilityoftheinstallertoensurethat all

mountings to the door are sufficient to withstand the necessaryforces in cases of overload.

•It is highly recommended that a set ofsafety infra-redbeams be used in conjunctionwiththis product.

•Overand abovetherecommendation touse safetyinfra-redbeams withthisproductitismandatory toinstall

and use a safetybeam set whenusing the automaticclosingfeature.

•Weaccept no responsibilityregardingsafetyand correct operationoftheautomationifothermanufacturer’s

equipment is added to this product.

•Do not make any modificationsoralterationstothisproduct.

•Anything other than expresslyprovidedfor in these instructions is not permitted.

•Priorto installation:

oThe door must be balanced correctlyto the tensioningsystem.Whenoperatedby hand the door

should be free of hindrance and easilymoved. Whenleft at any positioninits travel,thedoor should

neitherrisenor fall.If thedoor does riseor fall,re-balance the tensioningsystem.(Tensioning should only

be carriedout by a qualifiedand experiencedperson)

oThe doormaterialmust be sound and whole. Ensure theareas where the operatorattacheshavebeen

re-enforced.The door hardware must be in good serviceablecondition.

oEnsure the wall abovethe door issound and strongenough toallowproper fixingof theoperator. If

necessaryuse throughboltsand/or crossbrace platetospreadtheload. (Typicallyoncinder brickor

hollowwalls)

oThe DC BlueAdvancedisdesignedforweatherproofapplicationsonly.Installincompletelywalledand

roofedgarages only.

oEnsure the area of installationis not subject to explosivehazards. There should be no volatilegassesor

fumes as thesecan present aserioussafetyhazard.

oThe DC BlueAdvancedisdesignedtobe usedinlowtrafficapplicationsonly.Do not installondoors

usedfor multiparkinggarages likeofficeparksor apartment blockswithasingleentrance.

oThe DC BlueAdvanced issuppliedwithasealed15Asafetyplug on leadfor use in an electrical code

of practiceapprovedplugpoint.Do not extend,modify orreplacethe plug lead unless dulyqualified

as an electrician.Before installingthe unit,ensure the mains supply is switchedoff.

oItisthe responsibilityoftheinstallertoascertainthat thedesignatedpersons(includingchildren)

intendedto use thesystem, do not sufferreducedphysical sensoryormental capabilities,orlack of

experienceand knowledge, unlesstheyhave beengivensupervisionor instructionconcerningthe use

of thesystem by a person responsible fortheir safety.

oThe drivemaynotbe installedona doorincorporatingawicketdoor,unlessthe driveisdisabledbythe

releaseof thewicket door. (Wicketdoor:- A pedestriandoor withinthemain door)

Cont.…..

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

4

www.et.co.za

•Installation:

oRemoveall cables, latches/locks orcatchesnot necessaryfor automation.

oEnsure the working areaisclearof obstructionsandobstacles.

oInstall thedoorstickerdepictingthesafetyreversetest andkeeping door area clear.This stickershould

be fixed to theinside surface of the door or near any permanent door control switches suchas a wall

consoleifinstalled.

oThe emergencyreleasecordmust be installedwhereit isno higher than 1.8mfrom thefloorlevel.

oAny additionalfixeddoor control switchessuchas wallconsoles,ifinstalled,must be at a heightof at

least 1,5m, withinclear sight of the door and away from any movingcomponents of the system.

oDo not substitute any component of DC BlueAdvanced withany other manufacturer’s part. ET

Systemsacceptsnoresponsibilityforthesafetyand correctoperationofthe automationsystemifany

of thesepointsare ignored.

•After Installation: It isthe responsibility of the installer to ensure the user:

oIs proficient intheuse of themanual emergency releasemechanism.

oIs issuedwiththe documentationaccompanying this product.

oUnderstandsthat the door may not be operatedout of clearsight.

oEnsures that childrenare kept clear of thedoor area and that childrendo not play withthe remote

transmitters.

oIsinstructednottoattempttorepairoradjusttheautomationsystemand tobeawareofthe danger

of continuingtouse the automationsystemin an unsafe conditionbefore a service providerattends to

it.

oIs proficient intestingthe unit’s safetyobstructionsensing systemby means of placinga 40mm high

object (woodenblock) below the door in the closedposition.On contact withtheobjecttheunit must

reversethedooraway and back to theopen position.

* Based on the assumption that the door is balanced correctly and moving freely.

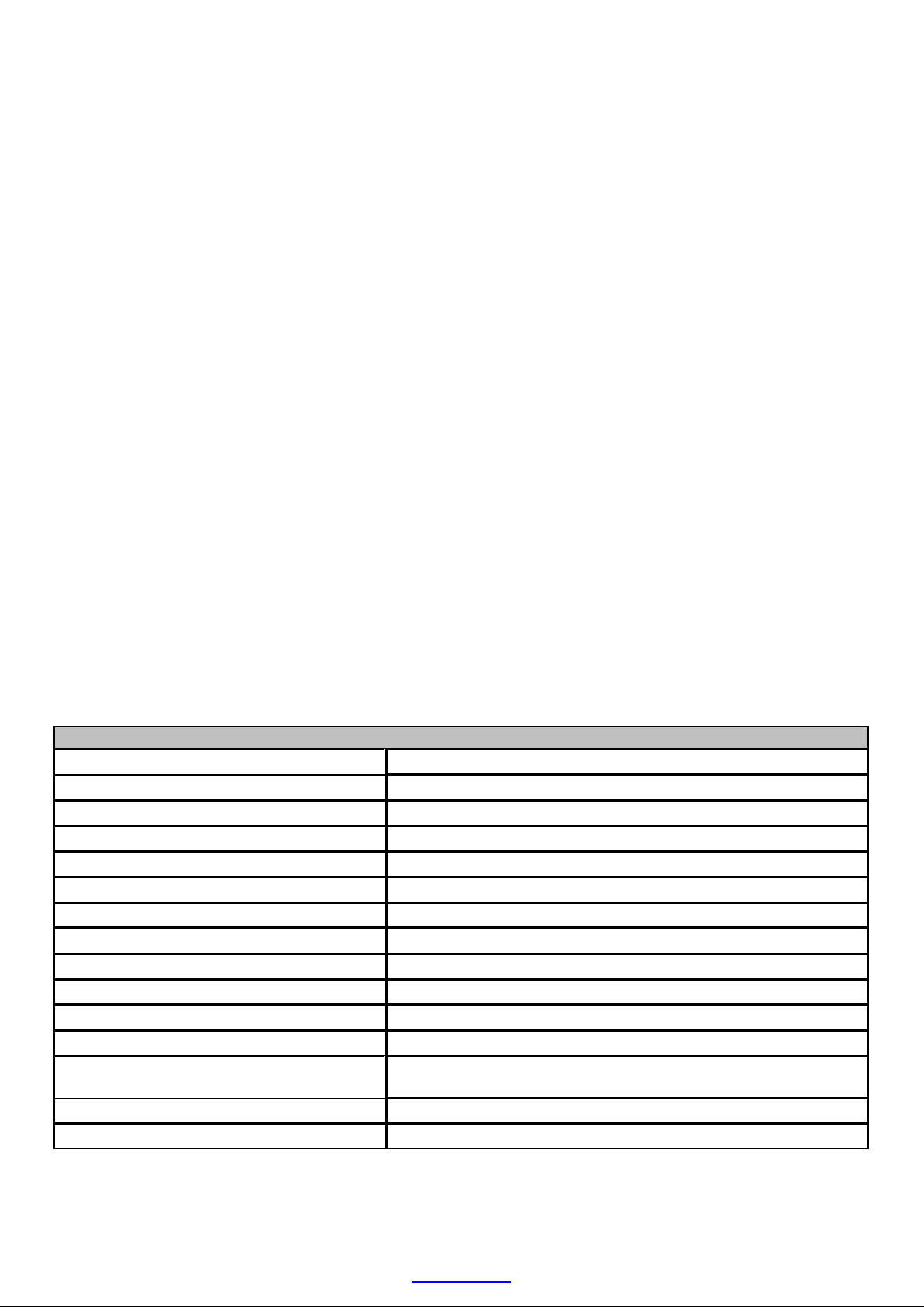

TECHNICAL SPECIFICATIONS

Primary power supply

220 – 240Vac @ 50hz

Power consumption

120W peak @ (220 -240vac)

Motor voltage

24V dc

Maximum operations per day

50 full cycles per 24hrs @ a rate of Max. 2 per hour

Traveller speed*

8m/min

Operating temperature range

-10 to 50° C (14F to 122F)

Anti-crushing safety sensing

Yes - Electronic digital profiling

Auxiliary supply output

24Vdc @ 250mA peak or 150mA continuous

Rated battery charging voltage

27.5Vdc

Built in receiver format

ET BLU MIX © enhanced rolling code.

Receiver frequency

433.92Mhz

Memory

EEPROM

Applicable door types

One piece trackless tip-up or multiplepanel sectional

overhead doors

Drawbar options(Ex-stock)

2.2m or 3.2m or 3.7m

Applicable door sizes

<13m²

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

5

www.et.co.za

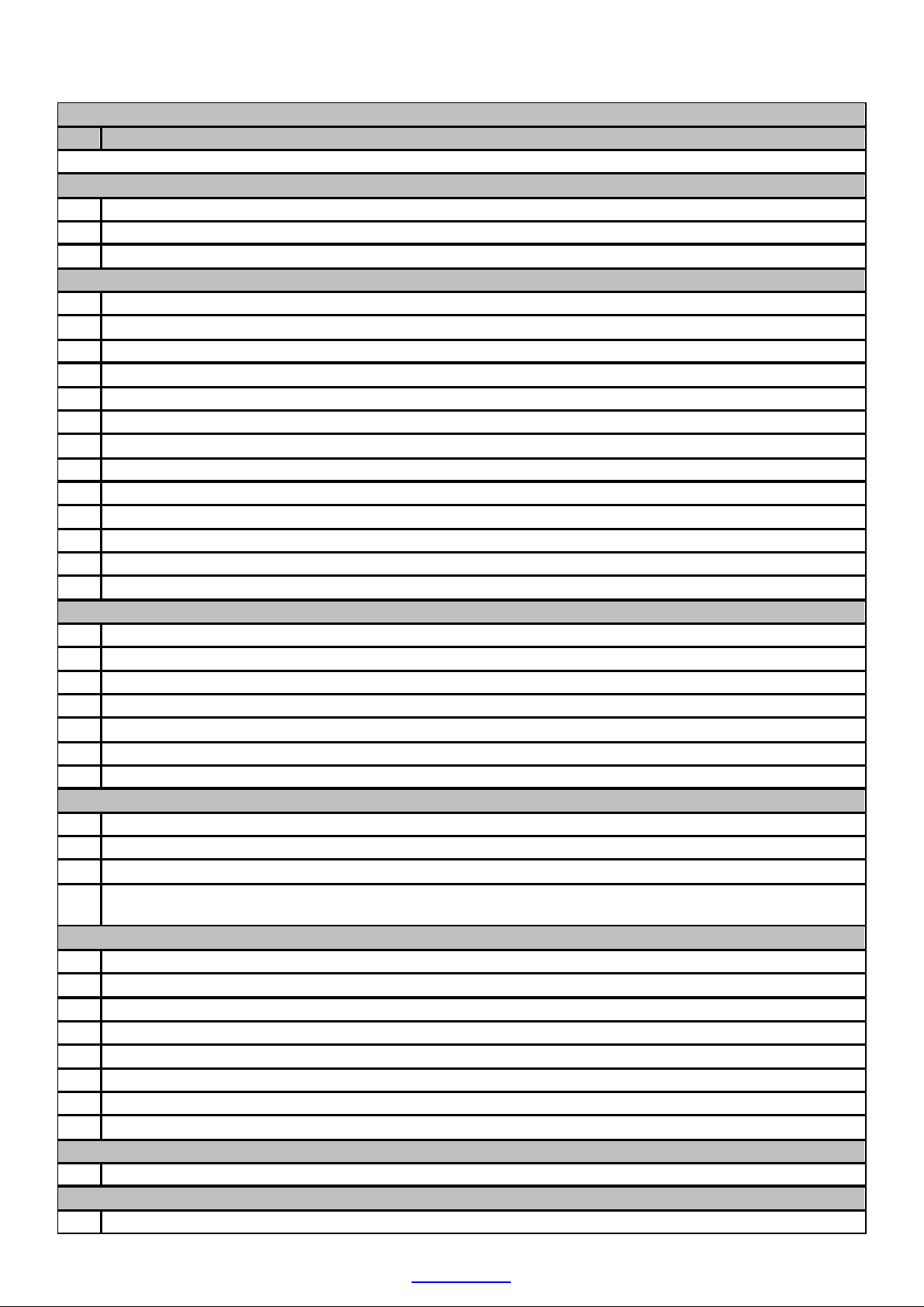

COMPONENT IDENTIFICATION AND DESCRIPTIONS

Diagram

number Description Qty

Diagram

number Description Qty

1

Wall mount bracket

1

20

Nylock nuts M8

8

2

Pivot pin8mm x 90mm

1

21

Flat washers M6

6

3

Cotterpins1.8mm x 35mm

3

22

Coach screws8 x 60mm

2

4

Door mount bracket

1

23

Coach screws8 x 40mm

6

5

Straightlinkarm

1

24

Wallplugs10mm

2

6

Curved linkarm extension

1

25

Warning sticker

1

7

Emergency releaseassembly

1

26

24Vdc3.5A/hBattery(Optional extra)

1

8

Round head machine screws M6 x

20mm 4

27 Motor-head 1

9

Emergency releasecord1.1m with

warning tag

1

28 Control panel dashboard 1

10

Emergency releasecordplastic

knob/handle

1

29 Courtesylight diffuserlens 1

11

Pivot pins8mm x 25mm

2

30

Drawbar

1

12

Hanging strapdrawbar attachment

bracket

1

31

Drawbar spring dampener and shock

absorber

1

13 Drawbar brackets 3

32

Batteryconnectionbeneathdust

coversticker

1

14 Batterystraps 2

33

E-Coms connectionplug with dust

cover 1

15

Hanging straps 1m

3

34

Drawbar back-end

1

16

Machine bolts10mm head M6 x 15mm

2

35

Splinedsprocket withchain

1

17

Machine bolts14mm head M8 x 15mm

8

36

Household mains cord 1.5m

1

18 Machine nuts M6 4

37

Auxiliariesconnectionplugwithdust

cover 1

19

Nylock nuts M6

6

38

Coverscrews

4

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

6

www.et.co.za

HARDWARE INSTALLATION

INSTALLING THE MANUAL OVERRIDE CLUTCH ASSEMBLY ONTO THE SLEDGE/TRAVELLER

(See page 5 for component identification)

The diagrams below show how to install themanual override clutch assembly onto the

sledge traveller. Ensure the 4 machine screws are securely fastened. Do this prior to

installing thedrawbar.

! CAUTION

TO DISENGAGE AND

MOVE DOOR

MANUALLY:

Warning! Door may plummet

closed when released.

W hile pulling the emergency

release cord downw ard, move

t he door open or closed by

hand.

TO RE-ENGAGEAND

LOCK DOOR BACK

ONTODRIVE:

Let the cord go and move

door open or closed unt il the

sledge/t raveller locks back

onto the chain drive.

Install the manual override label as shown here.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

7

www.et.co.za

HARDWARE INSTALLATION

Standard Single Track or Double Track Sectional Garage Door Method

INSTALLING THE WALL MOUNT BRACKET (See page 5 for component identification)

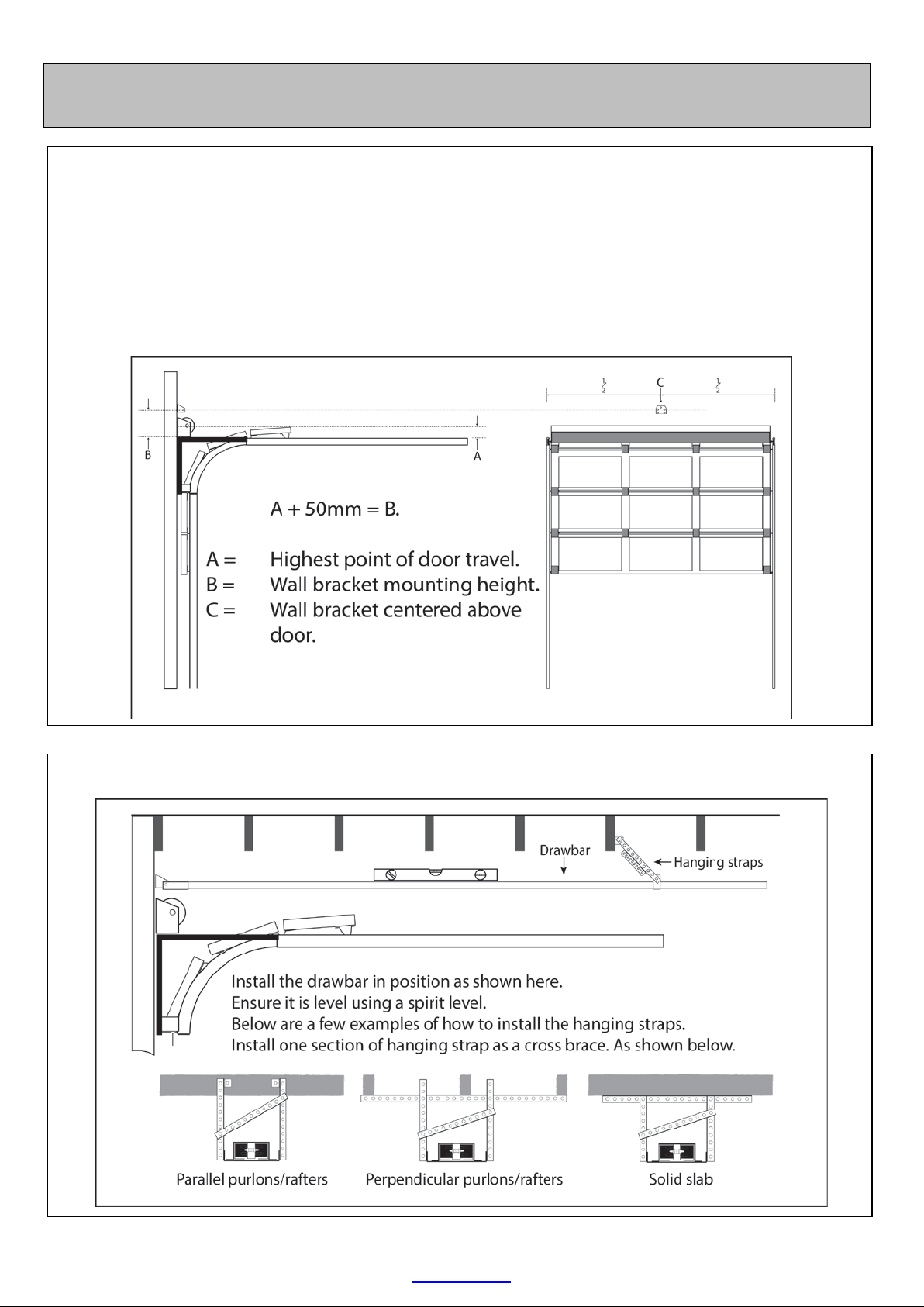

The diagram below shows how to determine the mounting height and position of the wall mount bracket,

in the case of a standard single track or double track overhead sectional garage door system.

NB!!! The wall mount bracket is one of the components that take the majority of the load in a garage door

automation system. Extra care needs to be taken to ensure the bracket is securely fastened and that

whatever the bracket is fastened to, can withstand force equal to the force of the door when the spring

balancing of the door is removed (snapped)

INSTALLING THE DRAWBAR AND HANGING STRAPS (See page 5 for component identification)

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

8

www.et.co.za

TESTING THE MECHANICAL DRIVE AND LINKAGE

It is now possibleto test the mechanical movement of the door with thelink arm attached and the

sledge/traveller engaged onto the chain drive. The movement of the door throughout its travel should be

approximately the same whilepulling the chain around the drawbar, as it is when the chain is not

engaged.

If satisfied that the drawbaris not causing unnecessary drag or hindrance to the door movement, then go

ahead and attach the motor-head to the drawbar. (Page 11)

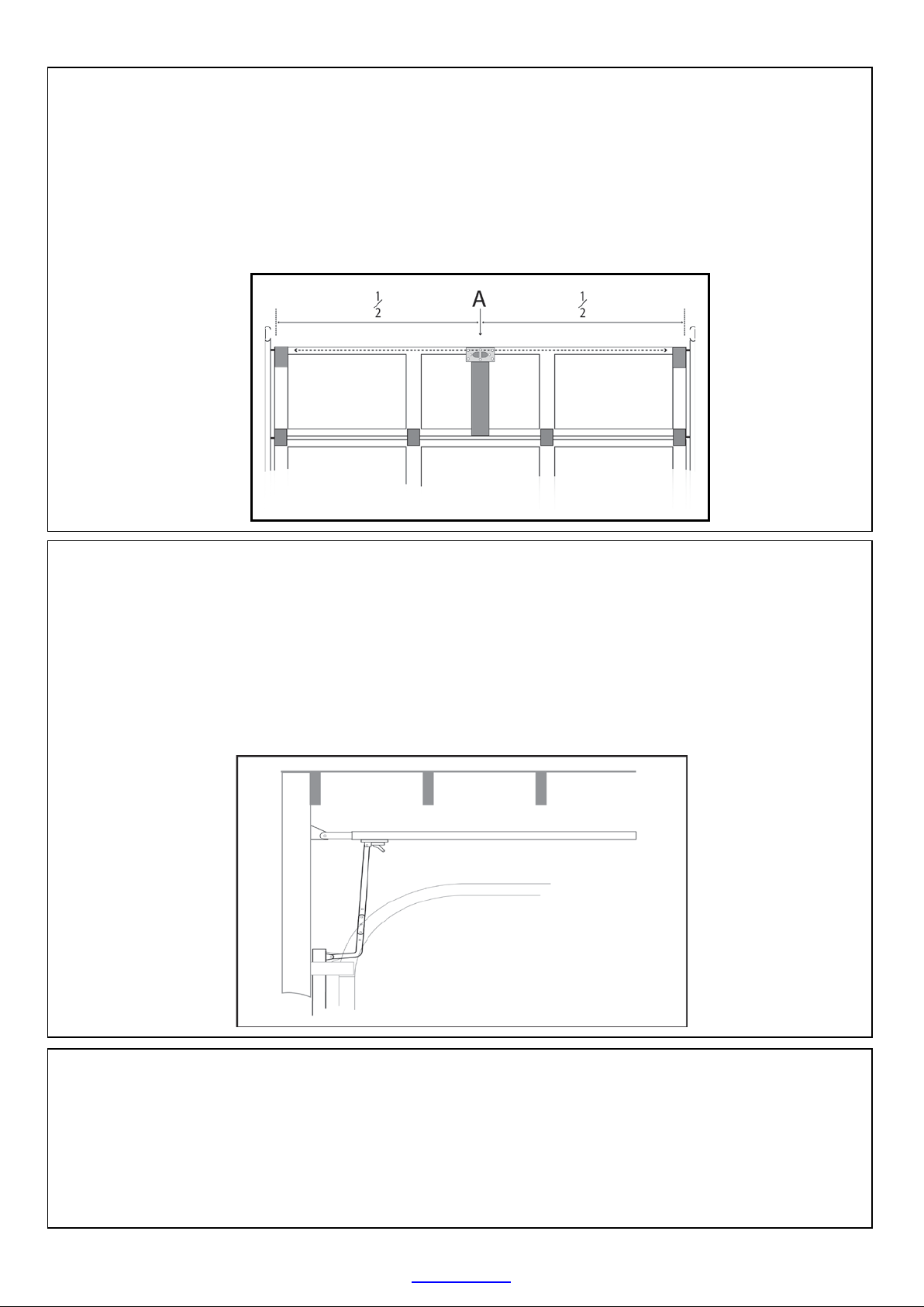

INSTALLING THE DOOR MOUNT BRACKET (See page 5 for component identification)

Mount the door mount bracket on the inside fascia of the dooras shown below. Keep it as in line as

possible with thetop guide rollers and centred from side to side of the door.

NB!!! The door mount bracket is one of the components that will take the majority of the load in a garage

door automation system. Extra care needs to be taken to ensure that the bracket is securely fastened.

Whatever the bracket is fastened to, must also withstand a force equal to the force of the door when the

spring balancing of thedoor is removed. For example if a balancing spring snaps.

INSTALLING THE LINK ARM (See page 5 for component identification)

Close the door fully. Install the curved link arm extension in the door mount bracket using one of the cotter

pins and 25mm long pivot pinssupplied.Next using the other 25mm longpivot pin and cotter pin, install

the straight link arm in the traveller/sledge that has been moved all the way to the front of the drawbar.

Finally bolt thecurved extension to the straight link arm, so that the two combined form the same angle as

shown below.

This method providesbetter positivelockingofthe doorin the closed positionthanthe commonlyused 45⁰

angled link arm. This method also produces less backward force on the gearbox when trying to compress

the seal at the bottom of thedoor as the downward force is generated by the link arm camming up and

over the door.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

9

www.et.co.za

HARDWARE INSTALLATION

Trackless tip-up door

INSTALLING THE WALL MOUNT BRACKET (See page 5 for component identification)

From the top edge of the door in the closed position, measure 275 – 300mm perpendicular to the top

edge of the door. Install the wall mount bracket at this height where it is positioned above the centre of

the door as shown in the diagram below.

NB!!! Thewall mount bracket is one of the components that will take the majority of the load in a garage

door automation system. Extra care needs to be taken to ensure that the bracket is securely fastened.

Whatever the bracket is fastened to, must also withstand a force equal to the force of the door when the

spring balancing of thedoor is removed. For example if a balancing spring snaps.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

10

www.et.co.za

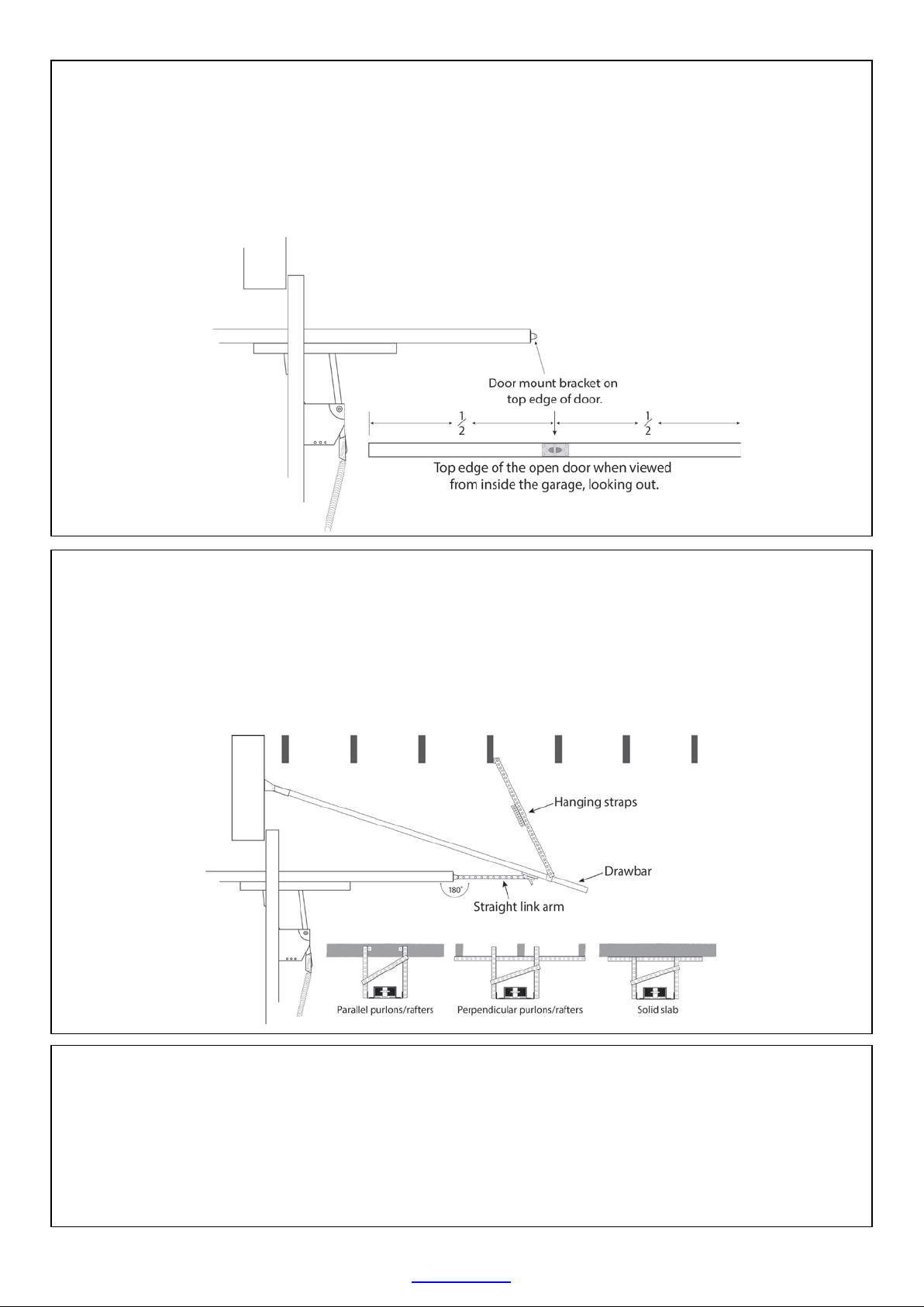

INSTALLING THE DOOR MOUNT BRACKET (See page 5 for component identification)

Mount the door mount bracket on the top edge of the door, where it is centred from side to side of the

door.

NB!!! The door mount bracket is one of the components that will take the majority of the load in a garage

door automation system. Extra care needs to be taken to ensure that the bracket is securely fastened.

Whatever the bracket is fastened to, must also withstand a force equal to the force of the door when the

spring balancing of thedoor is removed. For example if a balancing spring snaps.

INSTALLING THE LINK ARM AND HANGING STRAPS (See page 5 for component identification)

Install the front end of the drawbar in the wall mount bracket using the 90mm pivot pin and one of the

cotter pins. Raise the drawbar up and out of the way of the door. Install the link arm into both the

sledge/traveller and door mount bracket using the 25mm pivot pins and remaining two cotter pins.

Prepare and install the hanging straps so that when the door is in the full open position, thelink arm lays

180⁰to the door. Do not use the curved link arm extension in thistype of installation. The diagram below

shows the final position of the drawbar when installedand examples of how to prepare the hanging

straps.

TESTING THE MECHANICAL DRIVE AND LINKAGE

It is now possibleto test the mechanical movement of the door with thelink arm attached and the

sledge/traveller engaged onto the chain drive. The movement of the door throughout its travel should be

approximatelythe same whilepullingthe chain around the drawbar, as it is when the chain is not

engaged.

If satisfied that the drawbar is not causing unnecessary drag or hindrance to the door movement, then go

ahead and attach the motor-head to the drawbar. (Page 11)

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

11

www.et.co.za

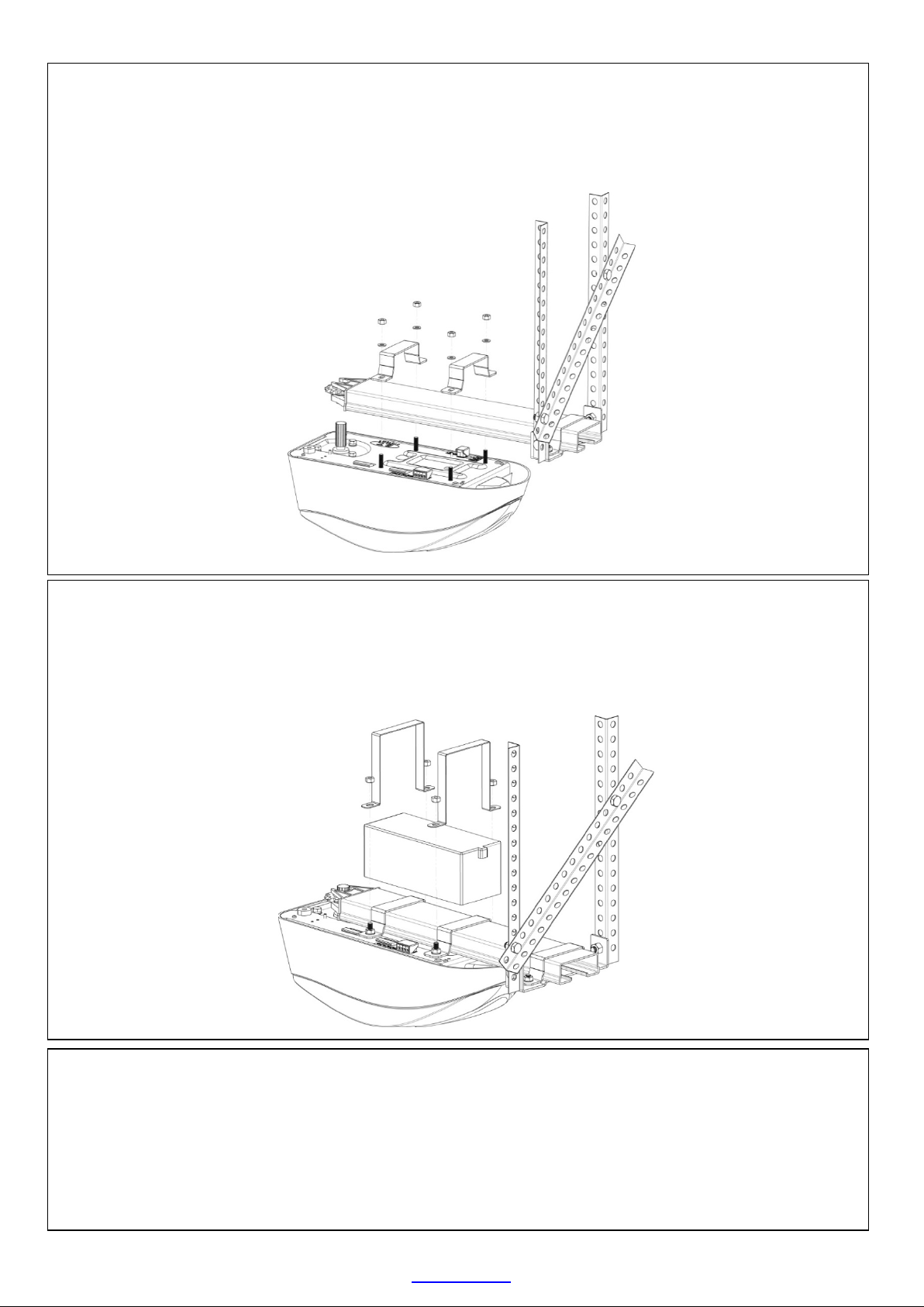

ATTACHING THE MOTOR-HEAD TO THE DRAWBAR (See page 5 for component identification)

Insert the splined motordriveshaft intothe splined sprocket at the back-end of the drawbar. Swivel the

motor-head around so that the motor mounting straps are able to fit over the drawbar and onto the

mounting studs on the motor-head. Fasten the drawbar mounting straps onto the motor-head using the 4

M6 machine nuts and M6 flat washers.

ATTACHING THE BATTERY TO THE DRAWBAR (See page 5 for component identification)

Making use of the extended length mounting straps and 4 of the M6 Nylock nuts fasten the batteryatop

the drawbar as shown below. Remove the sticker covering the battery plug socket on the motor-head

and insert the battery lead plug. The battery plug is moulded in such a way as to only be inserted in one

direction. Ensure the plug is in firmly.

SUPPLYING HOUSEHOLD POWER TO THE MOTOR-HEAD

The DC BLUE ADVANCED © comes supplied with an IEC and SANS compliant 220Vac power cord, 1,5m in

length. Plug the sealed non-serviceable 3 pin 15Amp plug into a certified 15Amp plug socket that is

installed outside of the workingsof the garage door system, yet still within reach of the power cord. Ensure

the there is no strain on the cord once installed. Also ensure that nothing will catch or snag the power

cord when the garage door is moving or when people or cars pass below the system.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

13

www.et.co.za

CONTROL PANEL DASHBOARD AND PROGRAMMING MENU SUMMARY

(How to navigate the menu options)

NOTE! Before attempting to execute the instructions, read the

complete instruction table, for a setup option. Some steps require a

response before a safety timeout expires and you may still be

reading the next step when the timeout expires.

•To enter the Programming menu from Standby mode, press and

hold the “SET” button until the buzzer beeps twice.

•Once in the Programming menu, use the up and down buttons to

scroll between options.

•For further instruction on changing settings, refer to the instruction

tables on the page indicated for each option.

EXIT BUTTON

•To exit a setup option

without changing the

current setting for that

option, press and

release the “EXIT”

button. The menu will

exit back one level.

•Note 1: If the “EXIT”

buttonispressed

before completing

the Limit and door

profile setup, no limit

and door profile

settings will bein

memory. You must

complete this setup

to operate the door.

(See “P” symbol

displayed inthe

Trouble shooting

table on page 31)

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

14

www.et.co.za

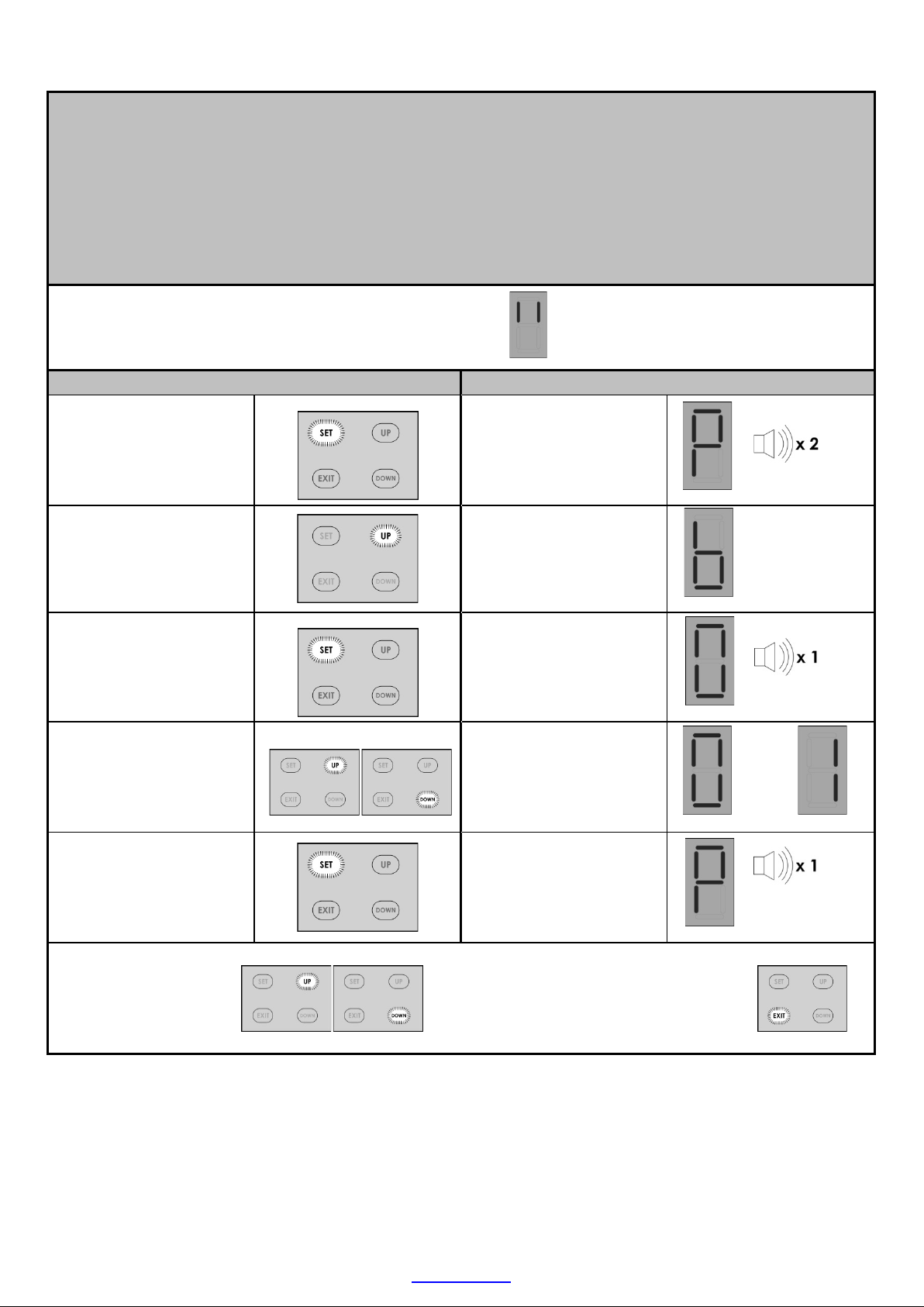

PROGRAMMING

Open and closed limit position setup and door load profiling.

From StandbyMode

Action

Response

To enter the program

menu. Press and hold SET

button until buzzer beeps

twice.

Displaybeginsflashing “P”

and buzzer beeps twice

to confirm the main

program menu is active.

Scroll up with the UP

button until “L” flashes.

Display flashes “L” to

confirm limit setup mode

is selected.

Press and release SET

button to begin limit

setup.

Buzzer beeps once and

“O” displays to indicate

open limit position must

be set.

Press and hold the UP

button to raise the door to

the required open

position.

The “n” symbol displays as

the door opens.

Fine tune using the UP

and DOWN buttons.

The “n” and “u” symbols

confirm thedoor direction

while fine tuning.

or

When satisfied the door is

in the correct open

position, press the SET

buttontoadvanceto the

close limit setup.

The buzzer beeps once

and the “C” symbol

displays to indicate the

closedlimit position must

be set.

Press and hold the DOWN

button to lower the door

to the required closed

position.

The “u” symbol displays as

the door closes.

Fine tune using the UP

and DOWN buttons.

The “n” and “u” symbols

confirm thedoor direction

while fine tuning.

or

When satisfied the door is

in the correct closed

position, press the SET

buttontoadvanceto the

automatic door load

profiling stage.

Door opens and closes

again.

The display confirms the

direction and the buzzer

will beep intermittentlyas

the motor runs.

When complete, the

control returns tothemain

program menu.

Display= Flashing “P”and

buzzer beeps once.

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

See Note 1 on page 13!!!

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

15

www.et.co.za

SAFETY OBSTRUCTION SENSING IN ACTION:

In the case of the door being resisted physically or obstructed while opening.

•The motor will stop running,

•The buzzer will beep once and operator reverts to standby mode.

•On the next BT buttontrigger the motor will start closing thedoor.

In the case of the door being resisted physically or obstructed whileclosing.

•The motor will stop running,

•The buzzer will beep once as the motor immediatelybegins opening the door once again.

•On reaching the open position the operator reverts to standby mode.

•On the next BT buttontriggerthe motor will beginthe door closing.

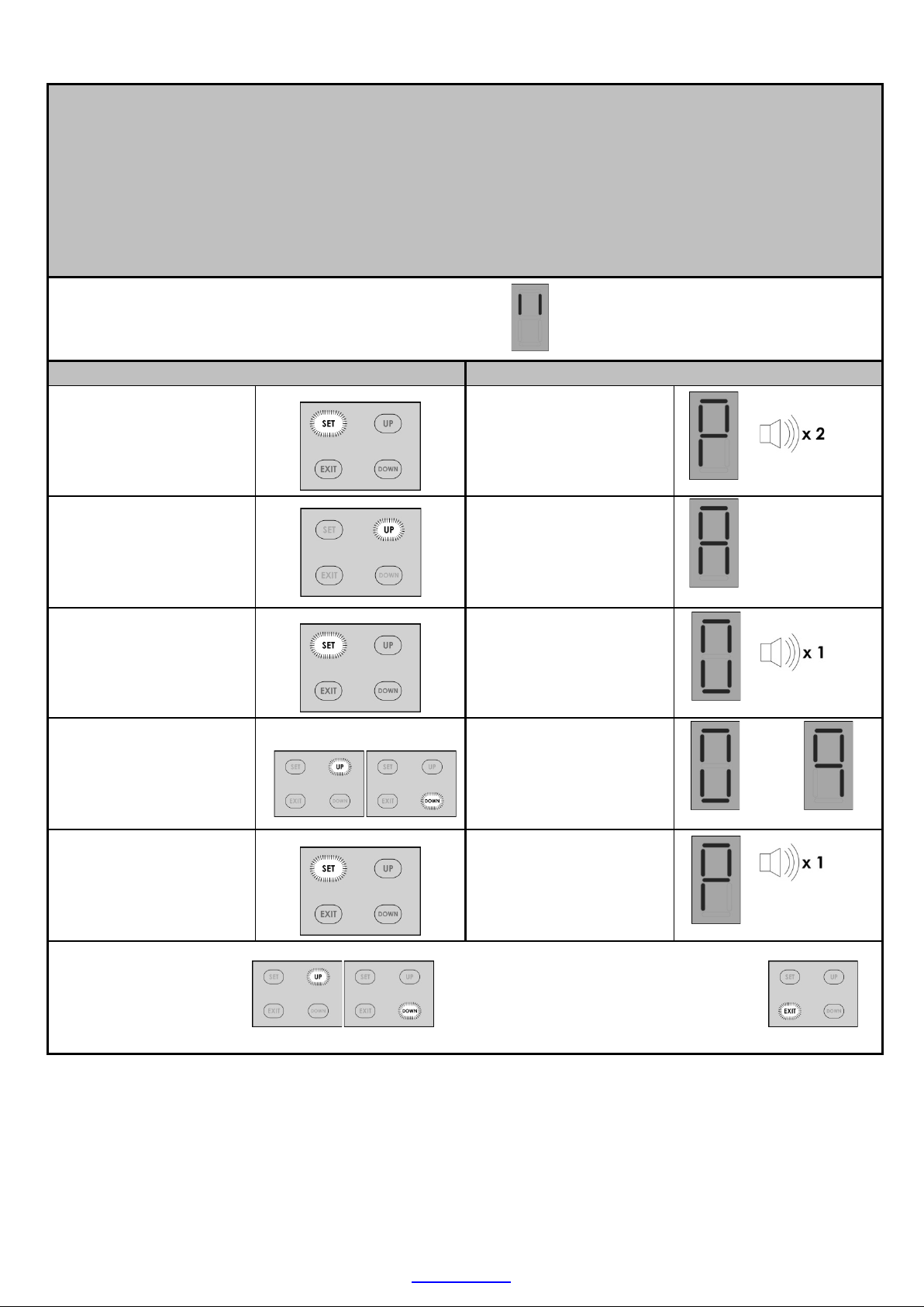

SETTING THE OBSTRUCTION FORCE SENSING, SAFETY LEVEL.

Default level - 3

From StandbyMode

Action

Response

To enter the Program

menu. Press and hold SET

button until buzzer beeps

twice.

Displaybeginsflashing “P”

and buzzer beeps twice

to confirm the main

program menu is active.

Scroll up with the UP

button until “F” flashes.

Display flashes “F” to

confirm safetyforce setup

mode is selected.

Press and release SET

button to enter safety

force setup.

Buzzer beeps once and

current safety force level

is displayed. (1-9)

Press and release the UP

or DOWN buttons to scroll

to the desired safety force

level. (1-9)

1 = most sensitive to

resistance in movement of

the door.

9 = least sensitive to

resistance in movement of

the door.

Press and release the SET

button to save the new

setting to memoryand

exit back to the main

program menu.

The buzzer beeps once

and the display returns to

flashing “P”.

To

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

16

www.et.co.za

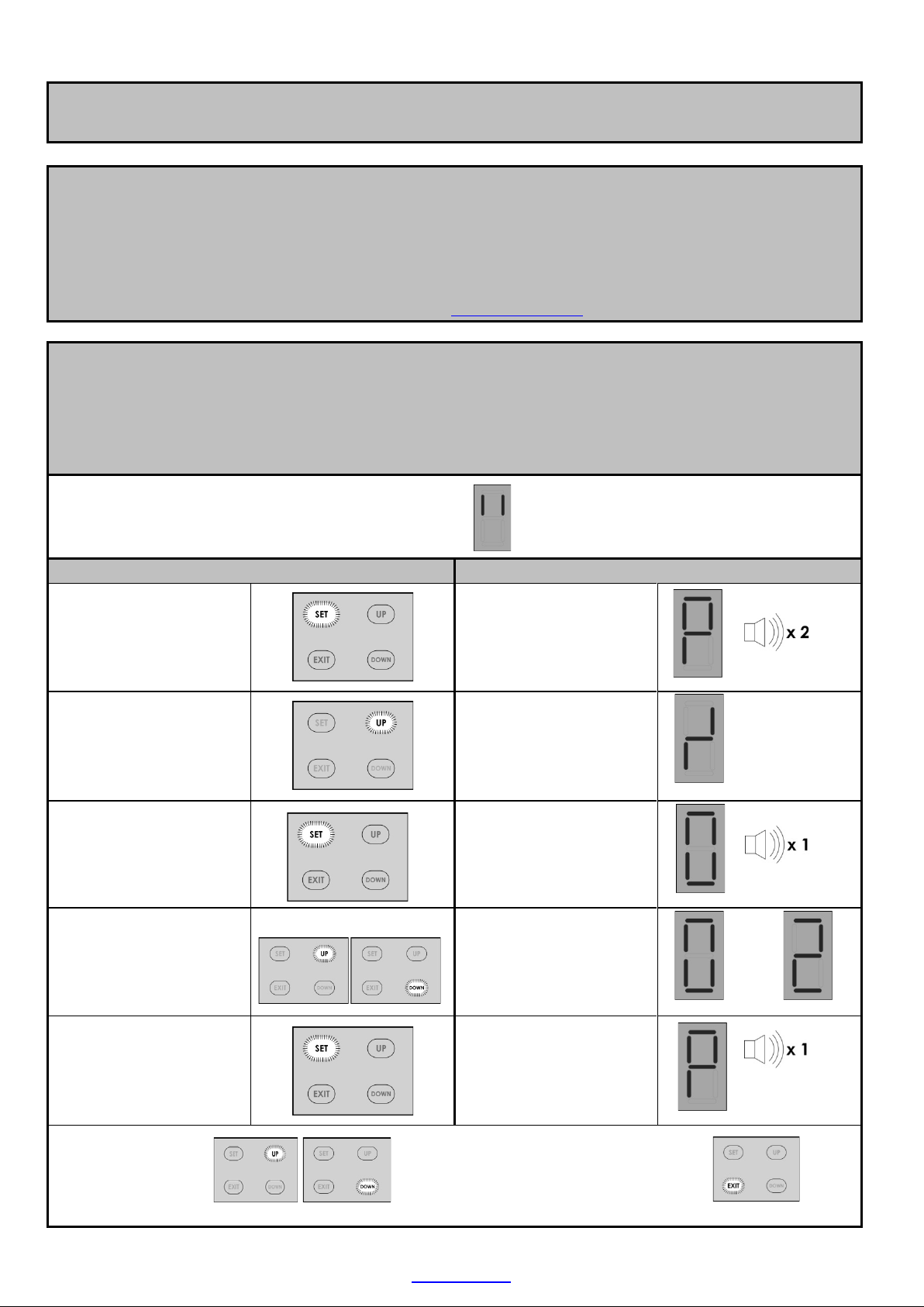

ACTIVATING SAFETY BEAM MODE.

Default – Off (Disabled)

NB! When auto-close mode is activated, the safety beam mode automatically becomes active.

This is mandatory as auto-close mode may never be used without a set of safety beams installed.

With auto-close active, safety beam setup mode is no longer available in the setup menu.

From Standby Mode

Action

Response

To enter the Program

menu. Press and hold SET

button until buzzer beeps

twice.

Display begins flashing

“P” and buzzer beeps

twice to confirm the

main program menu is

active.

Select safety beams

setup by scrolling upwith

the UP button until “b”

flashes.

Display flashes “b” to

confirm safety beam

setup mode is selected.

Press and release SET

button to enter safety

beam setup.

Buzzer beeps once and

current beam status is

displayed.

0 = Off and 1 = On

Press and release the UP

button for On or DOWN

button for Off selection.

0 = Off (Disabled)

1 = On (Active)

Press and release the SET

button to save the new

setting to memoryand

exit back to the main

program menu.

The buzzer beeps once

and the display returns to

flashing “P”.

OR

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

17

www.et.co.za

ACTIVATING THE AUTO-CLOSE MODE AND SELECTING AN AUTO-CLOSE TIME.

Default – Off

NB! When auto-close mode is activated, the safety beam mode automatically becomes active.

This is mandatory as auto-close mode may never be used without a set of safety beams installed.

With auto-close active, safety beam setup mode is no longer available in the setup menu.

From Standby Mode

Action

Response

To enter the Program

menu. Press and hold SET

button until buzzer beeps

twice.

Display begins flashing

“P” and buzzer beeps

twice to confirm the

main program menu is

active.

Select auto-close setup

by scrolling up with the

UP button until “A”

flashes.

Display flashes “A” to

confirm auto-close setup

mode is selected.

Press and release SET

button to enter auto-

close setup.

Buzzer beeps once and

current auto-close status

is displayed.

Press and release the UP

or DOWN buttons to scroll

to the desired setting.

0 = Off. 5 = 50 sec.

1 = 10sec. 6 = 60sec.

2 = 20sec. 7 = 70sec.

3 = 30sec. 8 = 80sec.

4 = 40sec. 9 = 90sec.

Press and release the SET

button to save the new

setting to memoryand

exit back to the main

program menu.

The buzzer beeps once

and the display returns to

flashing “P”.

To

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

18

www.et.co.za

SELECTING A LOCK MODE.

Default – Off

NB!! The “E-Coms” output on the control card is designated to be used with an “E-Coms” Relaymodule,

when using any electric lock. These modules are onlyavailable via ET Systems.

For further instructions on the E-Coms relaymodule, consult the instructions included with it.

For assistance the product support department can be contacted on:

0861 109 9238 or support@et.co.za

In strike lock mode, the lock relay will energise 0.5sec before the motor begins opening and release

again 0.5sec after the motor has begun moving. (Total 1sec. pulse length)

In magnetic lock mode, the lock relay will energise, 0.5sec before the motor starts opening and 5 seconds

later, the lock relaymodule switches off again. (Total 5sec. pulse length)

From Standby Mode

Action

Response

To enter the Program

menu. Press and hold

SET button until buzzer

beeps twice.

Display begins flashing

“P” and buzzer beeps

twice to confirm the

main program menu is

active.

Select lock setup by

scrolling up with the UP

button until “” flashes.

Display flashes “” to

confirm lock setup

mode is selected.

Press and release SET

button to enter lock

setup.

Buzzer beeps once and

current lock status is

displayed.

Press and release the UP

or DOWN buttons to

scroll to the desired

setting.

0 = Off.

1 = Strike lock.

2 = Magnetic lock.

Press and release the SET

button to save the new

setting to memoryand

exit back to the main

program menu.

The buzzer beeps once

and the display returns

to flashing “P”.

To

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

19

www.et.co.za

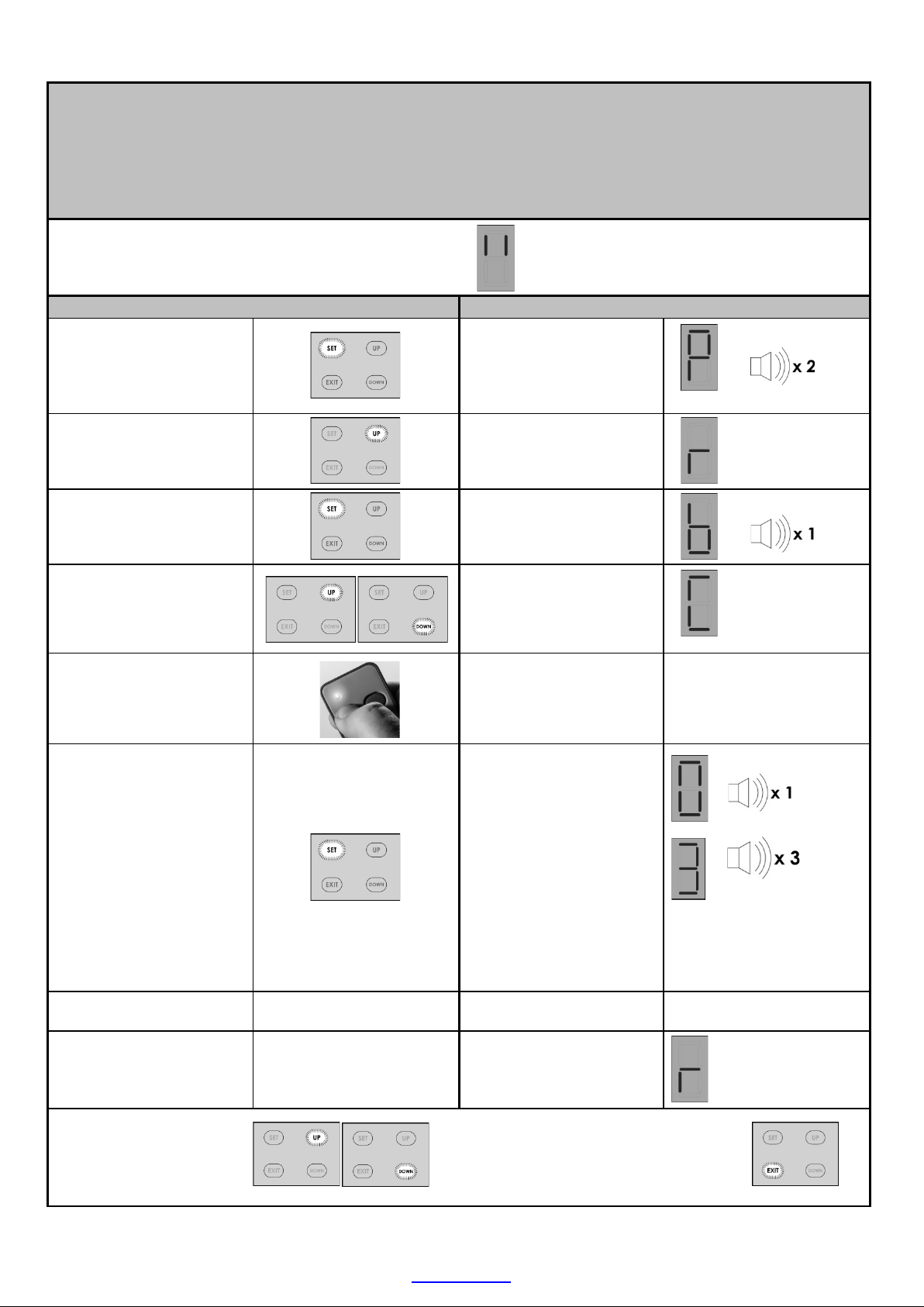

LEARNING A TRANSMITTER CODE IN THE RECEIVER MEMORY.

Max users (BT) button trigger channel = 35 user codes

Max users (LT) courtesy light trigger channel = 5 user codes

NB!! The built in receiver will only work with the ET BLU MIX © enhanced rolling code or ET BLUE rolling code

transmitters.

From StandbyMode

Action

Response

To enter the Program

menu. Press and hold SET

button until buzzer beeps

twice.

Displaybeginsflashing “P”

and buzzer beeps twice

to confirm the main

program menu is active.

Select receiver setup by

scrolling up with the UP

button until “r” flashes.

Display flashes “r” to

confirm receiver

programming menu is

selected.

Press and release SET

button to enter receiver

programming.

Buzzer beeps once and

“b” for (BT) is displayed.

Press and release the UP

or DOWN buttons to scroll

to thechannel theremote

button mustbe learnt into

.

b = (BT) button trigger

channel.

L = (LT) Courtesy light

trigger channel.

or

Press and hold desired

remote button.

LED onremotetransmitter

illuminates.

While still holding the

desired remote button,

press and release the

“SET” button.

“1”on displayand 1 beep

= user code successfully

learnt.

“2” on display and 2

beeps = user code

already in the receiver

memory.

“3” on display and 3

beeps = Unsuccessful

because no code was

seen within 4 sec of the

SET button being pressed.

Mandatorytimeout.

“F” on display and

multiple rapid beeps =

Memoryfull

The display returns to

flashing “r”. Receiver

programming menu.

Release the remote

button

Memory ful l

Code already in

memory

Successful

Unsuccessful

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

ET DC BLUE ADVANCED INSTALLER 2012.025.12.05.2014

20

www.et.co.za

CLEARING A SINGLE TRANSMITTER BUTTON CODE FROM THE RECEIVER MEMORY.

This can only be completed if the remote control that must be erased is present.

If the remote control that must be removed is missing or unobtainable, then a master erase procedure

(Page 21) must be performed and the remaining, valid user codes must all be learnt into the memory once

again.

From Standby Mode

Action

Response

To enter the Program

menu. Press and hold SET

button until buzzer beeps

twice.

Display begins flashing

“P” and buzzer beeps

twice to confirm the

main program menu is

active.

Select receiver setup by

scrolling up with the UP

button until “r” flashes.

Display flashes “r” to

confirm receiver setup

mode is selected.

Press and release SET

button to enter receiver

setup.

Buzzer beeps once and

“b” is displayed.

Press and release the UP

or DOWN buttons to

scroll to the “C” option.

“C” is displayed.

Press and hold desired

remote button to be

erased.

LED on remote

transmitter illuminates.

While still holding the

desired button, press

and release SET button.

“0” on display and 1

beep = user code

successfully erased.

“3” on display and 3

beeps = Unsuccessful

because no code was

seen within 4 sec of the

SET button being

pressed.

Mandatory timeout.

Release the remote

button

Display reverts back to

flashing “r” to indicate

you have returned to the

receiver setup menu.

Unsuccessful

Scroll up or down

to next program

option.

OR

Press and release EXIT to

return to Standby mode.

Table of contents

Other E.T. Systems Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

CTM International

CTM International nfinity owner's manual

Craftsman

Craftsman 139.53915D owner's manual

LEXMAN

LEXMAN 3276007317091 instruction manual

Roger

Roger BG30 Series INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

B&D

B&D Easylifter installation instructions

Chamberlain

Chamberlain Series 651-2MM-1/2HP owner's manual

Henderson

Henderson g60 installation manual

Chamberlain

Chamberlain PD220 Assembly instructions

Chamberlain

Chamberlain Whisper Drive Security+ WD962KD owner's manual

Leb Electronics

Leb Electronics ARGO230 Instructions and warnings for installation, use and maintenance

Proteco

Proteco Q60S manual

Digidoor

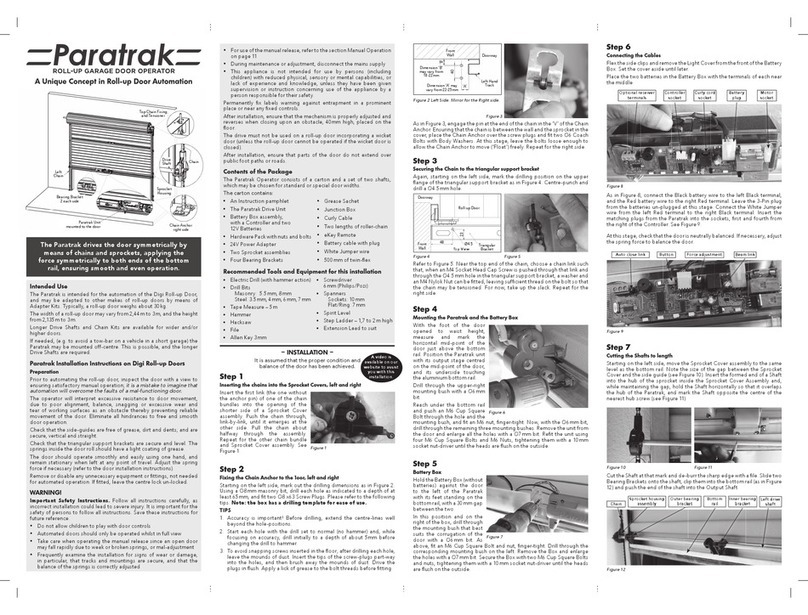

Digidoor Paratrak installation instructions