Do not use the machine as a crane.

Do not place or attach fixed or overhanging

loads to any part of this machine.

Do not push the machine or other objects with

the platform.

Do not operate the machine with the chassis

trays open.

Do not contact adjacent structures with the

platform.

Do not alter or disable the limit switches.

Do not tie the platform to adjacent structures.

Do not place loads outside the platform

perimeter.

Do not alter or disable machine components

that in any way affect safety and stability.

Do not replace items critical to machine

stability with items of different weight or

specification.

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine

stability.

The lithium battery: Each battery must weigh

50 kg. (For S06-HAE/ACE, S0608-HAE/ACE,

S0808-HAE/ACE, and S0812-HAE/ACE);

each battery must weigh 62 kg. (For

S1012-HAE/ACE, S1212-HAE/ACE, and

S1412-HAE/ACE).

The lead-acid battery: Each battery must

weigh 28 kg. The batteries must weigh a

minimum of 112 kg. (For S06-HAE/ACE,

S0608-HAE/ACE, S0808-HAE/ACE,

S0812-HAE/ACE); Each battery must weigh

30 kg. The batteries must weigh a minimum of

120 kg (For S1012-HAE/ACE); Each battery

must weigh 37 kg. The batteries must weigh a

minimum of 148 kg (For S1212-HAE/ACE,

S1412-HAE/ACE).

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for

holding tools or other materials onto the

platform, toe boards or guard rail system can

increase the weight in the platform and the

surface area of the platform or the load.

Do not place ladders or scaffolds in the

platform or against any part of this machine.

Do not transport tools and materials unless

they are evenly distributed and can be safely

handled by person(s) in the platform.

Do not use the machine on a moving or mobile

surface or vehicle.

Be sure all tires are in good condition, air-filled

tires are properly inflated and lug nuts are

properly tightened.

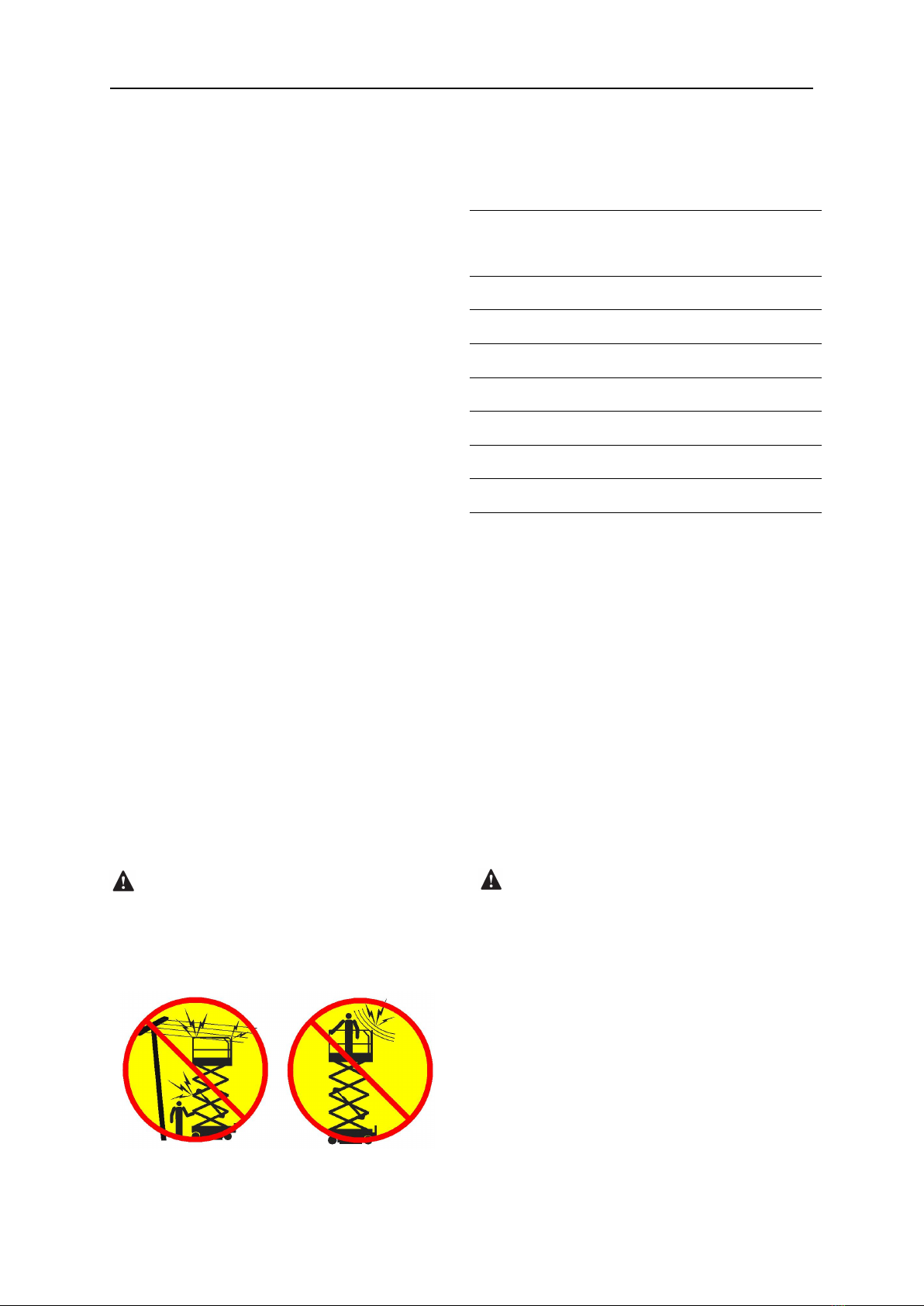

Crushing Hazard

Keep hands and limbs out of scissors.

Keep hands clear when folding rails.

Maintain a firm grasp on the platform rail when

removing the rail pins. Do not allow the

platform guard rails to fall.

Use common sense and planning when

operating the machine with the controller from

the ground. Maintain safe distances between

the operator, the machine and fixed objects.