_______________________________________________________________________________________________________________________________

European

Safety

Systems

Ltd.

Impress House, Mansell Road, Acton, London W3 7QH [email protected] Tel: +44 (0)208 743 8880 www.e2s.com Fax: +44 (0)208 740 4200

Document No. D191-00-501-IS Issue 218-01-2021 Sheet 1 of 5

D1xJ2 Junction Box

For use in Hazardous Locations

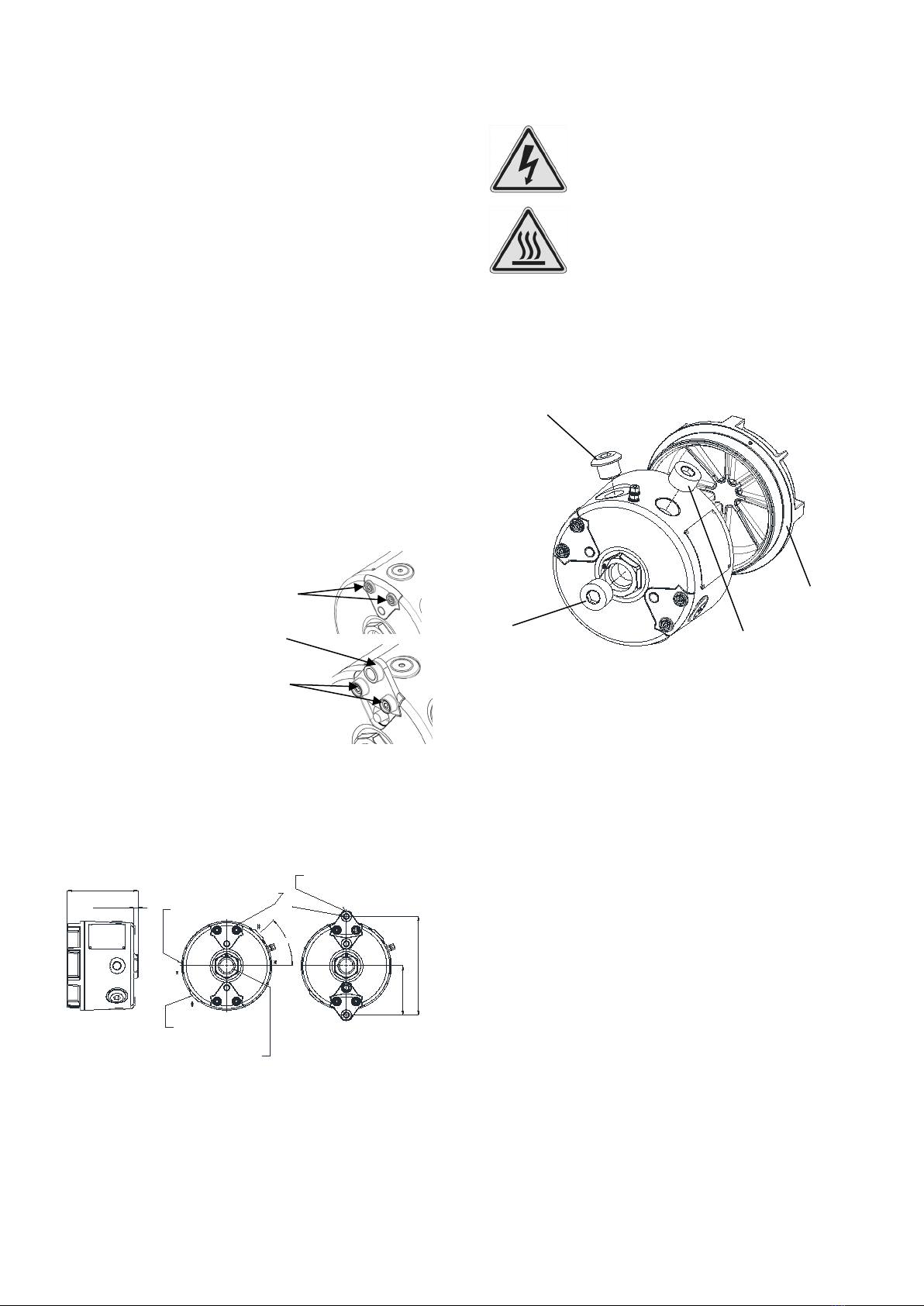

1) Warnings

•DO NOT OPEN WHEN AN EXPLOSIVE

ATMOSPHERE IS PRESENT

•DO NOT OPEN WHEN ENERGISED

•POTENTIAL ELECTROSTATIC CHARGING

HAZARD - CLEAN ONLY WITH A DAMP

CLOTH

•DO NOT PAINT

•TO REDUCE THE RISK OF IGNITION OF

HAZARDOUS ATMOSPHERES, THE FIRST

CONDUIT RUN MUST HAVE A SEALING

FITTING CONNECTED WITHIN 18 INCHES

OF ENCLOSE. SUBSEQUENT CONDUIT

RUNS MUST HAVE A SEALING FITTING

CONNECTED AS CLOSE AS PRACTICAL TO

THE WALL OF THE ENCLOSURE, BUT IN

NO CASE MORE THAN THE SIZE OF THE

CONDUIT OR 50MM, WHICHEVER IS THE

LESSER.

•TO PREVENT IGNITION OF GROUP A, B, C

AND D ATMOSPHERES - SEE

INSTRUCTION FOR CHEMICAL

COMPATIBILITY

Avertissement:

•NE PAS OUVRIR UN PRESENCE

D’ATMOSPHERE EXPLOSIVE

•NE PAS OUVRIR ENERGIE

•DANGER POTENTIEL CHARGE

ÉLECTROSTATIQUE - NETTOYER

UNIQUEMENT AVEC UN CHIFFON HUMIDE

•NE PAS PEINTURER

•POUR RÉDUIRE LE RISQUE

D'INFLAMMATION DES ATMOSPHÈRES

DANGEREUSES, LE PREMIER CONDUIT DE

CONDUIT DOIVENT AVOIR UN RACCORD

D'ÉTANCHÉITÉ RACCORDÉ À MOINS DE 18

POUCES DE L'ENFERMEMENT. POUR

SUBSÉQUENT LES CONDUITES DE

CONDUIT LA DISTANCE ENTRE LA

SURFACE DE LA MASSE DE REMPLISSAGE

AU PLUS PRÈS DE L’ENVELOPPE DOIT

ÊTRE AUSSI PETITE QUE CE QUI EST

RÉALISABLE MAIS EN AUCUN CAS

SUPÉRIEURE À LA PLUS PETITE DES

DIMENSIONS CORRESPONDANT À LA

TAILLE DU CONDUIT OU À 50 MM.

•POUR PRÉVENIR L'INFLAMMATION DES

ATMOSPHÈRES DES GROUPES A, B, C ET

D-VOIR L'INSTRUCTION POUR LA

COMPATIBILITÉ CHIMIQUE

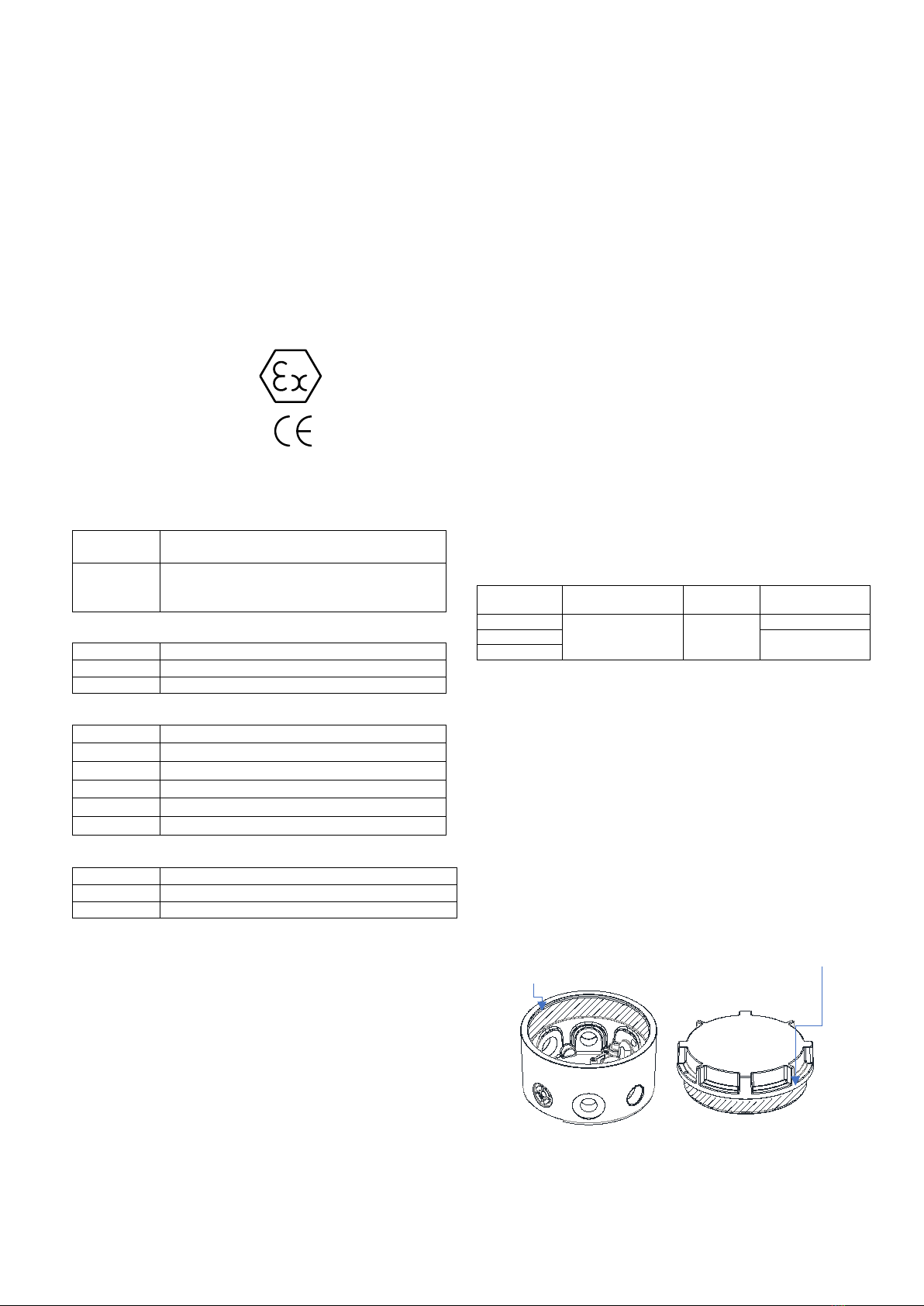

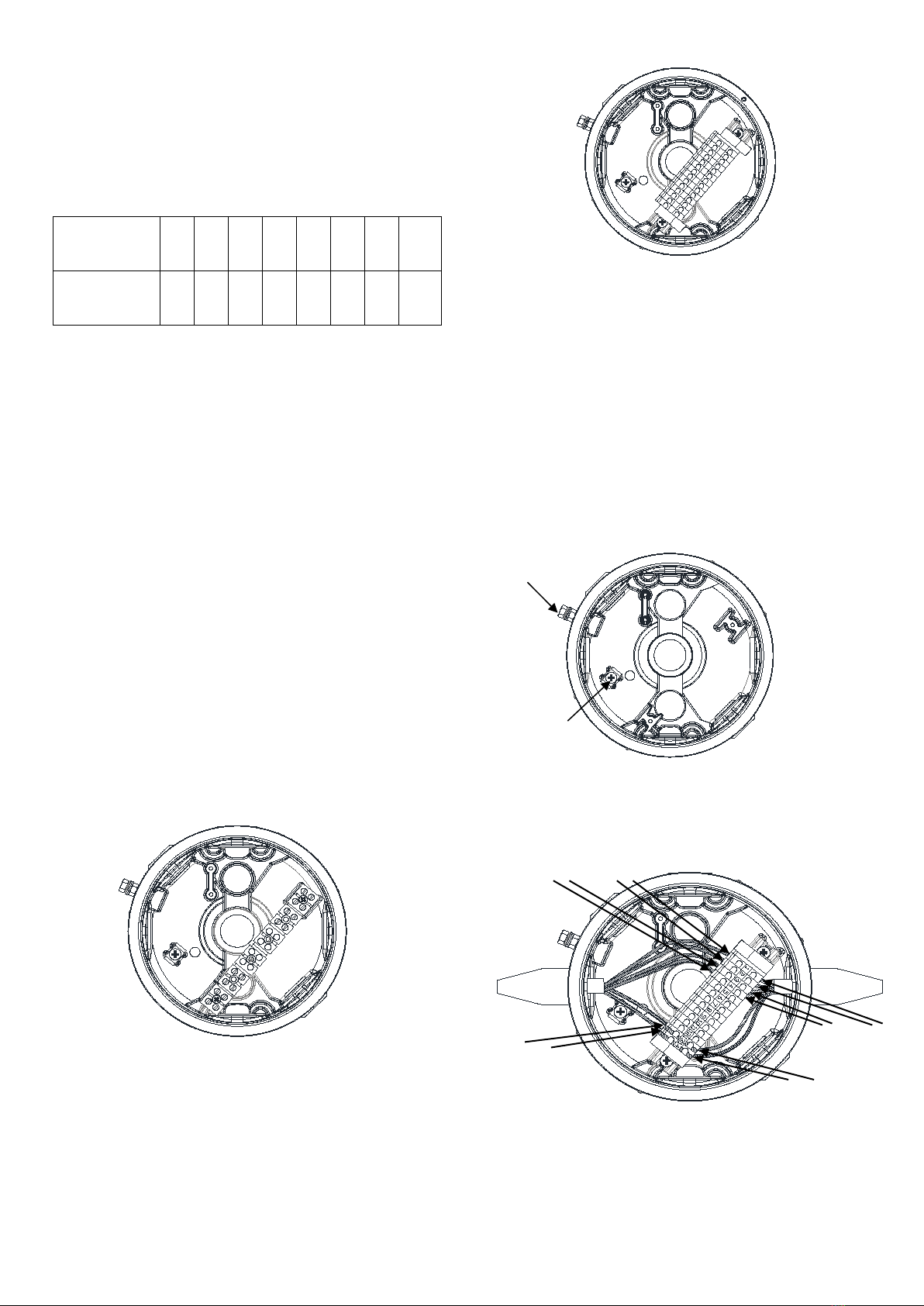

2) Rating & Marking Information

2.1 NEC & CEC Class / Division Ratings for US / Canada

The D1xB2J2 Junction Box complies with the following

standards:

UL 1203 (Ed. 5) 2018

CSA C22.2 No. 30-M1986 (Ed. 3) 2016

CSA C22.2 No. 25 (Ed. 4) 2017

CSA C22.2 No. 205 (Ed. 3) 2017

The D1xJ2 Junction Box is rated as follows:

Class I Div 1 Group ABCD T4A Ta -55°C to +80°C

Class I Div 1 Group ABCD T5 Ta -55°C to +75°C

Class I Div 1 Group ABCD T6 Ta -55°C to +60°C

Class II Div 1 Group EFG T4A Ta -55°C to +80°C

Class III Div 1 Ta -55°C to +80°C

Installation must be carried out in compliance with the

National Electric Code / Canadian Electric Code

2.2 NEC Class / Zone ratings US

The D1xJ2 Junction Box complies with the following

standards:

UL 60079-0 (Ed. 6) 2017

UL 60079-1 (Ed. 7) 2015

UL 60079-31 (Ed. 2) 2015

The D1xB2J2 Junction Box is rated as follows:

Class I Zone 1 AEx db IIC T4 Ta -55°C to +80°C

Class I Zone 1 AEx db IIC T5 Ta -55°C to +70°C

Class I Zone 1 AEx db IIC T6 Ta -55°C to +55°C

Zone 21 AEx tb IIIC T106°C Ta -55°C to +80°C

Installation must be carried out in compliance with the

National Electric Code.

2.3 CEC Class / Zone ratings Canada

The D1xJ2 Junction Box complies with the following

standards:

CAN/CSA C22.2 No. 60079-0 (Ed. 3) 2015

CAN/CSA C22.2 No. 60079-1 (Ed. 3) 2016

CAN/CSA C22.2 No. 60079-31 (Ed. 2) 2015

The D1xB2J2 Junction Box is rated as follows:

Ex db IIC T4 Ta -55°C to +80°C

Ex db IIC T5 Ta -55°C to +70°C

Ex db IIC T6 Ta -55°C to +55°C

Ex tb IIIC T106°C Ta -55°C to +80°C

Installation must be carried out in compliance with the

Canadian Electric Code

2.4 ATEX / IECEx certification

The D1xJ2 Junction Box complies with the following

standards: