ILER-DDS V2.1 VFO/DDS. Page 3

INTRODUCTION

The ILER-DDS VFO is a RF generator based on the Analog Devices AD9850 DDS chip

(www.analog.com). At present, the direct digital synthesis (DDS) is an excellent solution for the LO on

single-band and multiband amateur equipment, at a very moderate cost. Due to the very high frequency

reference (125 MHz), the ILER-DDS offers a very clean signal when working at relatively low frequencies

as 11, 20 or even 30 MHz. (< 25% of the reference frequency). If you want to delve deeper into the

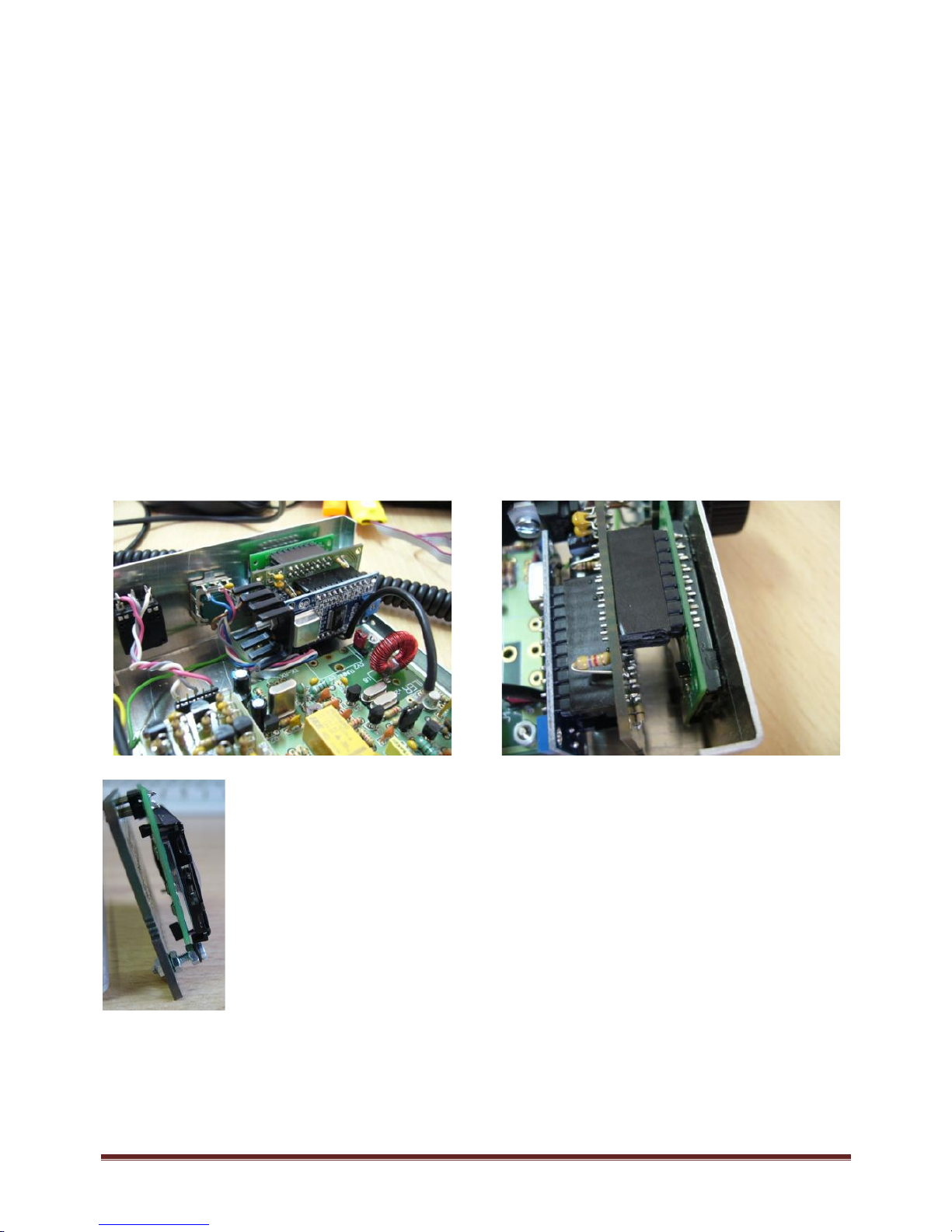

theory of DDS we advice you to read the abundant internet literature. The use of a "sandwich" single

block mechanical configuration and a single encoder with a built-in push-button to control the operation

makes this VFO/DDS an extremely versatile "block" easy to integrate in many projects for amateur rigs.

SPECIFICATIONS

Universal VFO for all ILER, MFT, EGV transceivers and similar projects.

S-METER level indicator with digit from S-0 to S9+ and 10-level graphical bar.

S-METER voltage input from 0 to 5V direct or inverted, with independent adjustment of each level.

Dual VFO A/B

RIT / SPLIT function without limit

Configurable Tuning Steps: selected ones or all steps (from 10 Hz to 10 MHz).

Programmable IF Offset. IF=RF+VFO, IF=RF-VFO, IF=VFO-RF, IF = 0 (RF generator).

Programmable upper and lower band limit.

Fine calibration of the frequency reference by software (up to 1 Hz accuracy).

Voltmeter display with 0.1 V accuracy (0.01 V calibration).

Auxiliary I/O pins for expansion.

2 x SINUSOIDAL WAVE OUTPUT.

2 x SQUARE WAVE OUTPUT.

LOW SPURIOUS. TX and RX mixers spectrum is equal to or better than a VXO one.

DDS AD9850BRS integrated circuit.

Reference clock: 125 MHz.

Signal output level at 200 ohms: 300mVpp 35MHz // 800mVpp 20MHz

User programmable “Welcome message”: callsign or name.

LOCK function for push button and encoder.

Automatic record of last used frequency or current frequency.

2 Line x 8 character LCD with AUTO-ON-OFF configurable backlight.

Power supply: 7.5-14 V about 90-100mA (no backlight)

Outboard encoder for a more versatile mechanical configuration.

Small size "sandwich" module, easy to fix with screws or glue.

Total space used: 51 x 36 x 40 mm W-H-L (with soldered LCD 35 mm L). LCD window size 29 x 19 mm.

Soft touch non-stop rotary encoder (like commercial equipment).

24 steps per revolution rotation encoder (maximum speed 36 step/s).

All operations are executed with the encoder and pushbutton.

Simple, direct, and immediate configuration through menus.

All settings are stored in EEPROM (1 million write/read cycles (minimum) and 100-year).

PIC18F2525-I/SP microcontroller 20 MHz clock.