of impulse response, diaphragm settling time and polar technologies. Those

who have heard Earthworks High Definition Microphones™, say that they

hear more of attack, more subtle details and a more pristine quality in the

sound than with any other microphones, regardless of price. The Demo CD in

the Earthworks Mini-Brochure should capture your interest in this respect.

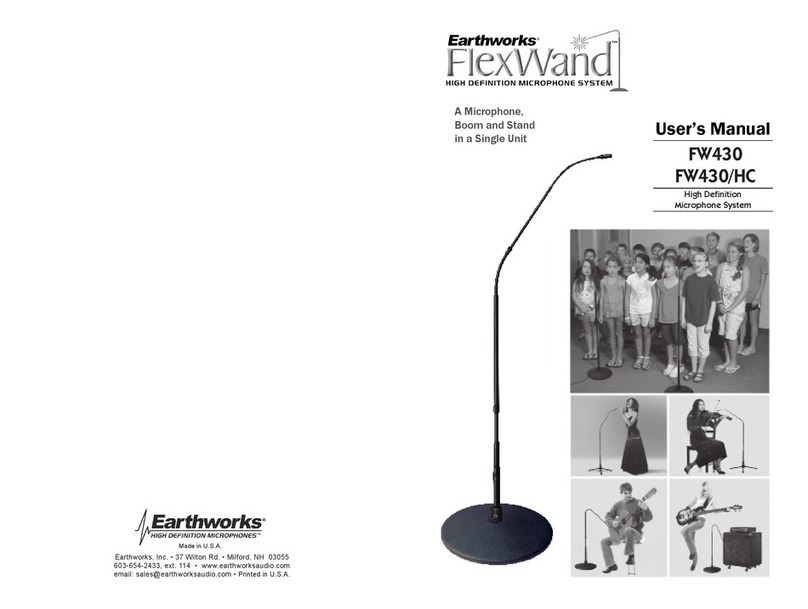

A Mini-Brochure with a Demo CD is included with this manual. Even though

you have purchased Drum Periscope microphones, we suggest that you take

the time to listen to the other High Definition Microphones demonstrated on

this enclosed Demo CD.

Miking Drums

There are many ways to mic drums and it seems that most every recording or

live sound engineer has their own way of doing so. Our objective is not to in-

dicate which drum miking approach is better, but to make suggestions and look

at advantages and disadvantages of each. Every engineer or producer uses their

own methods to obtain the results they desire, and that’s what matters.

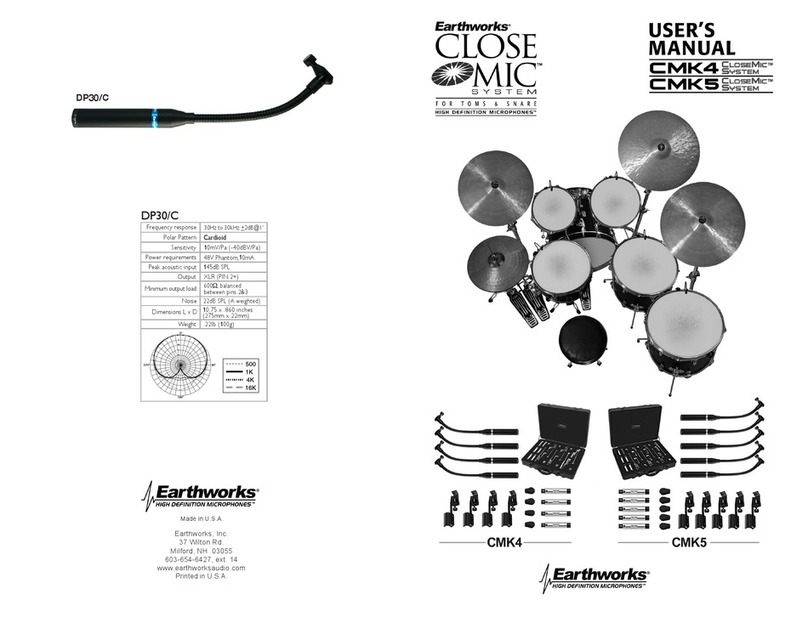

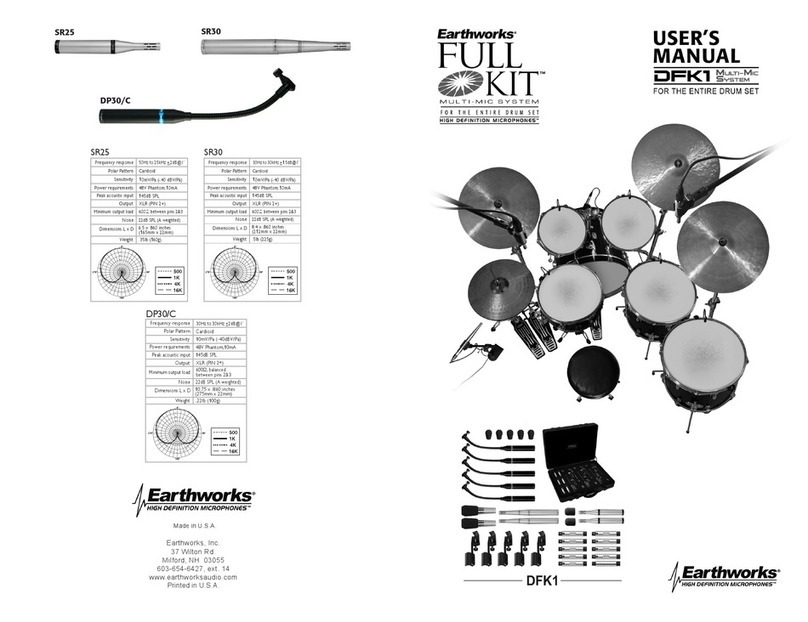

Multi-microphone Method

The objective in multi-microphone drum miking is to place a separate mi-

crophone on either most or all the elements of a drum set. Typically, sepa-

rate mics are used on snare, toms, high-hat and kick drum with one or two

overhead microphones. The overhead mics pick up the overall sound of the

drums including cymbals, which are typically not miked separately. With

this method, the mixing engineer can control the level, and signal process-

ing (limiting, EQ, etc.) for each element of the drum set (toms, snare, hi-hat,

etc.). This provides a great deal of control over the sound of the entire drum

set and allows bringing out certain patterns on sock cymbal, snare, etc. Multi-

miked drums may be desirable when you are recording in a large room with

high ambient sound as it will reduce the amount of unwanted room sound.

Multi-miking is also a popular practice for miking drums in “live sound” ap-

plications such as concerts, as it will provide more gain before feedback in

addition to greater control of the drum mix.

No Phase Cancellation Issues

with Earthworks™Microphones

One of the typical disadvantages in the multi-microphone approach, when

using conventional microphones, is the interactive microphone phasing prob-

lems that result in the cancellation of certain frequencies. These phasing

problems are a result of the poor polar response of conventional microphones.

Conventional microphones have a drastically different frequency response

between the front and sides of the microphone. It is common for conventional

6