Aerial Platform Features

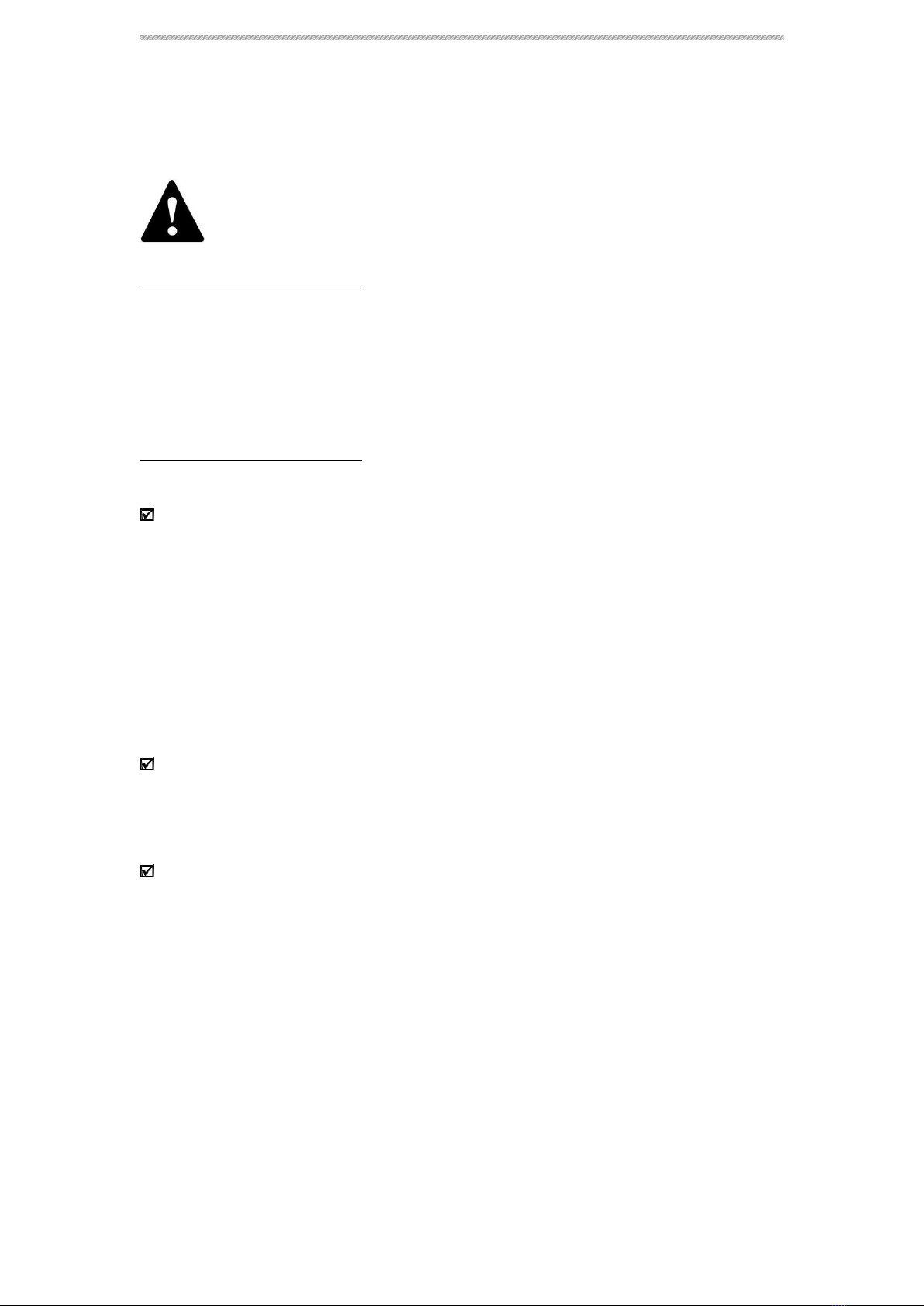

The aerial platform is not electrically insulated.

Death or serious injury will result from contact

with, or inadequate clearance from, an energized

conductor.

Do not go closer than the minimum safe approach

distance as defined by the Minimum Safe

Approach Distance section in Chapter 2–Safety.

Regard all conductors as energized.

Allow for electrical wire sag and aerial platform

sway.

If the platform, scissors structure, or any part of the

aerial platform contacts a high-voltage electrical

conductor, the entire machine can become

electrically charged.

If that happens, remain on the machine and do not

contact any other structure or object. This includes

the ground, adjacent buildings, poles, and any other

objects that are not part of the aerial platform.

Such contact could make your body a conductor to

the other object, creating an electrical shock hazard

resulting in death or serious injury.

If an aerial platform is in contact with an energized

conductor, the platform operator must warn ground

personnel in the vicinity to stay away. Their bodies

can conduct electricity creating an electrical shock

hazard resulting in death or serious injury.

Do not approach or leave the aerial platform until

the electricity has been turned off.

Do not attempt to operate the lower controls when

the platform, scissors structure, or any part of the

aerial platform is in contact with a high-voltage

electrical conductor or if there is an immediate

danger of such contact.

Personnel on or near an aerial platform must be

continuously aware of electrical hazards,

recognizing that death or serious injury can result

from contact with an energized conductor.

Operator’s Manual

This manual provides information for safe and

proper operation of the aerial platform. Some

information in this manual refers to options that

may not be on your machine. Read and understand

the information in this Operator’s Manual before

operating the aerial platform on the job.

Additional copies of this manual may be ordered

from EHM. Supply the model and manual part

number from the front cover to assure that the

correct manual will be supplied.

All information in this manual is based on the latest

product information at the time of publication.

Eastman reserves the right to make product

changes at any time without obligation.

Safety Alerts

A safety alert symbol is used throughout this

manual to indicate danger, warning, and caution

instructions. Follow these instructions to reduce the

likelihood of personal injury and property damage.

The terms danger, warning, and caution indicate

varying degrees of personal injury or property

damage that can result if the instruction is not

followed.

Danger

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word is to be used in the most extreme

situations.

Warning

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Caution

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Notes

Notes are used to provide special information or

helpful hints to assist in aerial platform operation,

but do not indicate a hazardous situation.

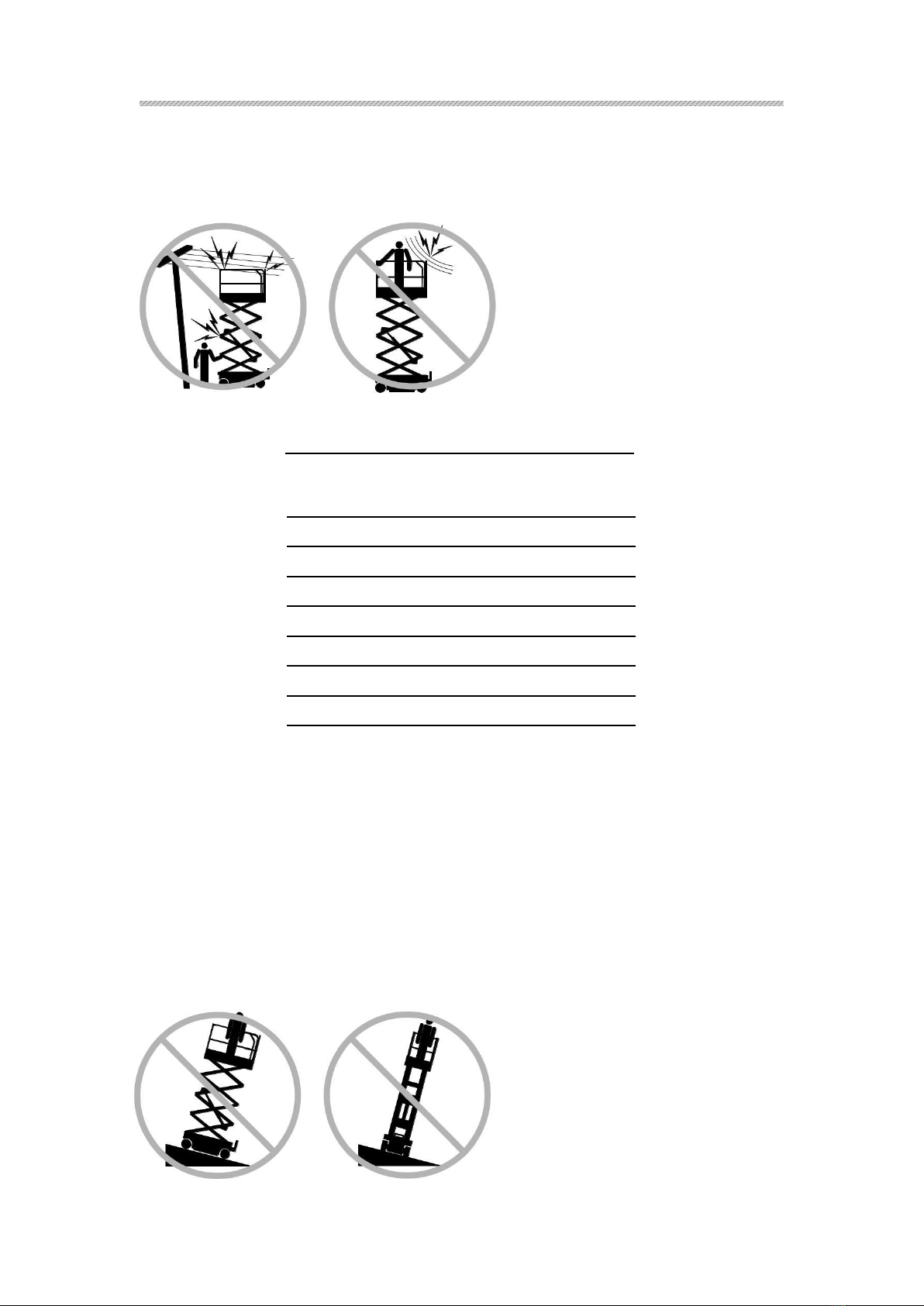

Operation

The aerial platform has built-in safety features and

has been factory tested for compliance with

Eastman specifications and industry standards.

However, any personnel lifting aerial platform can

be potentially dangerous in the hands of untrained

or careless operators.