EW-5010A OPERATION MANUAL

the automatic case, the cycle time is parallel to the manual take-up and

release time); The setting interface settings are displayed or closed.

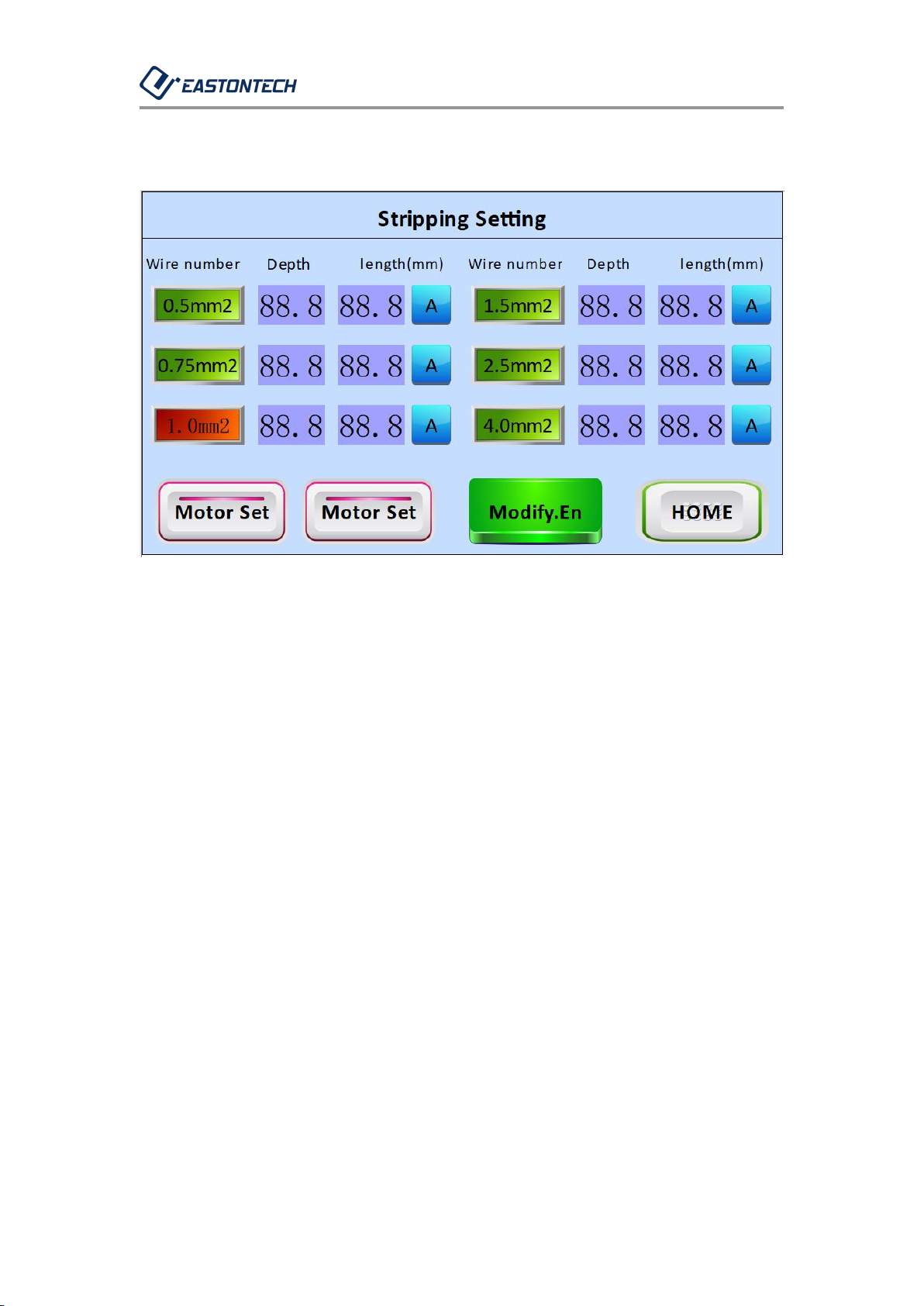

1-1-5. Peeling settings: pull down the menu key, see the related interface

for details.

1-1-6. Parameter setting: pull down the menu key. For details, please

refer to the related interface introduction.

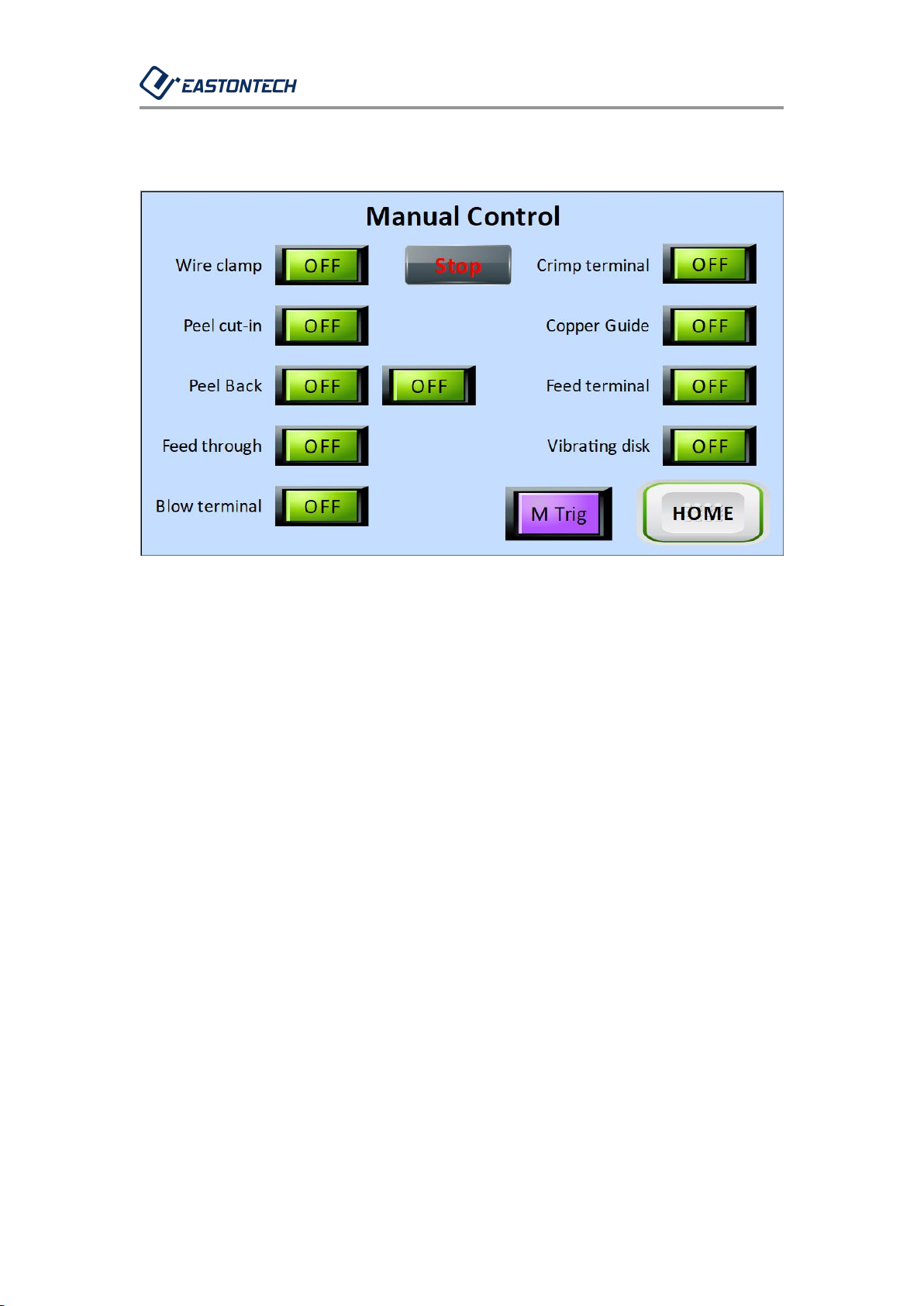

1-1-7. Manual control: pull down the menu button, see the related

interface for details.

1-1-8. Peeling and crimping: This button is a function selection, you can

click to switch to peeling.

1-1-9. Manual mode: This button is a function selection, you can click to

switch to automatic mode.

1-1-10. Jog: This button is used for jog control for single-step operation,

and it must be effective in the "manual mode"; the function is activated

when the jog button is pressed for about 2 seconds, and the background

color of the button turns red after startup , Click again to proceed to the

next action (click the next interval is valid for 1S).

1-1-11. The time in the upper right corner can be corrected in the system

settings interface.