SAFETY INFORMATION

Read and understand all instructions thoroughly.

Save this instruction manual for future reference.

Keep out of reach of untrained persons and children.

HEALTH & INJURY HAZARDS!

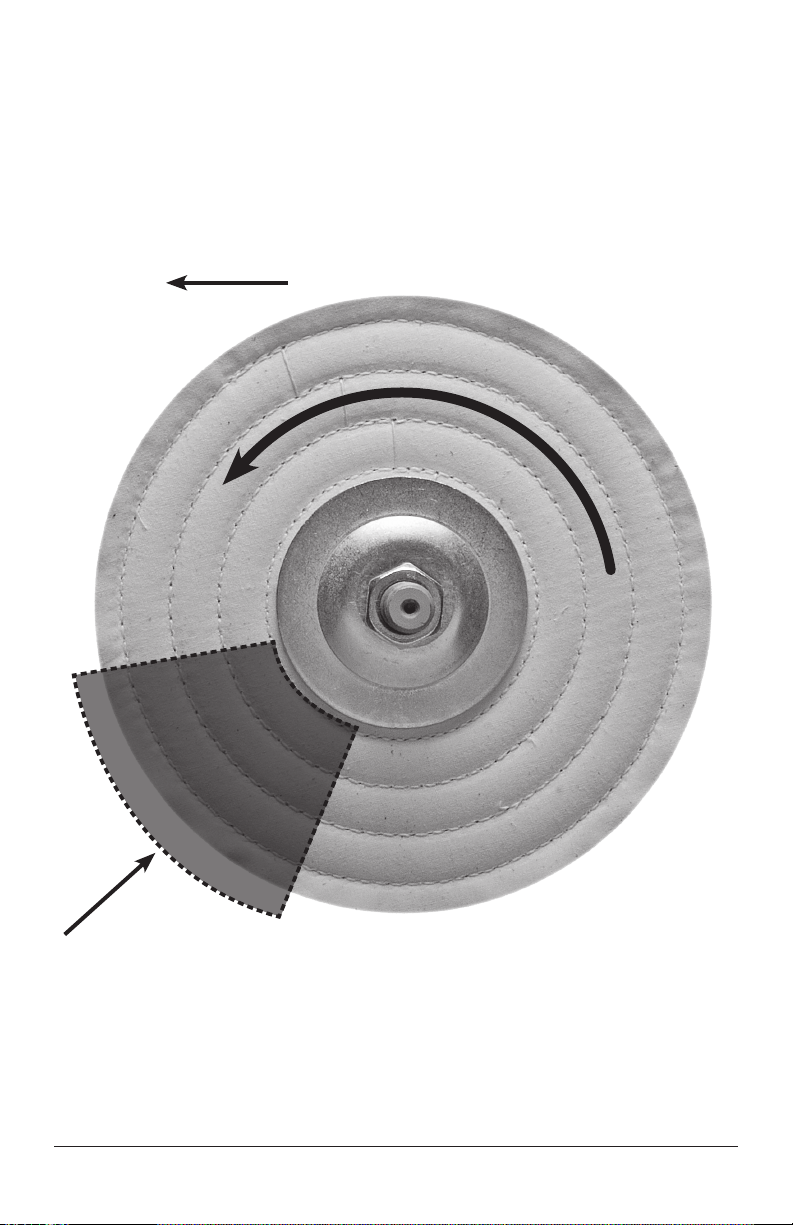

• Under certain conditions the buff wheel can grab the work piece and

throw it at the operator with great force causing personal injury and

damage to the surroundings. Always wear a face shield and ANSI

approved safety glasses when buffing to protect the face and eyes.

• The dust produced by buffing can contain hazardous toxic compounds

depending on the substrate being buffed. Always wear a NIOSH approved

breathing apparatus when buffing.

• Spinning buff wheels can cause burns and abrasions if touched by the

operator. Do not touch the wheels while they are spinning. Always wear thick

close fitting leather gloves while buffing to protect your hands from injury.

• Unplug the buff motor before changing buff wheels to avoid injury.

• DO NOT USE GRINDING WHEELS ON THIS BUFF MOTOR. This buff motor

is designed for fabric buff wheels ONLY as it does not have the machine

guards necessary to protect the operator from the flying debris produced

when a wheel shatters. Severe personal injury and death could result from

using grinding wheels on this buff motor.

• Loose clothing, long hair or jewelry can become caught in the rotating

parts of this machine causing severe physical injury. Wear appropriate

clothing and contain long hair.

• Keep bystanders, observers and children away when operating this tool.

• Never leave the tool running while unattended.

• Secure buff motor to a bench or stand before use.

ELECTRICAL SHOCK HAZARD!

This equipment is equipped with a power cord having an equipment-

grounding conductor. An outlet with a properly functioning grounding

conductor must be used. Do not remove the grounding pin from the plug

of this cord or use an adapter which does not allow proper grounding.

To order parts and supplies: 800.343.9353 >> eastwood.com 3