1

Technical Support

1-800-248-0892

Ext. 2

Air Commander

Part No. 27325, with air

Part No. 27332, without air

www.airliftcompany.com

Please read these instructions completely before proceeding with installation.

The oil level in the compressor must be checked BEFORE running the engine or

compressor. Failure to do so will result in a faulty compressor and a void warranty.

MN-494

(02204)

ECN 3827

Item Description Part Number Qty.

Compressor 24325 1

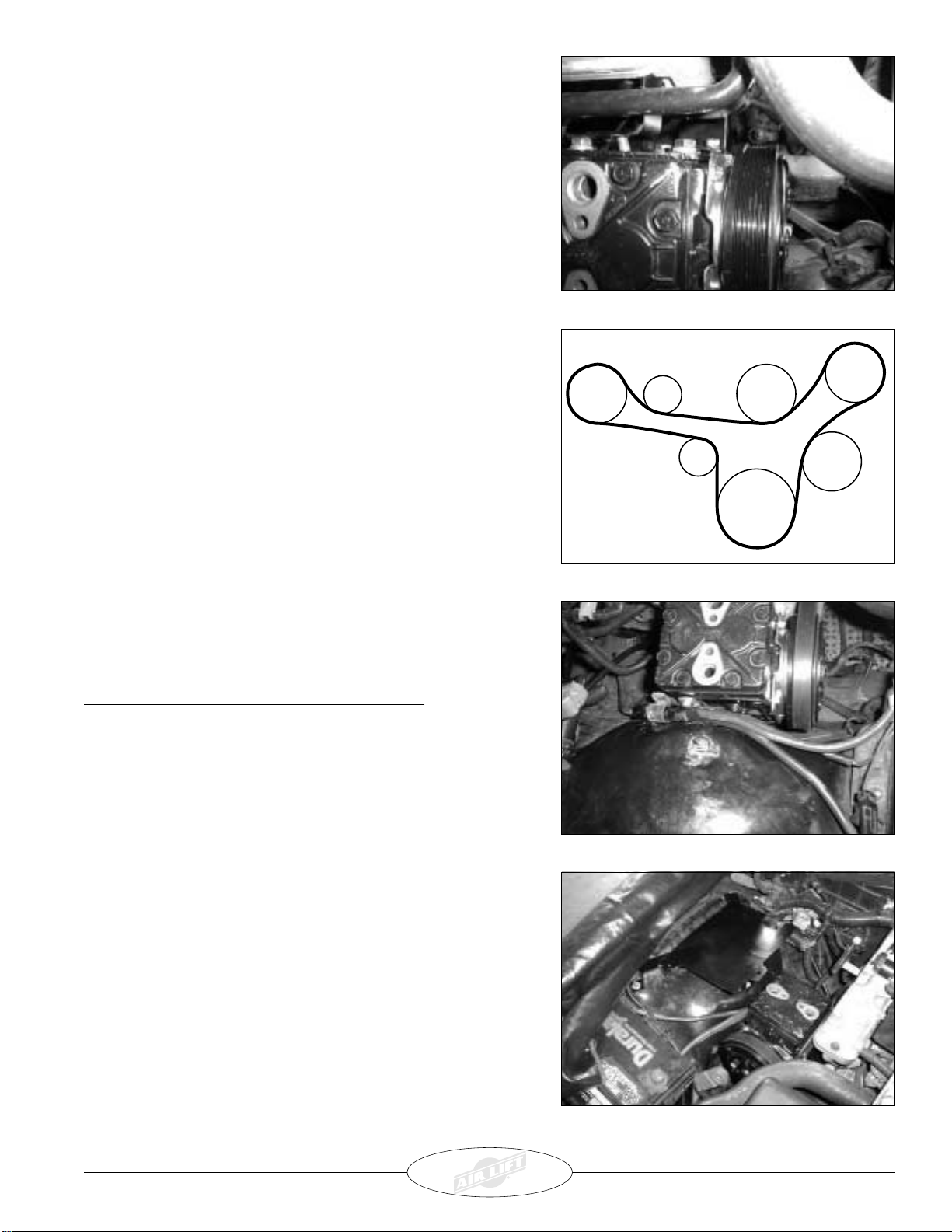

Serpentine Belt (with air) 10652 1

Serpentine Belt (without air) 10655 1

Alternator Pulley 10230 1

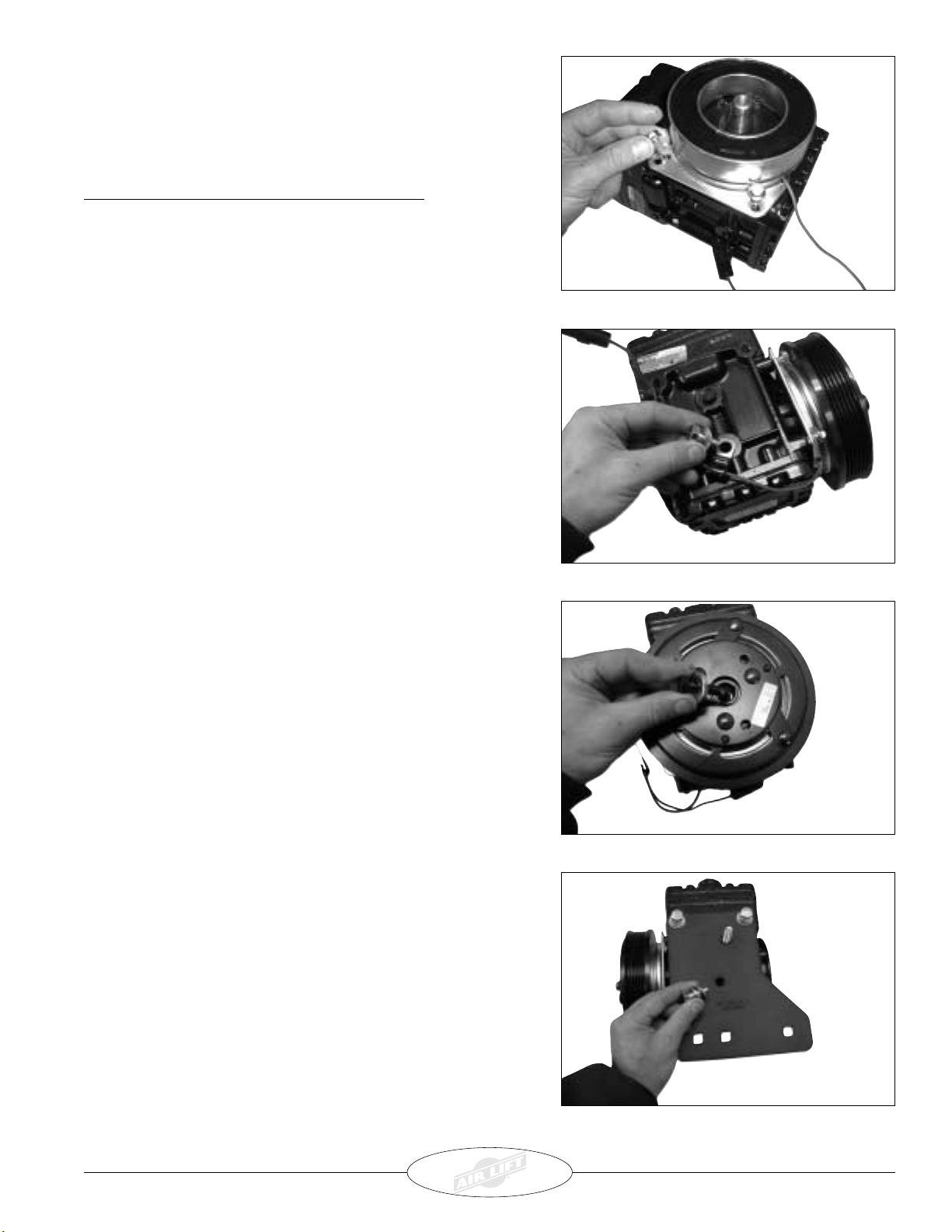

Clutch/Pulley Assembly 26615 1

Idler/Pulley Assembly 26630 1

Overflow Reservoir 21135 1

Coelescing Filter 21107 1

Inlet Filter 10670 1

Leader Hose 22024 1

Computer Bracket 10730 1

Compressor Plate 10755 1

Coolant Reservoir Bracket 10179 1

Upper Bracket 10761 1

Lower Left Bracket 10762 1

Lower Right Bracket 10763 1

Air Filter Bracket 10479 1

Brass Cross Bracket 26237 1

Compressor Fitting 21130 2

Compressor Sleeve Insert 21125 2

O-ring 21578 2

1/2" NPT Check Valve 21285 1

1/4" NPT Relief Valve 24290 1

110-145 p.s.i. Pressure Switch 24551 1

1/2" NPTM x 1/2" Tube Straight 21369 5

1/2" NPTM x 1/4" NPTF Bushing 21247 1

1/2" Brass Cross 21221 1

Plug 21190 1

1/2" NPTM x 1/8" NPTF Bushing 21251 1

1/2" NPTF Coupling 21220 3

Important Warranty Information

1. Ifthecompressoror engineis runwithout having

oil in the compressor, then the warranty is void.

2. If the belt is misinstalled or the belt does not

have the proper tension, then the warranty is

void.

3. Failure to use included installation components

properly voids the warranty.

4. Failure to check proper oil level and conditions

will void the warranty.

5. This compressor must only be used in an air

compressor application only, not an air

conditioning application. No freon is required.

Front View Side View

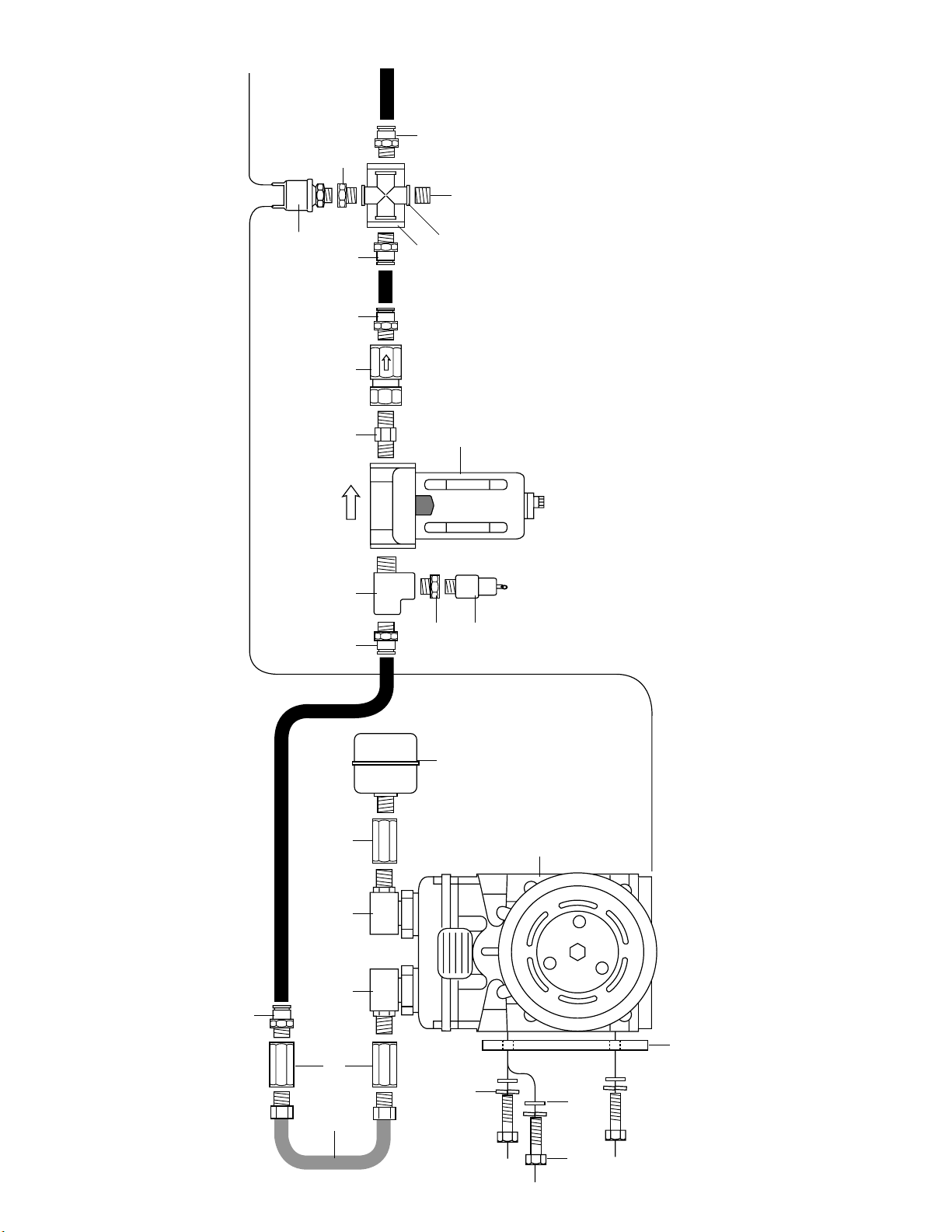

InstallationComponents

EASYSTREET

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

Item Description Part Number Qty.

1/2" Street Tee 21391 1

3/8"-16 x 3/4" Bolt 17101 2

3/8" Flat Washer 18444 9

3/8"-16 x 1 Carriage Bolt 17134 4

3/8"-16 x 7/8" Bolt 17187 3

3/8" Lock Washer 18427 7

3/8"-16 Hex Nut 18430 4

8mm-1.25 x 25mm Bolt 17177 1

8mm Flat Washer 18501 1

8mm Lock Washer 18503 1

Frame Clamp 10181 1

1/4"-20 x .75" Bolt 17175 8

Self Tapper 17102 2

5/16" Flat Washer 18405 6

10-32 x 3/8" Machine Screw 18496 2

1/4"-20 Kep Nut 18452 8

1/4" Hose Clamp Worm 10550 1

20 amp AGC Fuse 24739 1

Red 16 Gauge Wire 24643 8'

ATC/ATO Fuse Tap In 24542 1

Mini Fuse Adapter 24561 1

Butt Connector 24645 2

1/4" Female Terminal 24594 3

AGC Fuse Tap In 24543 1

3/16" Female Terminal 24524 1

Thread Sealant 23586 2

1/2" Nylon Hose 20966 15'

Hose Cutter 10530 1

Oil Dipstick 10159 1

Pipe Nipple 21729 1

EE

FF

GG

HH

II

JJ

KK

LL

MM

NN

OO

PP

QQ

RR

SS

TT

UU

VV

WW

XX

YY

ZZ

AB

AC

AD

AE

AF

AG

AH

AI