Polar Air Electric Operated, Piston Compressors

3

Model PP05H080I1 PP07H080V1 PP10H120Y1 PP07H080V3 PP10H120Y3

Tank Type

Dimensions

Horizontal

76 x 30 x 56

Horizontal

76 x 30 x 56

Horizontal

78 x 32 x 50

Horizontal

76 x 30 x 56

Horizontal

78 x 32 x 50

Model PP05V080I1 PP07V080V1 PP10V120Y1 PP07V080V3 PP10V120Y3

Tank Type

Dimensions

Vertical

34 x 24 x 72

Vertical

34 x 24 x 72

Vertical

50 x 32 x 78

Vertical

34 x 24 x 72

Vertical

50 x 32 x 78

Tank Size 80 Gallon 80 Gallon 120 Gallon 80 Gallon 120 Gallon

Description 5HP

Single Phase

7.5HP

Single Phase

10HP

Single Phase

7.5HP

Three Phase

10HP

Three Phase

SCFM @ 175 psi 17.0 26.0 35.0 26.0 35.0

Max PSI 175 175 175 175 175

Motor HP 5HP 7.5HP 10HP 7.5HP 10HP

Motor RPM 1750 1750 1750 1750 1750

Voltage 208V/230V 208V/230V 208V/230V 208/230/460/575 208/230/460/575

Pump Model APP2I0524T APP4V1043T APP3Y1544T APP4V1043T APP3Y1544T

Pump RPM 650 640 600 640 600

Noise DB(A) 73 73 76 73 76

Outlet Connection NPT 3/4” NPT 3/4” NPT 1” NPT 3/4” NPT 1”

Weight (±5 lbs.) 715 958 1095 958 1095

Shipping Weight 800 1043 1242 1043 1242

Model Specication Charts . . . . . . . . . . . . .3-4

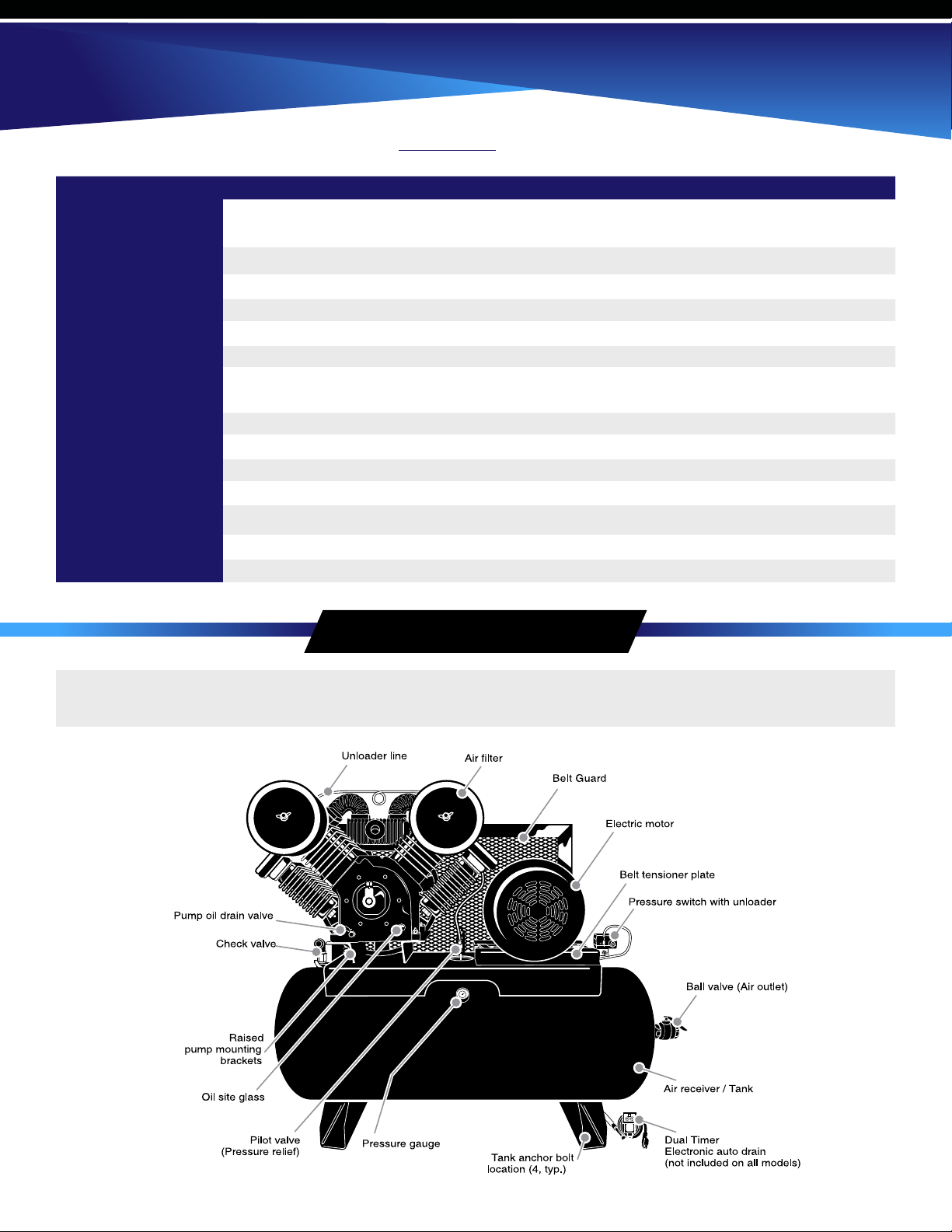

Description . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . 5

TagDenitions....................5

BasicGuidelines.................5

BreathableAir....................6

PressurizedComponents..............6

PersonalProtectiveEquipment..........6

Inspection.........................6

ForkliftSafety.....................7

LiftingSafety......................7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

Area...........................8

PipingSafety.....................8

Piping/TankInstallation.............9

ElectronicAutoDrain(ifequipped)....10

ElectricalSafety...................11

WiringInstallation..................12

Operation..........................13

SafetyRules......................13

StartUp........................14

ContinuousRunFeature..........15

Maintenance........................15

SafetySteps......................15

BeltAdjustment..................16

ChangingOil.....................17

SafetyValve.....................17

Tank.......................17

Maintenance Schedule................18

Troubleshooting....................18

Warranty..........................19

Contents

Polar Air Electric Operated, Two-Stage, 5-10 Hp Piston Air Compressors

L•W•H

(inches)

L•W•H

(inches)