2. INTRODUCTION & SPECIFICATION

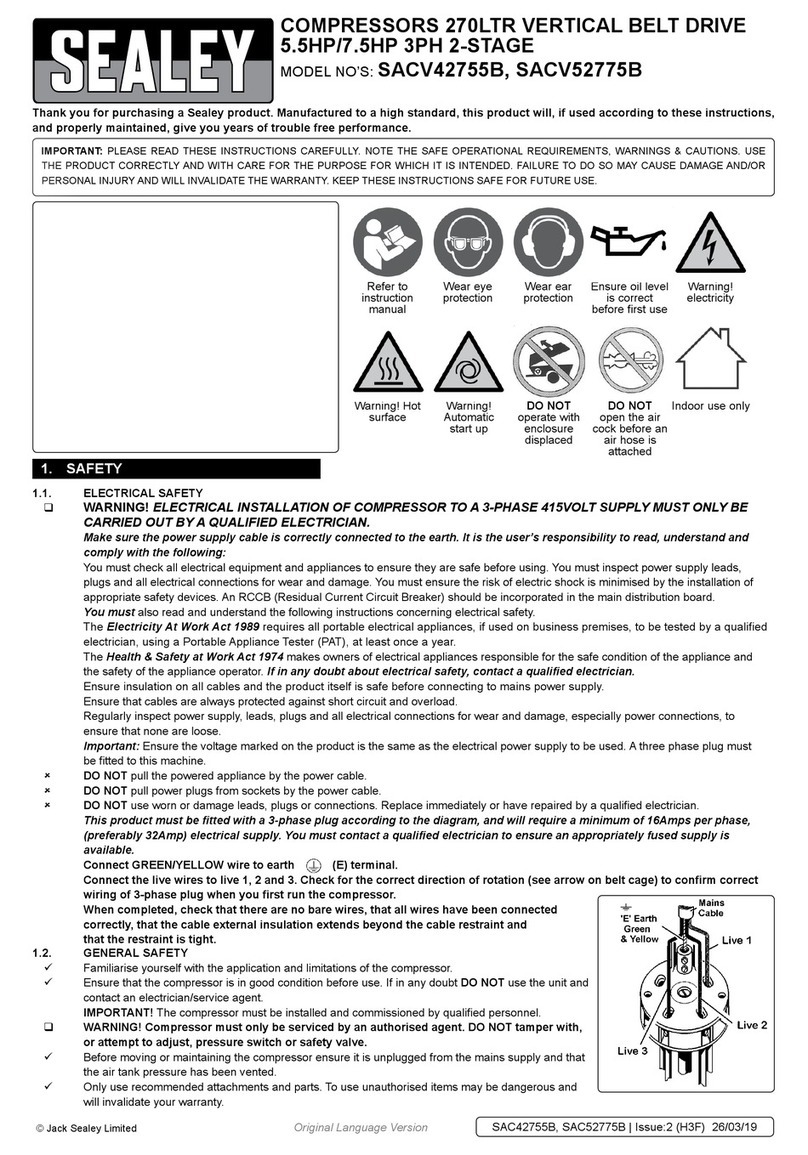

Static compressor with Honda GX200 6.5hp power unit coupled to

heavy-duty, two stage twin piston, cast iron pump. Pump has heavy-

duty full cast cylinders capped by alloy heads for improved heat

dissipation and long life. Heavy-duty drive guard protects belt and

flywheel that is designed to force air over the pump to aid cooling.

Features single gauge and air outlet. Runs on unleaded fuel.

3. PREPARATION

3.1. Remove compressor from packaging and inspect for any

missing or damaged parts. If anything is found to be missing

or damaged contact your supplier.

3.2. Save the packing material for future transportation of the

compressor. It is recommended to store the packing in a safe

location, at least for the period of the guarantee. Then, if

necessary, it will be easier to send the compressor to the

service centre.

3.3. Take care to transport the compressor correctly, do not

overturn it or lift it with hooks or ropes.

3.4. Positionthecompressoronaatsurfaceorwithamaximum

permissible inclination of 10°. Site in a well ventilated area.

If the surface is inclined and smooth, check if the compressor

moves whilst in operation.

If the surface is in a raised position, make sure the

compressor cannot fall, securing it in a suitable way.

3.5. Toensuregoodventilationandefcientcooling,the

compressor’s belt guard must be at least 100cm from any

wall.

3.6. Before using the compressor, check the oil level by looking

at the dipstick as shown in fig.5C. If the oil is not between the

min and max. mark, it should be topped up with synthetic oil

(see section 5.4. for recommended oils). We do not

recommend using mineral oil in these compressors. Do not

overfill.

3.7. The compressor should be located in a position that allows

good air circulation around the unit and where there is good

ventilation. Remember that the compressor's engine

produces harmful exhaust fumes.

2.1. SPECIFICATION

4. OPERATION

WARNING! Ensure that you read, understand and apply

Section 1 Safety Instructions.

4.1. STARTING

IMPORTANT! Always check and, if necessary, top-up the

engine oil and the pump oil before starting. Severe engine

and/or pump damage may otherwise result.

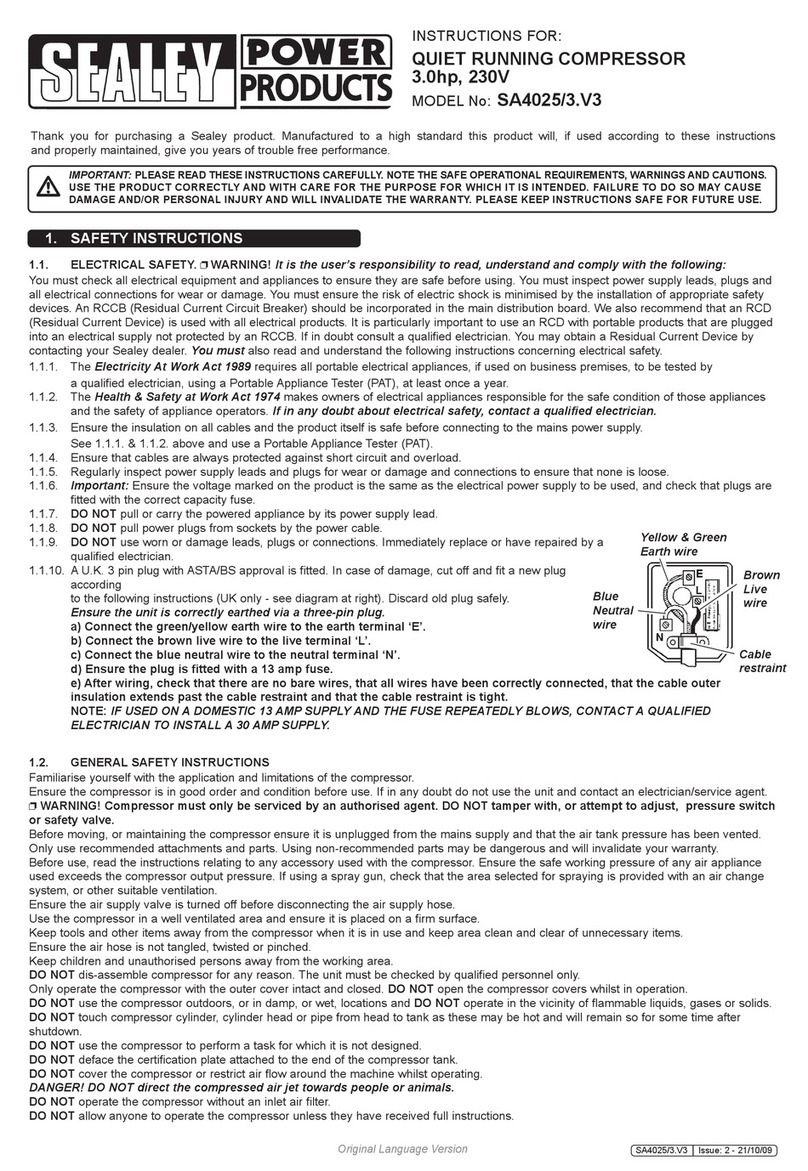

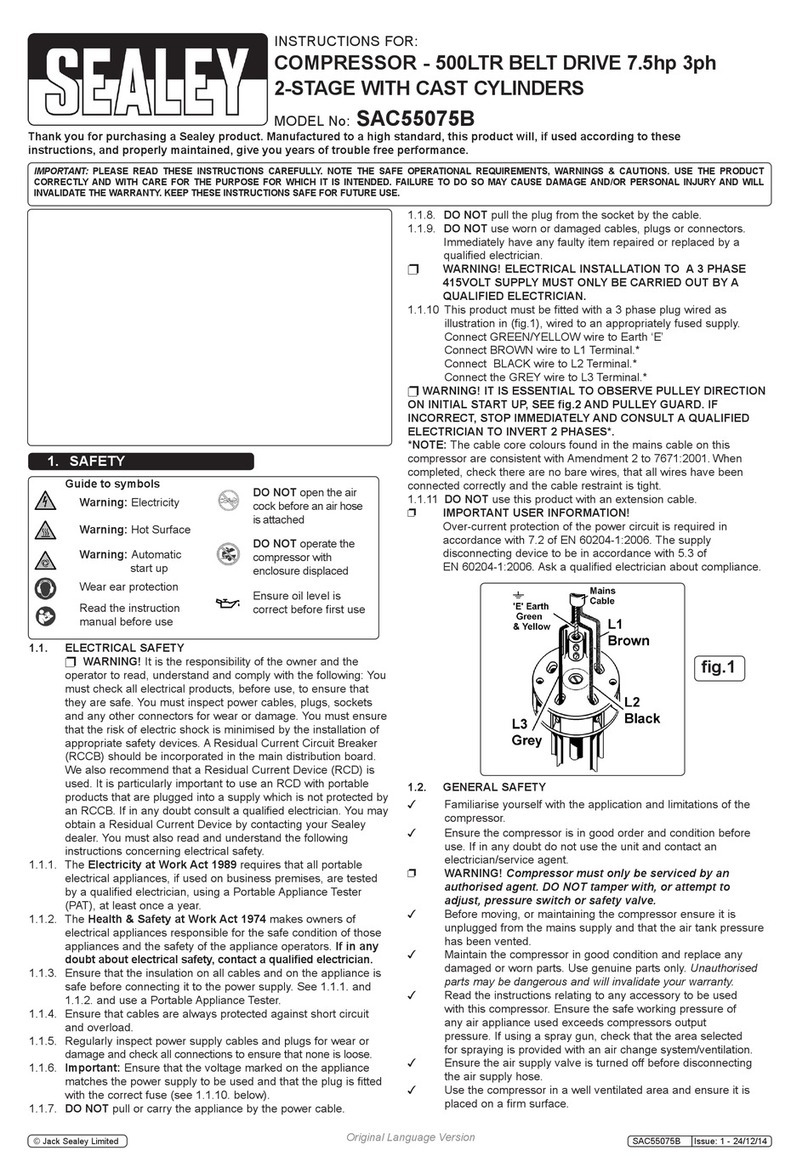

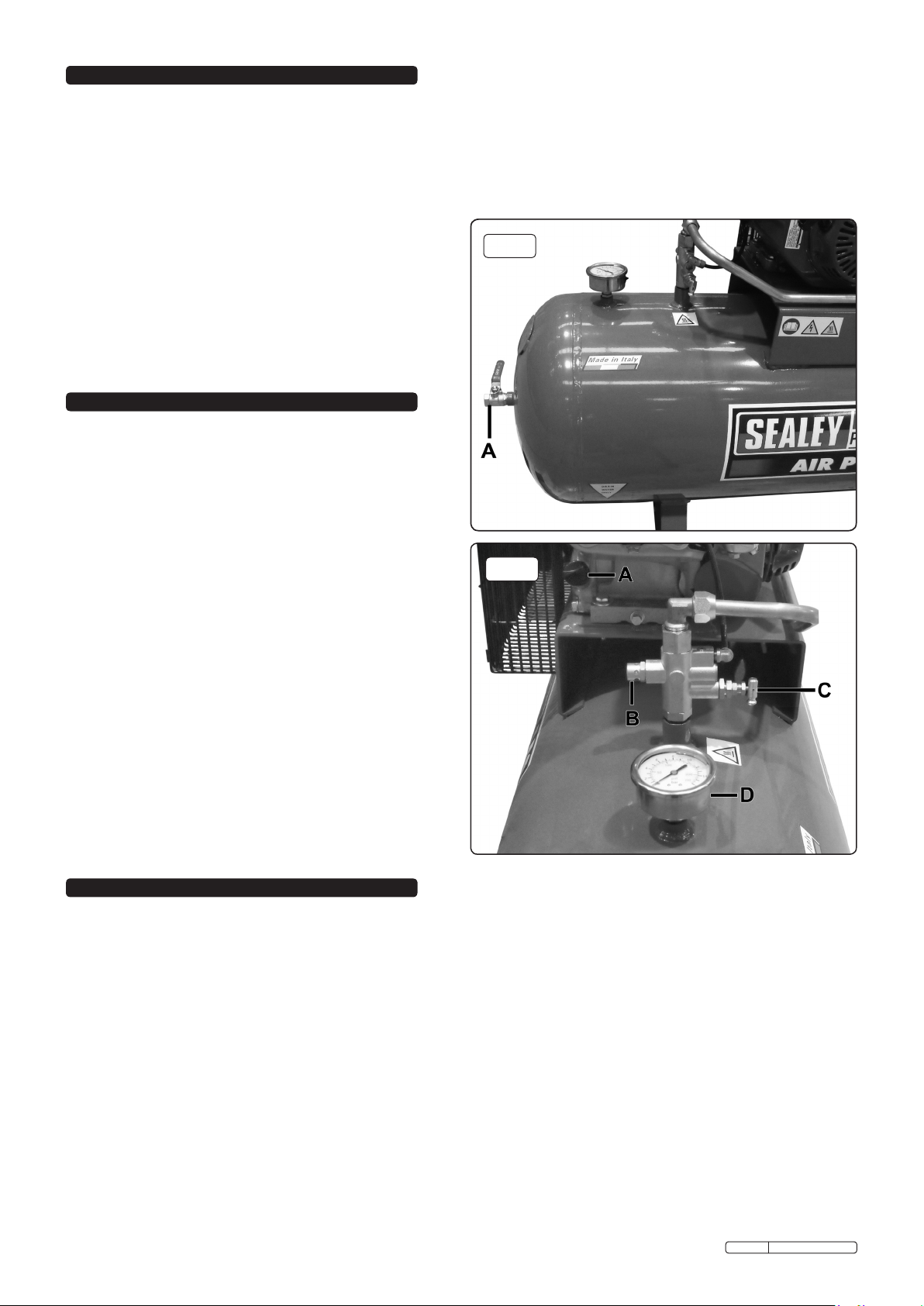

4.1.1. Check that the air outlet valve on the tank end-plate (fig.1.A)

is closed.

4.1.2. Start the compressor engine, following the procedure

detailed in the manufacturer’s handbook supplied.

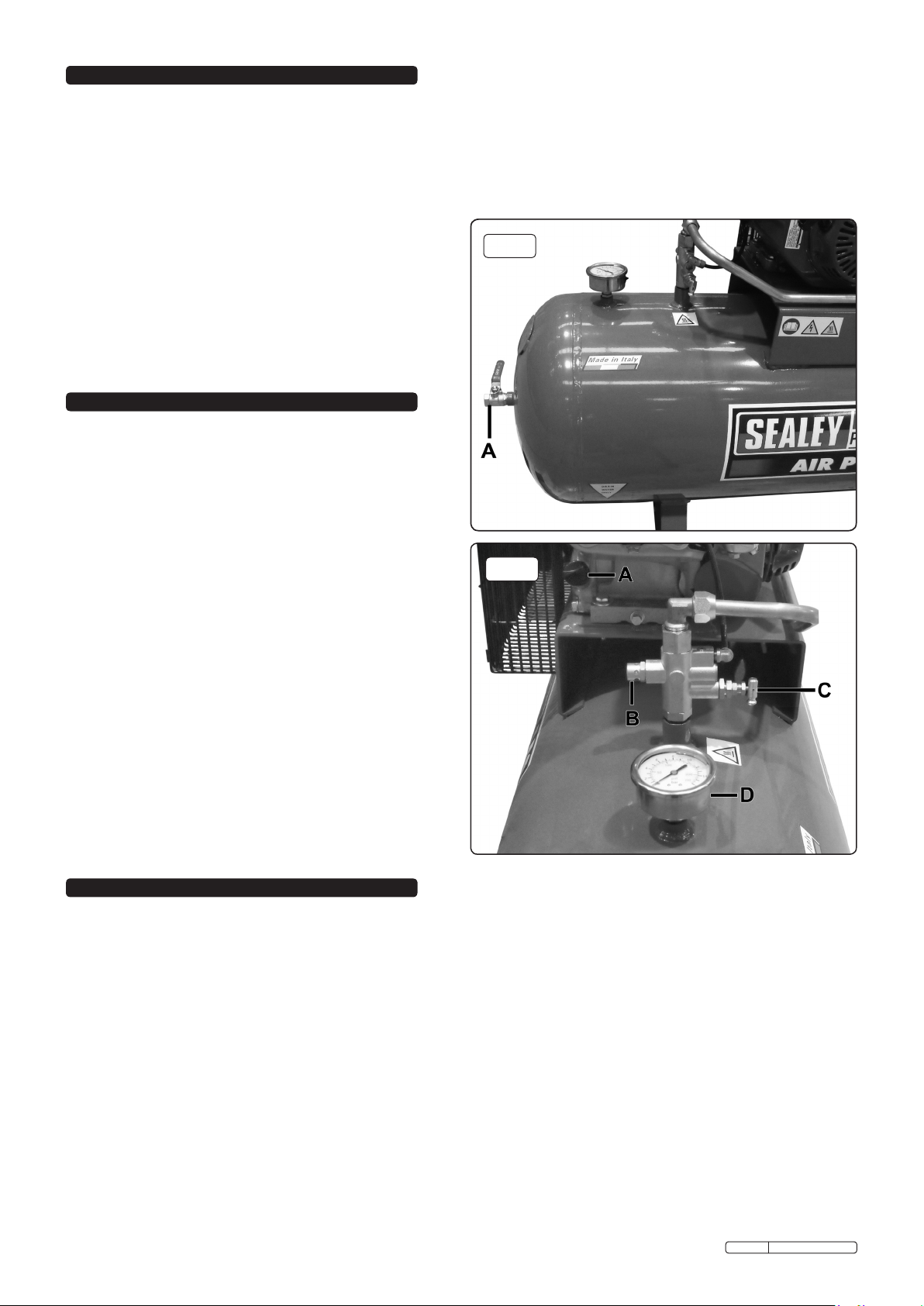

Ensure the oil is topped up. Oil filler/dipstick - fig.2A.

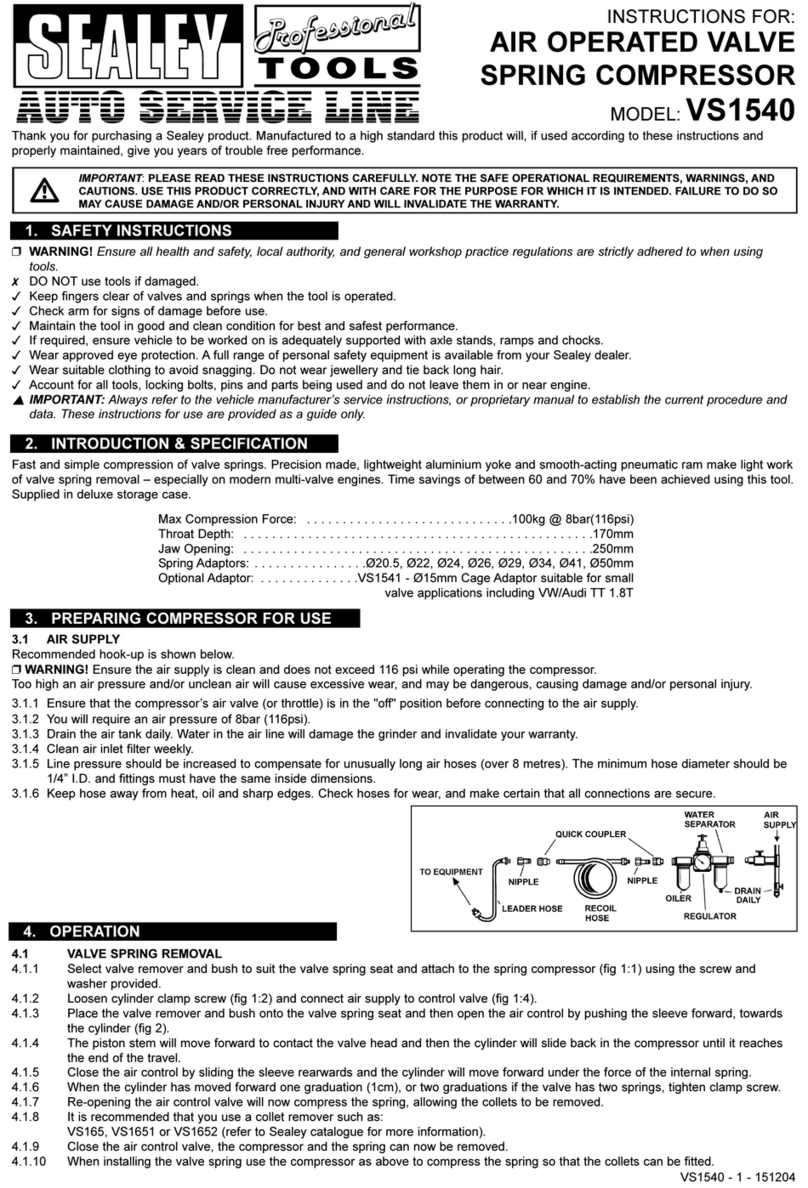

4.1.3. When the engine is running smoothly, the compressor will

operate automatically, building up the pressure in the tank,

which is shown on the pressure gauge (fig.2D), to the

maximum setting (factory set). When the maximum tank

pressure is reached, the relief valve (fig.2B) will

automatically vent the pump output. When the tank

pressure falls below the minimum threshold

(approx.2bar/29psi less than the maximum pressure), the

relief valve will automatically close, and the tank pressure will

increase back to it's maximum.

fig.1

Model No: ..........................SA1565

Engine Output: ........................6.5hp

Speed............................1500RPM

Noise Level: ........................ 97dB.A

Noise LwA Level: .....................99LwA

Air Displacement:....................20.9cfm

Maximum Free Air Delivery: ...........15.2cfm

Width x Depth x Height:... 1360 x 540 x 1110mm

Tank Capacity: ........................150ltr

Maximum Pressure: ..............145psi/10bar

Weight: .............................103kg

4.2. STOPPING.

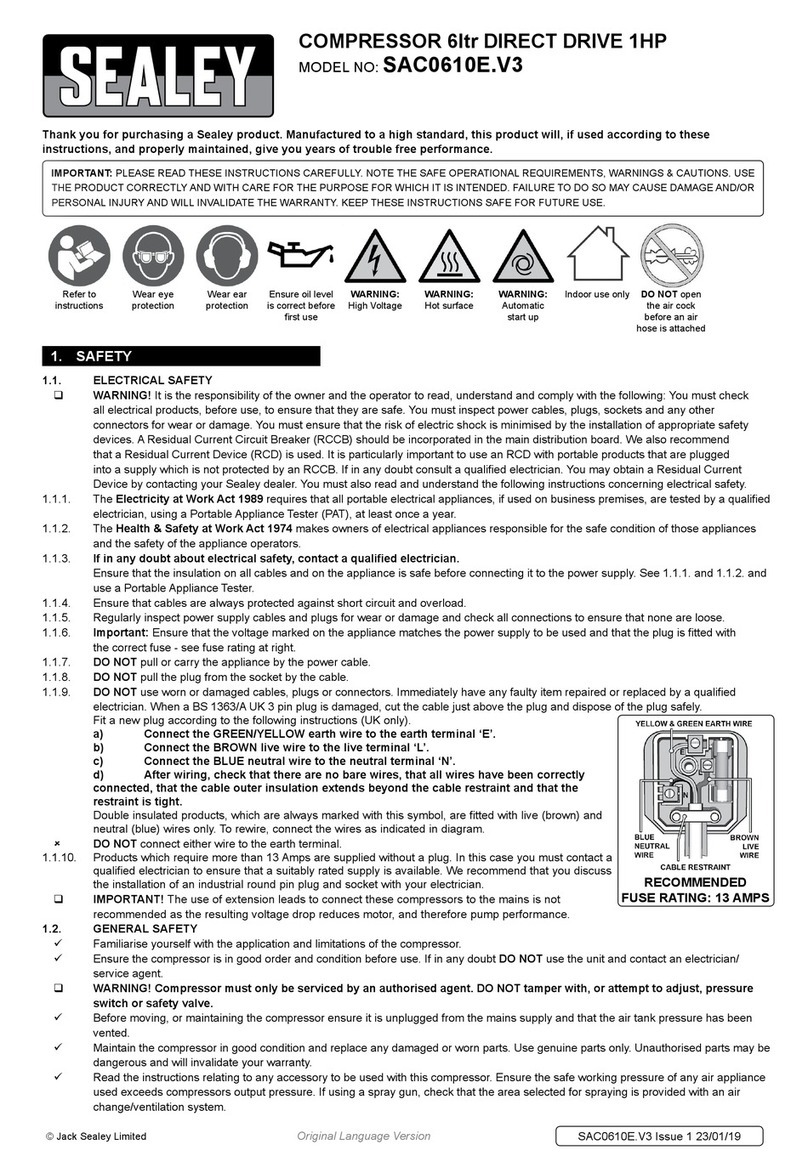

4.2.1. To stop the compressor turn the engine ignition switch (fig.3)

to Off (O). See the engine manufacturer’s handbook for the

complete engine shutdown procedure.

4.3. CONNECTING AIR POWERED EQUIPMENT.

4.3.1. After fitting the desired coupling to the outlet valve (fig.1)

connect an air hose and hook up to air system. An outlet

regulator is necessary to use air equipment direct from the

compressor.

Note: To determine the correct working pressure and air flow

requirements for any piece of equipment check the

corresponding manual. Be aware that the air flow figure

stated on tools and accessories refers to ‘Free Air Delivery’

and not the piston displacement of the compressor. When

adjusting the regulator, always adjust up to the required

pressure.

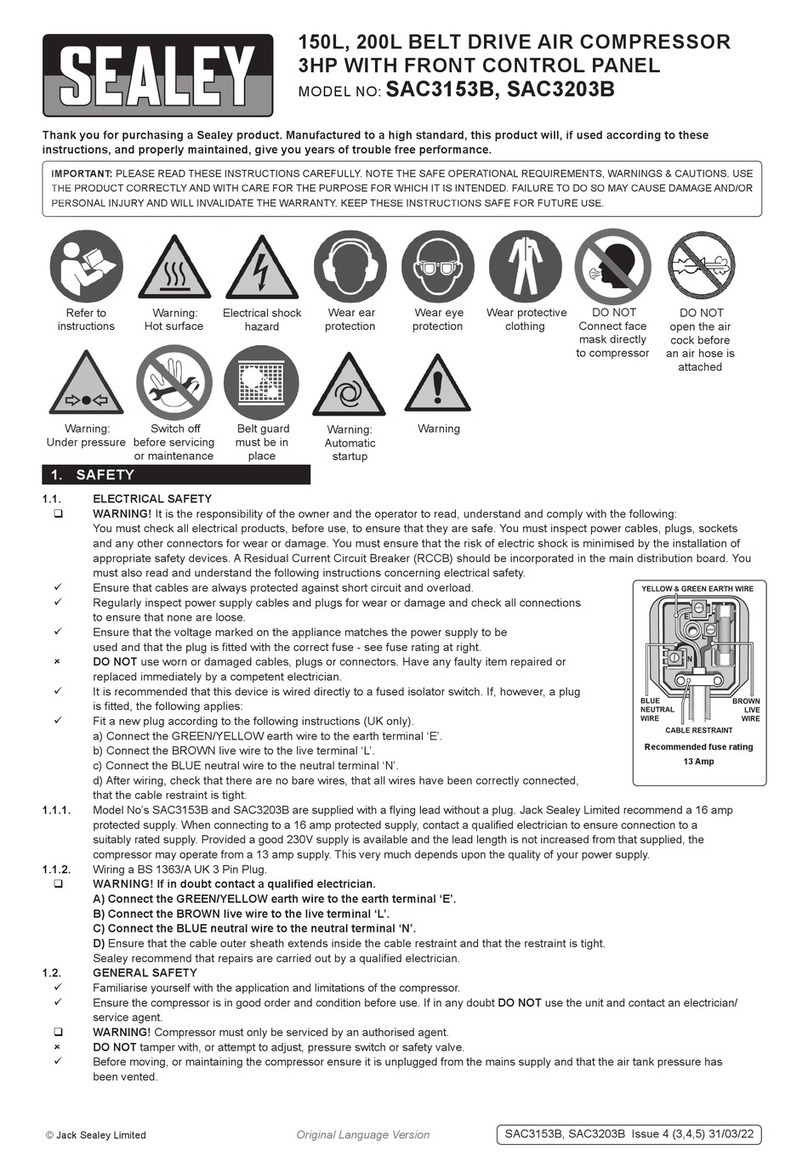

4.4. WHEN WORK IS COMPLETE.

At the end of each working day, drain any moisture from the

main tank. Place a container under the drain plug and then

carefully unscrew it (fig.4). DO NOT allow moisture to

accumulate in the tank as this will corrode the inside of the

tank and affect the pressure rating of the tank.

WARNING! Wear safety goggles and gloves when performing

this task.

fig.2

Note: a) If the relief valve does not cut in and out, but is

continuously closed whilst using an air appliance, the

capacity of the compressor may be too small for the

equipment or tool.

b) The gauge (fig.2D) indicates the pressure inside the tank,

NOT the pressure supplied to the air equipment. If the

pressure in the tank exceeds the relief valve maximum, a

safety valve (fig.5E) will open. WARNING! For this reason

DO NOT tamper with, or adjust, the relief valve or the

safety valve.

Original Language Version SA1565 Issue: 2 - 20/02/12