EN

7

EN

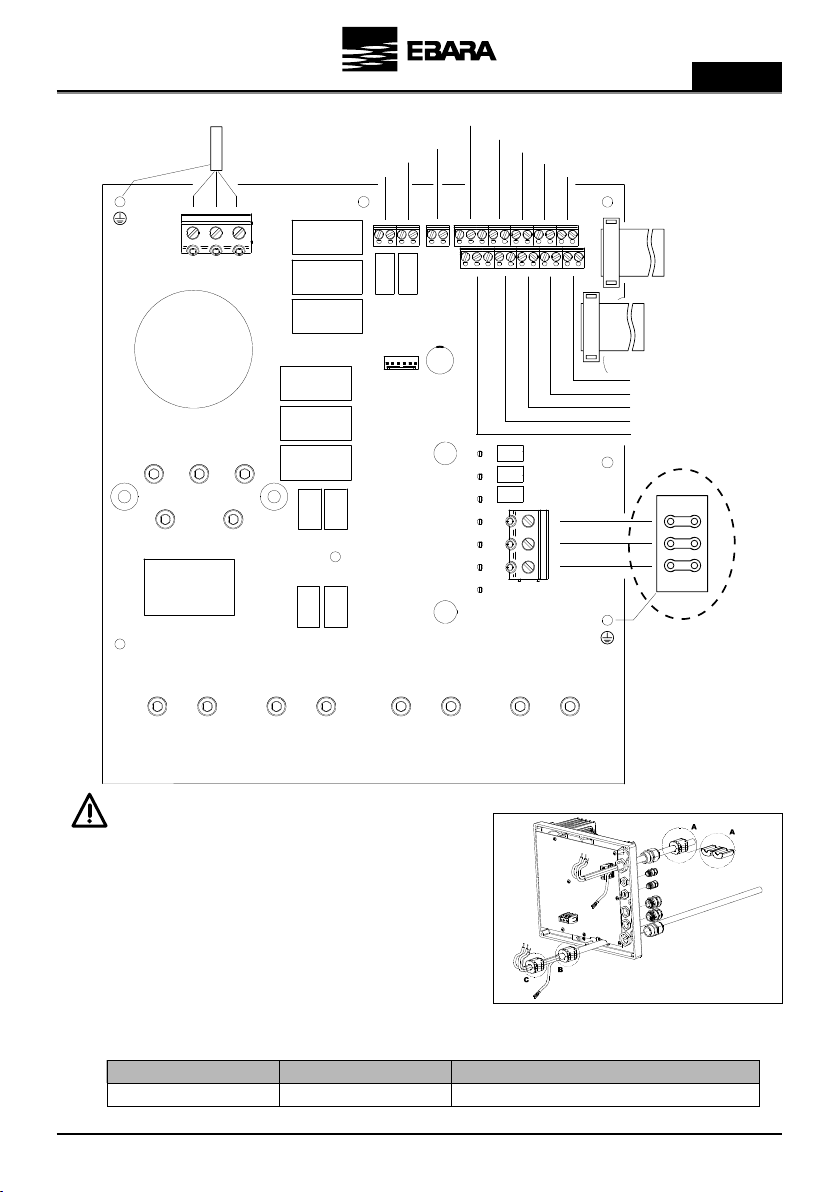

country in question. A table with the maximum recommended lengths according to the cross-section of the electrical

cable can be found below.

- Each interface cable length for communication and/or pressure transducer should be shorter than 3 meters.

- Use the appropriate cable glands to attach the cable.

- Also ensure that the grid has electrical protection; a high-sensitivity dedicated differential switch (30 mA, class A

for domestic applications, Class B for industrial applications) is particularly recommended.

The type B should be installed for all the residual current-operated protective or monitoring from an

inverter up to the supply voltage.

- In addition to the differential switch, it is advisable to install magneto thermal protection and a voltage disconnect

switch to control the power supply to each Inverter individually.

Ground cable must be connected properly. If the ground cable is not connected, there is an increased risk

of electric shock or fire.

- Use recommended circuit breakers on the supply side as a protection in case of a component failure inside the

inverter. Recommended circuit breaker size are as follows:

b) Installation of pressure units with an inverter:

- The multiple pump units must always consist of pumps that are the same and that, therefore, have the same power

and hydraulic performance. Failure to comply with this point can cause the pump system to malfunction.

- For the Inverter to work, it is essential to use a pressure transducer (4-20 mA).

- The location of the pressure transducer must always be as close as possible to the pump unit, as close as possible to

the pressure tank, and always after the non-return valve of the pump unit. It is essential to install a general cut-off

valve for the pump unit, after the physical location of the pressure transducer.

- If there is more than one pressure transducer in a multiple pump unit (more than one Inverter with a pressure

E-SPD+ MT 2200

E-SPD+ TT 4000

E-SPD+ TT 11000

51

134

64

12

49

-

19

76

38

28

81

40

35

120

61

1∼ 230 Vac

3∼ 400 Vac

3∼ 400 Vac

MT 2200

TT 4000

TT 11000

20 A

16 A

32 A

8

46

-

Section of frequency converter output (mm2)

Maximum distance (meters)

Section of frequency converter input (mm2)

Maximum distance (meters)

2,54

Voltage Supply E-SPD+ Model Circuit breaker size

1,5 41,52,5