4

EN

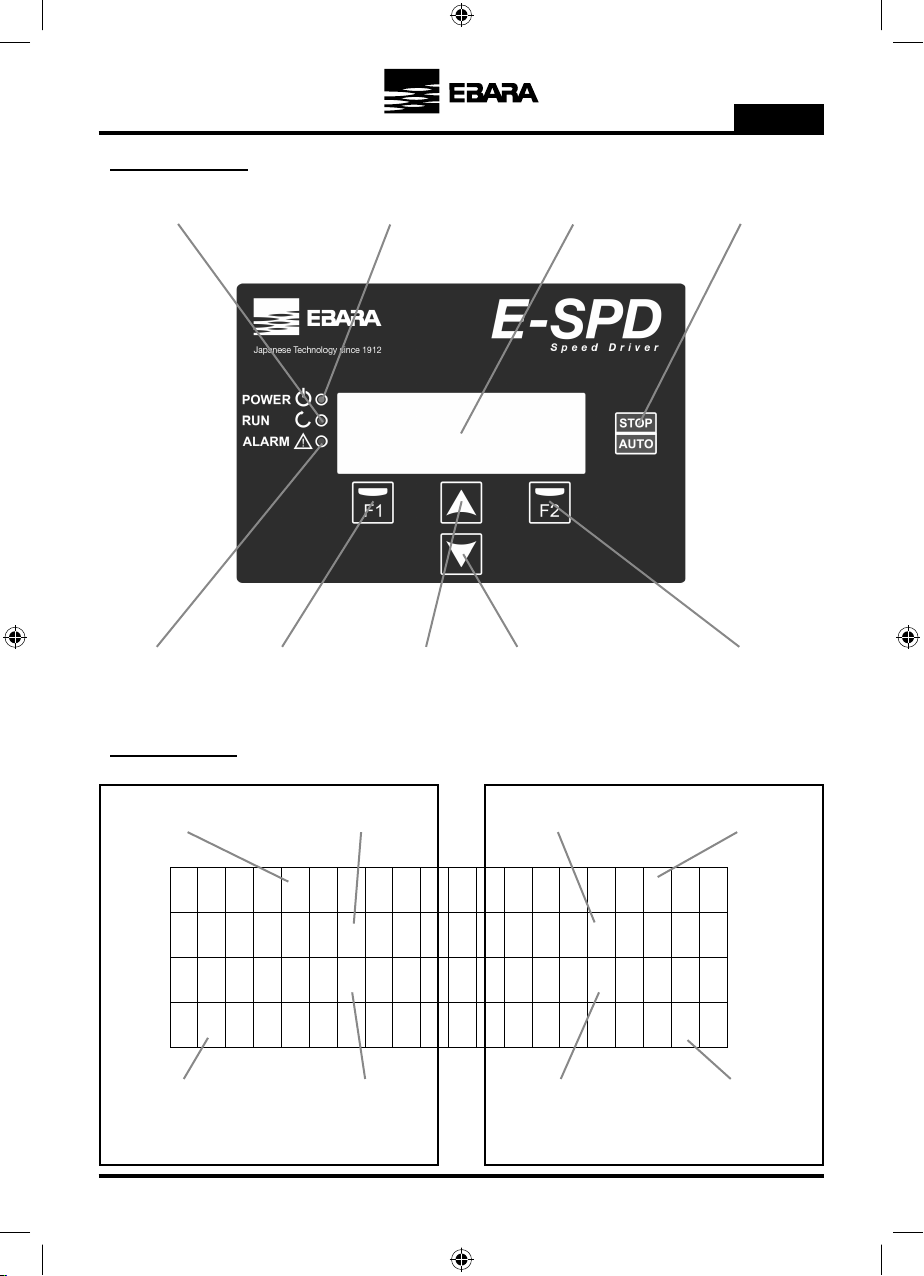

1. PRESENTATION

The following product is an electronic device for the control and protection of pump systems according to the fre-

quency of the pump’s power supply. The inverter can be connected to any pump to manage its operation and main-

tain a constant pressure. In this way, the pump or pump system is only activated when needed, avoiding unnecessary

waste of energy and prolonging its useful life.

The following symbols have been used in this instruction booklet:

Risk of harm to people or property. Electrical risk.

2. SAFETY RULES (ADD ELECTRICAL AND WARNING SYMBOLS)

Before installing and using the product:

- Carefully read the whole of this manual before using the device for the first time and keep it for future reference.

The user must strictly observe the accident prevention regulations in force in their respective country. Check at the

time of receipt of the product that there is no damage to the product and/or missing components. If so, contact the

supplier immediately.

- Check that the data indicated on the plate is what is required and appropriate for the installation, and in

particular that the nominal current of the motor is compatible with the data indicated on the specifications plate

of the frequency converter.

- The installation and maintenance must be carried out solely and exclusively by authorised personnel, responsible

for making the electrical connections in accordance with the current safety regulations.

- The frequency converter must not be used by people with reduced physical, sensory or mental capabilities,

or without the due experience or knowledge, except if a person responsible for their safety has explained the

instructions and supervised their operation of their frequency converter.

- Do not let children play with the frequency converter.

- Do not use the product in a manner other than that specified in the following instruction manual.

- The manufacturer accepts no liability for damage caused by improper use of the product and shall not be held

responsible for damage caused by maintenance or repairs carried out by unqualified staff and/or with non-original

replacement parts.

This device is intended for use in a residential environment. If this device is used in an industrial envi-

ronment, it may not opérate.

Use of this device in a residential environment may cause electromagnetic interference. In this case, the

user may be required to take appropiate measures.

Inverter may product the very high surge voltaje on the motor. When the motor is applied this tight

surge voltaje repeatly, the motor will be caused deterioration of insulation by accumulating the stress of

surge. Please make sure the motor specification that can be driven by inverter.

- This inverter does not incorpórate electric gradual termal protection functions.

Residual Risks:

- Before removing the cover of the frequency converter for any maintenance work, ensure you disconnect the mains

voltage and wait 5 minutes for the electronic circuit board to discharge any residual voltage inside.

- Never disconnect the frequency converter while the motor is rotating. This action can cause irreparable damage

to the frequency converter and affect the other electronic systems connected to the same electric grid.