Error: No Tachometer

If the Tachometer should fail your machine will shut down for safety

reasons. This can also be caused by a stalled motor or unplugged

Tachometer cable. The No Tachometer Error message will be flashed

across the top line. It is possible to run the machine without a

Tachometer although the accuracy of the speed may vary. To do this

follow the prompt and select yes to run in open loop mode.

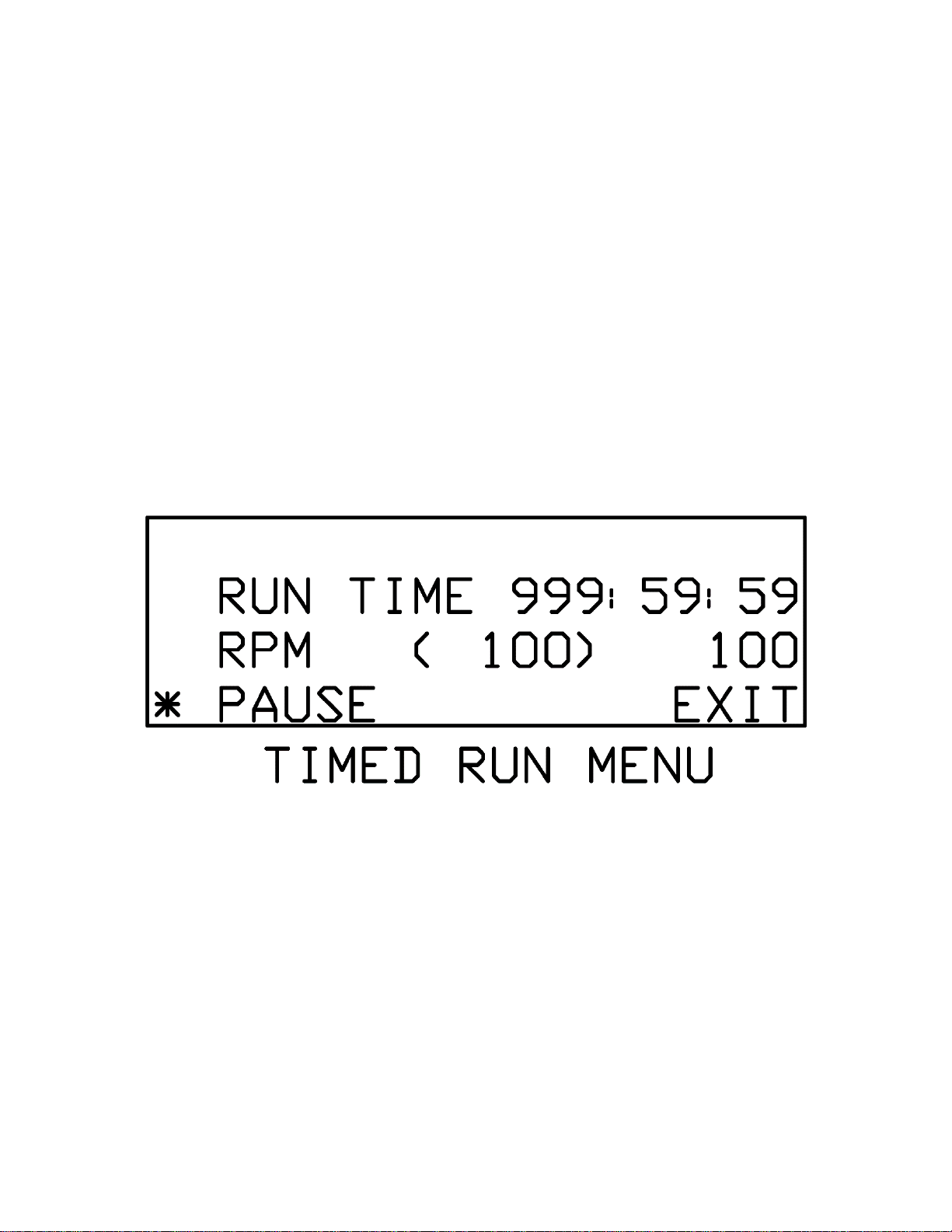

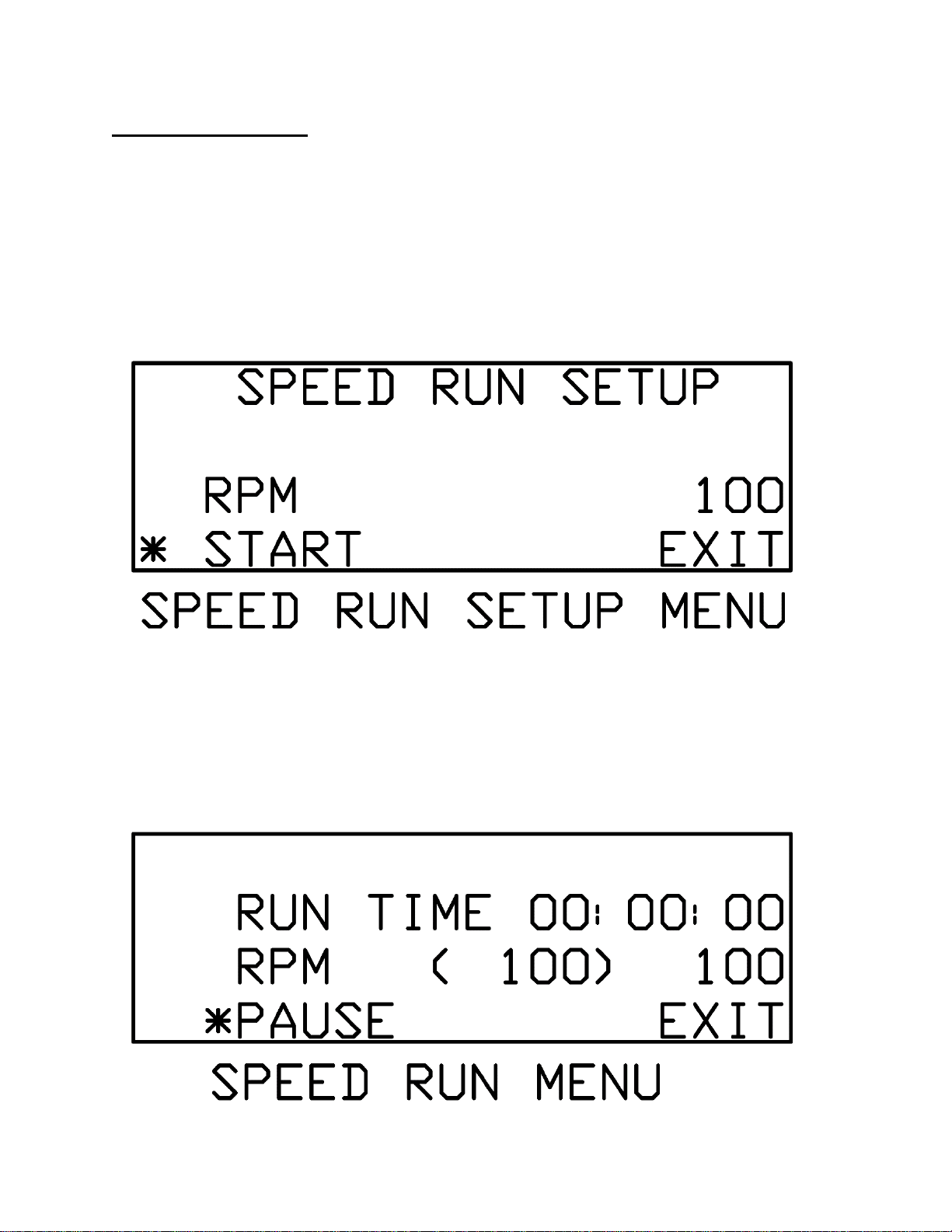

Note: All run menus will have two speeds listed. The leftmost speed

will be displayed inside parenthesis. This is the target speed controlled

by the user. The shaker will attempt to match this speed and should do

so within ten seconds after making an adjustment. The rightmost speed

is the tachometer reading, which shows the user what the shaker is

actually running at. The tachometer reading will not necessarily match

the target speed at all times, but is guaranteed to be within +/- 1% RPM.

Note: Reciprocating shakers will display OSC (oscillations) instead of

RPM (revolutions per minute).

Note: Use slowest speed necessary to produce required shaking

action.

If you have any doubts or inquiries concerning operation contact your

supplier or Eberbach Corporation technical service.

LOADING: