USE AND CARE FOR CATALOG NUMBER:

EL680.Q Digital Variable Speed Reciprocating Shaker -

115V - 50/60 Hz

CAUTION!

UNPLUG THE POWER CORD BEFORE DOING ANY

MAINTENANCE ON THIS MACHINE.

FAILURE TO DO SO MAY CAUSE INJURY

!!THE USER OF THIS DEVICE IS RESPONSIBLE FOR OBTAINING THE

PROPER PERSONAL PROTECTIVE EQUIPMENT DEPENDING ON THE

MATERIAL BEING PROCESSED!!

IF THE EQUIPMENT IS USED IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER, THE PROTECTION PROVIDED BY THE EQUIPMENT

MAY BE IMPAIRED.

SERVICE ON THE UNIT SHOULD BE PERFORMED BY QUALIFIED /

TRAINED PERSONELL ONLY.

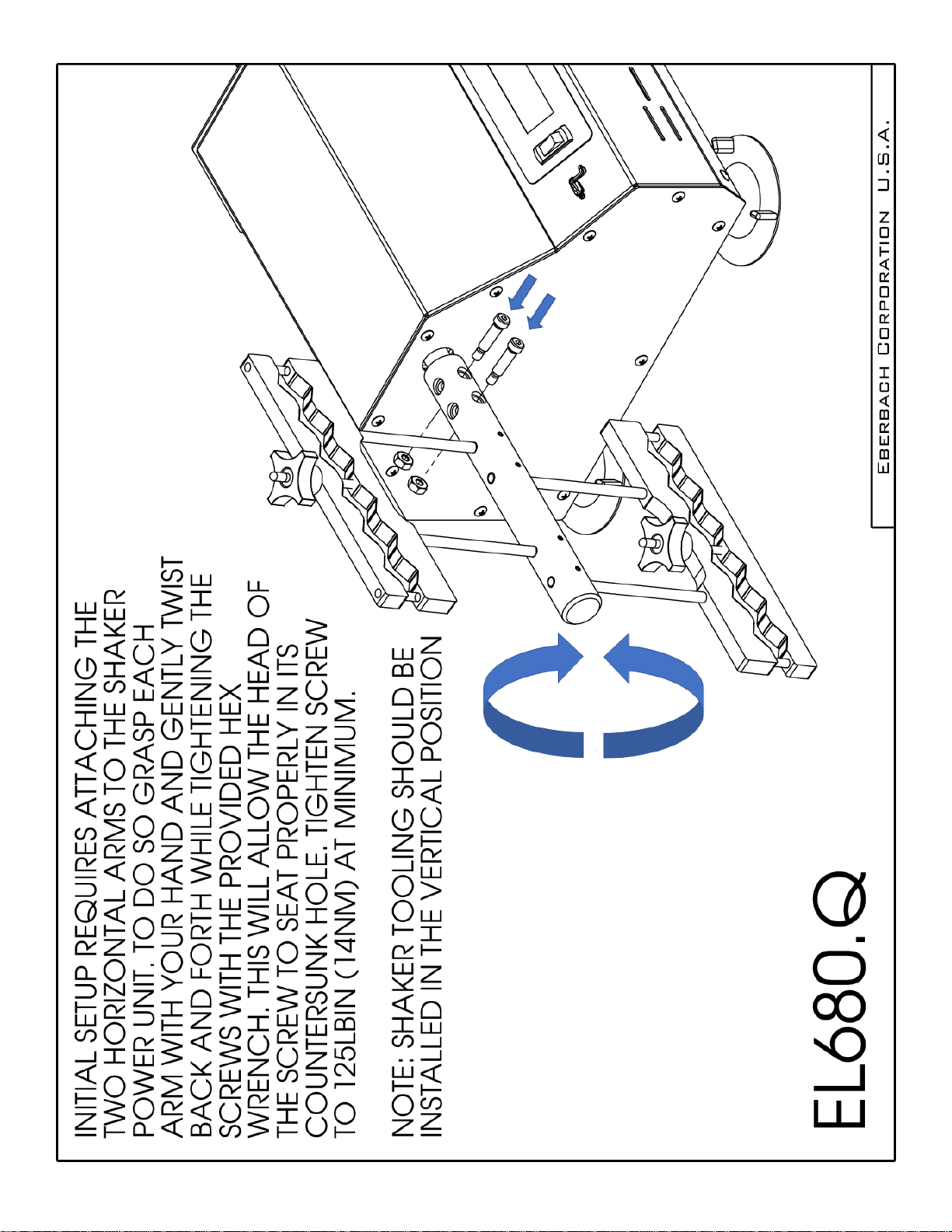

INITIAL PREPARATION:

Place shaker on a level table or bench.

NOTE: This unit should be operated by trained personnel.

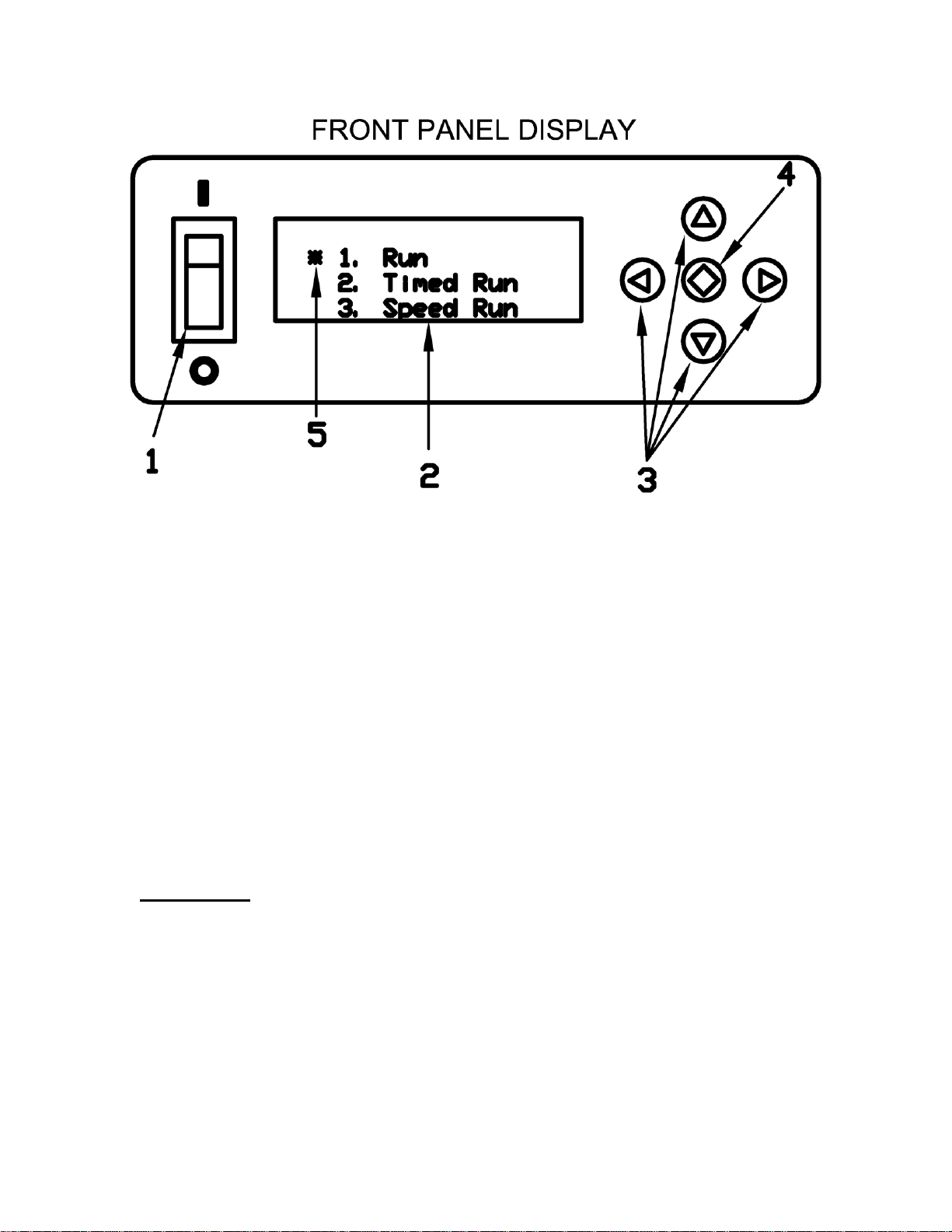

With the power switch on the front panel in the off position ( 0 ), plug the line cord

into a 115 Volt, 50/60 Hz source. Turn shaker on by moving switch to the On

position ( I ).

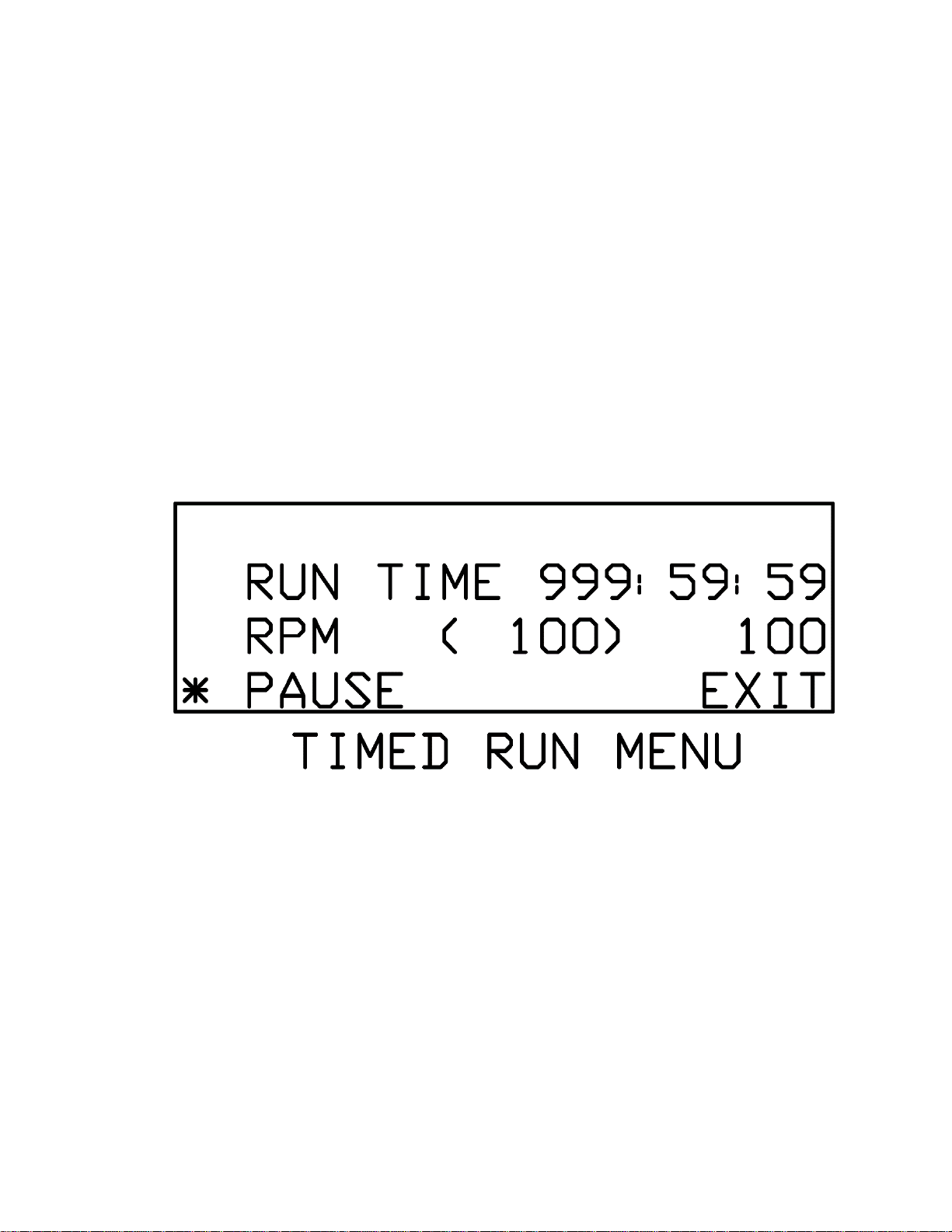

NOTE: Speed adjustments should be made only when the shaker is operating.

Use slowest speed necessary to produce required shaking action.

NOTE: This unit emits less that 70.0 dB(A).

CAUTION: Extra effort may be needed when lifting machine due to suction

adhesion with table and rubber feet.

IN AN EMERGENCY TURN OFF UNIT OR UNPLUG AC CORD