USE AND CARE FOR CATALOG NUMBER:

- E6003.00 Shaker Power Unit

Variable Speed 60-260 rpm with Tachometer and Timer

115-230V 50/60Hz

GENERAL INFORMATION

oHandle this unit with care. Unpack and check that the contents coincide

with the packing-list. If any part is damaged or missing, please advise

the distributor immediately.

oDo not install or use this equipment without first reading this manual.

oThis manual should always be attached to the equipment and made

available to all users.

oNEVER TOUCH THE RECIPRICATING PORTION OF THE SHAKER

WHILE THE UNIT IS RUNNING!!

oIf you have any doubts or inquiries, please contact your supplier or

Eberbach Corporation technical service.

OPERATION

The Eberbach bench top reciprocating shaker (catalog E6003.00) features:

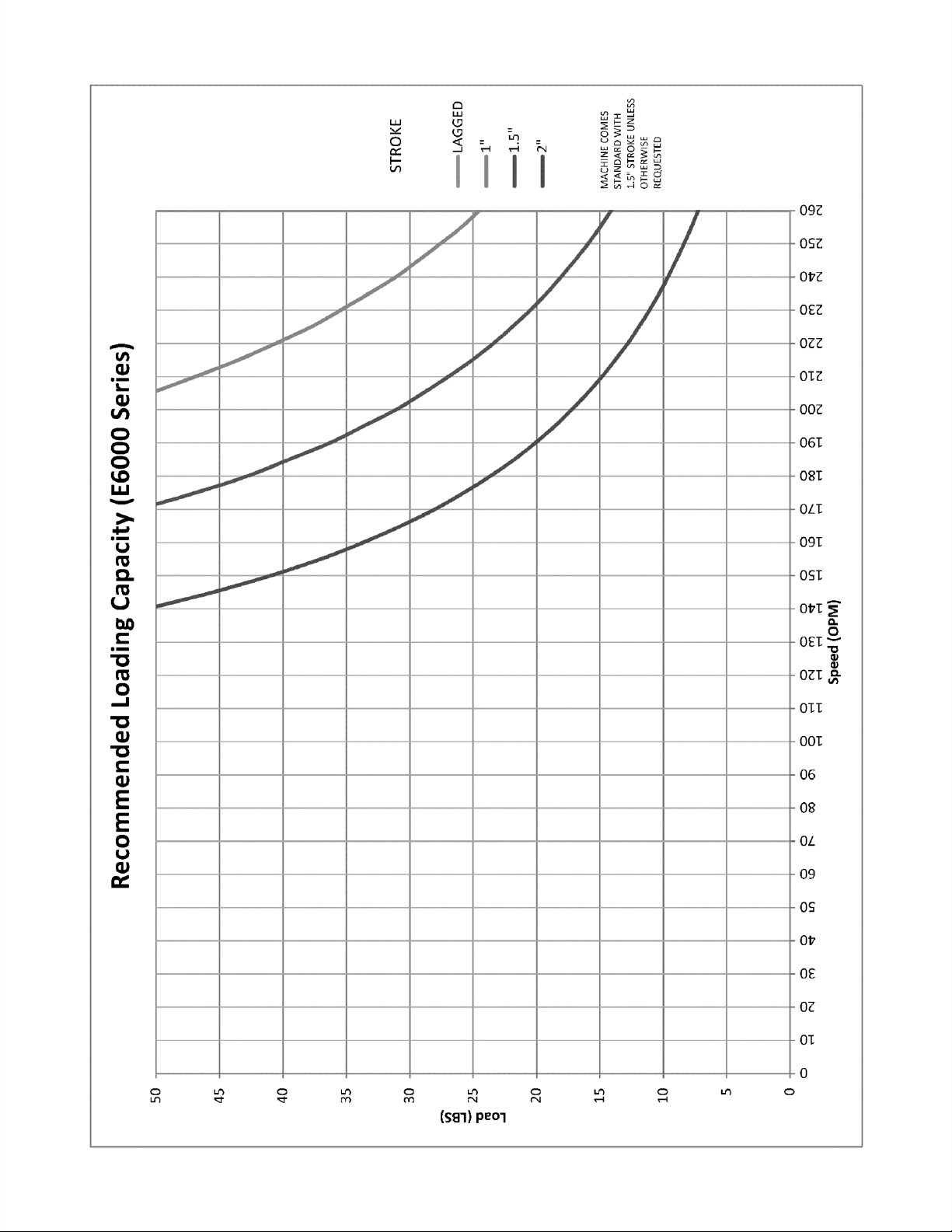

oA continuously variable speed range, adjustable between 60 and 260

osc/min with fixed stroke length set to 1.5” (38mm).

oA digital tachometer and programmable digital timer for simple and

accurate use.

oA maximum shaking weight of 50lbs.

See the chart on the following page for the recommended loading capacity at

various speeds.