2/28 Item no.: 601.2055 · ENU · Change V1.1 · Release 2022-10-11

Drive conceptsDrive concepts

SIMATIC MICRO-DRIVESIMATIC MICRO-DRIVE

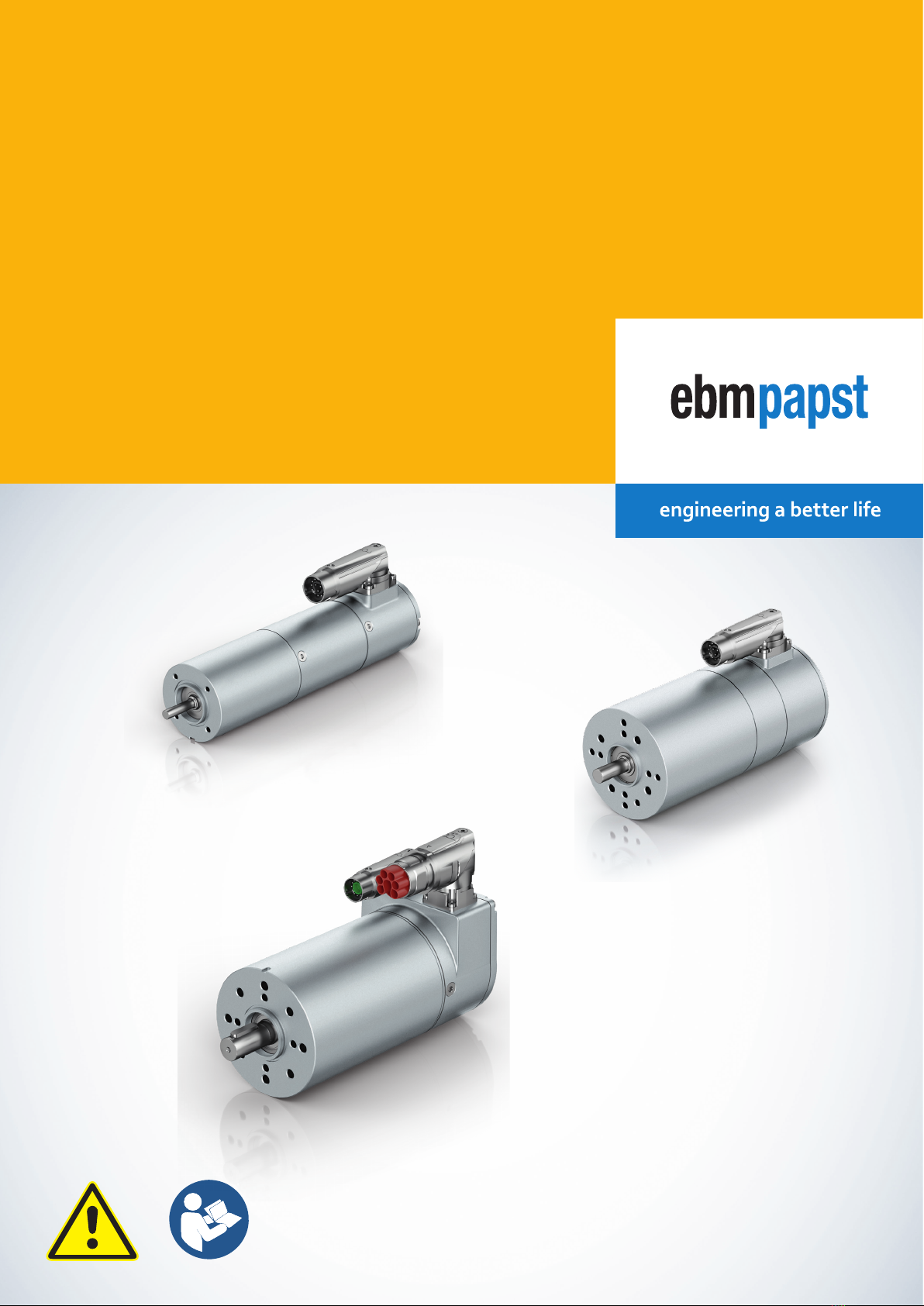

Content

1 Introduction ............................................................................................................... 5

1.1 Foreword........................................................................................................................................................5

1.2 Target group ..................................................................................................................................................5

1.3 Written styles in this document ...................................................................................................................5

1.4 Warning notices and notices ........................................................................................................................5

2 Safety information..................................................................................................... 6

2.1 General safety information ...........................................................................................................................6

2.2 Documentation ..............................................................................................................................................6

2.3 Mechanical safety..........................................................................................................................................6

2.4 Legal requirements .......................................................................................................................................6

...............................................................................................................................7

2.6 Safety of persons ..........................................................................................................................................7

2.7 Electric/electromagnetic safety....................................................................................................................7

2.8 Intended use ..................................................................................................................................................8

2.9 Improper use..................................................................................................................................................8

...................................................................................................................9

2.11 Transport and storage...................................................................................................................................9

2.12 Behavior in the event of malfunctions and irregularities ...........................................................................9

3 Description ................................................................................................................ 10

3.1 Description of the drives for SIMATIC MICRO-DRIVE.................................................................................10

............................................................................................................................10

3.2.1 Nameplate ................................................................................................................................................. 10

.......................................................................................................................... 11

3.2.3 Scope of delivery....................................................................................................................................... 11

3.3 Device view ....................................................................................................................................................12

4 Technical data............................................................................................................ 13

4.1 ECI-42.XX-K1..................................................................................................................................................13

4.2 ECI-63.XX-K1..................................................................................................................................................14

4.3 ECI-80.XX-K1..................................................................................................................................................15

4.4 Encoder system.............................................................................................................................................16

.............................................................................................................................................16

4.6 Dimensional drawings ..................................................................................................................................17

..................................................................................................................... 17

........................................................................................................ 17