ECCO STOVE E580 User manual

1|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

ECCO STOVE MODEL E580 Installation instructions

Manufactured in England by:

LANDY VENT UK LTD, FOSTER HOUSE, 2 REDDITCH ROAD, STUDLEY, B80 7AX

TESTED TO: EN13240 DATE 04/03/14

CAUTION: HOT WHILE IN OPERATION. DO NOT TOUCH, KEEP CHILDREN, CLOTHING AND FURNITURE

AWAY. CONTACT MAY CAUSE SKIN BURNS - SEE NAME PLATE AND INSTRUCTIONS

THIS STOVE MUST BE INSTALLED IN CONJUNCTION WITH THE REQUIREMENTS OF BSEN 15287-

1:2007 –DESIGN INSTALLATION AND COMMISSIONING OF CHIMNEYS.

WARNING NOTE:

Properly installed, operated and maintained this stove will not emit fumes into the dwelling.

Occasional fumes from de-ashing and re-fuelling may occur. However, persistent fume emission is

potentially dangerous and must not be tolerated. If fume emission does persist, then the following

immediate action should be taken:-

a) Open doors and windows to ventilate the room and then leave the premises.

b) Let the fire go out.

c) Check for flue or chimney blockage and clean if required.

d) Do not attempt to relight the fire until the cause of the fume emission has been identified

and corrected. If necessary seek expert advice.

The most common cause of fumes emission is flueway or chimney blockage. For your own safety

these must be kept clean at all times.

A CO detector must be fitted in the same room as this appliance to conform to UK requirements of

installation.

“The Clean Air Act 1993 and Smoke Control Areas”Under the Clean Air Act local authorities may declare the

whole or part of the district of the authority to be a smoke control area. It is an offence to emit smoke from a

chimney of a building, from a furnace or from any fixed boiler if located in a designated smoke control area.

It is also an offence to acquire an "unauthorised fuel" for use within a smoke control area unless it is used in

an "exempt" appliance ("exempted" from the controls which generally apply in the smoke control area). The

Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless

fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests

2|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

with Ministers in the devolved administrations for those countries. Separate legislation, the Clean Air

(Northern Ireland) Order 1981, applies in Northern Ireland. Therefore it is a requirement that fuels burnt or

obtained for use in smoke control areas have been "authorised" in Regulations and that appliances used to

burn solid fuel in those areas (other than "authorised" fuels) have been exempted by an Order made and

signed by the Secretary of State or Minister in the devolved administrations. Further information on the

requirements of the Clean Air Act can be found here : http://smokecontrol.defra.gov.uk/Your local authority

is responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of Clean Air Act requirements “The Ecco 580 appliance

has been recommended as suitable for use in smoke control areas when burning” seasoned wood logs only”.

1. INTRODUCTION

2. PURPOSE

3. MATERIALS

4. FLUE OUTLET

5. GLASS

6. CLEAR GLASS OPERATION

7. AERATED BACK PANELS

8. ASH GRATE

9. ROPE SEALS

10. FINISHES

11. AIR CONTROLS

a) TERTIARY AIR

b) PRIMARY AIR

c) SECONDARY AIR

d) OUTSIDE AIR

e) RELIGHTING (WITH OUTSIDE AIR)

f) CLOSING DOWN

g) FLUE DAMPER

12. FIRING THE STOVE

1) COMISSIONING AND HANDOVER

a) INITIAL FIRING

b) SUBSEQUENT FIRING

c) REFUELING AFTER STARTING

d) OVER FIRING WARNING

e) UNDER FIRING WARNING

13. CONTINUOUS BURNING

a) INITIAL FIRING

b) SUBSEQUENT FIRING

c) REFUELING AFTER STARTING

d) REFUELING ON A LOW FIRE BED

3|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

e) OPERATION WITH DOOR OPEN

14. ASH REMOVAL

15. FUELS

a) WOOD

16. REFUELING

17. TAR DEPOSITS

18. FLUE CONNECTION/LININGS

19. CLEANING AND MAINTENANCE

20. FINISHES

21. ASSEMBLY

22. HEARTH REQUIREMENTS

23. TECHNICAL

24. GENERAL AND HEALTH AND SAFETY

25. PARTS LIST

a) PARTS DRAWING

26. WARRANTY

27. WARRANTY REGISTRATION

4|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

IMPORTANT

FIRST FIRING MUST BE LOW –kindling only with 50mm or so diameter logs for 2 hours to dry the

refractory Silicon Carbide slowly. FAILURE TO DO SO WILL CRACK THE APPLIANCE.

1. INTRODUCTION

We would like to thank you for choosing our product and wish you every success and

happiness with your Ecco Woodburning Stove E580.

Your stove is tested to EN13240 for Europe and the UK, when burning wood logs only.

Installation of this appliance must be carried out with regard to the requirements of

BS8303-2:1994

Please read these instructions carefully: The installation and use of your Ecco Stove E580 is

subject to in country regulations where it is to be used eg. Building Regulations in the UK.

The installer must be aware that all local regulations, including those referring to National

and European standards must be complied with when installing this appliance.

The efficiency and suitability of the chimney to be used must be checked before installation

–not all chimneys are suitable.

The Ecco Stove E580 is tested for use with wood logs –you must check with your local area

authority to ensure it is permissible to burn wood logs in the area where the stove is to be

installed.

Your installer will be able to advise you on the suitability of this stove to be installed for the

space you wish to heat.

You may need fresh air from outside introducing in to the room despite an outside air kit

being available. This combustion air must be introduced into the room within which the

stove will stand.

Some, but not all, of the technical information required to install the Ecco Stove E580 is

contained within this handbook. Its technical details are to be found at the rear.

2. PURPOSE

Wood burning stoves are intended as a secondary form of heating to support the home

heating system. Over use or overheating of the appliance may damage it; therefore please

use it within the parameters of this handbook.

5|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

3. MATERIALS

The Ecco Stove E580 is primarily constructed from Silicon Carbide, a material that has a high

affinity to absorb heat but radiate it slowly and gently, therefore permeating greater

distances within the home than conventional materials of stove construction.

Radiant heat is omitted from the outer surfaces and initial heat from the glass door panel.

4. FLUE OUTLET (150 DIAMETER)

Your Ecco Stove E580 is delivered with a top flue outlet only. If the installation demands, a

45° bend may be taken from the top of the stove and back into the chimneys flue.

The pipe directly off the stoves top must include a soot door/access plate within 200mm of

the stoves top for access for flue ways cleaning which are located beneath the stoves top

and forward of the flue outlet. The Ecco Stove E580 must have its own, dedicated flue. It

must not be shared with another appliance.

Do not connect to a flue serving another appliance.

Access must be provided for cleaning the chimney’s flue and stove connector pipe as

described above.

5. GLASS

The door glass fitted to your Ecco Stove E580 is 4mm ceramic. It is deemed a consumable

item and is not covered by the warranty.

When replacing the glass ensure that the screws retaining the glass clips are tightened to

hand tight only as over tightening will crack the glass.

Breakage of the door glass is usually as a result of closing the door onto an over filled fire

box or onto a larger log than the fire box can accommodate.

6. CLEAR GLASS OPERATION

Blackening of the door glass results from poor quality (unseasoned) wood or the stove being

burned at less than 160°C on its top plate.

A chimney draught of less than 0.06 inches water gauge will impair the stoves performance

and hence it’s ability to keep the door glass clean. Your installer must check this for you

before installation.

6|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

Do not load logs with their end grain pointing towards the door as this will result in

blackening of the door glass.

Always arrange logs across the fire box. We cannot guarantee the glass will stay clear

however, high temperature burning will allow the secondary/tertiary air inlets to

substantially clear any blackening of the glass. White or grey fly ash deposits should be

wiped off before restarting the stove when the glass is cold using a damp cloth and ash from

the stove’s grate, as a cleaner.

7. AERATED BACK PLATES (Panels)

The back panels (pre drilled panels at the rear of the stove) are consumables and will

deteriorate in use. The panels are not covered by the manufacturer’s warranty. Damage to

the back panels can be caused by over firing but more typically by logs being smashed

against them when refuelling the stove.

Load the stove with care.

8. ASH GRATE

The cast iron grate within your Ecco Stove E580 is highly durable but will be damaged if ash

is allowed to build up in the grate bars. Ash build up will also impair the stoves primary

combustion as the air flow will be choked.

Riddle the grate by hand upon relighting, retaining only charcoal for re starting the fire.

For removal, the grate can be lifted out through the door when opened.

The raised section of the grate is the top back with its purpose being to hold the back panels

(see 7) in place.

7|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

9. ROPE SEALS

Rope seals will deteriorate. When worn or flattened such that they do not make a

satisfactory seal, replace the rope seal with 8mm ceramic rope but ensure the indent within

the rope groove is well cleaned/scrapped and degreased before fitting new seals.

Compressive seals between the Silicon Carbide sections do not need replacement unless the

stove is stripped and moved, then 8mm rope and 20mm ladder back self- adhesive tape

must be used.

Door ropes should be replaced with 8mm rope and ash pit seal should be replaced with

10mm flat tape adhered with rope adhesive (when showing signs of wear or after 2 years,

whichever comes first).

Rope seals are not covered by the manufacturer’s warranty.

10. FINISHES

The Ecco Stove E580 is produced from a self coloured material and as such, variations in

colour and texture of the material will be evident, but adding to the uniqueness of the

product, unless ordered as pre factory painted.

Initially and for the following 3 to 5 firings your stove will produce what appears to be toxic

fumes and is often mistaken for smoke leaking out of the appliance.

Typically this smoke has a “factory” type smell and is generally not wood smoke, simply the

paint curing on the stoves outer surfaces.

Please ensure the room is well ventilated in this eventuality. Do not add more logs to the

stove; let such fumes dissipate.

WARNING –Never spray aerosols in the vicinity of the stove when the stove is under fire.

8|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

11. AIR CONTROLS

Your Ecco Stove E580 has three systems for air inlets for combustion.

a) TERTIARY AIR

The aerated back panels provide Tertiary air from an air inlet at the back of the stove.

This is set fully open and non-adjustable.

b) PRIMARY AIR

Open the ash pit drawer 10mm or so to fire the stove up to its optimum 160°C to 180°C

operating temperature on the top plate.

Only when the stove has reached its minimum 160°C should the primary air ash pit

drawer be closed. At this stage the pre-set secondary and tertiary openings will

automatically take over.

b.1) PRIMARY AIR WITHOUT OUTSIDE AIR OPTION

Primary air is provided for initial combustion and will remain fully open whilst the stove

reaches its minimum optimum operating temperature of 150°C on the top plate.

c) SECONDARY AIR

Secondary air is automatically fed into the fire box as in Primary and Tertiary air with no

other control available.

This secondary air provides an air wash of very hot oxygen to burn down the inside of

the Ecco Stove’s glass door to provide clean combustion in conjunction with the Tertiary

Air and clear the majority of the blackening on the door glass.

It is important to note that poor flue draft will impair the stoves performance (less than

0.04 inches water gauge). Equally important excessive flue draft (over 0.06inches water

gauge) will cool the stove too quickly.

d) OUTSIDE AIR

Outside air is an extra option. When fitted the Ecco Stove E580 draws its combustion air

predominately from outside via the flexible 1 metre long air tube provided. Outside air

reduces drafts into the room in which the appliance stands but doesn’t obviate the need

for separate and fresh air into the room (to satisfy UK requirements)

This air is pre-heated before being delivered into the same points of combustion as with

the standard stove operation

1. Primary air to beneath the grate bed

2. Secondary air down the face of the glass

3. Tertiary air through the same pre drilled back boards.

The combustion characteristics have not changed.

9|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

e) RE LIGHTING (WITH OUTSIDE AIR)

Open the ash pit drawer 3mm or so to begin combustion and only close when the stove

has reached its optimum 160-180˚C top surface temperature. No other adjustments

can be made. Close the drawer at optimum temperature for automatic operation to

continue.

f) CLOSING DOWN

Your Ecco 580 will continue in combustion at all times. No facility to shut it down exists.

Close the flue damper if fitted (only after combustion is completed).

g) FLUE DAMPER

To retain maximum heat within the appliance when heat retention is required and only

AFTER Primary combustion, close the flue damper, if fitted. ALWAYS open the damper

30 seconds before opening the stoves door or ash pit drawer.

Dampers left open

Operation with the air controls or appliance dampers open can cause excess smoke. The

appliance must not be operated with air controls, appliance dampers or door left open

except as directed in the instructions.

12. FIRING THE STOVE

1. Commissioning

Ensure all parts are fitted in accordance with these installation instructions.

Ensure that any wet items such as fire cements or adhesives for rope seals are allowed

to dry before lighting the stove.

When the stove is first lit, check all seals for soundness and check the flue is functioning

correctly and all products of combustion are venting safely to atmosphere via the

chimneys terminal.

Ensure the homeowner is given the operating instructions and a brief run through using

the instructions to demonstrate operation is made to familiarise the new user with the

procedures as set out in the operating instructions.

Clearly state fuels suitable for use on this stove (wood logs).

IMPORTANT advise the new user that should smoke or fumes be emitted from the stove

close the ash pit control on the stove; windows and doors should be opened

immediately to ventilate the room; and the room evacuated until specialist help and

advice (sweep or fire brigade) has been sought.

DO NOT OVER FIRE THE STOVE FOR ITS FIRST FIRING OR AFTER LONG PERIODS BETWEEN

BURN CYCLES.

10|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

Run for 2 hours with kindling and 50mm or less diameter wood for an initial gentle fire.

If the stove has been unfired/unused for a period of time and left in a damp location,

moisture will be absorbed into the Silicon Carbide and manifest itself as condensation on the

initial re-firing.

a) INITIAL FIRING

The stove may be started with fire lighters or paper twists and kindling.

Start with 1.5kg kindling with the ash pit drawer (primary air) open 3mm or so only to

start the fire.

Add 2 loads of 3kgs of logs for a further 2 batches to bring up to 200°C maximum

operating temperature.

When the stoves top has reached between 160 - 180°C the ash pit drawer should be

closed for normal operation.

The primary control ash pit drawer is now to remain closed until refuelling when it

should be opened by 3mm or so for only 3 minutes or so to start the new fuel charge

into initial combustion, then again fully closed for normal operation.

b) SUBSEQUENT FIRING

Re starting the fire after its initial firing should be carried out with the ash pit cleared out

and the ash pit drawer opened 3mm or so to raise the stove to 160-180˚C optimum

running temperature at which point the ash pit drawer must be closed.

Re start with approximately 3kg of wood provided the stove is still warm or kindling if

not.

A raging lively fire will be seen which is ideal. Run as such until the stoves top is up to

minimum 160°C, maximum 200°C.

Refuelling on a low fire bed - If there is insufficient burning material in the fire bed to

light a new fuel charge, excessive smoke emission can occur. Refuelling must be carried

out onto a sufficient quantity of glowing embers and ash that the new fuel charge will

ignite in a reasonable period. If there are too few embers in the fire bed, add suitable

kindling to prevent excessive smoke.

c) RE FUELLING AFTER STARTING

The re fuelling should be in 3kg batches to raise the stoves top temperature to 200°C

maximum. When the stoves top temperature has reached 160°C to 180°C the ash pit

drawer should be closed.

d) OVER FIRING WARNING

Never over fill the firebox. 3kg or so is a full load. Running the stove over 200°C

constitutes over firing, after which point damage may occur to the stove.

11|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

Fuel overloading - The maximum amount of fuel specified in this manual should not be

exceeded, overloading can cause excess smoke.

e) UNDER FIRING WARNING

When re lighting; re fuelling or re firing the Ecco Stove, it must be fired up to 160°C or

above in order that each new wood load turns into proper combustion –if allowed to

“tick over” on un-combusted wood, tar will build up within the stove and flue, causing a

fire hazard and blockages within the stove.

13. CONTINUOUS BURNING

a) INITIAL FIRING

WARNING RUN THE STOVE WITH KINDLING AND MAXIMUM 50 MM DIAMETER LOGS

FOR THE FIRST 2 HOURS OF OPERATION TO AVOID CRACKING THE SILICON CARBIDE.

The stove may be started with either a fire lighter or paper twists with kindling

(approximately 1.5kg) open the ash pit drawer for 3mm for start primary air. When

initial combustion is underway add a 3kg batch of wood laid across the fire box.

Continue running as such until the stoves top reaches a minimum of 160 - 180°C when

the ash pan for secondary and tertiary air flows.

Continue to run as such between 150°C to 200°C thereafter.

To maintain a higher sustained output from repeated intermittent firing. The stove may

be run day and night by repeated intermittent firings but will not burn for more than 2-4

hours on one filling or before re fuelling (dependent upon how well the fire draws and

the density of the fuel being burned).

To close the stove down as far as possible ensure the ash pit drawer is fully closed.

b) SUBSEQUENT FIRING

Re starting the stove after its initial firing should be carried out with the ash pit cleared

out and the ash pit drawer open 3mm or so for maximum primary air to see a bright fire.

This will rapidly warm up the stoves body. Burn brightly as required for heat output

needed, but minimum restart temperature of 150˚C on stoves top, upon which the ash

pit drawer must be closed.

c) RE FUELLING AFTER STARTING

Re fuelling before the initial fuel is fully burned away with 1.5kg of wood but ensure the

end grain is pointing away from the door glass. Run for 2 minutes or so to ensure the

new load of wood is in combustion then close the ash pit drawer to ensure best

combustion and to keep the door glass clear.

12|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

The stove may be run as such for as long as needed. Your Ecco Stove E580 is not

designed to stay in for long periods or overnight.

d) REFUELLING ON A LOW FIRE BED

If there is insufficient burning material in the fire bed to light a new fuel charge,

excessive smoke emission can occur. Refuelling must be carried out onto a sufficient

quantity of glowing embers and ash that the new fuel charge will ignite in a reasonable

period. If there are too few embers in the fire bed, add suitable kindling to prevent

excessive smoke.

e) OPERATION WITH DOOR LEFT OPEN

Operation with door left open can cause excess smoke. The appliance must not be

operated with the appliance door left open except as directed in the instructions.

14. ASH REMOVAL

Ash removal must only be carried out when your Ecco StoveE580 is not alight as removing

the ash drawer would over fire the appliance.

Remove the ash drawer fully for emptying but ensure it is re fitted to follow the lighting

procedure at 13a in this manual.

15. FUELS

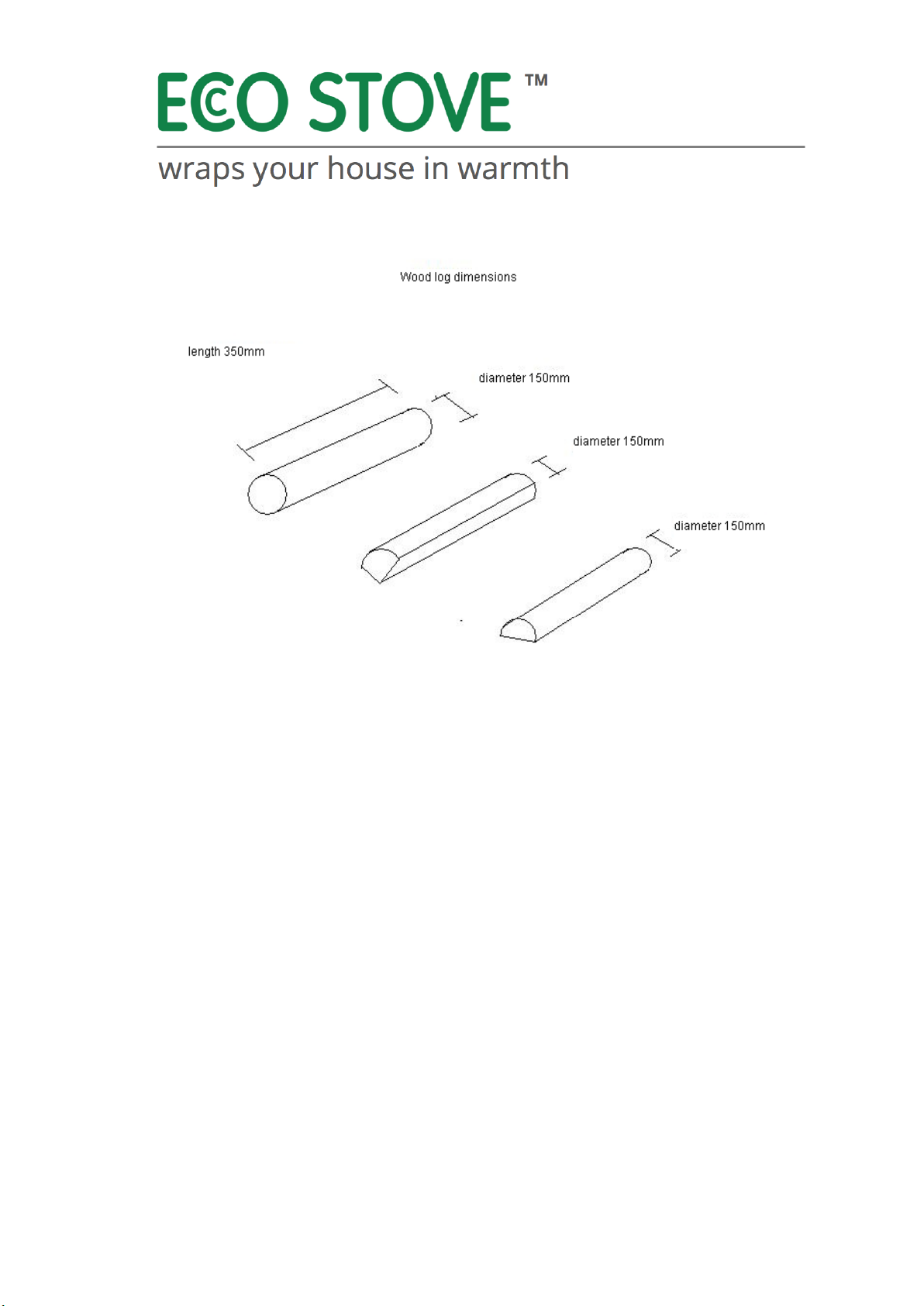

a) WOOD

Wood as a fuel should be 20-25% moisture content using split logs 100 to 150mm in

diameter for best combustion. Harder, more dense logs will generally burn more slowly.

Wood should ideally be loaded across the grate. Avoid end grain of logs pointing toward the

glass door to minimise tarring on the glass. Under no circumstances must the Ecco Stove

E580 be used as an incinerator to burn household waste or refuse.

13|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

16. RE FUELLING

After 2 or so hours burning your Ecco Stove will need re fuelling. You may either add 2 o 3

logs on a full 3kg charge –subject to how you intend to run the stove and the heat output

you are looking for. Either way, burn the fuel charge into full combustion then close the ash

pit drawer for the secondary and tertiary air flows to take over.

17. TAR DEPOSITS

WARNING when wood is burned slowly it produces tar and other organic vapours which

combine with the expelled moisture to form creosote. The creosote vapours will condense

in the relatively cool chimney flue of a slow burning fire. As a result creosote deposits form

on the flues lining presenting a fire hazard as they are highly combustible.

Creosote build up must be removed to prevent a fire hazard within the chimneys flue.

14|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

Tar deposits will not form if seasoned logs of 20-25% moisture are burned at 160°C or above

(recorded on the top plate) within your Ecco Stove. If tar deposits form within the stoves

flue ways or fire box it is clear indication of poor quality unseasoned wood being burned.

Damage will occur within your stove along with poor performance.

18. FLUE CONNECTION AND FLUE LININGS

Under no circumstances should the diameter of any flue or lining leaving the stove be

reduced less than its 150mm diameter flue outlet.

The stoves connector pipe must have an access panel/soot door built in within 200mm of

the stoves top for cleaning within the stove’s internal flue ways and for stove pipe lining

sweeping.

The flue lining and flue ways in the stoves top must be cleaned a minimum of twice every

seasons burning.

Any joints between pipes and linings should be self tapped together.

6” linings are suitable for flue heights up to 9 metres

7” linings should be used above 9 metres in height.

High temperature hot face linings are suitable but not above 225 x 225 in section.

It is advisable not to connect the Ecco Stove E580 to clay linings within chimneys, unless

those clay linings have a hot face liner fitted within, in order to reduce condensation within

the chimney flue.

ANY FLUE INTENDED FOR USE MUST BE SWEPT IN ADVANCE AND TESTED FOR SUITABILITY

PRIOR TO THE APPLIANCE BEING INSTALLED. IF INSTALLINGTHIS STOVE ONTO AN

EXISTING FLUE WHICH IS DEEMED/TESTED AS SUITABLE WHICH WAS PREVIOUSLY USED

FOR AN OPEN FIRE, THE FLUE MUST BE SWEPT AGAIN WITHIN A MONTH OF INSTALLATION

AS THE HIGHER TEMPERATURE OF FLUE GASES MAY LOOSEN THE OLD OPEN FIRES BUILT

UP DEPOSITS, TO ENSURE BLOCKAGE DOESN’T OCCUR.

19. CLEANING AND MAINTENANCE

The Ecco Stove E580 under top flue way must be cleaned at least twice in a burning season.

Access must be left in the stoves pipe within 200mm of the stoves top and brushed forward

into the stove under top flue way from there.

a) SEASONAL USE

b) Repairs or replacements must be carried out by a competent engineer.

c) Ensure the flue way accessed through the stove pipes cleaning door (within 200mm of

the stoves top) is brushed or vacuumed out

15|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

d) Remove the two horizontal baffles from within the fire box (in the top of the stove) by

removing the 6mm round pins set into the side walls of the stove. Clean above the

baffle and replace in reverse order.

e) Check that the flue off the stoves top (including the flue lining throughout) is swept and

free of debris both at the end of the burning season and prior to restarting the stove.

f) Clean the door glass to remove fly ash or tar deposits with a propriety glass cleaner or a

damp cloth and the ash from the fire box.

THE STOVE IS NOW READY FOR RE-USE

20. FINISHES

a) SILICON CARBIDE –needs only a light dusting down –as it is a natural finish

discrepancies in overall effect or colours are to be expected.

b) PAINT FINISHES

The heat resistant paint used to colour/finish your Ecco Stove will give off a noxious

smell for a number of initial firings as the heat from the stove “cures” the paint in place.

If and when this occurs, open doors and windows in the room to ventilate the “factory

like” odour but avoid refuelling the stove until the smell has dissipated.

If the finish becomes dirty to the colour changes over time (heat resistant paint finishes

do change with heat intensity which is normal) the Ecco Stoves paint can be “touched

up” but only when cold, by using a paint supplied by the manufacturer or retailer.

Never respray the stove body when the stove is in fired use or hot.

A light oil can be used to “freshen” the paint finish (but only when the stove is cold and

not under fire) such as WD40. Apply such oil with a nylon pad such as Scotch Brite or

similar rather than using a lint cloth –which will leave bits of lint on the stoves surface.

21. ASSEMBLY

Your Ecco Stove E580 is delivered in 7 main structural parts being base section; grate

section; 2 x sides; one back section; lower top; upper top and one baffle block. Nine further

secondary parts one door and frame including glass; cast iron grate; 2 x back baffle boards; 2

x inner left and right cheeks one spacer block and two horizontal baffles.

Ancillary parts and one pair of gloves for operating the handles and fueling and one circular

thermometer.

16|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

APPLIANCE ASSEMBLY

Silicon Carbide parts are both heavy and can be damaged. Lifting by two people is

recommended.

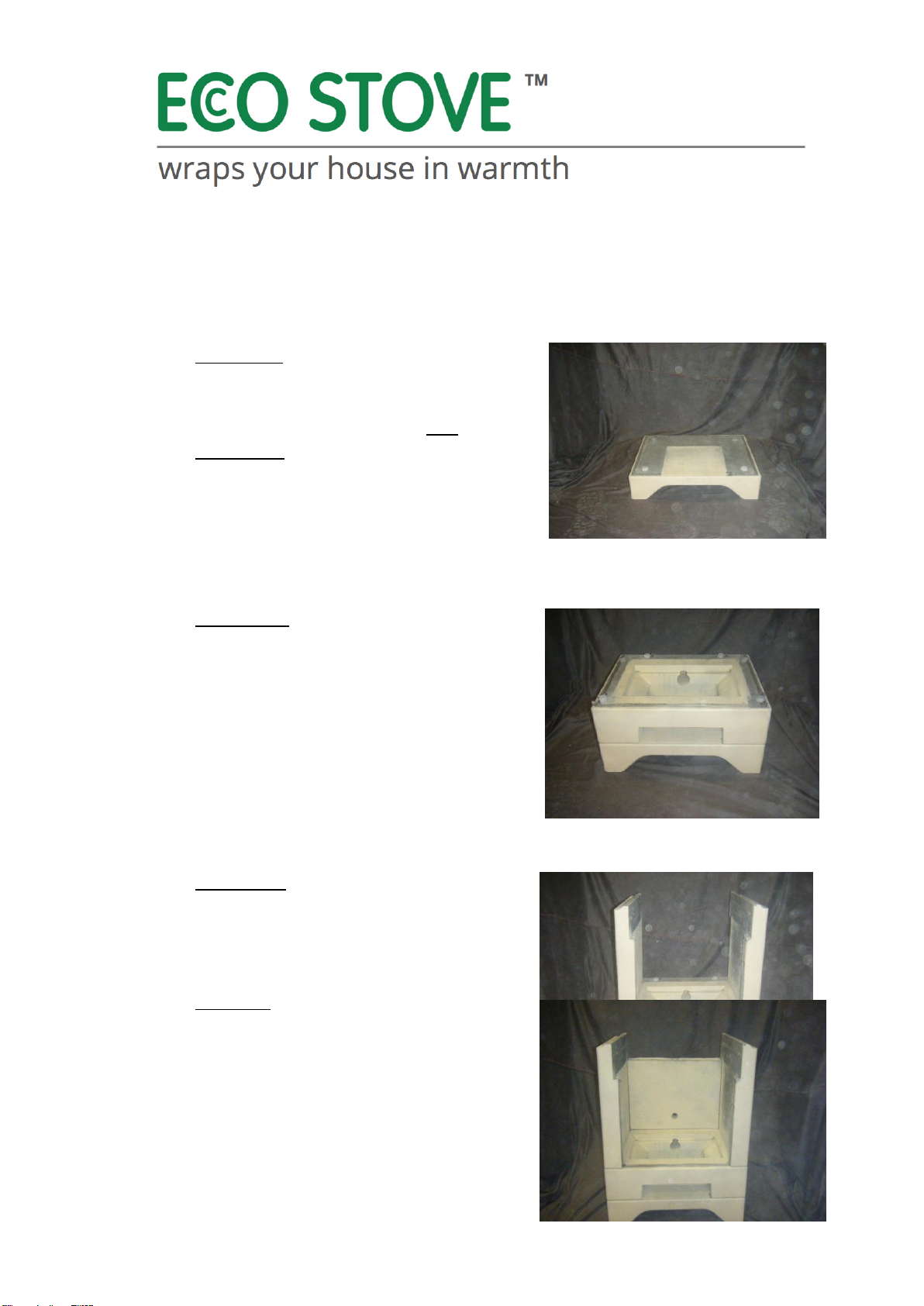

a) Base Section To be placed on a level structural

hearth capable of bearing 200kg. The hearth

must be laid level and the stove positioned a

minimum of 75mm away from a non-

combustible wall to allow space the outside

control assembly or 350mm from sides and 200

mm from stoves rear to a combustible

wall.

b) Grate Section Fit cone shaped diablos into

the sockets of the base section to locate the

grate section. Place the grate section on and

bump into position with a rubber mallet to

bed in.

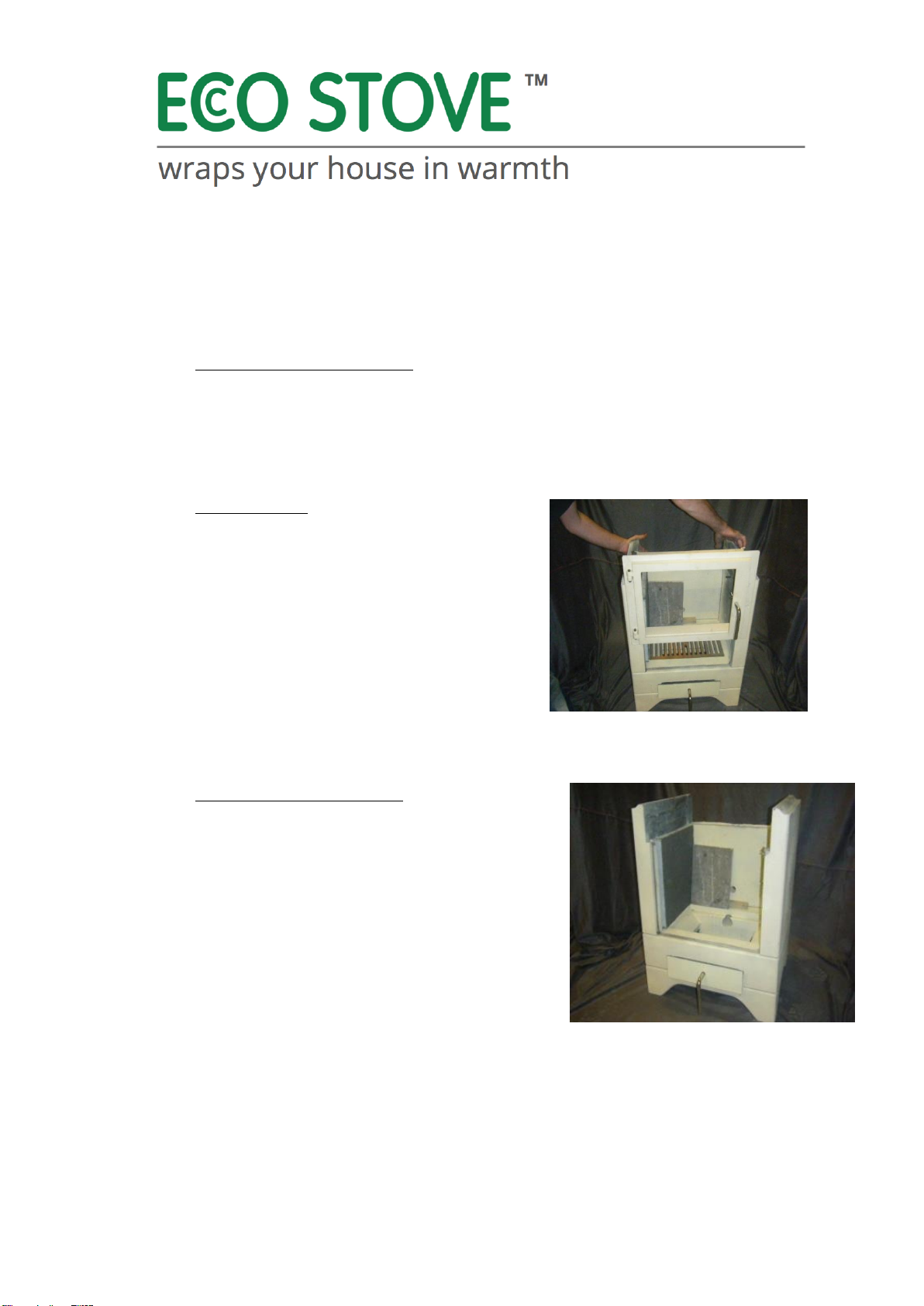

c) Side Sections Place the cone shaped diablos

into the sockets on the grate section. Place

both side sections into place and bump

vertically down to bed in.

d) Back Panel Fit the back panel between the

sides, it may help to spread the sides a little

at their tops to easily fit the back in.

Ensure the circular Tertiary hole is towards

17|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

the bottom. Add a bead of Fraxil sealant to the inside edges of the rope seal and flat

mating faces to adequately seal.

e) Ash Can and grate Spacer Block Fit the ash can

Assembly into the grate section; fit the 2 spacer

blocks to distance the back boards off the back

wall. Fit the grate ensuring the raised back is

to the back.

f) Door and Frame Slide the door section down

Into place between the side sections ready for

the lower top to be fitted.

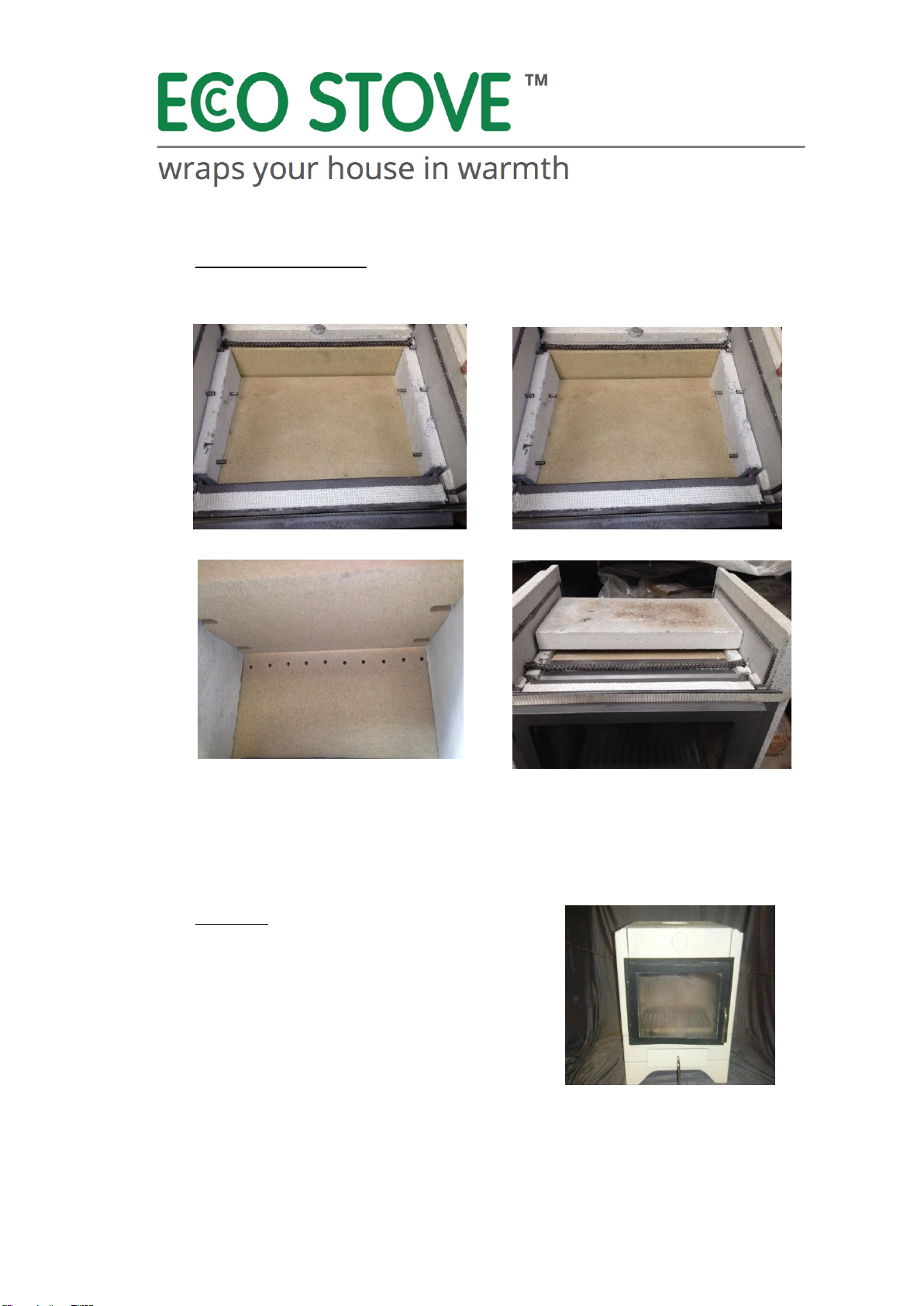

g) Baffle Boards and Baffle Block Lay baffle board

behind the grate section and against the back

panel ensuring the spacer block keeps them

off the back panel. Locate the baffle block into

place ensuring the adhered on tape is to the

back and dresses over the back panel of the stove

to form a seal.

18|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

h) Horizontal baffle boards 4 steel pins a) must be fitted into the 2 holes either side of the

side walls above the inner SIC side cheeks onto which the Silicon Carbide baffle block

must locate firmly over the these four pins.

The lower horizontal baffle boards curved edge must be down facing (sharp edge up)

and to the front and set against the back board without any gap at the rear. The upper

baffle board fits with the steel deflector forward and a 20mm gap to the back between it

and the upright boards.

i) Lower Top Add diablos to locate this next section.

Lay on the lower top over the baffle block and

between the sides and back.

a)

a)

a)

a)

a)

19|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

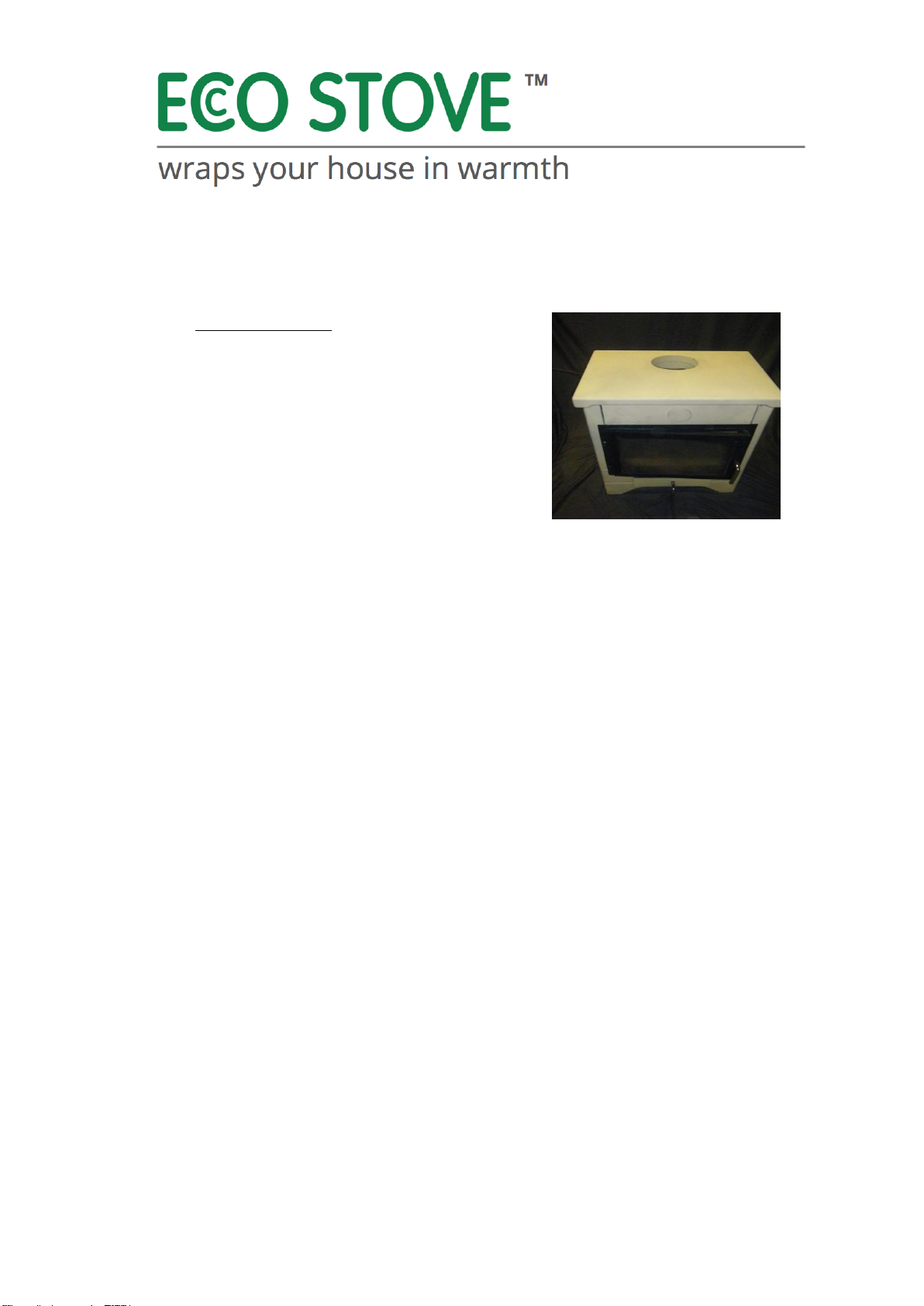

j) Upper Top Section Lower the final top section

over the side tapers onto/over the 3 pins to

locate and loct the whole stove together –

ensuring the flue holes line up.

22. HEARTH CONSTRUCTIONAL

a) Your Ecco Stove must stand on a constructional hearth of non-combustible materials

capable of carrying 270kg with an overall width of 880mm (UK) minimum and an overall

depth of 800mm (UK) minimum which allows/includes 75mm gap for the stove off the

rear non combustible wall (200mm to a combustible wall) to accommodate the rear air

control.

These dimensions must be checked for local or in country requirements.

b) HEARTH (DECORATIVE)

Must extend 150mm either side and 300mm in front as a minimum (or differently if in

country or local regulations dictate).

THE STOVE MAY NOW BE LIT

23. TECHNICAL

Heating appliance BS13240

a) Outputs

b) Weight: Complete appliance = 270kg: the Ecco Stove must be installed onto a structural

hearth capable of bearing this weight.

c) Air Supply –9 sq centimetres required within the UK (Refer To ADJ2010)

Outside the UK to those countries of local area requirements.

d) Extractor Fans: No extractor fans are to be fitted into the same room as the Ecco Stove.

e) Flue Draught: Minimum cold flue 0.04inches water gauge

f) Flue gas mass flow: 6

g) Flue gas temperature: Average 230°C at nominal output.

20|P a g e

E580 Defra instructions manual | current as of May 2015

All information supplied by Ecco StoveTM is a trade mark of Landy Vent UK Limited copyright©EccoStove2015

Ecco Stove | Foster House| 2 Redditch Road,Studley,B80 7AX, United Kingdom

Patent pending USA, Canada, Europe & Russia | UK Patent nos: 2467433 & 2498883

h) Flue Outlet: 150mm top exit only (dampers are necessary if the flue draught is in excess

of 0.06 inches water gauge or for slow heat release) from the stove.

i) Heat Stored: typically 30% after 4 hours (subject to flue draught)

j) CO Concentration at 13% oxygen 0.28

Excessive flue draught may remove too much heat from the Ecco Stove on slow

combustion. A damper may be fitted into the flue pipe off the stove to reduce the flues

draught; but only closed after the stoves burning process is completed –dampers must

always allow or leave 20% of flues area when closed.

A CO-DETECTOR MUST BE FITTED IN THE SAME ROOM AS THIS APPLIANCE TO CONFORM

TO UK REQUIREMENTS OF INSTALLATION

k) Efficiency 80.4%

l) Minimum distances to combustibles:

Rear 250mm

Sides and top 300mm

Minimum distances to non-combustibles

Rear 75mm

Sides 100mm

Top 125mm

24. GENERAL AND HEALTH AND SAFETY

a) Safe Operation: The outside surface temperature of your Ecco Stove should not be fired to

over 200°Centigrade so must not be touched or burning will occur. In the event of

overheating (over 200°C) close the fire door and ash pit door and do not refuel until the

body has cooled adequately.

ai) Minimum distances to combustible materials must be maintained (see page )

Plasterboard or plaster will crack within 300mm of the top or sides and 200mm from the

rear. Minimum distance to Non-combustibles is 100mm to sides and 125mm to top 75mm

behind.

b) No structural modification must be made to the Ecco Stove or structural work carried out

upon it unless by authorised personnel (aesthetic changes may be made by the

manufacturer without notice).

c) Replacements must only be of the manufacturers supply and design.

HEALTH AND SAFETY

The requirements of the Health and Safety At Work Act must be met when installing this

stove.

Other manuals for E580

1

Table of contents

Other ECCO STOVE Wood Stove manuals

Popular Wood Stove manuals by other brands

RAIS

RAIS attika NEXO 100 GAS installation guide

WoodPro

WoodPro WS-TS-1500 owner's manual

Contura

Contura C 586W installation instructions

Palazzetti

Palazzetti EVA GENERAL INFORMATION - WARNINGS - INSTALLATION - MAINTENANCE

Lopi

Lopi 1250 Republic owner's manual

Panadero

Panadero CAPRI 3V Usage and maintenance instructions