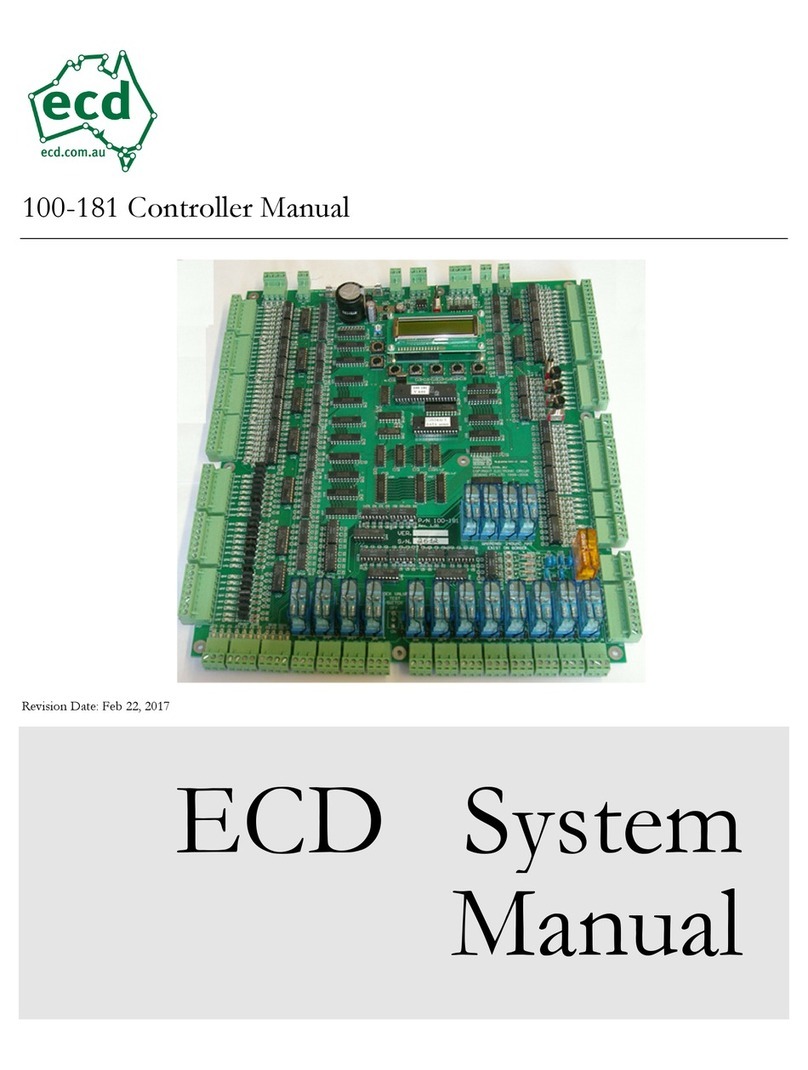

ECD 100-194 EN81 User manual

100-194 EN81 Controller Manual

Revision Date: Jan 23, 2023

ECD System Manual

E L E C T R O N I C C I R C U I T D E S I G N S P T Y . L T D .

Operation Guide

This manual is for controller 100-194 to comply with the Lift

Standard EN81-20/50

Electronic Circuit Designs Pty. Ltd.

Factory 11/30 Perry Street • Matraville • NSW • Australia • 2036

Phone 61 2 9316 6909 • Fax 61 2 9316 6797

Email sales@ecd.com.au Web www.ecd.com.au

Table of Contents

Table of Contents ............................................................................................ i

Section 1: Safety Regulations & Introduction .............................................. 4

1.2.1 Following operating instructions. ............................................ 4

1.2.2 Obligations of operator. ............................................................ 4

1.2.3 Obligations of personnel. .......................................................... 4

1.2.4 Hazards associated with the equipment. ................................. 5

1.2.5 Warranty and liability. ............................................................. 5

1.2.6 Organizational measures. ......................................................... 5

1.2.7 Protective equipment. ............................................................... 5

1.2.8 Informal safety measures. ........................................................ 6

1.2.9 Training of personnel. .............................................................. 6

1.2.10 Machine controls. ...................................................................... 6

1.2.11 Safety measures during normal operation. ............................. 6

1.2.12 Hazards caused by electric power. ........................................... 6

1.2.13 Hazards caused by hydraulic power. ....................................... 7

1.2.14 Special danger areas (examples). ............................................. 7

1.2.15 Controller Installation Environmental Requirements .............. 7

1.2.16 Introduction ................................................................................. 8

Testing RCD / RCBO on 110vac Safety circuit. .................................... 8

Section 2: EEPROM (Lift Parameter) Settings ............................................ 9

EEPROM Version 6.04 Parameter Summary ............................................. 10

EEPROM Definitions (Full description) .................................................... 13

ADO - Advanced Door Opening setup .................................................. 13

ALP – Auxiliary Leveling Pump operation setup ................................ 13

ANS – Anti Nuisance setup .................................................................... 13

BCC Bottom Car Call setup .................................................................. 13

BOT - Bottom floor setup ...................................................................... 13

BST – Brake Switch Time ...................................................................... 13

BSW – Brake SWitch Polarity ............................................................... 14

CIM - Car call InterMediate setup ........................................................ 14

CI1 - Car Intermediate 1 setup .............................................................. 14

CCM - Car Call Mask setup .................................................................. 14

CC1 - Car Call 1 setup ........................................................................... 15

CNT – CNT input setup ......................................................................... 15

COD – parameter lockout function ....................................................... 15

DCM - Down Call Mask setup ............................................................... 15

DC1 – Down Call 1 setup ....................................................................... 15

DLI - Door Limit Invert setup ............................................................... 15

DLM - Door Limit setup ........................................................................ 16

DPT - Door Protection Time .................................................................. 16

DRV - DRiVe type setup ........................................................................ 16

DT - Door Time close setup.................................................................... 17

DTC - Door Time Car call close setup .................................................. 17

DTH - Door Time Hall call close setup ................................................. 17

DTL - Door Time Lobby call close setup .............................................. 17

DTR - Door Time Recall ........................................................................ 17

FD1 – Front Doors 1 setup, levels 1-8 .................................................... 18

FD2 – Front Doors 2 setup, levels 9-12 .................................................. 18

HFS - Hall Fire Service return floor setup ............................................ 18

HF1 – Hall Fire 1 setup........................................................................... 18

HRF – Hospital / Hall Recall Floor ........................................................ 18

HR1 – Hospital / Hall Recall 1 setup ..................................................... 18

LCK – Parameter lockout function ....................................................... 18

LOK – number of door LOcKs .............................................................. 19

LOB - LOBby floor setup ....................................................................... 19

LO1 - LObby 1 setup .............................................................................. 19

L.# - Lift Number setup .......................................................................... 19

MOD – MODe Inputs setup ................................................................... 19

MSL – Magnet SLowing type ................................................................. 20

NR - Door Nudging setup ....................................................................... 20

PI - Position Indication setup ................................................................. 20

PRK – PaRK / zone with doors open ..................................................... 20

RD1 – Rear Doors 1 setup, levels 1-8 ..................................................... 20

RD2 – Rear Doors 2 setup, levels 9-12 ................................................... 21

RPT - Run Protection Timer / motor run timer setup ..................... 21

RTM – Run TiMe short floor run setup ................................................ 21

SD1 – Selective rear Doors setup, Levels 1-8 ........................................ 22

SD2 – Selective rear Doors setup, Levels 9-12....................................... 22

SDX - Star Delta eXchange time setup .................................................. 22

SDX – VF Drive setting 06,07,08 brake drop time................................ 22

SFR - Short Floor Run setup .................................................................. 22

SF1 - Short Floor 1 setup ........................................................................ 23

StF – Start Fast ....................................................................................... 23

StM – Start Medium ............................................................................... 23

SlF – Slow Fast ........................................................................................ 23

SlM – Slow Medium ................................................................................ 23

SSD – Soft Start Drive ............................................................................ 23

ST2 - STar delta 2 setup ......................................................................... 23

ST2 – VF Drive setting 06,07,08 end run time ...................................... 23

TCC - Top Car Call setup ...................................................................... 23

TC1 – Top Call 1 setup ........................................................................... 24

TOP - Top floor setup ............................................................................. 24

UCM - Up Call Mask setup .................................................................... 24

UC1 – Up Call 1 setup............................................................................. 24

UIM – UnIntended Movement testing ................................................... 24

XTM – Extend run time short floor run ................................................ 26

ZON - Zoning floor setup ....................................................................... 26

ZO1 – Zoning 1 setup ............................................................................. 27

ZTM - Zoning time setup ....................................................................... 27

#.L - Number of Lifts setup .................................................................... 27

Section 3. Group .......................................................................................... 28

Group Connections and Communication .............................................. 28

Group Checks ......................................................................................... 29

Group / Duplex faults ............................................................................. 29

Section 4. Inputs – Outputs, onboard switches, push buttons, terminals ... 30

BKS1 - BraKe Switch 1 input ................................................................ 30

BKS2 - BraKe Switch 2 input ................................................................ 30

BRK - BRaKe relay output .................................................................... 30

BSL - Bottom Slowing Limit input ........................................................ 31

BYPASS onboard switch ........................................................................ 31

BPAV - Bypass Switch Audio Visual alert output ................................ 31

CFS - Car Fire Service input ................................................................. 31

CFSS - Car Fire Service Start input...................................................... 31

CG – Car Gate input .............................................................................. 31

CG relay – Car Gate relay ..................................................................... 31

CGBP relay ............................................................................................. 32

CGM LED – Car Gate Monitoring LED .............................................. 32

CLP – Car Light and Power output ...................................................... 32

COR – COrrection Run output ............................................................. 32

DC - Door Close relay output ................................................................ 32

DCB - Door Close Button input ............................................................. 32

DDN - Direction DowN output .............................................................. 32

DF - Down Fast relay output ................................................................. 32

DFC - Door Fully Closed input .............................................................. 32

DFO - Door Fully Open input ................................................................ 35

DN - DowN relay output ........................................................................ 36

DO - Door Open relay output ................................................................ 36

DOB - Door Open Button input ............................................................. 36

DOOR Disable onboard toggle switch .................................................. 37

DS - Down Slow relay output ................................................................. 37

DUP - Direction UP output .................................................................... 37

DZ - Door Zone input ............................................................................. 37

DZR – Door Zone Rear output .............................................................. 37

DZ relay .................................................................................................. 37

EDP - Electronic Door Protection input ............................................... 37

EP - Emergency Power input ................................................................. 38

EQK – EarthQuaKe detection input. (Siesmic or Counterweight

displacement switch) .............................................................................. 38

HBS - Hall Button Stop .......................................................................... 38

HCB – Hall Call Bypass ......................................................................... 38

HFS - Hall Fire Service input ................................................................ 39

HRI – Hospital / Hall Recall Input ........................................................ 39

HRO – Hall (Hospital) Recall Output ................................................... 39

IDN - Inspection DowN input ................................................................ 39

IND - INDependent service input .......................................................... 39

INSP - INSPection control input ........................................................... 39

INSP Controller onboard switch ........................................................... 40

INSP COM onboard push button .......................................................... 40

INSP DN onboard push button.............................................................. 40

INSP UP onboard push button .............................................................. 40

IRO – Inspection Relay Output ............................................................. 40

IUP - Inspection UP input ...................................................................... 40

LCK1 – LoCK 1 input ............................................................................ 40

LCK1M LED – LCK1 Monitoring LED ............................................... 40

LCK1 relay .............................................................................................. 40

LCK2 – LoCK 2 input ............................................................................ 41

LCK2 relay .............................................................................................. 41

LEV relay ................................................................................................ 41

LOCK VALVE SWITCH onboard toggle switch ................................. 41

L1BP relay ............................................................................................... 41

L2BP relay ............................................................................................... 41

MSD – Magnetic Switch Down input..................................................... 41

MSD relay ................................................................................................ 42

MSU – Magnetic Switch Up input ......................................................... 42

MSU relay ................................................................................................ 42

M1 – M1 output terminal ....................................................................... 42

M3 – M3 Input ........................................................................................ 43

M4 – M4 terminal ................................................................................... 43

N – Neutral terminal ............................................................................... 43

NDG - NuDGing buzzer output ............................................................. 43

NR - Nudging Relay output .................................................................... 43

OIL – OIL overheat input ...................................................................... 43

OS - Out of Service output ..................................................................... 43

OVL – OVerLoad input ......................................................................... 44

OVLO – OVerLOad output ................................................................... 44

PAWL – PAWL device output ............................................................... 44

PCOM – Pit Inspection COMmon Input .............................................. 44

PINS – Pit INSpection input ................................................................... 44

PRES – Pit inspection RESet input ........................................................ 45

PRK – PaRKing input ............................................................................ 45

PRV - PRoVing circuit input.................................................................. 45

PULSE – PULSE counting input ........................................................... 45

PWLE – PaWL device Extended input ................................................. 45

PWLR – PaWL device Retracted input ................................................ 45

SAF - SAFety circuit input ..................................................................... 45

SIn1 - Input ............................................................................................. 45

SIn2 - Input ............................................................................................. 46

SIn3 - Input ............................................................................................. 46

SO1 - Output ........................................................................................... 46

SO2 - Output ........................................................................................... 46

SO3 - Output ........................................................................................... 46

SO4 - Output ........................................................................................... 46

SP1 – SPare relay output 1 ..................................................................... 46

SP2 - SPare relay output 2...................................................................... 46

SP3 - SPare relay output 3...................................................................... 46

SP4 - SPare relay output 4...................................................................... 46

SX- Serial communication input ........................................................... 46

SX+ Serial communication input .......................................................... 46

TCOM – Top of car Inspection COMmon input.................................. 46

TSL – Top Slowing Limit input ............................................................. 47

UD – Up Dn relay output ....................................................................... 47

UF - Up Fast relay output ...................................................................... 47

UIM – UnIntended Movement output .................................................. 47

UP – UP relay output ............................................................................. 47

US - Up Slow relay output...................................................................... 47

1C/12C - Car Call input / output ........................................................... 47

2D/12D - Down Hall Call input / output ............................................... 47

1P/12P - PosItion output ........................................................................ 48

1U/11U – Up Hall Call input / output .................................................... 48

Section 5. Liquid Crystal Display (LCD) ..................................................... 49

LCD Position & Direction ...................................................................... 49

LCD Lift Mode ....................................................................................... 49

LCD Lift Status ...................................................................................... 50

LCD Door Modes .................................................................................... 51

LCD Control Buttons ............................................................................. 51

LCD Display Options ............................................................................. 51

LCD Fault Log ........................................................................................ 53

Section 6. Motion ......................................................................................... 55

Motion Control Outputs ........................................................................ 55

Drive settings and their output status. .................................................. 55

Counting Method “00” - Magnet Counting. ......................................... 64

Counting Method “01” - Pulse Counting. ............................................. 66

Counting Method “02” - Pulse Counting. ............................................. 73

Counting Method “03” - Pulse Counting. ............................................. 75

Section 7: Faults – Fault finding. ............................................................... 76

On board fuse blows ............................................................................... 76

Testing 24Vdc ......................................................................................... 76

Testing RCD / RCBO on 110vac Safety circuit. ................................... 76

Doors do not open ................................................................................... 76

Doors don’t open at terminal floors ...................................................... 76

Lift gets out of step ................................................................................. 77

Lift performs correction runs intermittently ........................................ 77

Lift does not answer car calls................................................................. 77

Lift does not answer hall calls ................................................................ 77

Lift misses calls ....................................................................................... 77

Red3 LED is not blinking ....................................................................... 77

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

4

Section 1: Safety Regulations & Introduction

Section 1.1 Safety Regulations

Elevator controllers and other electrical components can cause serious harm or death if installation guides are not

met. It is the responsibility of the installer of our equipment to ensure that once installed, the equipment does not

pose any threat, danger or hazard.

Installation of this equipment shall be done in accordance with AS1735 for Australia and with all applicable local

codes.

Section 1.2 Obligations and Liability

1.2.1 Following operating instructions.

In order to ensure safe handling and problem free operation of this equipment, it is absolutely

essential for the relevant personal to be fully acquainted with the relevant safety regulations.

These operating instructions contain the most important information for operating the machine correctly

and safely.

These operating instructions, in particular the safety regulations, must be observed by all those persons

who work on the equipment.

Furthermore, all locally applicable rules and regulations relating to accident prevention and installation

must be observed.

1.2.2 Obligations of operator.

The operator undertakes to allow only those persons to work on the equipment who

Are fully acquainted with the basic regulations relating to safety in the workplace and accident prevention

and to have been trained in handling the equipment.

Have read the safety regulations and the warning notices contained in these the operating instructions.

Regular checks are conducted to ensure that personnel perform their duties with safety considerations

foremost in their minds.

1.2.3 Obligations of personnel.

All personnel charged with working on the machine undertake prior to starting work to

Observe the basic regulations relating to safety in the workplace and accident prevention.

Read the operating instructions, in particular the safety regulations, and confirm by way of their signature

that they have understood them.

Secti

on

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

5

1.2.4 Hazards associated with the equipment.

The equipment is built with state-of-the-art technology and recognized safety regulations. Nevertheless, use of the

equipment can result in dangers to life and limb for the installer, user or a third party and in impairments to the

equipment or to other material property. The equipment must only be used

For its intended purpose.

In perfect condition in terms of safety requirements.

Operate the equipment in technically perfect condition and for its intended use only while bearing in mind all

safety and hazard considerations and following the operating instructions. In particular, faults which restrict safety

must be rectified immediately after they have been identified and at the latest before the equipment is started up.

Compliance Testing for AS/NZS CISPR 22:2002 Class A

1.2.5 Warranty and liability.

Our “Sales terms and conditions” apply. These terms and conditions will have been available to the purchaser at

time of sale. Warranty and liability shall be limited to repairs and replacement to the equipment purchased from

us. Warranty and liability claims shall not be entertained if they can be traced back to one or more of the following

causes.

Equipment not used for its intended purpose.

Improper installation, startup, operation and maintenance of the equipment.

Operation of the equipment with faulty safety devices or improperly installed or non-operational safety

and protective equipment.

Failure to observe the information, instructions and notices contained in the operating instructions

relating to transportation, storage, installation, startup, operation, maintenance and setting up of the

equipment.

Inadequate monitoring of the equipment parts which are subject to wear.

Improperly conducted repairs.

Catastrophes caused by the influence of foreign bodies and force majeure.

1.2.6 Organizational measures.

The installer and or maintainer shall provide the necessary protective equipment for the personnel

All existing safety equipment must be checked at regular intervals.

1.2.7 Protective equipment.

At all times, prior to putting the machine into operation, all protective equipment must be correctly

installed and in proper working condition.

Protective equipment may only be removed

- after the machine has come to a complete stop and the machine has been disabled to ensure it

cannot be started up again.

WARNING !

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

6

- if subcomponents are delivered, the operator must install the protective equipment in

accordance with regulations

1.2.8 Informal safety measures.

Keep the operating instructions and circuit diagrams permanently at the site where the equipment is

installed.

In addition to the operating instructions, the generally valid and local regulations relating to accident

prevention and environmental protection must be provided and observed.

Maintain all safety and danger notices on/next to the machine in legible condition and comply with

them.

If the equipment is sold or transferred, the operating instructions must be included with the equipment.

1.2.9 Training of personnel.

Only personnel who have been trained and instructed are allowed to work on the machine.

The responsibilities of the personnel must be clearly defined for the machine/controller installation, start

up, operation, setting-up, maintenance and repairs.

Personnel still in the process of being trained are only permitted to work at the machine under the

supervision of an experienced person.

1.2.10 Machine controls.

Under no circumstances carry out any program modifications to the software!

Only properly instructed personnel are permitted to operate the controls.

The machine must not be operated if potential electromagnetic interference sources are acting on the

machine. Interference sources are e.g. welding equipment, portable phones.

1.2.11 Safety measures during normal operation.

Only operate the machine when all protective equipment is fully operational.

Prior to switching on the machine, ensure that the start up can cause no harm to personnel.

Regularly maintain and check machine for externally identifiable damage and check that all the safety

devices are operational.

1.2.12 Hazards caused by electric power.

Ensure 0v and +24V are free from other voltages. High voltages may be superimposed on 0V

and +24V lines as no reference to ground exists. See Warning 1.2.14

Work on the electric power supply may only be carried out by a qualified electrician.

Check the electrical equipment of the machine at regular intervals.

Repair loose connections and scorched cables immediately.

Keep the control cabinet locked at all times. Access is only permitted to authorized personnel with a key

or tool.

If work has to be carried out on live parts, do this only in the presence of a second person who can

switch off the master switch in an emergency.

The machine causes electromagnetic interference sources. For this reason, do not use any sensitive

equipment in its vicinity.

For EMC reasons, the controller must not be modified.

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

7

1.2.13 Hazards caused by hydraulic power.

Only personnel with special knowledge and experience in the field of hydraulics may work on hydraulic

equipment.

Before beginning repairs, depressurize system sections and pressure lines which are to be opened.

1.2.14 Special danger areas (examples).

When on inspection, always ensure either of the common or direction control buttons stops the lift.

The common button shall break the safety line and the 0V up/down direction input.

Never place yourself or any party in a position of danger where relying on any single safety measure.

Automatic machines start without warning. Care must be taken at all times.

1.2.15 Controller Installation Environmental Requirements

Controller cabinet must be installed in a location free from;

Dust and dirt.

Excessive heat and humidity. Ambient temperature should not exceed 40°C /104°F.

Excessive vibrations.

Mist or water

When mounting controller cabinet, ensure it is suitably supported.

WARNING!

Always treat terminals and conductors as dangerous. High voltages may be

superimposed on 0v and 24VDC lines as no reference to ground exists. Always

meter these points to ensure correct voltage exists.

E E P R O M S E T T I N G S

8

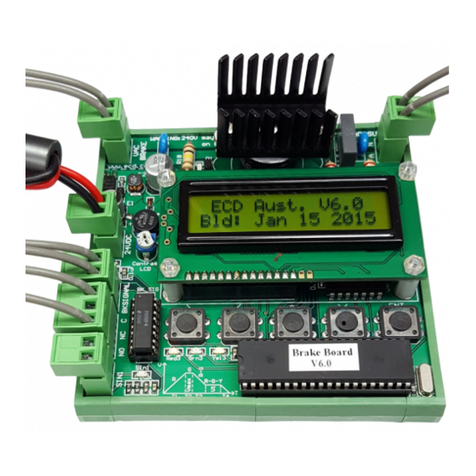

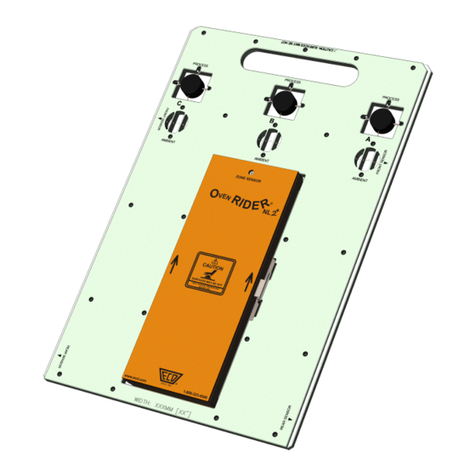

1.2.16 Introduction

The 100-194 lift controller is a 12 stop, simplex or duplex (up to 6 car group), fully collective controller that has been

manufactured to comply with the EN81-20/50 standard.

Processor

Under normal operation;

The red Red3 LED blinks to confirm that the microprocessor is running.

The yellow Yel3 LED comes on to confirm outputs are enabled.

The green Grn3 LED comes on during power up and turns off during normal operation. It will

also flash once when a new value has been written in to EEPROM.

When re-powering; ensure the lift is off for 10 seconds before turning back on.

On power up, a delay of approximately 2 seconds is given on start up to ensure voltages are stable prior to reading

and writing outputs.

Testing RCD / RCBO on 110vac Safety circuit.

To test the trip operation of an RCD / RCBO supplied with a 110VAC safety circuit, place a 1.2K ohm resistor

between the load side of the RCD / RCBO and earth.

E E P R O M S E T T I N G S

9

Section 2: EEPROM (Lift Parameter) Settings

EEPROM: How to read LCD and modify settings

The lift Parameters such as number of floors, door, drive and input settings are adjustable using the on-board LCD

and buttons. Parameters are stored in the EEPROM. Each setting has a definition followed by its value in hex

followed by its value in bit format. To adjust see below. For parameter definitions and examples see the proceeding

EEPROM Parameter Summary.

See also: “Section 5. Liquid Crystal Display” for more LCD information

LCD information from the power up state.

To inspect the settings from the power up state,

press the forward “>” button located to the left

below the LCD until the EEPROM setting appears.

Use the up “” and down “” buttons

to scroll through the settings. If you want to change

a setting value, press the enter “ENT” button. * shall

appear on the screen to indicate you are in edit mode.

Now use the up “” and down “” buttons to

change the setting value. When you are at the required

value, press the enter “ENT” button again and the *

shall disappear and new value shall be stored.

Section

01- NOR IDL ][

ECD Aust. V-6.05

01- NOR IDL ][

BOT: 01:00000001

01- NOR IDL ][

TOP:*08:00000010

01- NOR IDL ][

TOP: 06:00000010

E E P R O M S E T T I N G S

10

EEPROM Version 6.05 Parameter Summar y

Note: Refer to EEPROM Definitions (Full description) for more information.

BOT Bottom floor number

Setting example: BOT 01: 00000001 (Level 1)

TOP Top floor number.

Setting example: TOP 08: 00001000 (Level 8)

BCC Bottom floor car call for “BOT CALL” button on the circuit board

Setting example: BCC 80: 10000000 (Level 1)

TCC Top floor car call for “TOP CALL” button on the circuit board

Setting example: TCC 01: 00000001 (Level 8)

TC1 Top floor car call extension. Ext. of TCC

Setting example: TC1 00: 00000000

CCM Car call mask. Floors allowed.

Setting example: CCM FF: 11111111 (Levels 1-8)

CC1 Car call mask extension. Ext. of CCM. Floors allowed ext.

Setting example: CC1 00: 00000000

UCM Up call mask. Floors allowed.

Setting example: UCM FF: 11111111 (Levels 1U-8U)

UC1 Up call mask extension. Ext. of UCM. Floors allowed ext.

Setting example: UC1 00: 00000000

DCM Down call mask. Floors allowed.

Setting example: DCM 7F: 01111111 (Levels 2D-8D)

DC1 Down call mask extension. Ext. of DCM. Floors allowed ext.

Setting example: DC1 00: 00000000

LOB Lobby floor.

Setting example: LOB 40: 01000000 (Level 2 master floor)

LO1 Lobby floor mask extension. Ext. of LOB

Setting example: LOB 00: 00000000

ZON Zone floor.

Setting example: ZON 10: 00010000 (Zone to Level 4)

ZO1 Zone floor mask extension. Ext. of ZON

Setting example: ZO1 00: 00000000

ZTM Zoning time.

Setting example: ZTM 06: 00000110 (= 60seconds)

HFS Hall fire service floor.

Setting example: HFS 80: 10000000 (Level 1)

HF1 Hall fire service floor mask extension. Ext. of HFS

Setting example: HF1 00: 00000000

SFR Short Floor Run

Setting example: SFR 9F: 10011111 (Short floor between 2&3)

SF1 Short Floor Run mask extension. Ext. of SFR

Setting example: SFR CF: 00111111 (Short floor between 9&10)

L.# Lift Number

Setting example: L.# 02: 00000010 (Lift #2)

#.L Number of Lifts in the group

Setting example: #.L 03: 00000011 (3 Lifts in group)

MOD Mode inputs

E E P R O M S E T T I N G S

11

Setting example: MOD 02: 00000010 (CFS input inverted)

CNT CNT inputs

Setting example: CNT 02: 00000010 (DOB input inverted)

CIM Intermediate floor car call for “INTER” button on the circuit board

Setting example: CIM 23: 00100011 (Set to Levels 3, 7 and 8)

CI1 Intermediate floor car call extension. Ext. of CIM

Setting example: CI1 40: 01000000 (Set to Level 10)

LOK Single or Dual Lock circuit.

Setting example: LOK 01: 00000001 (Single door locks)

Setting example: LOK 02: 00000001 (Dual door locks)

RPT Run protection timer

Setting example: RPT 14: 00010100 (20s). Min 14, Max 2D

DRV Drive control type.

Setting example: DRV 02: 00000010 (3010/2CH/S block)

ST2 Star Delta time

Setting example: ST2 08: 00001000 (= 800ms)

SDX Star Delta Exchange time.

Setting example: SDX 01: 00000001 (= 100ms)

MSL Magnet slowing type.

Setting example: MSL 00: 00000000 (MSU/MSD slowing)

MSL 01: 00000001 (Pulse slowing)

RTM Extend run time. If slowing is obtained less than this time, then add the value

of XTM on before dropping high speed.

Setting example: RTM A5: 10100101

XTM Extend run time. If a short floor is determined by RTM then add XTM time on

before dropping high speed.

Setting example: XTM 20: 00100000 (extended fast speed run time by 20)

StF Start Fast. Number of pulses it takes to reach fast speed.

StM Start Medium. Number of pulses it takes to reach medium speed.

SlF Slow Fast. Number of pulses it takes to slow from fast speed.

SlM Slow Medium. Number of pulses it takes to slow from medium speed.

BST Brake Switch Time. Time for BKS1 and BKS2 inputs to be initiated

Setting example: BST 13: 0001001 (3s)

DPT Door Protection Time. Maximum time allowed for doors to reach fully open

Setting example: DPT FF: 11111111 (25s)

UIM UnIntended Movement testing

Setting example: UIM 01: 00000001 UIM Test enabled

BSW Brake Switch Polarity

Setting example: BSW 01: 00000001 (normally open brake contact)

DLM Door limit mask.

Setting example: DLM 00: 00000000 (Single doors)

DLI Door limit invert.

Setting example: DLI 00: 00000000 (Limits not inverted)

NR Nudging Relay for door nudging/Passing tone

Setting example: NR 00: 00000000 (Nudging off.)

ADO Advanced Door Opening.

Setting example: ADO 00: 00000000 (off )

DTC Door time car call. Time doors stay fully open after answering a car call

Setting example: DTC 32: 00110010 (5000ms, “5 seconds”)

DTH Door time hall call. Time doors stay fully open after answering a hall call

Setting example: DTH 32: 00110010 (5000ms, “5 seconds”)

DTL Door time lobby. Time doors stay fully open after answering a “LOB” call

Setting example: DTL 32: 00110010 (5000ms, “5 seconds”)

ANS Anti Nuisance EDP.

E E P R O M S E T T I N G S

12

Set to the number of times a car call is answered without EDP activation before calls are cancelled.

SSD Soft Starter Drive setting

Setting example: SSD 01: 00000001. Hydraulic lift with Soft Starter motor starting

FD1 Front doors 1-8 mask.

Setting example: FD1 F0: 11110000 (Front doors 1-4)

FD2 Front doors 8-16 mask.

Setting example: FD2 00: 00000000

RD1 Rear doors 1-8 mask.

Setting example: RD1 08: 00001000 (Rear doors 5)

RD2 Rear doors 8-16 mask.

Setting example: RD2 00: 00000000

SD1 Selective rear doors 1-8 mask.

First floor of selective front/rear doors.

Setting example: SD1 10: 00010000 (Levels 4 & 5 selective)

SD2 Selective rear doors 9-16 mask.

First floor of selective front/rear doors.

Setting example: SD2 10: 00010000 (Levels 12 & 13 selective)

DTR Once the lift arrives at the HR floor, the doors shall remain open for the time set as per DTR

Setting example: DTC 32: 00110010 (5000ms, “5 seconds”)

HRF Hospital/Hall Recall Floor

Setting example: HRF 40: 01000000 (Set to Level 2)

HR1 Hospital/Hall Recall Floor extension. Ext. of HRF

Setting example: TC1 40: 01000000 (Set to Level 10)

PRK Park/Zone with doors closed/open. Set to 00 – doors closed.

ALP Auxiliary Leveling Pump. Turns on Auxiliary Leveling Pump, for Up Re Level operation.

Setting example:- ALP FF:11111111 (No Auxiliary pump Re-level.)

ALP 01: 00000001 (Re-leveling with Auxiliary pump)

--- Spare

--- Spare

PI Position Indication

Setting example: PI 00: 00000000 (Decimal outputs.)

DT Door Time Close Setup (Enable “DTC/DTH cancelling function”)

Setting example: DT 01: 00000001 (DTC/DTH cancelling activated)

LCK EEPROM Lock (unlock default 67)

COD Lock Code (unlock default 89)

--- Spare

--- Spare

E E P R O M S E T T I N G S

13

EEPROM Definitions (Full description)

ADO - Advanced Door Opening setup

When ADO is set to on, the doors open whilst traveling into the floor. The doors shall commence opening when

the lift is within the door zone and the MSU or MSD vane pending direction.

00: 00000000 - Off

01: 00000001 - On

ALP – Auxiliary Leveling Pump operation setup

For hydraulic lifts, ALP can be set to control S01 output to allow Up Re-Leveling using the Auxiliary Pump motor.

For “S01” output to energise when performing an Up Re level set ALP to “01” and DRV to “00”, “02” or “05”.

ALP EEPROM Auxiliary Leveling Pump.

FF: 11111111 “Off”

01: 00000001 “On – operates SP3 for Up Re-Level or inspection”

ANS – Anti Nuisance setup

Set to the number of times a car call is answered without EDP activation before calls are cancelled. Counter is reset

to zero if EDP is activated. If a hall call is present as well as a car call, the counter will not increment.

00: 00000000 “Off”

03: 00000011 ”On – operates after 3 car calls of no EDP in a row.”

1e: 00011110 ”On – operates after 30 car calls of no EDP in a row - Default”

BCC Bottom Car Call setup

The controller shall enter a car call to this setting when the “BOT CALL’ button on the circuit board is pressed.

Eg;

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

BOT - Bottom floor setup

Set value to lowest floor served. (01 to 07 valid values)

Lift resets to “BOT” value when BSL limit is activated.

01: 00000001 (Level 1)

02: 00000010 (Level 2)

03: 00000011 (Level 3)

04: 00000100 (Level 4)

05: 00000101 (Level 5)

06: 00000110 (Level 6)

07: 00000111 (Level 7)

BST – Brake Switch Time

For Traction Lifts only

To prove the machine brakes have lifted, brake monitoring switches mounted on each machine brake in

conjunction with BST and BSW setting, must be used.

The brake monitoring switches are wired to BKS1 and BKS2 inputs.

BST sets the time for BKS1 and BKS2 input to be initiated, once the brake command (BRK relay pulled in) has

been given.

Setting example 01-05: 01: 00000001 = 1s

(Immediate stop) 02: 00000010 = 2s

E E P R O M S E T T I N G S

14

03: 00000011 = 3s

04: 00000100 = 4s

05: 00000101 = 5s

If the input is not detected within the specified time (setting 01-05) the lift shall stop immediately and display BST

in LCD Lift Status.

Setting example 11-15: 11: 00010001 = 1s

(stop next floor) 12: 00010010 = 2s

13: 00010011 = 3s

14: 00010100 = 4s

15: 00010101 = 5s

If the input is not detected within the specified time (setting 11-15) the lift shall stop at the next available floor,

open and close the doors and display “BST” - BRK Lifting Timeout, in the LCD Lift Status. Door open button will

still operate.

BST is a fatal error. Reset is only via a processor POR. BST error shall be disabled when the lift is on inspection

Nb: Default BST setting shall be “13” (stop at next floor). Any other setting than above will default to setting “01”

BSD and BST errors shall be disabled when the lift is on inspection

See also Input - Output, BKS1, BKS2

See also LCD lift status BSD, BST.

See also EEPROM setting BSW

BSW – Brake SWitch Polarity

Used to set brake switch inputs to normally open or closed:

00: 00000000 Normally closed brake contact. Brake not energised, BKS1 and BKS2 inputs must be on

01: 00000001 Normally open brake contact. Brake not energised, BKS1 and BKS2 inputs must be off

Nb: Default BSW setting shall be “01” (Normally open contact)

See also Input - Output, BKS1, BKS2

CIM - Car call InterMediate setup

The controller shall enter a car call(s) to this setting when the “INTER’ button on the circuit board is pressed

40: 01000000 (Level 2)

20: 00100000 (Level 3)

30: 00110000 (Level 3 and 4)

01: 01010101 (Level 2,4, and 8)

CI1 - Car Intermediate 1 setup

Extension of CIM

80: 10000000 (Level 9)

10: 00010000 (Level 12)

CCM - Car Call Mask setup

Floors allowed. (MASK). For this lift only.

This setting lets you define the floors which the lift can serve via car calls.

Set bits to a “1” car call allowed or a “0” for not allowed.

C0: 11000000 (1c,2c)

E0: 11100000 (1c,2c,3c)

F0: 11110000 (1c,2c,3c,4c)

F8: 11111000 (1c,2c,3c,4c,5c)

FC: 11111100 (1c,2c,3c,4c,5c,6c)

FE: 11111110 (1c,2c,3c,4c,5c,6c,7c)

FF: 11111111 (1c,2c,3c,4c,5c,6c,7c,8c)

Note: This feature is not to be used to place a floor on security, as this would also disable the car calls in Fire

E E P R O M S E T T I N G S

15

Service and other modes of emergency operation.

CC1 - Car Call 1 setup

Extension of CCM

80: 10000000 (9c)

C0: 11000000 (9c,10c)

E0: 11100000 (9c,10c,11c)

F0: 11110000 (9c,10c,11c,12c)

Note: This feature is not to be used to place a floor on security, as this would also disable the car calls in Fire

Service and other modes of emergency operation

CNT – CNT input setup

Enables 3 CNT inputs to be inverted

00: 00000000 No inputs inverted.

01: 00000001 DCB. Door close input inverted

02: 00000010 DOB. Door open input inverted

04: 00000100 EDP. EDP input inverted

06: 00000110 DOB and EDP inputs inverted

COD – parameter lockout function

To stop unauthorised adjustments to the EEPROM parameters and to also disable the “Clear fault log” function

(see Section 5 – LCD Fault Log), the COD and LCK parameters are used

COD and LCK must be both set to the default values below to allow other parameters to be adjusted

See also EEPROM setting LCK

COD default. 89: 10001001

LCK default. 67: 01100111

DCM - Down Call Mask setup

Down hall calls allowed for this lift only

This setting lets you define the DOWN floors which the lift can serve via DOWN HALL CALLS

With this setting you may disable DOWN hall calls to floors not allowed

Set bits to a “1” hall call allowed or a “0” for not allowed

40: 01000000 (2d)

60: 01100000 (2d,3d)

70: 01110000 (2d,3d,4d)

78: 01111000 (2d,3d,4d,5d)

7C: 01111100 (2d,3d,4d,5d,6d)

7E: 01111110 (2d,3d,4d,5d,6d,7d)

7F: 01111111 (2d,3d,4d,5d,6d,7d,8d)

DC1 – Down Call 1 setup

Extension of DCM

80: 10000000 (9d)

C0: 11000000 (9d,10d)

E0: 11100000 (9d,10d,11d)

F0: 11110000 (9d,10d,11d,12d)

DLI - Door Limit Invert setup

DLI is only valid when DLM is set to 00, 03 , 04 or 06. See also EEPROM setting DLM.

DLI setting is used to invert the DFO and DFC inputs when normally open (n/o) door limit contacts are used.

DLI: 00 “Limits not inverted.”

DLI: 01 “Limits inverted.” Any setting other than 00 shall default to inverted limits.

E E P R O M S E T T I N G S

16

DLI set to 00 - Limits not inverted. Using n/c limits.

Doors fully open – DFC LED will be on. DFO LED will off

Doors fully closed – DFC LED will be off. DFO LED will on

Doors midway – DFC LED will be on. DFO LED will on

DLI set to 01 - Limits inverted. Using n/o limits.

Doors fully open – DFC LED will be off. DFO LED will on

Doors fully closed – DFC LED will be on. DFO LED will off

Doors midway – DFC LED will be off. DFO LED will off

DLM - Door Limit setup

DLM setting is used to configure the DFO and DFC inputs and the DO and DC relay operation.

Generally; if you have a single door operator, set DLM to 00.

For two door operators, set DLM to 01. (DLI setting shall be ignored).

See also EEPROM setting DLI, DFC, DFO.

Door limit mask.

Setting example: DLM 00: 00000000 The door open and door close limits are wired directly to DFO and DFC

inputs. These inputs may be inverted using the DLI setting.

DLM 01: 00000001 (Used for front and rear doors) The door open and door close limits are

used to operate open and close relays. Normally open contacts from these

relays are wired to DFO and DFC inputs (DLI setting shall be ignored)

DLM 02: 00000010 (Door cam control) DC relay output used to control Cam operation.

Nb: 2 sec delay from DO picking up after DC has dropped. (to allow time

for cam to drop and locks to break, to avoid lock “snagging”).

See also Input - Output, DFC.

DLM 03: 00000011 As per DLM setting “00”, except DO and DC are held up

DLM 04: 00000100 (Used to hold door closed when running) As per DLM setting “00”, except

DC relay picks up whilst running

DLM 05: 00000101 Used for Goods lifts with Peele door operators that automatically Open but

are manual close.

DLM 06: 00000110 (Used to hold door closed when running) As per DLM setting “00”, except

DO has a 400 millisecond drop delay after DFO changes state and DC relay

picks up whilst running and door locks may be opened whilst no demand i.e

the door spear has relaxed.

DLM 07: 00000111 (Manual doors with cam control) DC relay output used to control Cam

operation.DO relay not used. DOP and DCP Faults disabled

Nb: 2 sec delay from DO picking up after DC has dropped. (to allow time

for cam to drop and locks to break, to avoid lock “snagging”).

DPT - Door Protection Time

Sets the amount of time (20 or 50 secs) for doors to reach fully open or fully closed, before DOP or DCP failure.

01: 00000001 = 25 seconds. Default

02: 00000010 = 50 seconds.

All other remaining settings will default to the value of 25s.

DRV - DRiVe type setup

This sets the drive output type. Relay output configurations are changed to suit equipment installed.

Refer to operation section for motion outputs.

00: 00000000. Hydraulic. “Standard hyd. block valve. 3010EN”

01: 00000001. Hydraulic.”DA DynaHyd valve.”

02: 00000010. Hydraulic.“Soft valve. 3010/2CH/S”

03: 00000011. Traction. “VF type 1”. Keb, B&F, Gefran, Zetadyn, C.T.

04: 00000100. Traction. “1,2 speed AC”

E E P R O M S E T T I N G S

17

05: 00000101. Hydraulic. “GMV 3010/S, Blain EV100”, Maxton, Bucher LRV, EECO

06: 00000110. Traction. “VF type 2” C.T.

07: 00000111. Traction. “VF type 3; ABB VF drive”

08: 00001000. Hydraulic. “Bucher VF hydraulic”

09: 00001001. Traction. “CPIK VF drive”

0A: 00001010. Traction. “Same as DRV=03, except with 1.0 sec delay on UD drop (for DB contactor motor short)

Keb, B&F, Gefran, Zetadyn, C.T. See also Inputs-Outputs IRO

0D:00001101 Hydraulic. “Blain EV-4”

DT - Door Time close setup

DT 00: 00000000. Pressing the Door Close Button shall not cancel the door open time (DTC/DTH)

DT 01: 00000001. Pressing the Door Close Button shall cancel the door open time (DTC/DTH)

See also EEPROM setting DTC, DTH

DTC - Door Time Car call close setup

Sets the amount of time before the doors close for a car call whilst on normal operation

Set value for door close time

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

32: 00110010 = 5000ms, “5 seconds”

37: 00110111 = 5500ms, “5.5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values)

DTH - Door Time Hall call close setup

Sets the amount of time before the doors close for a hall call whilst on normal operation

Lobby time (DTL) overrides this setting when lift is at the lobby floor

Recommend DTH is set equal to or greater than DTC

Set value for door close time

The time is set in 100ms increments.

32: 00110010 = 5000ms, “5 seconds”

37: 00110111 = 5500ms, “5.5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values)

DTL - Door Time Lobby call close setup

Sets the amount of time before the doors close after a lobby call is answered when on normal operation

DTL value over-rides DTH value when answering a hall call at the lobby floor

Recommend DTL is set equal to or greater than DTH and DTC

Set value for door close time

The time is set in 100ms increments.

32: 00110010 = 5000ms, “5 seconds”

37: 00110111 = 5500ms, “5.5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values)

DTR - Door Time Recall

When on HR mode, DTR sets the amount of time the doors shall remain open once the lift arrives at the

designated HRF or HR1 recall floor

Setting example: 32: 00110010 = 5000ms, “5 seconds”

See also EEPROM settings, HRF, HR1

See also Inputs-Outputs HRI

E E P R O M S E T T I N G S

18

FD1 – Front Doors 1 setup, levels 1-8

This sets the levels for the front doors to operate on levels 1-8

May be used in conjunction with RD1 and SD1 for selective rear door operation

FD1 A0: 10100000 (Level G and level 2 have front doors)

RD1 50: 01010000 (Level 1 and level 3 have rear doors)

FLOOR DESIG. FRONT DOORS REAR DOORS

3 3 (rear) 4C, 4D

2 2 (front) 3C, 3U, 3D

1 1 (rear) 2C, 2U, 2D

G G (front) 1C, 1U

See also EEPROM setting RD1, SD1

FD2 – Front Doors 2 setup, levels 9-12

This sets the levels for the front doors to operate on levels 9-12

Setting example: E0: 11100000 (Levels 9-11)

May be used in conjunction with RD2 and SD2 for selective rear door operation

See also EEPROM setting RD2, SD2

HFS - Hall Fire Service return floor setup

This sets the hall fire service return floor when HFS input turns on

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

02: 00000010 (Level 7)

01: 00000001 (Level 8)

See also Inputs-Outputs HFS

HF1 – Hall Fire 1 setup

Extension of HFS.

80: 10000000 (Level 9)

40: 01000000 (Level 10)

20: 00100000 (Level 11)

10: 00010000 (Level 12)

HRF – Hospital / Hall Recall Floor

This sets the Hospital /Hall Recall Floor when lift is in HR mode

See also Inputs-Outputs HRI

eg. 40: 01000000 (Level 2)

HR1 – Hospital / Hall Recall 1 setup

Extension of HRF

eg. 40: 01000000 (Level 10)

See also Inputs-Outputs HRF

LCK – Parameter lockout function

To stop unauthorised adjustments to the EEPROM parameters and to also disable the “Clear fault log” function

(see Section 5 – LCD Fault Log), the COD and LCK parameters are used

Table of contents

Other ECD Controllers manuals

Popular Controllers manuals by other brands

BIFFI

BIFFI RPD Series Installation, operation and maintenance manual

Evco

Evco EV3B23 manual

Siemens

Siemens RWD44U Application guide

Autopilot

Autopilot APCLC8DX instruction manual

Tekram Technology

Tekram Technology HOYA IrWave 520UK USB-IrDA installation guide

Rockwell Automation

Rockwell Automation Allen-Bradley Micro820 user manual