ECD Brake Board User manual

Brake Board Manual

Revision Date: Jan 19, 2018

ECD System

Manual

2

E L E C T R O N I C C I R C U I T D E S I G N S P T Y . L T D .

Operation Guide

This manual covers all versions of Brake Board

hardware and software, although some features

mentioned in this manual might not be available on

earlier versions

Electronic Circuit Designs Pty. Ltd.

Factory 11/30 Perry Street • Matraville • NSW • Australia • 2036

Phone 61 2 9316 6909 • Fax 61 2 9316 6797

Email sales@ecd.com.au Web www.ecd.com.au

3

Table Of Contents

Section 1.1 Safety Regulations ...................................................................................... 4

Section 1.2 Obligations & Liability ............................................................................... 4

1.2.1 Following operating instructions................................................................................. 4

1.2.2 Obligations of operator. ................................................................................................ 4

1.2.3 Obligations of personnel. .............................................................................................. 4

1.2.4 Safety during normal operation. .................................................................................. 5

1.2.5 Hazards caused by electric power. .............................................................................. 5

2.1 Product Overview .................................................................................................... 6

2.2 Contents of the Brake Board Kit. ............................................................................. 6

2.3 Connection of ECD Brake Board ............................................................................ 6

2.3.1 24VDC ............................................................................................................................ 6

2.3.2 BKSIGNAL ................................................................................................................... 7

2.3.3 AC SUPPLY .................................................................................................................. 7

2.3.4 VAC BRAKE ................................................................................................................ 7

2.3.5 NO NC C ........................................................................................................................ 7

2.3.6 SIN 1 ............................................................................................................................... 8

2.3.7 Brake Coil and Rectifier Connections ...................................................................... 9

2.4 Setup of Brake Board ............................................................................................. 10

2.4.1 Vmax Adjustment ...................................................................................................... 10

2.4.2 V1 Adjustment ........................................................................................................... 10

2.4.3 T1 .................................................................................................................................. 11

2.4.4 T2 .................................................................................................................................. 11

2.4.5 T3 .................................................................................................................................. 11

2.4.6 T4 .................................................................................................................................. 11

2.5 LED Sequence of Operation .................................................................................. 12

3. Specifications ........................................................................................................... 13

3.1. AC SUPPLY input voltage range ............................................................................. 13

3.2.1 VAC BRAKE output current capable ratings. .................................................... 13

3.3. 24VDC brake board power supply ........................................................................... 13

3.4. REL (NO NC C) contact ratings ............................................................................... 13

4 Example Connection ................................................................................................. 14

4

Section 1.1 Safety Regulations

Installation of this equipment shall be done in accordance with all applicable local

codes

Elevator controllers and other electrical components can cause serious harm or

death if installation guides are not met. It is the responsibility of the installer of our

equipment to ensure that once installed, the equipment does not pose any threat,

danger or hazard.

Section 1.2 Obligations & Liability

1.2.1 Following operating instructions.

In order to ensure safe handling and problem free operation of this

equipment, it is absolutely essential for the relevant personal to be fully

acquainted with the relevant safety regulations.

These operating instructions contain the most important information for

operating the equipment correctly and safely.

These operating instructions, in particular the safety regulations, must be

observed by all those persons who work on the equipment.

Furthermore, all locally applicable rules and regulations relating to accident

prevention and installation must be observed.

1.2.2 Obligations of operator.

The operator undertakes to allow only those persons to work on the equipment

who

Are fully acquainted with the basic regulations relating to safety in the

workplace and accident prevention and to have been trained in handling the

equipment.

Have read the safety regulations and the warning notices contained in these

the operating instructions.

1.2.3 Obligations of personnel.

All personnel charged with working on the machine undertake prior to starting

work to

Observe the basic regulations relating to safety in the workplace and

accident prevention.

Read the operating instructions, in particular the safety regulations, and

confirm by way of their signature that they have understood them.

5

1.2.4 Safety during normal operation.

Only operate the machine when all protective equipment is fully

operational.

Prior to switching on the machine, ensure that the startup can cause no

harm to personnel.

Regularly maintain and check machine for externally identifiable damage

and check that all the safety devices are operational.

1.2.5 Hazards caused by electric power.

Work on the electric power supply may only be carried out by a qualified

electrician.

Check the electrical equipment of the machine at regular intervals.

Repair loose connections and scorched cables immediately.

Keep the control cabinet locked at all times. Access is only permitted to

authorized personnel with a key or tool.

If work has to be carried out on live parts, do this only in the presence of a

second person who can switch off the master switch in an emergency.

The machine causes electromagnetic interference sources. For this reason,

do not use any sensitive equipment in its vicinity.

6

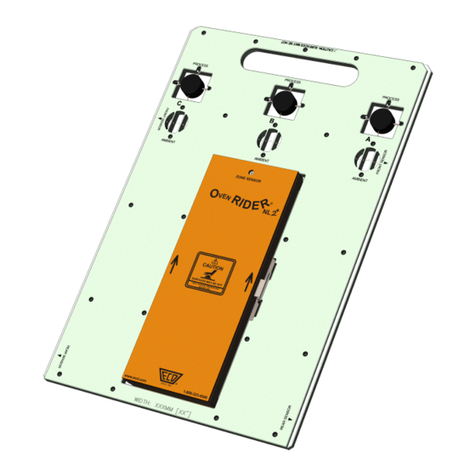

2.1 Product Overview

The brake board is specifically designed to control elevator machine brakes across a wide

range of voltages and loads. It may also be used to control door lock cams to ensure smooth

and quiet cam operation.

The following user adjustable parameters ensures smooth and quiet brake operation and

reduction of back EMF surges;

Brake lift time and voltage

Brake cooling time and voltage. (reduced holding voltage once brake has lifted)

Brake drop time

2.2 Contents of the Brake Board Kit.

1 brake board

1 ferrite core for 24VDC supply

1 1000v 35A bridge rectifier

4 crimp lugs for rectifier

1 power diode for brake coil back EMF protection

1 system manual

2.3 Connection of ECD Brake Board

Below is a list of the connection terminals on the brake board.

24VDC Brake board power supply

BKSIGNAL Brake lift input

AC SUPPLY Brake coil supply AC voltage only. Min 80VAC. Max 240VAC.

VAC BRAKE Brake coil connection

NO NC C Loss of AC output relay

SIN1 Spare input (not used)

For diagrams of the following terminals refer to see Section 4, Fig.7 & 8.

2.3.1 24VDC

The 24VDC input is the power supply to the microprocessor and as such should be as stable as

possible.

Supplied in the kit is a ferrite core that is to be installed on the 24Vdc supply. The wires for

this supply should be twisted together then looped once through the ferrite core (see fig.1).

Note this is particularly important if the board is being supplied from a switch mode power

supply.

7

Figure 1

2.3.2 BKSIGNAL

The BKSIGNAL input is the signal from the lift controller to initiate the brake lift sequence.

This input only requires a voltage free contact.

2.3.3 AC SUPPLY

The AC SUPPLY terminal is used for the AC voltage @ 50Hz for the brake board.

This voltage is regulated by the brake board and output from terminal VAC BRAKE to control

the brake

Important Note: This voltage cannot exceed 240Vac and must be @ 50Hz

2.3.4 VAC BRAKE

The VAC BRAKE terminal is the AC output from the Brake Board to the Brake coil.

As a DC voltage is required for most brake coils, use the supplied rectifier on this output.

2.3.5 NO NC C

The NO NC C relay contacts are used to signal to the lift controller that a fault has occurred

with the brake board, inhibiting any further lift operation. See example Section 4, Fig. 6 & 7,

where the relay C & NO contacts are used for the controller PRV (prove) input.

When the brake board is functioning normally, the fault relay will be energized.

When any of the faults listed below are detected the fault relay will drop out:

Loss of AC SUPPLY. “Loss of AC!” will be displayed on the LCD. (No AC voltage at

AC SUPPLY, Fig. 2). Brake board will remain inoperative until AC SUPPLY restored.

8

Figure 2

Loss of 24VDC

Triac shorted. “Triac damaged!” will be displayed on the LCD. (Fault detected with

Triac, Fig. 3).

This fault is a fatal error and requires a 24VDC reset. Note: If a triac fault is detected

while the brake board is operating, the brake board will finish the run and set the Triac

damaged fault when BK SIGNAL turns off.

Figure 3

The relay contacts are rated as follows:

Max Voltage: 125 VAC or 60VDC

Max Current: 0.5A

Note: This relay is not rated for use in the Safety Circuit of most elevator controllers. If the

intend use of relay C and NO contacts is to open the Safety Circuit then an appropriately rated

slave relay must be used.

2.3.6 SIN 1

This terminal is currently not used and no wires should be connected.

9

2.3.7 Brake Coil and Rectifier Connections

The wiring current rating from the VAC BRAKE output to the rectifier and brake should be

sized according to the load of the brake coil.

The supplied power diode shall to be connected reverse biased at the brake coil for back EMF

suppression.

+-

BRAKE

COIL

Figure 4

10

2.4 Setup of Brake Board

The Brake Board has 6 adjustable parameters which can be adjusted to optimize the operation of

the brake:

Vmax, V1, T1, T2, T3, T4.

T2 T3 T4

V1

Vmax

T1

Note: The graph show the sequence of operation from when BK SIGNAL is triggered

Figure 5

2.4.1 Vmax Adjustment

Vmax is used to set the maximum AC voltage output (VAC BRAKE) and is expressed as a

percentage value of the input voltage (AC SUPPLY)

Vmax is a code protected user adjustable setting. To adjust this setting, first go to LCK and set

to 6789.

E.g.1. Set to 50% if AC SUPPLY is 240VAC and you require 120VAC at VAC BRAKE.

E.g.2. Set to 100% if AC SUPPLY is 240VAC and you require 240VAC at VAC BRAKE.

The Brake Board is shipped with Vmax set at a default value of 35%. The minimum allowed

setting is 10% and the maximum setting is 100%.

After any adjustments to Vmax, it is recommended that LCK be changed to any value other

than 6789, so as to prevent an accidental vmax parameter change, which may cause an over

voltage supply to the brake coil.

2.4.2 V1 Adjustment

V1 is the holding voltage for the brake coil and is adjustable to a percentage of the input

voltage at the AC SUPPLY terminal; it is also interlocked to the Vmax setting so that it cannot

be set to a higher value than Vmax. The minimum allowed setting is 10% and the maximum

setting is 100% or Vmax whichever is the lesser.

The Brake Board is shipped with V1 set at a default value of 25%.

Once the lift is running this value can be adjusted either up or down to give the desired brake

hold voltage and thus cooling effect.

11

2.4.3 T1

This setting is used to control how fast the brake coil will get to full voltage (v max).

It is adjustable in steps of 50 ms.

The minimum allowed setting is 100ms and the maximum allowed setting is 5000 ms.

Default setting is 500ms.

2.4.4 T2

This setting is used to control how long the brake coil will stay at full voltage.

It is adjustable in steps of 50 ms.

The minimum allowed setting is 100ms and the maximum allowed setting is 5000 ms.

Default setting is 1500ms.

2.4.5 T3

This setting is used to control how fast the voltage will reduce to V1 level after the T2 time

expires.

It is adjustable in steps of 50 ms.

The minimum allowed setting is 100ms and the maximum allowed setting is 5000 ms.

Default setting is 500ms.

2.4.6 T4

This setting is used to set how fast the brake voltage will reduce to 0v after the BK SIGNAL is

switched off.

It is adjustable in steps of 50 ms.

The minimum allowed setting is 0ms and the maximum allowed setting is 3000 ms.

Default setting is 500ms.

12

2.5 LED Sequence of Operation

Fitted to the Brake Board are 3 LED’s which can be used to follow the sequence of operation

of the board. The LED’s are red, green and yellow.

During standby state both the red and yellow LED’s are illuminated.

During T1 operation only the red LED is illuminated.

During T2 operation only the green LED is illuminated.

During T3 operation the red and green LED’s are illuminated.

During T4 operation no LED is illuminated.

During V1 operation all LED’s are illuminated.

T2 T3 T4

V1

Vmax

T1

GREEN

LED

RED & GREEN LED

RED

LED RED,YELLOW,GREEN LED

ALL LED'S OFF

Figure 6

The graph shows the LED sequence of operation from when BK SIGNAL is triggered

Flashing yellow LED indicates the brake board is in the following fault state;

Loss of AC SUPPLY. “Loss of AC!” will be displayed on the LCD. (No AC voltage at

AC SUPPLY). Brake board will remain inoperative until AC SUPPLY restored.

Flashing red LED and illuminated yellow LED indicates the brake board is in the following

fault state:

Triac shorted. “Triac damaged!” will be displayed on the LCD. (Fault detected with

Triac). This fault is a fatal error and requires a 24VDC reset. Note: If a triac fault is

detected while the brake board is operating, the brake board will finish the run and set

the Triac damaged fault when BK SIGNAL turns off.

13

3. Specifications

3.1. AC SUPPLY input voltage range

80VAC – 240VAC @50Hz

For AC SUPPLY input voltage less than 80VAC contact ECD for resistor upgrade.

3.2.1 VAC BRAKE output current capable ratings.

Output current ratings reduce as V Max reduces.

Eg. (with 240VAC input);

10 Amps @ 120VAC (V max = 50%)

20 Amps @ 240VAC (V max = 100%)

(with 110VAC input);

10 Amps @ 55VAC (V max = 50%)

20 Amps @ 110VAC (V max = 100%)

3.3. 24VDC brake board power supply

24 VDC

3.4. REL (NO NC C) contact ratings

0.5 @ 60VDC/125VAC

3.5. Setting Values

Default:

Vmax 35%

V1 25%

T1, T3 & T4 500ms

T2 1500ms

Minimum

Vmax 10%

V1 10%

T1 to T3 100ms

T4 0ms

Maximum

Vmax 100%

V1 100%

T1 to T3 5000ms

T4 3000ms

14

4. Connection Example:

The diagrams below show an example of how the Brake Board may be connected

GRD

T1

N240V

10V 18V

TO MAIN

LIFT C/B

POWER CIRCUIT

100-174

100-174/1

15

A

C

B

D

G

123459

67810

OF

SHEET

Date

Control System

Drawing No:

Job No:

Drawn

APP

Rev:

SIGN:

DATE:

CHANGES

Revision:

A

B

C

E

F

L1 L2 L3

WVUPE

PE

OH

OH

KEB

COMBIVERT

Brake Resistor

Temp Sw.

++

-

PB

MOTOR 3

Isolate motor cables

from other wiring

C1

Interference

suppression filter.

L1 L2 L3 PE

2

1

4

3

6

5

440 VA

110V

c

C2

5

6

3

4

1

2

1999-2006

BRAKING

RESISTOR

C/B1 16A

N

R

S

T

OH1

OH2

SIS

SHAFT

INFORMATION

SYSTEM

0v 24v

C/B3 2A

WVU

TO SHEET 2

"10" G/1

Terminals on Circuit Boards

Field Terminals

Controller Terminals

X4

"See Inst. Man.

6.3.1 for Conns."

EN

30 31 32 33 34 35 shield

5v AABBGND

__

CAUTION: Ensure any

unused conductors

within encoder cables are

terminated or islolated.

100-174

CONTROLLER

0V 24V

10V 0V

BR1

-

+

F1 4A

Therm.

FAN

1

2

COL

CURTAIN

OF LIGHT

NE PH

C/B2 2A

KEB-1BrakeBoard-1SCHVF-PULSE BOARD

25-FEB-08

VF100 KEB

L2A

RCD

10 A

OPEN LIMIT

CLOSE LIMIT

SCHINDLER

VF DOOR OP

C/B5 6A

EARTH

5

6

7

4

3

2

1

1819

CBX

CBX

BR2

+

ECD BRAKE

BOARD

0V

24V

BK SIGNAL

SUPPLY(VAC)

BRAKE(VAC)

C2

14 13

C

NC NO

TO SHEET 2

E/10

IMPORTANT.

TWIST THE 24VDC SUPPLY

WIRES TOGETHER AND LOOP

ONCE AROUND THE SUPPLIED

FERRITE CORE

11 14

12

34

1000V 25A RECTIFIER

SUPPLIED BY ECD

C/B4 6A

1

2

4

3

C

CNO

NO

DO

DC

SP4

CNO

EDP

21 22 22

21

DOB

BK

X3.18 X3.19

KEB

CRAWL

SPEED

100-174

TO DFO

SHEET 5

0V

0V

TO DFC

SHEET 5

24V

0V

PULSE

A+ (5V)

GND

PULSE BOARD

TO SHHET 3

F/4

TO ENCODER 5V

POSITIVE CHANNEL

AND ENCODER GND

C/B6A

Figure 7

15

CAR DOOR

FRONT

LANDING LOCKS LANDING LOCKS

MSD MSD

MSU

LEV

DZ MSU

DN

DIR

LIMIT

UP

DIR

LIMIT

LR DZ

LR

SAF

LR

C

BRK-N/O

M2

N Neutral

M4

L2A

C N/O M1 M3

N Neutral

J29J6 J5

16

39 40 41

44

100-174

100-174

TOP OF CAR

INSPECTION

COMMON

INSP BOX

Terminals on Circuit Boards

Field Terminals

Controller Terminals

CONTROL CIRCUIT

100-174

100-174/2

2 5

A

C

B

D

G

1 2 3 4 5 96 7 8 10

OFSHEET

Date

Control System

Drawing No:

Job No:

Drawn

APP

Rev:

SIGN:DATE:CHANGES

Revision:

A

B

C

E

F

SAFETY

GEAR

SLACK

ROPE

C

46

C

0V

+24V

X3.15

X3.16

BK

A2

X3.20

X3.21

X3.3

X3.4

X3.5

N/ON/O N/O

47

Main cont.

control.

Braking

control.

C

DF UF SP3 SP1 SP2

N/O N/OC C C

DN UP

X2.1

X2.2

X3.1

BK

+24V

21 22

TO "C2-A1"

AREA D/9

TO "X3.21"

AREA C/5

C2

31 32

X3.9

X3.10

X2.23

X2.11

X3.11

X3.12

X3.17

Decel Control

PRV

1999-2007

0V

KEB COMBIVERT

C2

A2

X2.4

X2.3

C2

43 44

N/O N/OC C

LRX

c

BRK

C2

21 22

J18

PIT

LADDER

TOP

10

GOV

OVER

SPEED

STOP

BUTTON

IN CAR

D.O.T.

LIMIT

11 11/1 13

10/1

ETS

(if applies)

11 14

PIT

LADDER

BOTTOM

GOV

TENSION

WHEEL

12

U.O.T.

LIMIT

14

11 14

15

16/1

CAR DOOR

REAR

SRTD SG

TRAP

DOOR

MAINT. BOX

STOP

OT

21

24

A1

SPD

+24V

OT

(if applies)

NB. SPD relay and OT contacts

for lifts with ETS. (above 1.0 m/s)

(if applies-see NB)

A2

(if applies)

C1

A1

A2

X3.6

0V

1.2K 1W

0V

1.2K 1W

1.2K 1W

24v

TO SHEET 1

AREA D/6

SB

TR

TO SHEET 1

AREA D/6

KEB-BRAKEBOARD-1ECI

24-JULY-07

Positioning/Relevelling VE

Rated/Max. speed VN

Insp. speed VI

Control release

Reset

Cont. Control

+24V

+24V

+24V

GND

GND

GND

Forward

Reverse

Intermediate. speed V1

CBX

A1

A2

TO SHEET 1

B/6

BRAKE BOARD

BK. Use 2P

110vac relay

DDLR UDLR

DDLR UDLR

14 14

1111

A2 A2

A1 A1

Figure 8

16

E L E C T R O N I C C I R C U I T D E S I G N S P T Y . L T D .

Operation Guide

Electronic Circuit Designs Pty. Ltd.

Factory 11/30 Perry Street • Matraville • NSW • Australia • 2036

Phone 61 2 9316 6909 • Fax 61 2 9316 6797

Email sales@ecd.com.au Web www.ecd.com.au

Table of contents

Other ECD Controllers manuals

Popular Controllers manuals by other brands

YASKAWA

YASKAWA E1000 Technical manual

BoomToneDJ

BoomToneDJ EZ Strobe user manual

VERDER

VERDER Carbolite Gero EVT 12/450B Installation, operation and maintenance instructions

Robotis

Robotis 2XL430-W250 manual

PCS

PCS PulseWorx TEC Installation guide and owner's manual

JUMO

JUMO dTRANS CR 02 operating manual