ECD V-M.O.L.E. Solar User manual

QUICK REFERENCE GUIDE

INTRODUCTION

1

This procedure guides you through a

typical data collection process. If you need

additional detail, consult the Users Help

Guide in the software.

The M.O.L.E.®Thermal Profiler depends

on the MAP (Machine-Assembly-Process)

software to control how it collects and inter-

prets data. Several kinds of data runs may

need to be performed to achieve desired

information, or the same data run may be

performed repeatedly over time to monitor

one process. Either way, each data run

must be set up at least once.

The MAP software includes wizards that

help you get started quickly, even if you are

a beginner or infrequent user. With settings

for the five likely -workflows, you can get up

and running in no time. This Guide docu-

ments the process used with the Fresh

Start workflow wizard.

OPERATION - FRESH START 2

2) Using the USB cable, connect the

M.O.L.E.®Thermal Profiler to the com-

puter.

3) Make sure the M.O.L.E.®Thermal

Profiler Power Pack battery is fully

charged. When a M.O.L.E.®Thermal

Profiler is selected, the software status bar

displays the current battery voltage.

4) On the File menu, click New. The Start

dialog box appears with the five workflow

wizard options.

1) Double-click the M.O.L.E.®MAP

application icon to start the software.

Step 1: Set MAP information

OPERATION - FRESH START

3

When navigating through the wizard, the

step list on the left of the dialog box uses a

color key to inform the user of the progres-

sion through the wizard.

Current Completed Remaining

5) On the Start dialog box, click the Fresh

Start command button and the workflow

wizard appears.

6) Select the desired instrument from the

list box to make active. If there are none

listed, click the Scan for Instruments

command button to detect all available

instruments.

7) Click the Next command button.

OPERATION - FRESH START 4

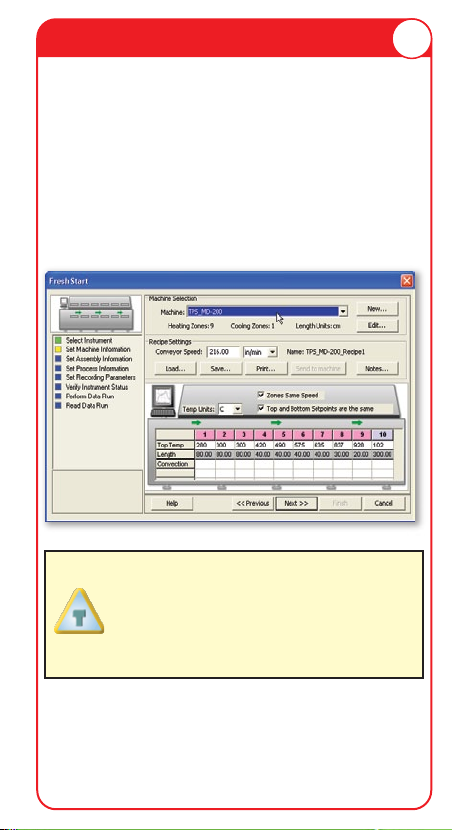

8) Select a machine from the drop-down

list. If the desired machine does not appear

in the list, click the New command button to

create a new machine.

9) Set the machine recipe settings, such as

Conveyor Speed, Zone Temperatures and

Temperature units.

The software includes features to save

and load machine recipe setting files

(*.OVS) These files are helpful so the user

can quickly recall machine information

and ensure it is always the same.

10) Click the Next command button.

5OPERATION - FRESH START

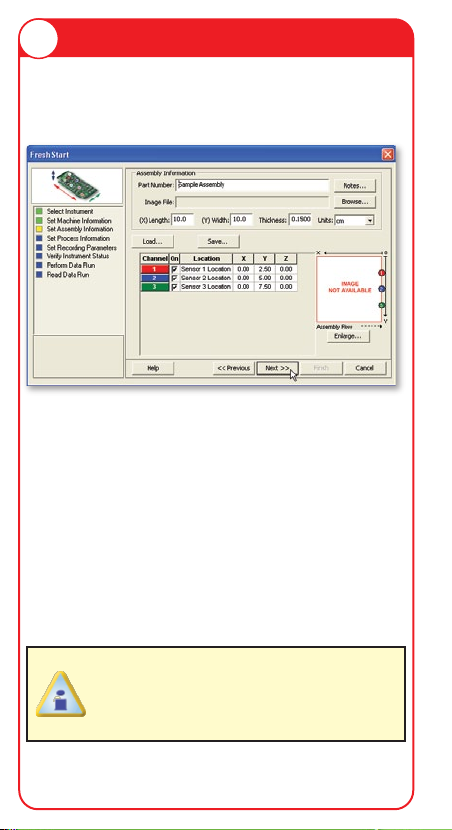

11) Enter the assembly information such as

part number, test product size, sensor

locations and a product image.

12) Click the Next command button.

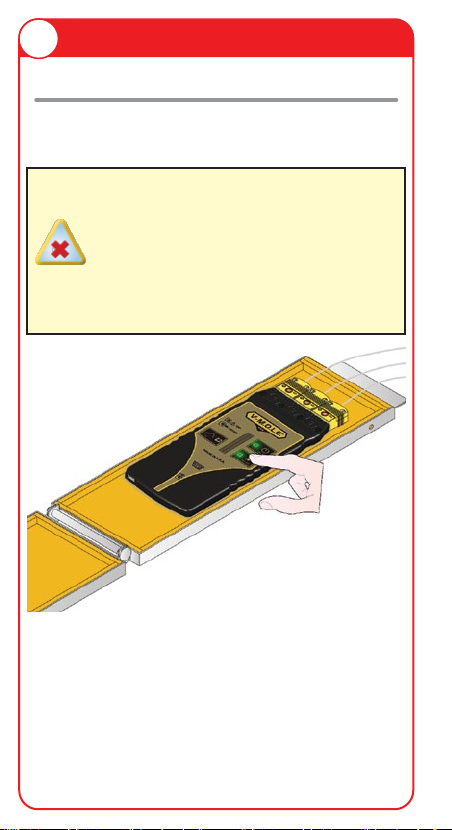

13) Unwind the sensor leads and insert the

connectors into the M.O.L.E.®Thermal

Profiler. Make sure to connect them to the

same channel(s) that were configured in

the wizard workflow.

14)

Locate the thermocouple sensors on a

test solar cell.

When locating a thermocouple sensor on

a test solar cell, make sure it is slightly

curved creating the proper tension

required to remain in place.

6

OPERATION - FRESH START

15) Select your process specification. The

user can select a standard or user created

Paste from the database. Then choose the

Profile Type (Ramp-Soak-Spike or

Ramp-to-Spike). If your Paste does not

appear in the database list click the New

command button to create a new one.

16) Click the Next command button.

When the user selects a paste from the

database, they can use the radio buttons

below the drop down box to filter the user

created pastes from the master paste

specifications.

OPERATION - FRESH START

7

The M.O.L.E.®Thermal Profiler

should be programmed to record data

every 0.1 seconds which is optimal

for solar metallization processes.

17) Set Recording Parameters such as the

instrument name, recording interval, start

parameters and stop parameters. This step

is where the user can also turn a sensor

channel ON or OFF, set the sensor location

description and sensor type.

18) Click the Next command button.

8

OPERATION - FRESH START

If everything is OK, the dialog box displays

a GREEN sign. If there are any items that

may prevent the user from collecting good

data, they are highlighted and a RED sign

is displayed.

19) Verify the instrument status. This dialog

box displays the health of the M.O.L.E.

Thermal Profiler such as battery charge,

internal temperature, thermocouple

temperatures.

20) Click the Next command button.

21) Review the oven settings and click the

Next command button to continue.

9OPERATION - FRESH START

Step 2: Perform Data Run

Never permit the M.O.L.E.®Thermal

Profiler to exceed the absolute maximum

warranteed internal temperature, as

permanent damage may result. The

thermal barrier supplied with the system is

specifically designed to protect the

M.O.L.E.®through typical solar metalliza-

tion processes.

2) After the oven stabilizes:

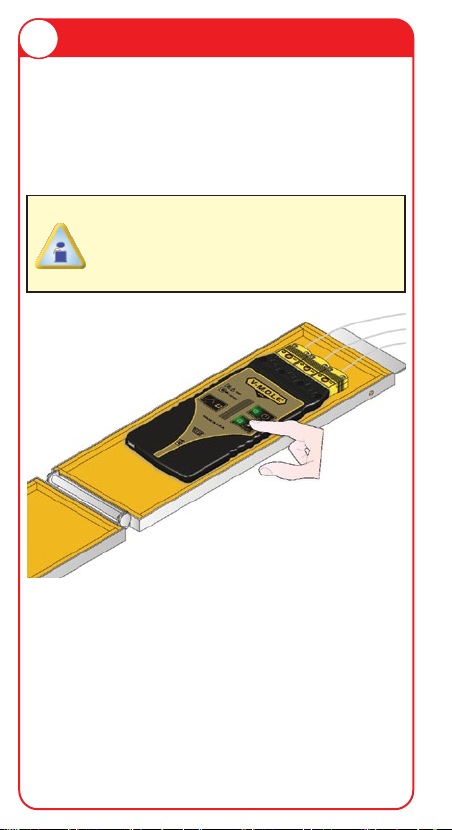

1) Place the M.O.L.E.®Thermal Profiler in

the thermal barrier.

• Press the ON/OFF button.

• Press the Record button.

• Close the thermal barrier making sure it

is fully latched and the thermocouple

sensor wires are not damaged.

10

OPERATION - FRESH START

The Record button will need to be

pressed even if the M.O.L.E.®Thermal

Profiler is configured to begin recording

data if start parameters Trigger Tempera-

ture or Points Delay are configured.

It is highly recommended that protective

gloves are used when retrieving the

thermal barrier from the oven and when

opening the thermal barrier.

3) Pass the thermally protected M.O.L.E.®

Thermal Profiler and test solar cell through

your process.

4) As the test solar cell and M.O.L.E.®

Thermal Profiler emerge from the machine

carry to a table or flat surface.

11 OPERATION - FRESH START

5) Open the thermal barrier and if the

Record LED is still flashing this means the

M.O.L.E.®Thermal Profiler is still record-

ing and it must be stopped by pressing the

Record button.

If a thermocouple sensor is removed

before the M.O.L.E.®Thermal Profiler has

stopped recording data, the data for that

channel will show as OPEN T/C.

6) Remove the M.O.L.E.®Thermal Profiler

from the thermal barrier. Handle it carefully,

as the case may still be warm.

7) Disconnect the thermocouple sensors

from the M.O.L.E.®Thermal Profiler.

12

OPERATION - FRESH START

Step 3: Read Data Run

1) Restore the software and click the

Finish command button to read the data

run from the M.O.L.E.®Thermal Profiler.

On this step of the wizard, the user has the

ability to remove a selected data run from

the V-M.O.L.E.®Thermal Profiler by either

selecting the Delete After Reading check

box or selecting the Delete command

button and removing it before download-

ing.

13 OPERATION - FRESH START

2) When the data run has been down-

loaded, the software will prompt the user to

save the data run file (*.XMG).

3) When finished, click the Save command

button.

14

OPERATION - FRESH START

4) The software then prompts the user if

they want to enter Prediction mode. Enter-

ing prediction mode enables the user to

change a zone temperature values or the

conveyor speed and predict the outcome of

that change on the data run profile.

5) Click the Predict command button to

enter Prediction mode or Done to complete

the workflow wizard.

The information is automatically saved in

the data run file (*.XMG) and the experi-

ment data can now be analyzed with the

software tools.

A47-6342-16 Rev-3.0

© 2010 ECD. All Rights Reserved. Foreign and US Products of

ECD are covered by US Patents and Patents Pending.

The trapezoidal ECD logo®, and M.O.L.E.® (Multi-Channel

Occurrent Logger Evaluator) are registered trademarks of ECD.

This manual suits for next models

1