35 Operating Instructions |airLPT216

Version 1.2 |Dated: 07.03.2017

Operating instructions

Air leakproof tester (airLeakProofTester 216)

airLPT216

Version 1.2 Dated 07 March 2017

An air leakage test on air conditioning systems is

necessary to check for compliance with the required

air tightness class and thus the airtightness of the

ductwork system. The relevant standard on which

ventilation and air conditioning systems are based

is EN 13779 “Ventilation for non-residential buildings

– Performance requirements for ventilation and

room-conditioning systems”.

Leaking ventilation systems consume unnecessary

energy. The more airtight the ducting the higher the

energy savings. Furthermore, leaking systems can

have negative effects on hygiene. Lack of air flow

rate in the destination due to leakages can have ne-

gative effects on the room conditions.

The airLPT216 air leakproof tester is used to deter-

mine the quantity of air leaked and the air tightness

class achieved according to EN 13779, or EN 1507 and

EN 12237, especially in HVAC systems. Due to the au-

tomatic determination of the air tightness class there

are a wide range of applications from very small sys-

tems (7 m2surface area) through to large systems.

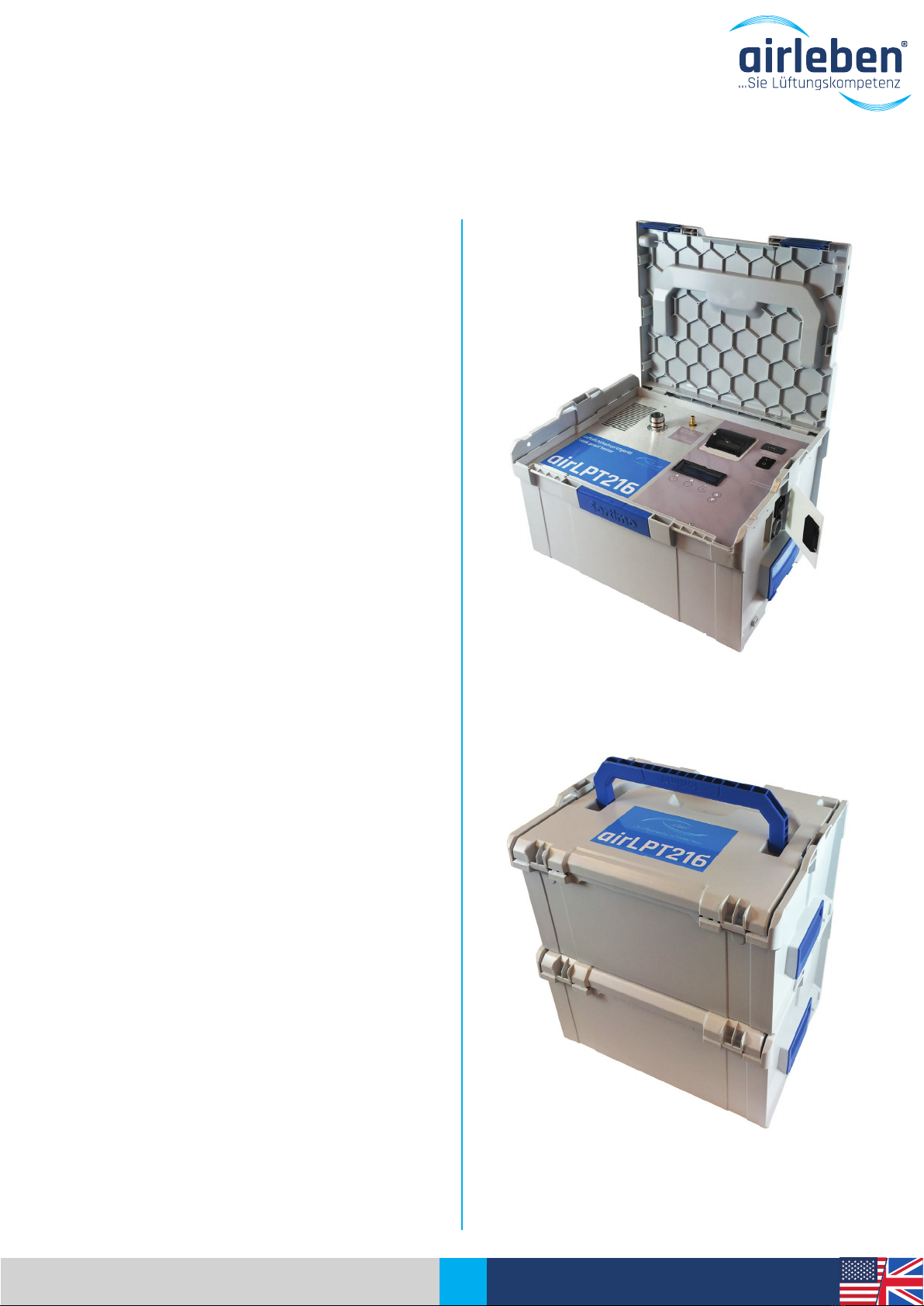

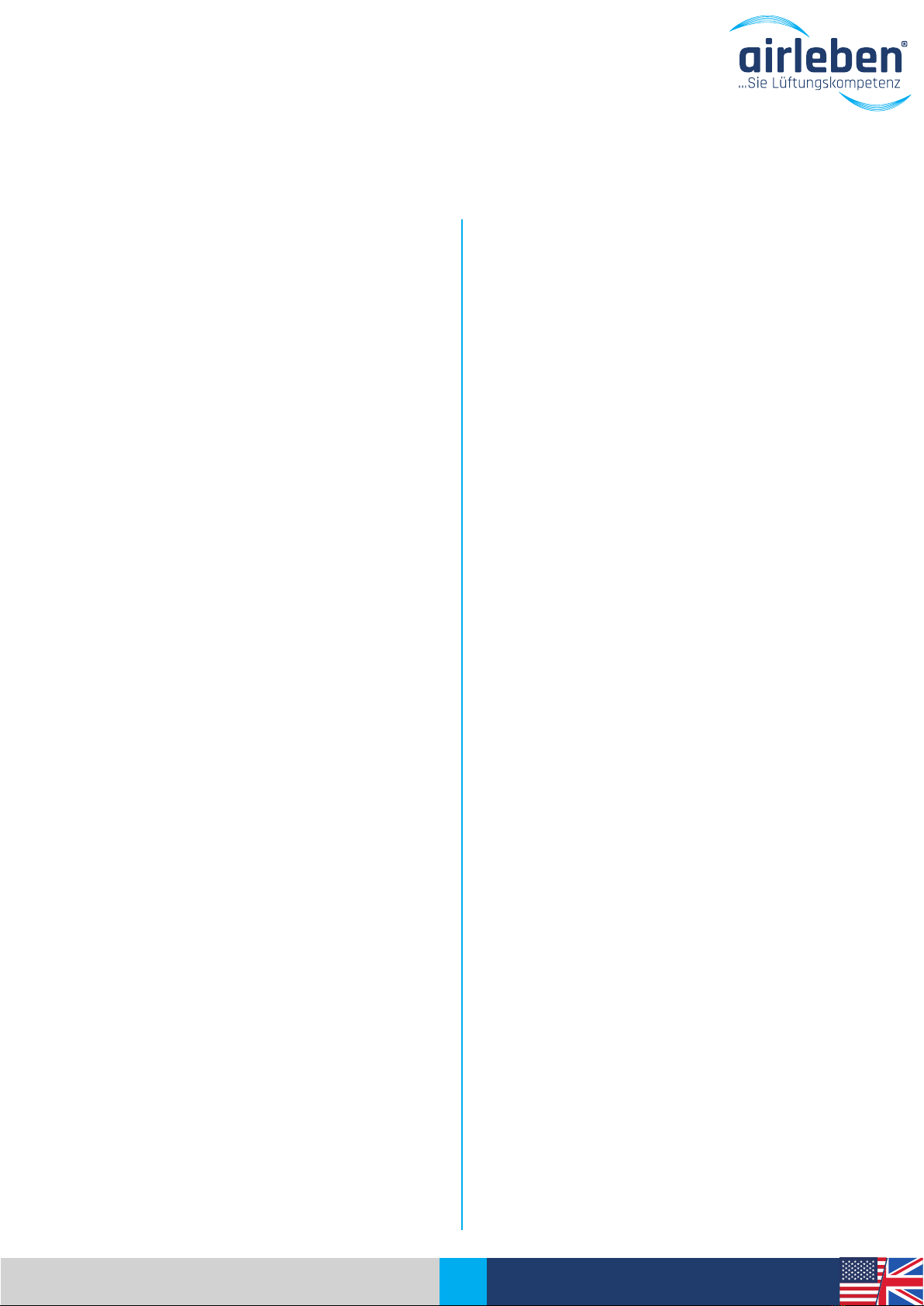

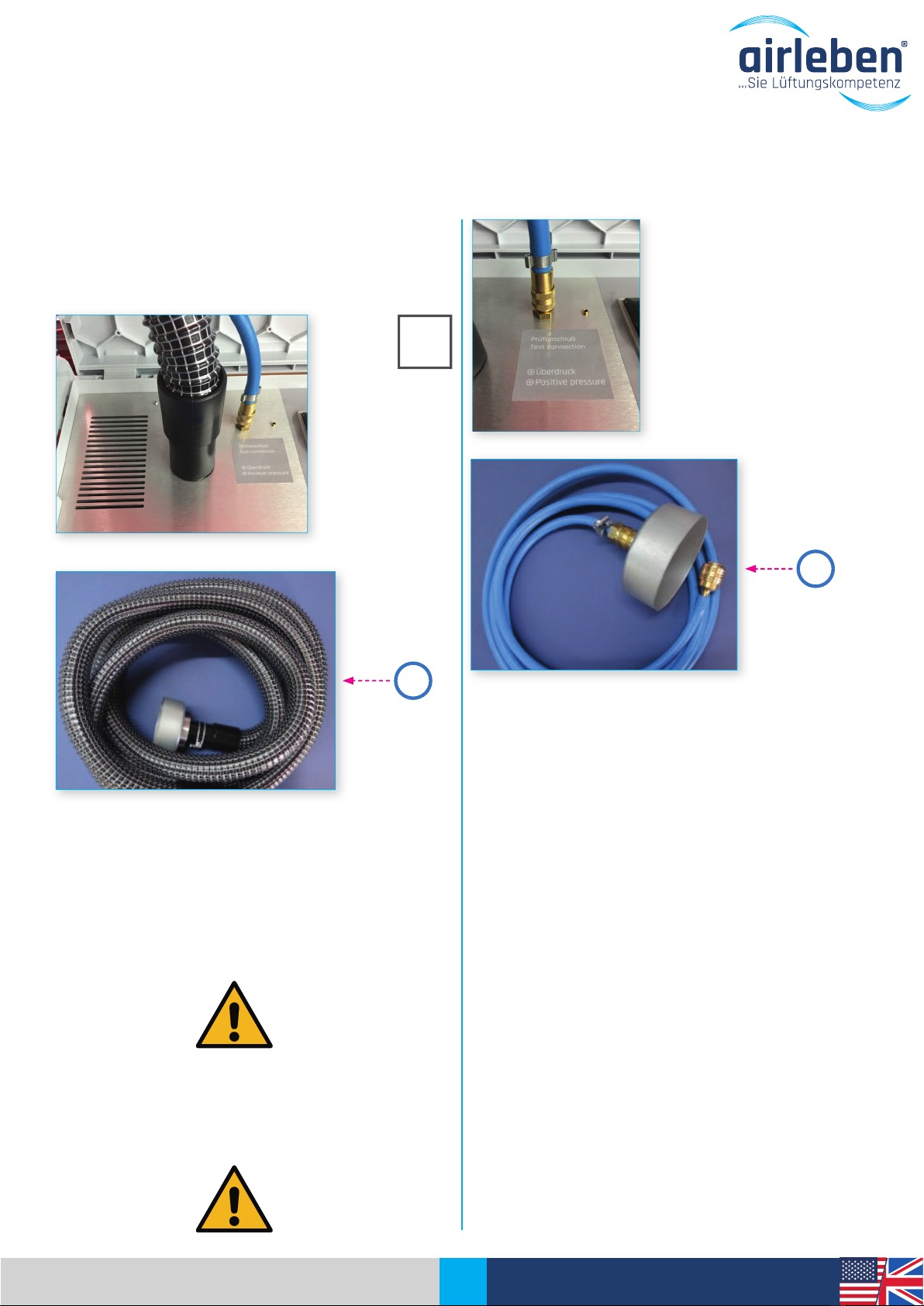

The airLPT216 air leak proof tester, with its complete

equipment and integration in a stable plastic case,

has been especially designed for use on construction

sites. It weighs less than 9.5 kg and is therefore light

and easy to transport. The hoses and accessories are

handily packed in a stable plastic case.

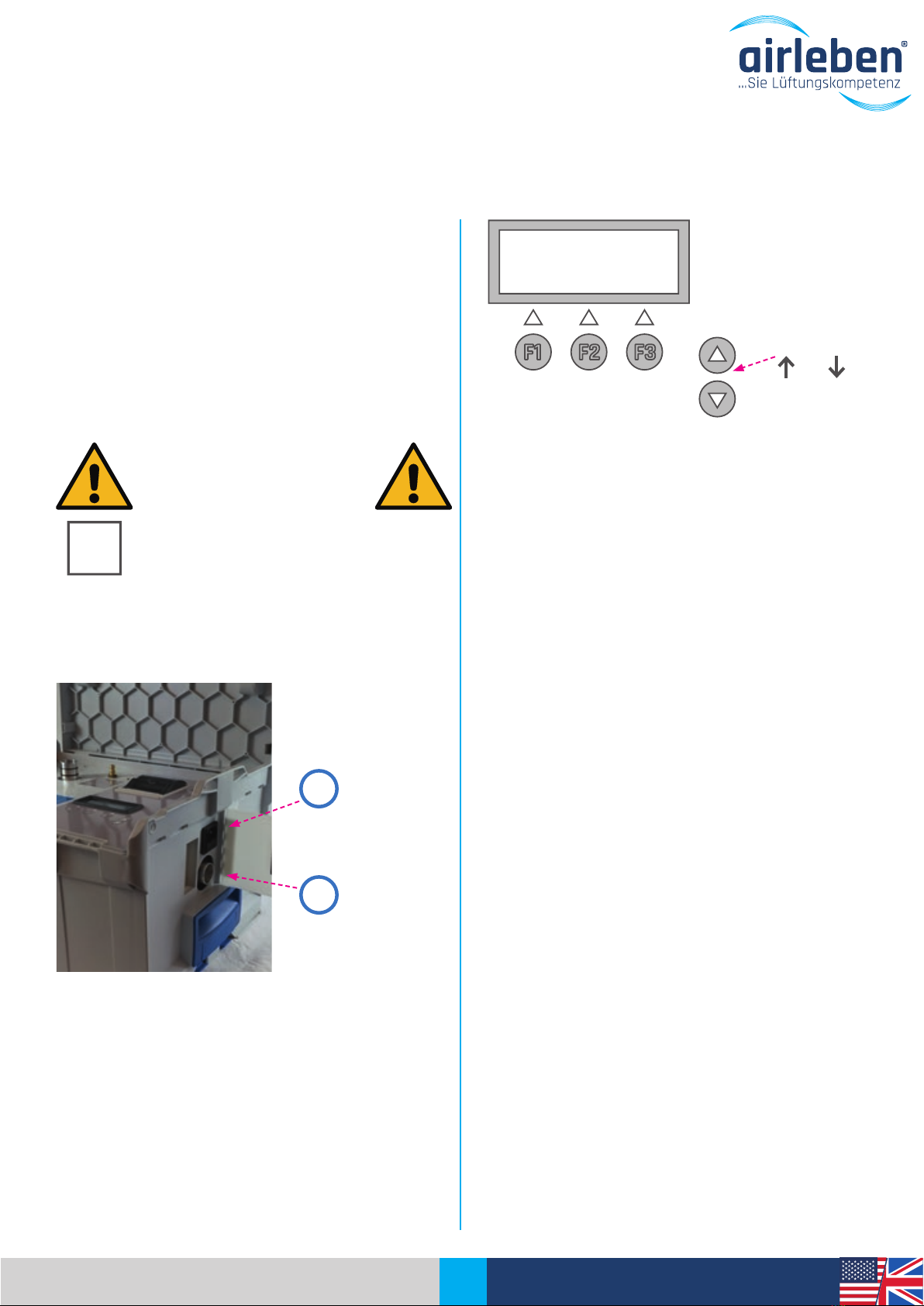

Clear and user-friendly menu navigation makes the

device easy to operate. It is suitable for positive and

negative pressure tests. All connections, the display

and the thermal printer are clearly arranged on the

top. The air hose connection for the negative pressu-

re measurement is at the side.

The automatic measurement sequence to EN 1507

and EN 12237 lasts 5 min. The air duct system to be

tested is sealed off airtight from the rest of the sys-

tem. It is pressurised, the test pressure is controlled

automatically and is kept constant (as defined by the

standard +/- 5 %) and the leakage air rate is deter-

mined. The measurement record is printed out using

an integrated thermal printer or the data is transfer-

red to a USB stick.

You are interested in further technical data and de-

tails of the airLPT216 air leak proof tester?

Then visit our website www.airleben.de or call us on

+49 3621 51445-0, we will be happy to advise you.