10

DM-4610

OPERATION

HANDLING FUEL

WARNING DANGER

• HANDLE FUEL CAREFULLY. IT IS EXTREMELY

FLAMMABLE. FOLLOW ALL RULES LISTED

BELOW TO HELP PREVENT FIRE OR

EXPLOSION WHICH MAY RESULT IN SEVERE

INJURY OR DEATH.

• AFTER REFUELLING TIGHTEN FUEL CAP

FIRMLY AND CHECK FOR LEAKAGE. IN CASE

OF FUEL LEAKAGE REPAIR BEFORE STARTING

OPERATION SINCE THERE IS A DANGER OF

FIRE.

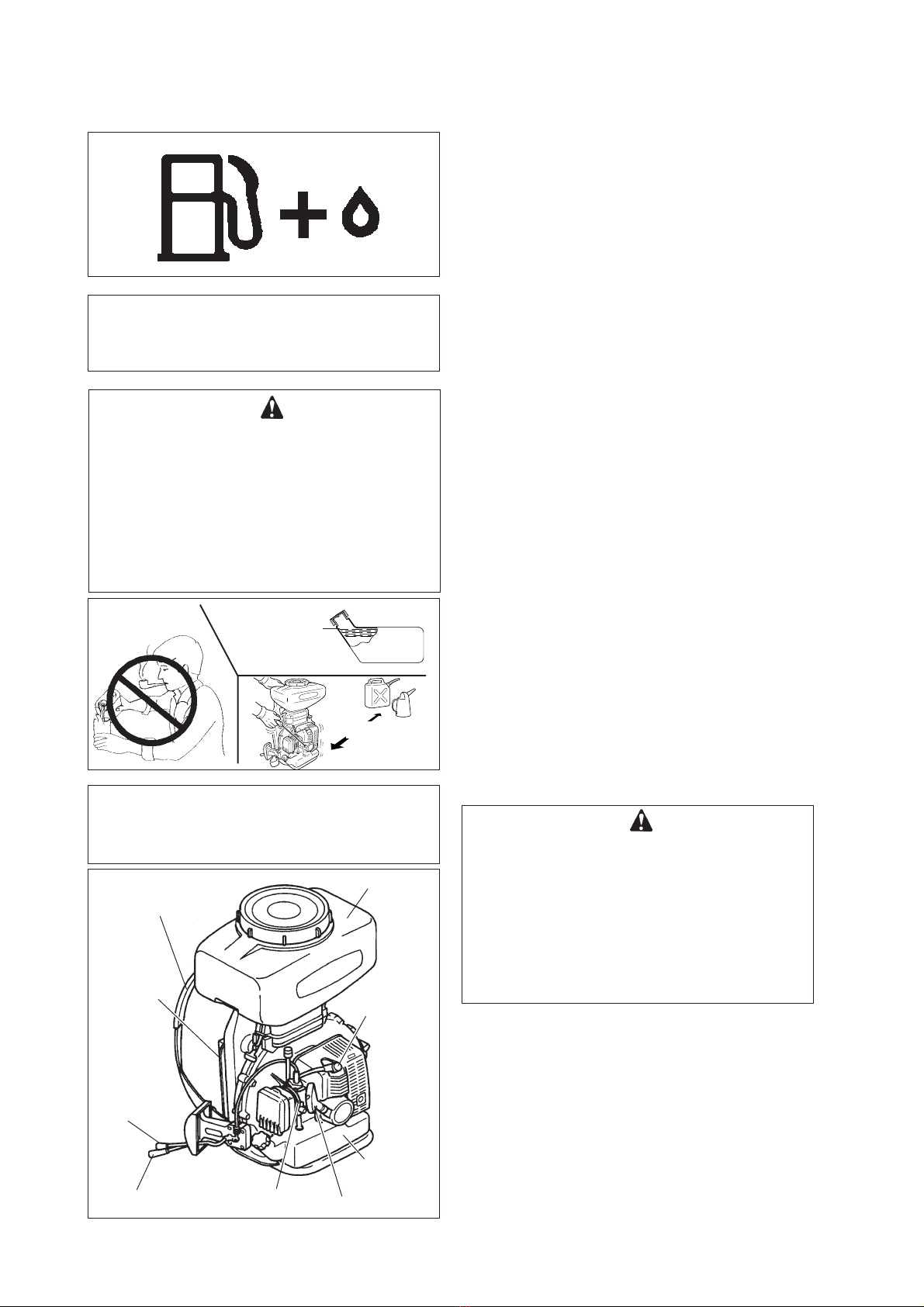

• Never smoke or allow flame or sparks near fuel.

• Always fill the fuel tank outdoors. Never pour fuel

indoors.

• Always remove the fuel cap slowly to relieve any

pressure buildup in the tank.

• Never refuel the engine when it is hot or running.

• Always use an approved, safe fuel container.

• It is not permitted to fill fuel above the shoulder level of

fuel tank.

• After fuelling, always wipe away spilled fuel.

• Always move at least 3 m away from the fuelling spot

before starting the engine.

• Never store the unit with fuel in the tank a fuel leak

could start a fire.

FUEL

•Fuel is a mixture of regular grade petrol and an air-

cooled 2-stroke engine oil of reputable brand name.

Minimum 89 Octane unleaded petrol is

recommended. Do not use fuel containing methyl

alcohol or more than 10 % of ethyl alcohol.

•Recommended mixture ratio; 50 : 1 for ISO-L-EGD

Standard (ISO/CD 13738), JASO FC,FD grade and

ECHO Premium 50 : 1 oil and 25 : 1 for JASO FB

grade oil.

- Do not mix directly in engine fuel tank.

- Avoid spilling petrol or oil. Spilled fuel should always

be wiped up.

- Handle petrol with care, it is highly inflammable.

- Always store fuel in approved container.

NOTE

Stored fuel ages. Do not mix more fuel than you

expect to use in thirty (30) days. Do not mix directly in

fuel tank.

CHEMICALS

WARNING DANGER

• AVOID DIRECT CONTACT AND INGESTION OF

CHEMICALS. SOME CHEMICALS MAY BE

STRONGLY HARMFUL TO HUMAN AND

ANIMALS. MISUSE OF THE CHEMICALS CAN

RESULT IN SERIOUS POISONING OR DEATH.

• SULFUR IS A VERY INFLAMMABLE MATERIAL.

WHEN SPRAYING CHEMICALS CONTAINING

SULFUR, CAREFULLY READ EXPLANATION ON

APPLICATION ATTACHED TO THE CHEMICALS

AND TREAT THEM WITH CARE.

• Stop engine and put the unit down when filling

chemicals.

• Be sure to close valve or shutter before filling

chemicals.

• Do not overfill chemicals and wipe spillage away

immediately.

• Follow all precautions and instructions in the label of

chemicals when handling.

• Never allow untrained persons or children to handle

chemicals and the unit.

• Secure chemical tank cap firmly to avoid leakage of

chemicals during the operation.

NOTE

Do not dilute chemicals directly in the chemical tank.

Always use fresh, dry (powder/granule/fertilizer)

chemicals.

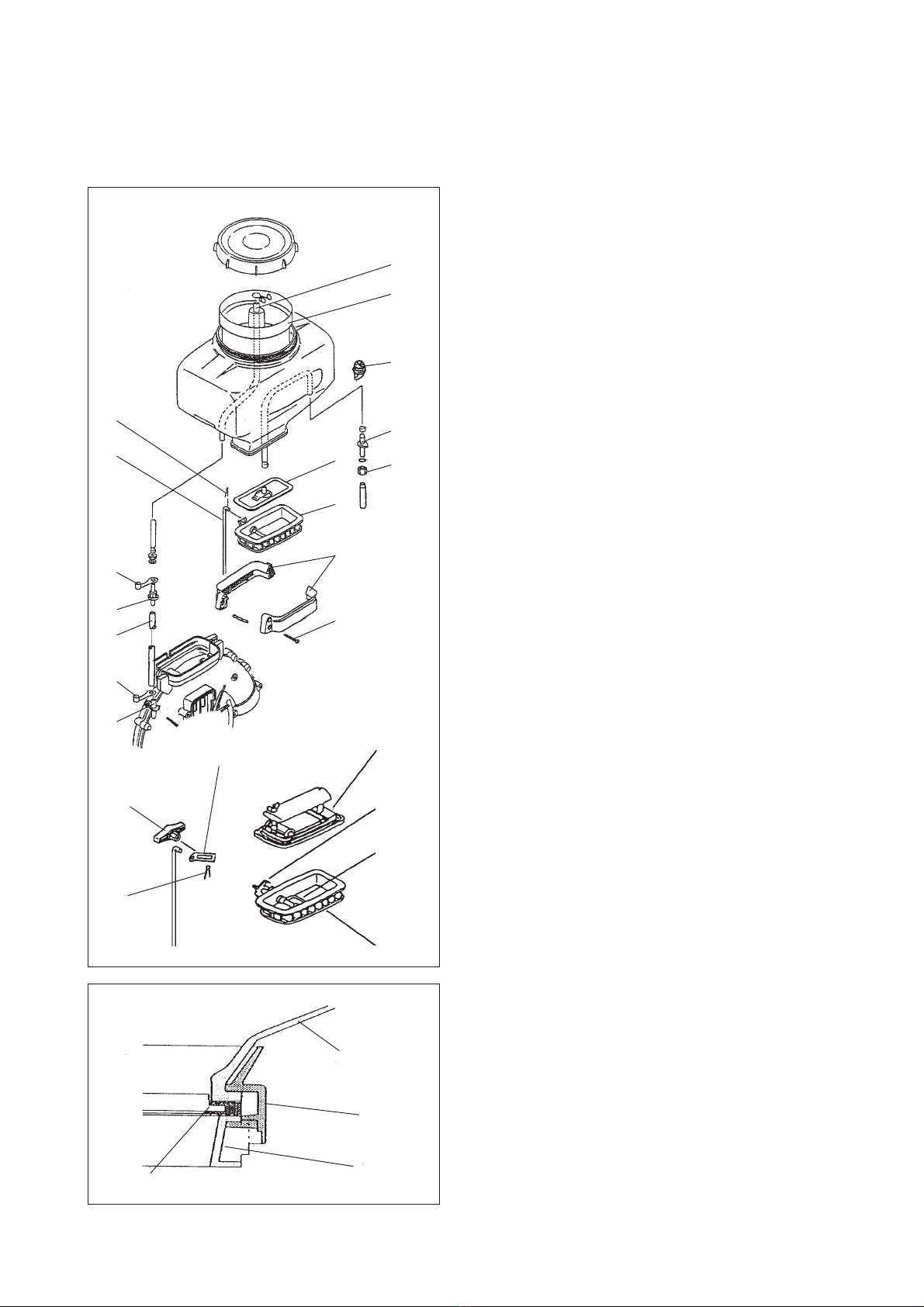

Throttle control

lever

Shutter control lever Carburettor Starter handle

Fuel tank

Spark plug

Straps

Cushion

back-plate

Chemical tank

Shoulder level

Fuel tank

3 m