2

Table of ConTenTs

Introduction................................................................2

- The Operator's Manual .......................................2

Safety .........................................................................3

- Manual Safety Symbols and Important

Information .........................................................3

- International Symbols.........................................3

- Personal Condition and Safety Equipment ......... 3

- Equipment Check................................................6

Description.................................................................7

Contents .....................................................................8

Assembly....................................................................9

- Install Blower Pipes............................................9

- Remove Blower Pipes.......................................10

Operation..................................................................10

- Fuel ...................................................................10

- Starting Cold Engine.........................................12

- Starting Warm Engine....................................... 13

- Stopping Engine................................................13

- Operating Blower..............................................14

Maintenance.............................................................15

- Skill Levels .......................................................15

- Maintenance Intervals.......................................15

- Air Filter ...........................................................16

- Fuel Filter..........................................................16

- Spark Plug.........................................................17

- Cooling System.................................................17

- Exhaust System.................................................18

- Carburetor Adjustment......................................20

- High Altitude Operation .................................20

Troubleshooting .......................................................21

Storage .....................................................................23

Specications ...........................................................24

Servicing Information ..............................................28

- Parts/Serial Number..........................................28

- Service ..............................................................28

- ECHO Consumer Product Support...................28

- Warranty Card...................................................28

- Additional or Replacement Manuals ................28

Specications, descriptions and illustrative material in this

literature are as accurate as known at the time of publica-

tion, but are subject to change without notice. Illustrations

may include optional equipment and accessories, and may

not include all standard equipment.

InTroduCTIon

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and on-the-

job dependability. Read and understand this manual. You will nd it easy to use and full of helpful operating tips and

SAFETY messages.

The operaTor'smanual

Keep it in a safe place for future reference. Contains specications and

information for operation, maintenance, storage, and assembly specic

to this product.

Copyright© 2013 By Echo, Incorporated

All Rights Reserved.

1

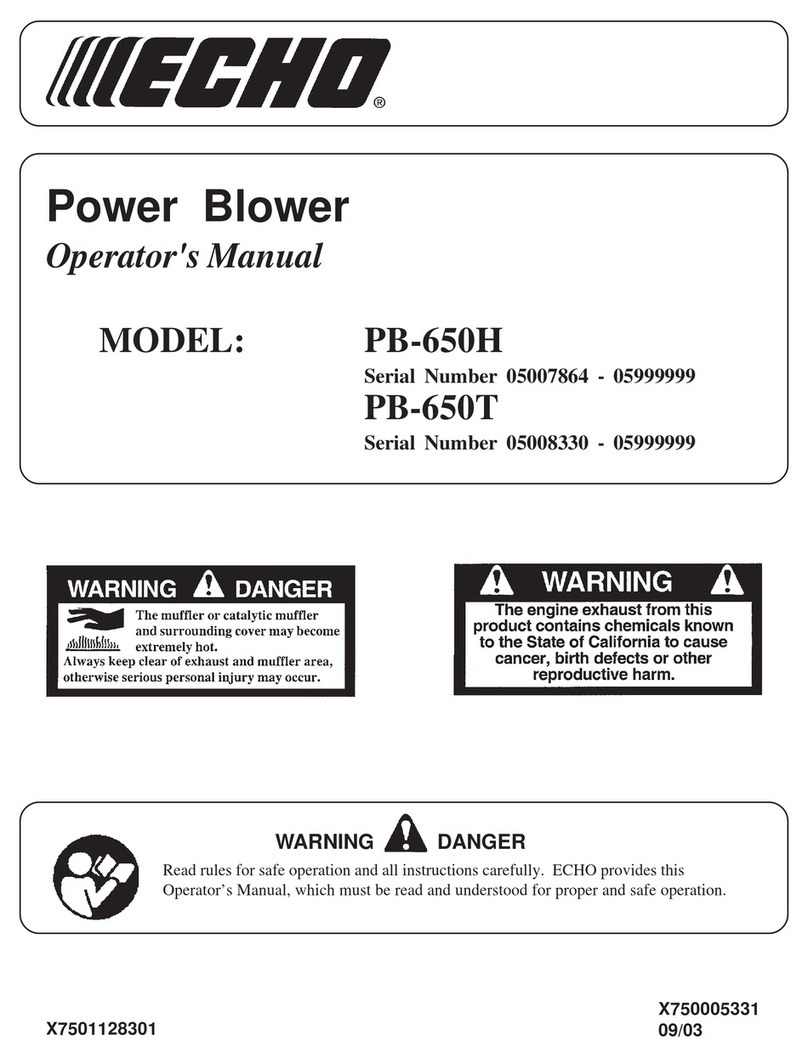

Power Blower

Operator's Manual

MODEL PB-251

X75300

09/06

X753118

WARNING

Read rules for safeoperation andinstructions carefully. ECHO providesthis Operator's

Manual,which must be read and understood for proper and safe operation.

PB251ef_091206.pmd

Power Blower

Operator's Manual

MODEL PB-250

WARNING

Read rules for safe operation and instructions carefully. ECHO provides this

Operator's Manual, which must be read and understood for proper and safe opera-

tion.

X750012940

X7501182000