2

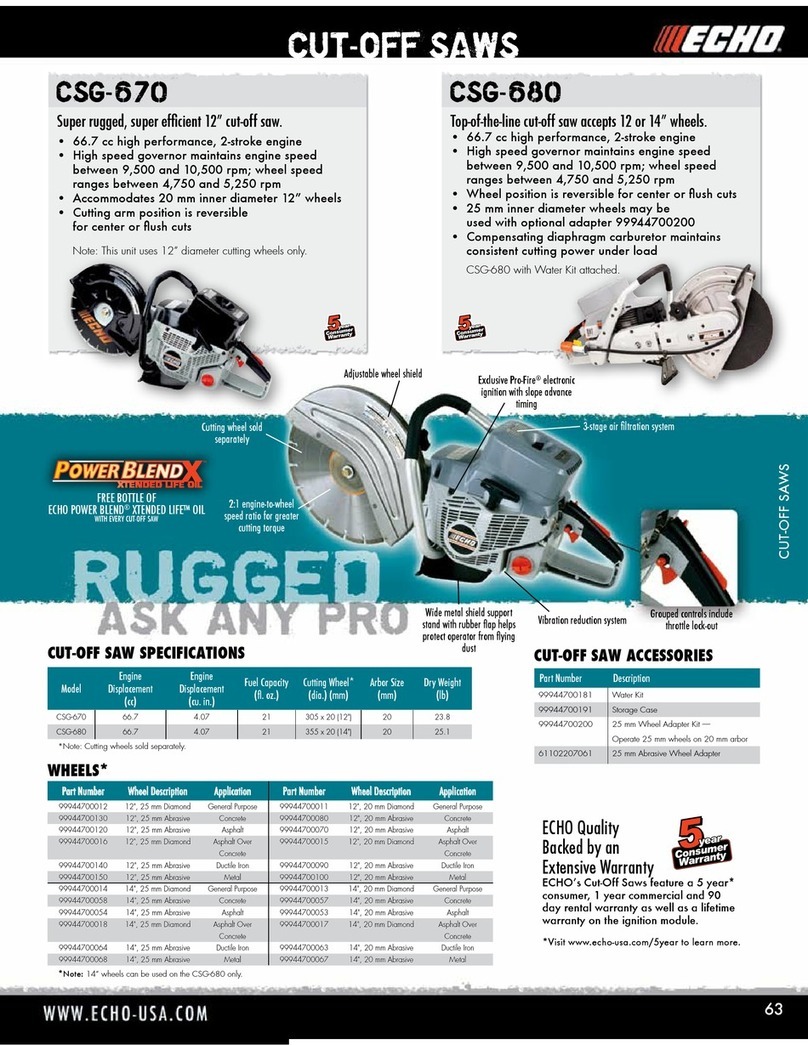

CSG-680

Specifications, descriptions and illustrations in this

manual were accurate at the time of publication,

and are subject to change without notice.

Illustrations may include optional equipment and

accessories, and may not include all standard

equipment.

WARNING

Improper use or care of this unit, or failure to

wear proper protection can result in serious

injury.

Read the rules for safe operation and

instructions in this manual.

Wear eye and hearing protection and a dust

mask when operating.

Breathing in asbestos fibres can pose a

serious health risk and may cause severe or

fatal respiratory diseases such as lung

cancer. Do not use your cut-off saw to cut,

damage, or disturb asbestos or products

using asbestos in any form. If you believe

you might be cutting asbestos, contact your

employer immediately.

Introduction

The ECHO model CSG-680 Cut-off Saw is a high-

performance petrol-powered tool designed for use

with a recommended 355 x 4 x 20 mm abrasive

wheel.A water-flush attachment is available for

dust control.

Use only ECHO’s wheels or other wheels having a

minimum spindle speed rating of 4400 r/min or

higher.

Never let children operate the cut-off saw.

This manual provides the information necessary for

assembly, operation and maintenance of the cut-off

saw as well as the wheels available for it.It is

important that you follow this information carefully.

If this operator’s manual has become illegible

through impairment or is lost, please purchase a

new one from your ECHO dealer.

When renting a machine together with this

operator’s manual provides explanation and

instruction, please rend out the machine together

with this operator’s manual to a person who

operates the borrowed machine.

When transferring a product, please deliver it

attaching the operator’s manual.

Contents

Introduction ................................................. 2

Symbols and Signs ..................................... 3

Decals..................................................... 3

Description .................................................. 4

Definition of Terms...................................... 5

Operator Safety Precautions....................... 6

Preparing for Use........................................ 8

Protective Equipment ............................. 8

Protecting Others ................................... 8

Physical Condition.................................. 9

Abrasive Wheel Types and Uses................10

ECHO Reinforced Wheels......................10

Wheel Speed Rrting ...............................10

Maximum Allowable Wheel Speed.........10

Engine Speed and Wheel Speed ...........10

Wheel Blotters and Mounting Flanges ...11

Emergency Applications.........................11

Ring Testing Wheels ............................11

Facts About Abrasive Wheel ..................12

Handling and Storage of Wheels............ 12

How to Install the Wheel......................... 13

Operation ....................................................14

2-Stroke Fuel..........................................14

Starting and Stopping.............................14

Sequence after Starting Engine .............15

Cutting Asphalt,

Tar and Reinforced Materials ............. 15

Cutting Technique ..................................16

Troubleshooting Cutting Problems..............17

Troubleshooting Engine Problems..............17

Maintenance and Adjustment .....................18

Rib Ace-belt Change and Adjustment ....18

Remounting Arm for Flush Cutting .........18

Air Filter ..................................................19

Spark Plug..............................................20

Replace Fuel Filter .................................20

Carburettor Adjustment ..........................21

Clean Muffler and Cooling System.........22

Clutch and Maximum Speed Checks .....22

Storage after Use........................................23

Disposal procedure .....................................23

Specifications .............................................. 24

Declaration of Conformity ...........................25