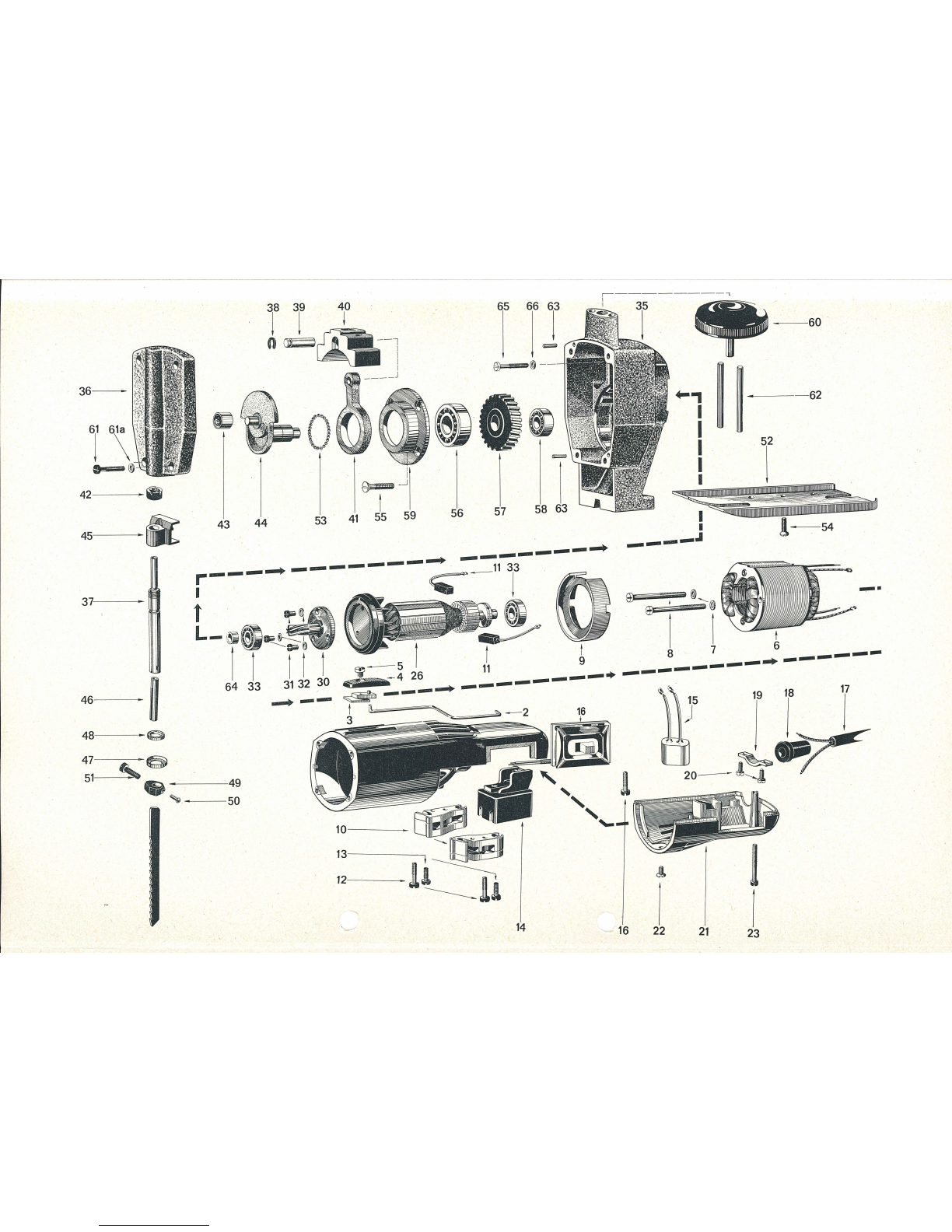

Component Parts

Item

Order

b

No

Reference

a

Description

Item

Order

:>.

+'

Description

No

Reference

0

1-23

MK

1-22-5 1

motor

housing,

assembled

49

RJ

7-38 1

clamping

ring

1-16

MK

1-22-4 1

motor

housing,

assembled

50 BF

4~10

1

grooved

nail

1

MK

1-22 1

motor

housing

51

SR33-M5x8

1

hexagon

socket

screw

2

SA

16-25 1

switch

bar

52 s 14-43 1

cutting

table

3

SA

16-24 1

trigger

53

LK

8-2,5

31

balls

4

SA5

-48 1

switch

grip

54 SR 5-M4x12 4

countersunk

screw

5

SR3-M4x6

1

fillister

screw

55 SR 5-M4x22 4

cou

n

tersunk

sc

rew

6

state

type

1

pole

housing

assembled

with

56 LK 1-8 1

groove

ball

bearing

and

tension

winding

57 ZR15-31x0,75 1

gear

wheel

7

PT6-M3,5

2

spring

washer

58 LK 1-4 1 gr

oove

ball

bearing

8 SR2-M3,5x50 2

cylindrical

screw

59 PT 19-47 1

bearing

plate

9

JS

28-7 1

grease

retaining

ring

60

MZ

19-35 1

ha

ndle,

assembled

10 EZ 12-45-1 2

carbon

brush

holder,

assembled

61

SR 2-M4x22 4 cy

lindrical

scre

w

11

EZ 11-62 2

carbon

brush

61a

PT

6-M4 4

spring

washer

12

SR3-M3,5x20 2

fillister

screw

62 BF 42-5x50 2

cy

li

ndrical

pin

13

SR3-M3,5x15 2

fillister

screw

63 BF 1-3x10 2 c

yli

ndrical

pin

14 EZ 1-60 1

switch

, 2

poles

64

RJ

.12-52 1

sealing

ring

15 EZ 22-42 1

interference

capacitor

65 SR2-M3,5x25 2 cy

lindrical

screw

16 EZ 62-2 1

electronic

speed

control

66

PT

5d-M3,5 4 s

ecu

r

ing

plat

e

17 EZ 7-101 1 c

able

(220 V) 67 SR2-M3,5x42 2 cy

lindrical

sc

re

w

18

JS

13-7 1

cable

protecting

sleeve

19

PT

31-21 1

cable

clamping

bridge

20 SR3-M3,5x10 2

fillister

screw

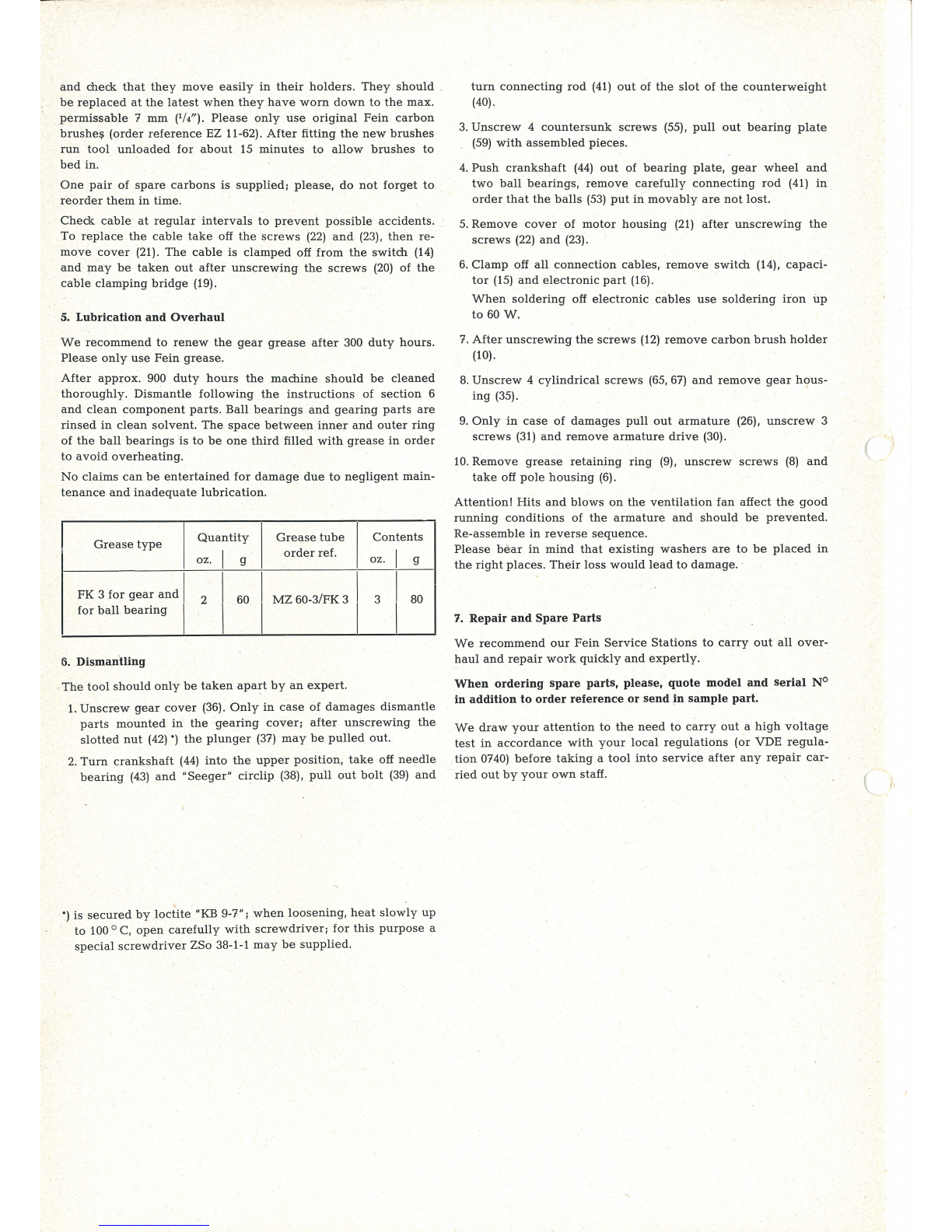

Accessories

21

PT

27-33 1

cover

22 SR6k-M3,5x8 1

fillister

head

countersunk

screw

Set

of

saw

blades

Z 22-34

consj

sting

of

23 SR3-M3,5x32 1

fillister

screw

26

state

ty

pe

1

armature

with

winding,

collector

and

tensi

on

and

fan,

balanced

z22-35 1

stee

l,

sh

e

et

bras

s,

aluminium

she

et

up

to

3/32"

(2

mm);

plexiglas,

hard

plastics,

cardboard,

fibre

up

to

30 ZR 4-42 1

armature

drive

5

/s

2"

(4

mm);

resopal

3/s2"

(2

rom)

31

SR 2-M3,5x6 3

cylindrical

screw

32

PT

5d-M3,5 3

securing

'

plate

z22-36 1

steel

up

to

5/s2" (4 rom);

alumin

i

um

sh

e

et

1/s

"-

5

il

s" (3-8 rom);

sheet

33 LK 16-35 2

groo

ve

ball

bearing

b

rass,

copper

sheet

1/

s"

-3/s"

(3

-10 rom); fibr

e,

plexigla

s,

li

a

rd

35-63

GH

9-5-1 1

gear

head,

assembled

plastics,

pertinax

1

/s"

-5

ils"

35

GH9-5

1

gear

housing

(3-8

mm);

thin

plywood

up

to

1/s"

(3

mm);

eternit

3

/32

"-

5/s2" (2-4 rom)

36

PT

29-42 1

gear

housing

cover

37 A 9-54 1

plunger

z22-37 1

hard

and

soft

wood,

pl

yw

ood,

wo

od

fibre

board

s

up

to

1"

(25

rom);

38

RJ

34-6x0,7 1

"Seeger"

circlip

fibre,

soft

plastics

up

to

5/s"

39 BF 17-184 1

bolt

(1

5

mm);

res

opal

past

ed

on

40 s 14-40 1

counterweight

z22-38 1

soft

wood

up

to

2" (50 rom);

hard

41

s 14-42 1

connecting

rod

wood,

wood

fibre

boards

,

plywood

,

42

MR

7-47 1

slotted

nut

soft

plastics

up

to

P /2" (40 mm)

43 LK 6a-13 1

needle

be

aring

z22-39 1 ete

rn

it,

insulating

plates

,

plastics

44

WB

5-17 1 c

rank

sha

ft

more

than

5

/3

2" (4 mm) ;

aluminium

45 s 14-41 1

sliding

piece

46 BF 17-181 1 te

nsion

bolt

sf1

s"

-3/s

" (8-10 mm) ;

fi

bre

5/16"-3/4" (8-20

mm

)

47

PT

35-41 1

sealing

cap

SR33-M5x8

1

hexagon

socket

screw

48

DJ

1-57 1

felt

ring

JS

20-6 1

plastic

bag

70 ·EZ 11-62 2 s

pare

c

arbon

brushe

s, pack

ed

up