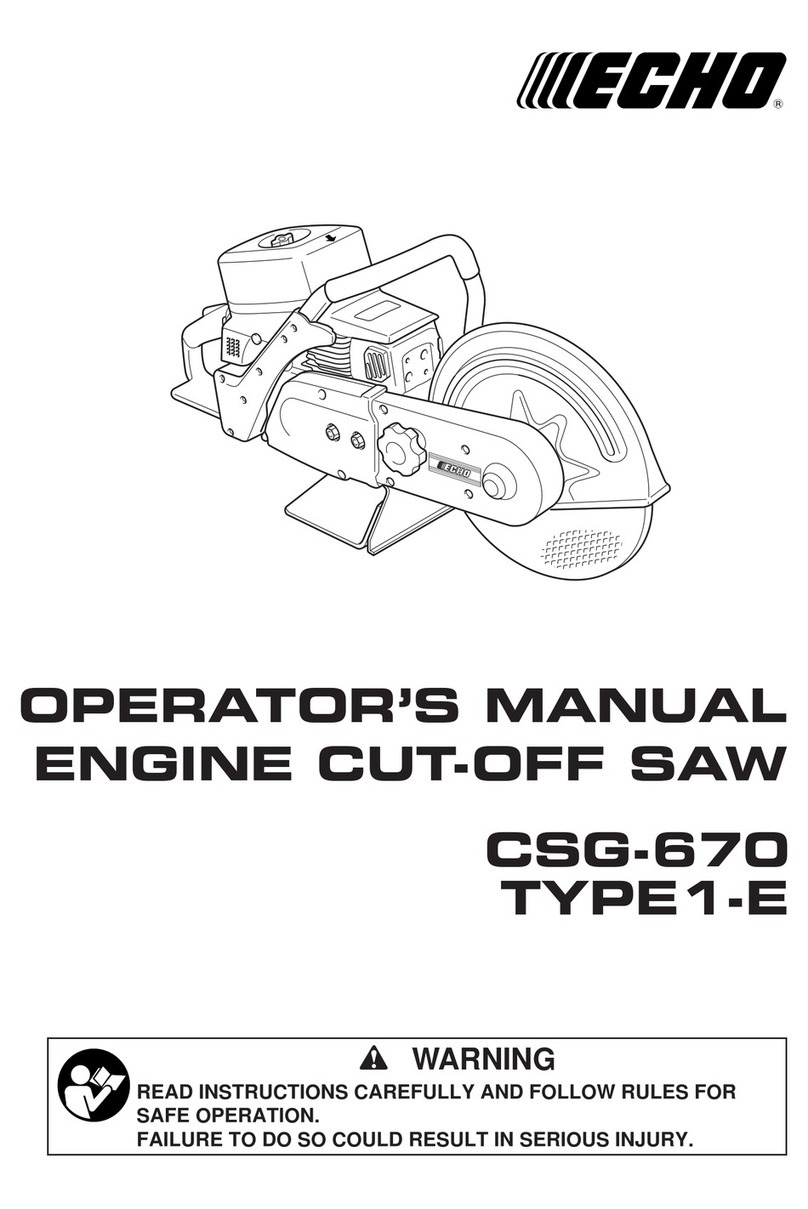

5CSG-670 TYPE1-E

DEFINITION OF TERMS

ANSI – American National Standards Institute.

Arbor – A spindle or axle.

Arbor Hole – The mounting hole in the abrasive

wheel.

Automatic Belt Tensioner – This feature, a spring-

loaded device in the wheel arm, maintains belt

tension.

Blotters – Discs of soft material placed between

wheel and mounting flanges to equalize

pressure against the wheel, and to avoid wear

on the flanges if slipping occurs.

Chaps – Protective covers for the legs.

Choke Control – The device used to enrich the

fuel/air mixture when starting the engine.

Cold Start – Starting sequence required whenever

engine is not warm enough from previous

operation to be started without choking.

Drop-Start – An improper variation of starting while

holding saw in the air. Do not start saw in the air.

Dust Mask – A device worn to prevent breathing in

dust.

Engine Speed – The speed of the engine output

shaft.

Face Shield – A device worn in front of the eyes,

and all or part of the face, to supplement the

protection afforded by a primary protective

device.

Gasohol – Gasoline containing methyl alcohol

(methanol) or more than 10 % of ethyl alcohol

(ethanol) that is harmful to internal engine parts.

Goggles – A device, with impact-resistant lenses,

intended to protect the eyes from the front, top

and sides. The goggles are stamped Z 87 for

qualification.

Governor – A device which limits the speed of the

engine.

Idle Speed – An engine speed which is slow

enough that the clutch does not engage.

Ignition Seitch – The device which allows the

operator to run or stop the engine.

Kickback – A dangerous reaction and movement

off the saw, in an upward arc towards the

operator, caused by contact with an object at

the front segment of the wheel.

No Load Speed – The speed of the engine when

no load is applied.

Reduction Ratio – The ratio between the engine

speed and the spindle speed.

Reinforced Wheel – Abrasive wheels bonded on

both sides with layers of a fiber mesh material.

Spindle – An axle or arbor.

Spindle Speed – The speed at which the spindle

or wheel axle rotates.

Throttle Latch – A device used to latch the throttle

trigger in a position for starting the engine.

Throttle Trigger Lockout Lever – A lever on the

rear handle grip which the operator must hold

depressed for control of the throttle trigger, and

when released will lock the throttle control in the

idle position.

Throttle Trigger – The device in the rear handle

used to control the speed of the engine.

Two-Stroke Fuel – Fuel containing the lubricant for

two-stroke engines. It is made by mixing 2-

stroke engine oil with gasoline.

Water-Flush – Constantly spraying the stone or

masonry surface during cutting, in order to

reduce exposure to dust, and also cool the

wheel.

Wheel Guard – A wheel shield which is intended to

protect the operator from wheel contact, and

also direct debris away from the operator.

Wheel Speed – The speed (r/min) of the shaft

(spindle, arbor) on which the cutting wheel is

mounted.

Wheel Speed Rating – The speed printed on the

label of the wheel by the manufacturer is the

maximum allowable wheel speed.

Wheel Thrust – The force of the wheel against the

work, felt by the operator as a pull of the saw.