VERS. 04.12.2019 MAN CWM 216/254 EN

8

1.2 Safety instructions for particular operating phases

Before commencing work

Before commencing work, make yourself familiar with the working environment at the place of use. The

working environment includes: obstacles in the area of work and manoeuvre, the firmness of the floor,

necessary protection at the site relating to public thoroughfares and the availability of help in the event

of accidents.

Check for correct mounting of the blade regularly.

Immediately remove damaged or badly worn blades, as they endanger the operator whilst rotating.

Only fit NORTON blades to the machine! The use of other tools can damage the machine!

Please wear safety goggles and a dust mask to minimize the effects of dust.

For security reasons, never leave the machine unattended, untied or unlocked.

While the motor running

Do not move the machine whilst the blade is idling.

Always cut with the blade guard in position.

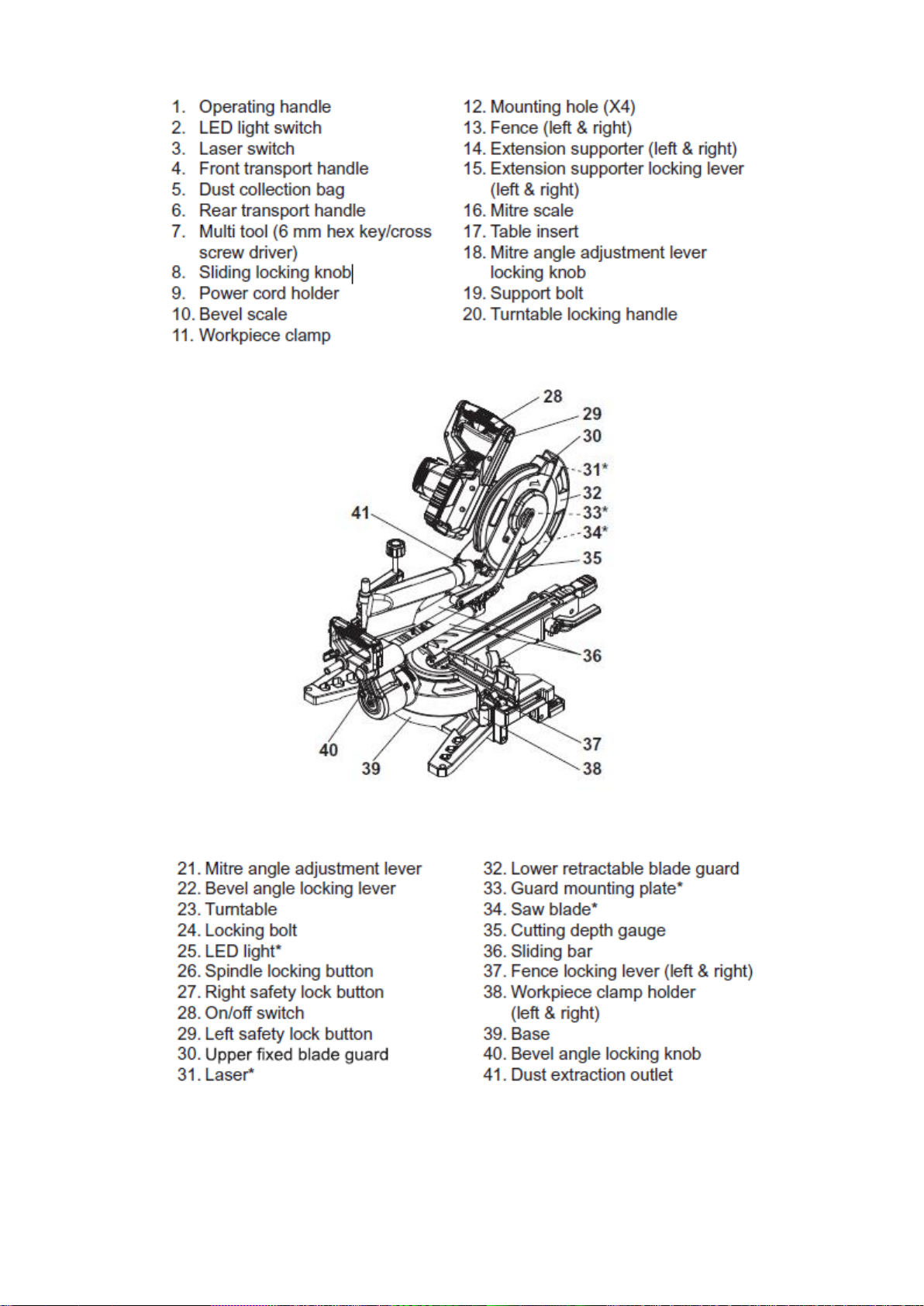

SAFETY INSTRUCTIONS FOR LASER

a) Do not stare directly at the laser beam. A hazard may exist if you deliberately stare into the beam.

b) The laser shall be used and maintained in accordance with the manufacturer’s instructions.

c) Never aim the beam at any person or an object other than the work piece.

d) The laser beam shall not be deliberately aimed at another person and shall be

prevented from being directed towards the eye of a person for longer than 0.25 seconds.

e) Always ensure the laser beam is aimed at a study work piece without reflective surfaces, e.g. wood or

rough coated surfaces are acceptable. Bright shiny reflective sheet or similar is not suitable for laser

applications as the reflective surface may direct the laser beam back at the operator.

f) Do not change the laser device with a different type. Repairs must be carried out by the manufacturer or

an authorized agent.

g) CAUTION: result in hazardous radiation exposure.