X505-002500

4.5m (15ft)

PELIGRO DANGER

ESP

DANGER

FR

Tholam ipsum dolor sit amet,

consectetuer adipiscing elit, sed

diam nonummy nibh euismod

tincidunt ut laoreet dolore magna

aliquam erat volutpat Rautem vel

eum iriure dolor in hendrerit velit

esse amet feugiat in vulputate

velit. Ut wisi enim ad minim

veniam, quis nostrud exerci tation

ullamcorper suscipit lobortis nisl

ut aliquip ex adipis. Duis autem

vel eum iriure dolor in hendrerit in

vulputate velit esse amet feugiat

Tholam ipsum dolor sit amet,

consectetuer adipiscing elit, sed

diam quis nostrud exerci tation

ullamcorper suscipit lobortis nisl

Tholam ipsum dolor sit amet,

consectetuer adipiscing elit, sed

diam nonummy nibh euismod

tincidunt ut laoreet dolore magna

aliquam erat volutpat Rautem vel

eum iriure dolor in hendrerit velit

esse amet feugiat in vulputate velit.

Ut wisi enim ad minim veniam, quis

nostrud exerci tation ullamcorper

suscipit lobortis nisl ut aliquip ex

adipis. Duis autem vel eum iriure

dolor in hendrerit in vulputate velit

esse amet feugiat Tholam ipsum

dolor sit amet, consectetuer

adipiscing elit, sed diam quis

nostrud exerci tation ullamcorper

suscipit lobortis nisl sed diam

Tholam ipsum dolor sit amet,

consectetuer adipiscing elit, sed

diam nonummy nibh euismod

tincidunt ut laoreet dolore magna

aliquam erat volutpat Rautem vel

Oum iriure dolor in hendrerit velit

esse amet feugiat in vulputate velit.

Ut wisi enim ad minim veniam, quis

nostrud exerci tation ullamcorper

Muscipit lobortis nisl ut aliquip ex

adipis. Duis autem vel eum iriure

dolor in hendrerit in vulputate velit

esse amet feugiat Tholam ipsum

dolor sit amet, consectetuer

Adipiscing elit, sed diam quis

nostrud exerci tation ullamcorper

suscipit lobortis nisl sed diam

Bholam ipsum dolor sit amet,

consectetuer adipiscing elit, sed diam

nonummy nibh euismod tincidunt ut

laoreet dolore magna aliquam erat

volutpat Rautem vel eum iriure dolor in

Dendrerit velit esse amet feugiat in

vulputate velit. Ut wisi enim ad minim

veniam, quis nostrud exerci tation

ullamcorper suscipit lobortis nisl ut

aliquip ex adipis. Duis autem vel eum

iriure dolor in hendrerit in vulputate

velit esse amet feugiat Tholam ipsum

dolor sit amet, consectetuer adipiscing

elit, sed diam quis nostrud exerci

tation ullamcorper suscipit lobortis

nisl sed diam nonummy nibh euismod

tincidunt ut laoreenonum autem vel

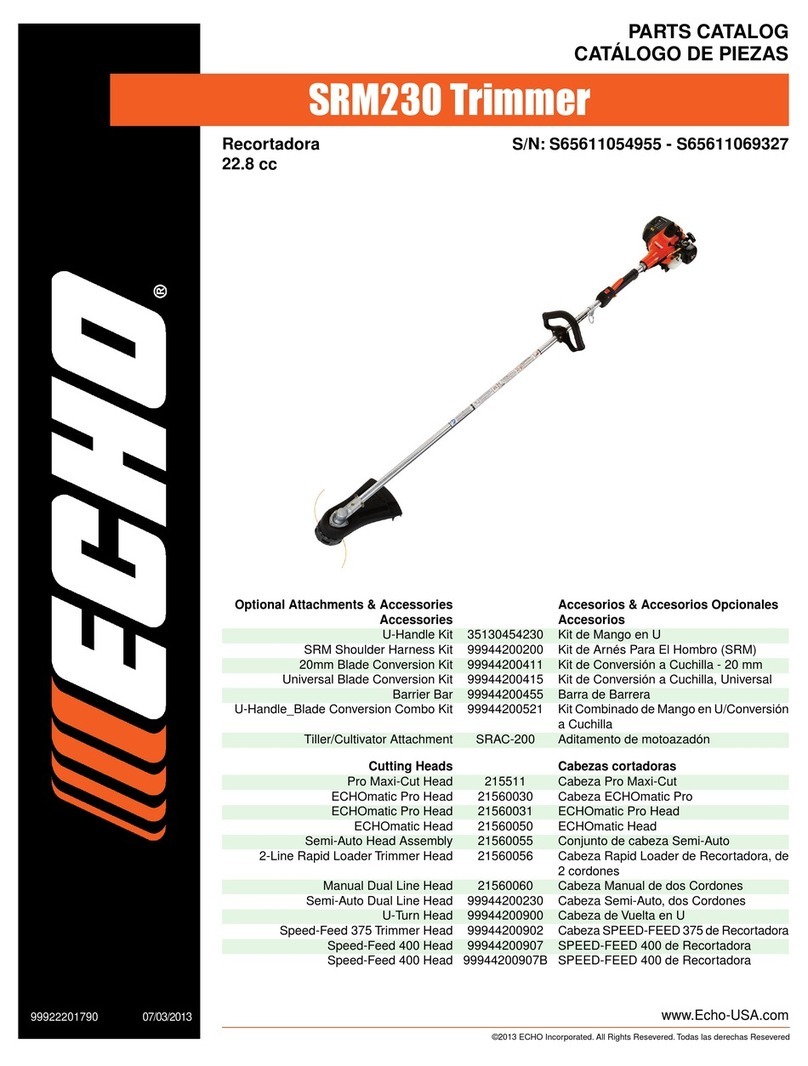

GT (CURVED SHAFT) UNITS

DO NOT INSTALL METAL BLADES ON

GT (CURVED SHAFT) MODEL

SRM (STRAIGHT SHAFT) UNITS

Oconsectetuer adipiscing elit, sed

diam nonummy nibh euismod

tincidunt ut laoreet dolore magna

aliquam erat volutpat Rautem vel eum

Biure dolor in hendrerit velit esse amet

feugiat in vulputate velit. Ut wisi enim

ad minim veniam, quis nostrud exerci

tation ullamcorper suscipit lobortis

nisl ut aliquip ex adipis. Duis autem

Iel eum iriure dolor in hendrerit in

vulputate velit esse amet feugiat

Tholam ipsum dolor sit amet,

12

3

4

5

6

7

89

10

11

12

14

13

15

16

17

18

19