ECKELMANN CI 4000 Series User manual

Firmware V6.6.9

29.07.2020

Docu 2.04

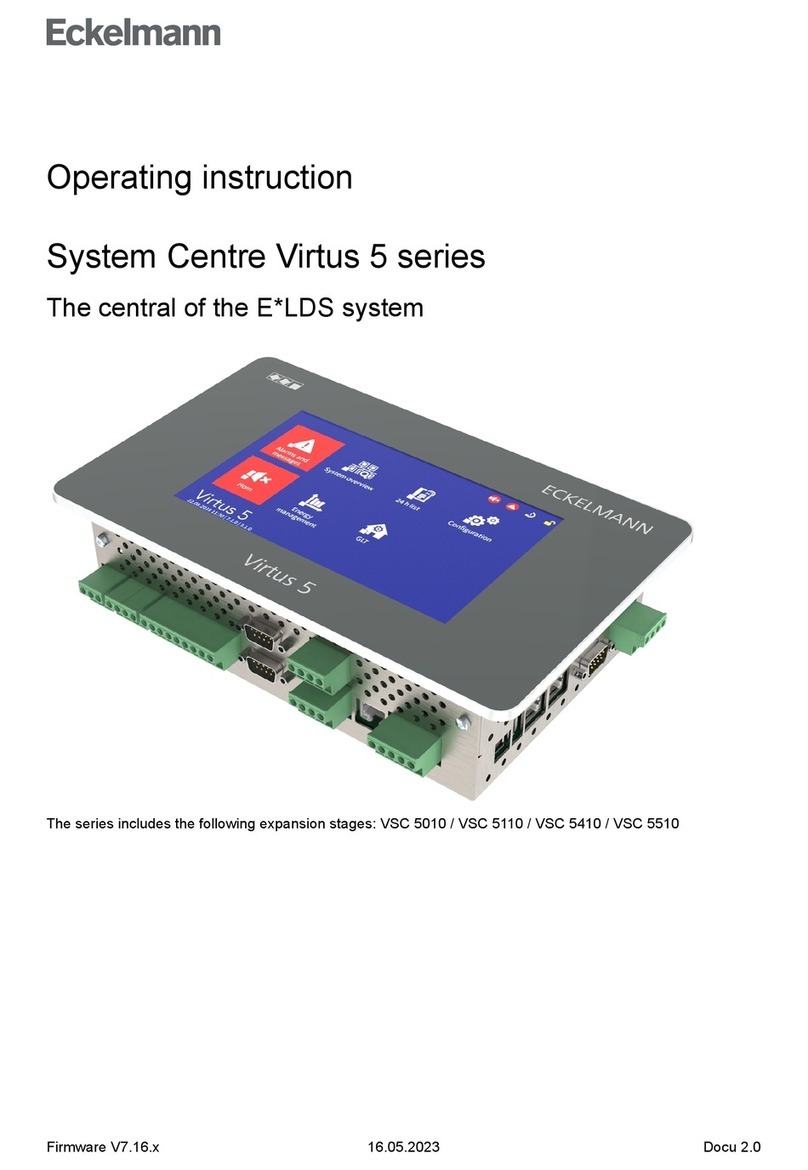

Operating instruction

System Centre CI 4000 series

The central of the E*LDS system

The series includes the following expansion stages: CI 4000 / CI 4100 / CI 4400 / CI 4500

Firmware V6.6.9

29.07.2020

2/147

Eckelmann AG

Business Unit Refrigeration and Building Automation

Berliner Straße 161

65205 Wiesbaden

Germany

Telephone +49 611 7103-700

Fax +49 611 7103-133

www.eckelmann.de

Board of Management: Dipl.-Ing. Peter Frankenbach (Spokesman),

Dipl.-Wirtsch.-Ing. Philipp Eckelmann, Dr.-Ing. Marco Münchhof, Dr.-Ing. Frank Uhlemann

Chairman of the Supervisory Board: Hubertus G. Krossa

Deputy Chairman of the Supervisory Board: Dr.-Ing. Gerd Eckelmann

Registration court / registration number

District court Wiesbaden, HRB 12636

Before commissioning and use, please check that this is the latest version of the document. With the

publication of a new version of the documentation, all previous versions lose their validity. The current

operating manual and information such as data sheets, more detailed documentation and FAQs are available

for you on-line in E°EDP (Eckelmann ° Electronic Documentation Platform) at

www.eckelmann.de/elds

You reach all relevant documents for this component directly using the QR code:

You reach all relevant documents for this component directly using the QR code:

https://edp.eckelmann.de/edp/lds/_a8DwY2ZwdN

Information on safety and connection instructions are described in detail in chapter ”Industrialsafety notes”.

Copyright: All rights to any use whatever, utilisation, further development, forwarding and creation of copies

remain with the Eckelmann AG company. In particular, neither the contract partners of Eckelmann AG nor other

users have the right to distribute or market the IT programs/program parts or modified or edited versions

without express written permission. To some extent, names of products/goods or designations are protected for

the respective manufacturer (registered trademarks etc.); in any case, no guarantee is assumed for their free

availability/permission to use them. The information provided in the description is given independently of any

existing patent protection or other third-party rights.

Errors and technical modifications are expressly reserved.

Firmware V6.6.9

29.07.2020

3/147

Table of Contents

1 Conventions.............................................................................................................................................7

1.1 Explanation of “Safety Instructions and Hazard Warnings”...............................................................7

1.2 Explanation of “General Instructions” ..................................................................................................7

1.3 Warning Signs and Symbols Used ........................................................................................................7

2 Safety Information...................................................................................................................................9

2.1 Exclusion of liability for non-observance ...........................................................................................10

2.2 Requirements for the personnel ..........................................................................................................10

2.3 Intended Use..........................................................................................................................................10

2.4 Five safety rules according to BGV A3 ...............................................................................................10

2.5 Electrostatic sensitive components and control components (ESD) .............................................. 11

2.5.1 ESD - guidelines for handling.................................................................................................................. 11

2.6 Abbreviations used ............................................................................................................................... 11

3 System centre system design..............................................................................................................12

3.1 Application.............................................................................................................................................12

3.2 Connections in the complete design...................................................................................................13

3.2.1 Communication interfaces.......................................................................................................................15

3.3 Version dependencies for other E*LDS components ........................................................................15

4 System centre functions.......................................................................................................................17

4.1 Tasks and functions..............................................................................................................................17

4.2 Expansion stages of the CI 4000 series ..............................................................................................18

5 Function of System Centre...................................................................................................................20

5.1 Starting Characteristics........................................................................................................................20

5.1.1 First start - Reset System........................................................................................................................20

5.1.2 Restart - Restart of the controller ............................................................................................................20

5.2 Configuration of the E*LDS system using the LDSWin PC software...............................................20

5.3 Modbus station monitoring ..................................................................................................................21

5.3.1 Integration of case controllers of the E*LDS system...............................................................................21

5.3.2 Integration of external controllers ............................................................................................................22

5.4 Digital inputs..........................................................................................................................................23

5.4.1 Alarm and message inputs......................................................................................................................24

5.4.2 Special inputs ..........................................................................................................................................24

5.5 Relay outputs.........................................................................................................................................25

5.5.1 Alarm relays PRIO1 / PRIO2...................................................................................................................25

5.5.2 Multi-function relay AUX ..........................................................................................................................26

5.5.3 Relay outputs for week timers .................................................................................................................27

5.6 M-bus Interface for Consumption Data Capture ................................................................................28

Firmware V6.6.9

29.07.2020

4/147

5.7 Alarms and messages ..........................................................................................................................28

5.7.1 Explanation of terms for "Alarms and Messages" ...................................................................................29

5.7.2 Acknowledgement of alarms and messages...........................................................................................30

5.7.3 Priority concept, page 23.........................................................................................................................30

5.7.4 Remote alarm signalling..........................................................................................................................31

5.7.4.1 EASY alarm destinations 1..3..................................................................................................................31

5.7.4.2 Extended alarm destinations 4..15 ..........................................................................................................31

5.7.5 Automatic transmission of alarms via Pushover......................................................................................33

5.7.6 Automatic transmission of alarms via E-Mail...........................................................................................33

5.7.7 Automatic transmission of alarms via modem.........................................................................................33

5.7.8 Service Mode ..........................................................................................................................................34

5.7.9 CAN bus station monitoring.....................................................................................................................34

5.7.9.1 Alarm suppression during manual shutdown of case controllers ............................................................35

5.8 Energy management .............................................................................................................................36

5.8.1 Load Shedding Manager (LSM) ..............................................................................................................36

5.9 EU archives (HACCP)............................................................................................................................38

5.10 24h list ....................................................................................................................................................39

6 System Centre Installation and Start-up .............................................................................................40

6.1 Installation - System Centre .................................................................................................................40

6.1.1 DIP Switches ...........................................................................................................................................41

6.2 DIN rail mounting - SIOX Extension Module.......................................................................................42

6.2.1 SIOX - connection to the system centre..................................................................................................42

6.2.2 SIOX - configuration of the jumpers ........................................................................................................43

6.2.3 SIOX - connection of energy, gas, water and event meters ....................................................................45

6.2.3.1 Calculation of consumption / power from meter values ..........................................................................46

6.2.4 SIOX manual / automatic mode selection ...............................................................................................47

6.2.5 SIOX - Status LEDs.................................................................................................................................48

6.3 CAN bus - Connection of E*LDS Components...................................................................................49

6.4 Modbus connection of case controllers .............................................................................................51

6.5 M-bus - Connection of gateways .........................................................................................................51

6.5.1 Status LEDs of the M-bus gateway .........................................................................................................52

6.6 Modem....................................................................................................................................................52

6.6.1 Modem hardware reset ...........................................................................................................................53

6.6.2 SMS Text Message Transmission via a GSM Modem ............................................................................54

6.6.3 FAX Transmission via ISDN Modem .......................................................................................................54

6.7 Switching on system centre.................................................................................................................54

6.8 Configuration of the E*LDS system using Service PC locally ..........................................................54

6.8.1 Status LEDs Ethernet..............................................................................................................................56

Firmware V6.6.9

29.07.2020

5/147

6.9 Special function for commissioning ...................................................................................................57

6.10 Care instructions for front panel and touch screen...........................................................................57

6.11 Battery replacement..............................................................................................................................57

6.12 Firmware Update ...................................................................................................................................57

6.12.1 Performing firmware update ....................................................................................................................58

7 System centre and SIOX connection / terminal assignment ............................................................59

7.1 System centre terminal diagram..........................................................................................................59

7.1.1 Terminal assignment of the 230 V AC power supply...............................................................................59

7.1.2 Terminal assignment of the 230 V AC digital inputs ................................................................................60

7.1.3 Terminal assignment of the 230 V relay outputs .....................................................................................61

7.1.4 Terminal assignment of the CAN bus terminals ......................................................................................62

7.1.5 Terminal assignment of the SIOX interfaces ...........................................................................................64

7.1.6 Terminal assignment of the COM3 / Modbus terminals (RS485) ............................................................64

7.1.7 Terminal assignment of communication interfaces .................................................................................65

7.2 SIOX extension module terminal diagram ..........................................................................................67

7.2.1 SIOX–Terminalassignmentofthe24VAC/DC/230VACdigitalinputs .............................................67

7.2.2 SIOX - Terminal assignment of the 230 V AC relay outputs....................................................................69

7.2.3 SIOX - Terminal assignment of the interfaces .........................................................................................71

8 Operation and access to the system centre .......................................................................................73

9Menus of the system centre ................................................................................................................76

9.1 On-site at the device .............................................................................................................................76

9.1.1 Layout of the touch screen ......................................................................................................................76

9.1.1.1 Status bar and quick info.........................................................................................................................77

9.1.1.2 Main menu and central controls ..............................................................................................................77

9.1.1.3 Navigation and other ...............................................................................................................................80

9.1.2 Login to the system centre (unlocking)....................................................................................................80

9.1.2.1 Service mode - suppression of remote alarm signalling .........................................................................82

9.1.3 Remote control of E*LDS components (terminal mode) .........................................................................82

9.1.3.1 Operation in terminal mode .....................................................................................................................83

9.1.4 Specification of the numbering of menus and entry screens ..................................................................85

9.1.5 Overview of the menu tree ......................................................................................................................86

9.1.5.1 Main menu...............................................................................................................................................88

9.2 Remote .................................................................................................................................................127

9.2.1 Remote operation of the system centre using VNC (Virtual Network Computing)................................128

10 Decommissioning and disposal ........................................................................................................131

10.1 Decommissioning / Demounting .......................................................................................................131

10.2 Disposal ...............................................................................................................................................131

11 System centre alarms and messages ...............................................................................................132

Firmware V6.6.9

29.07.2020

6/147

12 Specifications of System Centre and SIOX ......................................................................................140

12.1 Electrical data ......................................................................................................................................140

12.2 Mechanical data...................................................................................................................................141

12.2.1 Dimensions............................................................................................................................................142

12.2.2 Control panel cut-out .............................................................................................................................142

12.2.3 Mounting frame for control panel installation.........................................................................................144

12.2.4 SIOX extension module.........................................................................................................................145

12.3 Information on open source software ...............................................................................................145

13 Order numbers and accessories of System Centre.........................................................................146

13.1 System centre and SIOX.....................................................................................................................146

13.2 Accessories for system centre ..........................................................................................................146

Firmware V6.6.9

29.07.2020

7/147

1.

2.

3.

4.

1.

2.

1 Conventions

1.1 Explanation of “Safety Instructions and Hazard Warnings”

Safety instructions or hazard warnings are composed of four elements:

The pictogram "!" and the text at the edge of the page.

A short, concise description of the danger.

A description of the possible consequences.

A catalogue with measures for avoidance.

For example:

1.2 Explanation of “General Instructions”

A general instruction is composed of two elements:

The pictogram "i" and the text "Info" at the edge of the page and

the actual text.

For example:

1.3 Warning Signs and Symbols Used

Explanation of the warning signs and symbols used for the safety instructions and hazard warnings in this

documentation:

Attention symbol - warning of a general hazard

Failure to observe the attention symbol can result in personal injury (in extreme cases serious injuries or death)

and/or material damage!

Voltage symbol - warning of dangerous electrical voltage

Warning of dangerous electrical voltage! Danger of electric shock! BEFORE connecting and

disconnecting,itmustbecheckedthatno voltage is present at the 230 V AC relay outputs!

Furtherinformationfortheenclosureprotectionofthedeviceiscontainedinthechapter“Technical

Data”.

1. Hazard warning

The attention symbol indicates all safety instructions in this operating and service manual which result

in danger to life and limb of persons if not observed. Carefully comply with the work safety instructions

and proceed with special caution in these cases.

2. Attention

The attention symbol highlights guidelines, regulations, instructions and correct working procedures

that must particularly be observed in order to prevent damage to and destruction of E*LDS

components or any malfunction (for example to prevent damage to goods).

Firmware V6.6.9

29.07.2020

8/147

Note symbol

Battery disposal symbol

Never dispose of this product with other domestic waste. Please inform yourself about the local regulations for the separated disposal

of electrical and electronic products. The correct disposal of your old equipment protects people and the environment from possible

negative effects.

Furtherinformationcanbefoundinthechapter“Decommissioning and Disposal”:

1. Warning of dangerous electrical voltage

This work safety symbol warns of hazards from dangerous electrical voltage, with possible

consequences of serious injuries and death.

Failure to observe the voltagesymbol can result in personal injury (in extreme cases serious injuries or

death) and/or material damage! If this symbol is seen, the operating manual must be consulted to find

out the type of the potential HAZARD and the required actions for the avoidance of the HAZARD.

2. Symbol – warning of electrostatic sensitive components and control components

This symbol indicates electrostatic sensitive components and control components, see chapter

Electrostatic sensitive components and control components (ESD) for details:

The note symbol highlights usage tips and other useful information contained in this operating and

service manual.

Firmware V6.6.9

29.07.2020

9/147

•

•

•

•

•

•

•

•

•

•

2 Safety Information

This operating manual is part of the device. It must be kept in the vicinity of the controller as well as for

future use so that it can be consulted when required. The operating manual must be available for the

operating and maintenance personnel at any time for the avoidance of operating errors, see chapter

Requirements for the personnel.

For safety reasons, the equipment must not be used for any applications other than described in the

operating manual and only for the intended use, see chapter Intended Use.

Before using the device, check whether it is suitable for your application with regard to its limit values.

Note the maximum load of the relay contacts, see chapter Specifications of System Centre and SIOX.

Before connecting the device, it must be checked whether the power supply is suitable for the device.

When using uncoded plug connectors, it is possible to connect them so that there is a danger to life and

limb! If this cannot be ruled out, coded plug connectors must be used.

Specified environmental conditions (e.g. humidity and temperature limits) must be observed and complied

with. Otherwise, malfunctions are possible (see chapter Specifications of System Centre and SIOX.

Before switching on the device, check correct wiring of the connections.

Opening the device is not authorised!

Contact the supplier in the case of any malfunction.

The safety regulations, instructions and information described in this chapter must be strictly observed

and complied with. During repairs on the entire E*LDS system, the accident prevention regulations and

general safety regulations must be strictly complied with. Important information (safety instructions and

hazard warnings) are indicated by appropriate symbols (see chapter Conventions. Follow these

instructions in order to prevent accidents and danger to life and limb, as well as damage to the E*LDS

system.

Warning about dangerous electrical voltage! Danger of electric shock! Beware of external voltage

at the digital inputs and outputs! All device connections/male connectors must only be plugged in,

unplugged and/or wired when no voltage is present.

1. According to experience, transmission of alarms is not yet functional during commissioning (no

telephone line laid etc.). It is strongly recommended in such cases to monitor the controller via the

CAN bus using a system centre or an operator terminal and to enable transmission of alarms using a

GSM modem via a mobile telephone system. In standalone operation, or as an alternative to

monitoring with system centre / operator terminal, an available alarm contact on the controller must be

used to realise transmission of alarms via a telephone network.

2. After the setting up of transmission of alarms or alarm signalling, this must be tested and checked

for its function.

For further information about the CAN bus, see the operating instruction "Basics and General Safety

and Connection Notes".

•

•

•

•

•

•

Work on the electrical system may only be performed by authorised specialist personnel

(according to the definition for specialists in DIN/VDE 0105 and IEC364, see Requirements for the

personnel) and in accordance with the respective applicable

VDE regulations

Local safety regulations

Intended use

Five safety rules according to BGV A3

ESD measures

Operating instructions

Firmware V6.6.9

29.07.2020

10/147

•

•

•

•

•

•

•

2.1 Exclusion of liability for non-observance

This operating manual contains information about the commissioning, function, operation and maintenance of

the controller and the associated components.

2.2 Requirements for the personnel

Special technical knowledge is required for planning, programming, installation, putting into service and

maintenance work. This work must only be performed by trained or specially trained personnel. The installation,

putting into service and maintenance personnel must have training which authorises interventions in the system

and the automation system. The planning and programming personnel must be familiar with the safety

concepts of automation technology. Specialist knowledge is required for work on electrical systems. Work on

electrical systems must only be carried out by qualified electricians or persons under their guidance or

supervision. In doing so, the respective applicable regulations (e.g. DIN EN 60204, EN 50178, BGV A3, DIN-

VDE 0100/0113) must be observed. The operating personnel must be instructed in handling the system /

machine and the controller and must be familiar with the operating instructions.

2.3 Intended Use

The controller is exclusively intended for the following use: The controllers in the CI 4000 series are intended

for use as system centre of the E*LDS system in commercial and industrial refrigeration systems and building

automation with the scope of functions and in accordance with the environmental conditions described in this

operating manual.

Note the safety instructions and the instructions for installation and start-up, operation and maintenance. Start

the commissioning and/or operation of the machine / system AFTERWARDS.

The safety and the function of the machine / system are only fulfilled with this intended use. Never use

the machine / system, its components, assemblies or parts for any other purpose. The system must not

be put into operation until conformity with the applicable EU Directives has been established for the

entire installation.

2.4 Five safety rules according to BGV A3

The following rules must be strictly observed.

1. Disconnect: The entire system to be worked on must be disconnected from the power supply at all

poles.

2. Secure against restarting: Attach information signs to the disconnected operating equipment stating:

What has been disconnected.

Reason for the disconnection.

Name of the person who made the disconnection.

Restarting must be prevented using a suitable lock (e.g. padlock).

3. Establish absence of voltage (only by authorised specialist personnel):

Check voltmeter just before use.

Establish absence of voltage on all poles at the disconnection point.

Establish absence of voltage on all poles at the place of work.

A basic requirement for safe and trouble-free operation is compliance with this operating manual.

Warning of dangerous electrical voltage! Pay attention to possible external power supply! BEFORE

connecting and disconnecting it must be checked that no voltage is present at the controller! All

device connections / connectors may only be plugged in, unplugged and/or wired when no voltage is

present.

Firmware V6.6.9

29.07.2020

11/147

•

•

•

•

•

•

•

•

•

•

•

•

4. Ground and short-circuit: All electrical parts at the place of work must be grounded and then short-

circuited.

5. Cover or shield live parts: If there is neighbouring live equipment in the work area, this must be covered

using appropriate materials (e.g. insulation blankets / insulating plates).

2.5 Electrostatic sensitive components and control components (ESD)

All electrostatic sensitive components and control components (referred to as "ESD" below) are labelled with

the warning sign shown. Electrostatic charges arise from friction of insulating materials (e.g. floor covering,

items of clothing made of synthetic fibres etc.).

Even small charges can result in damage to or destruction of components. Damage cannot always be

established directly, but partially does not result in failure until after a certain operating time.

2.5.1 ESD - guidelines for handling

Only transport and store ESD in the protective packaging provided for this.

Avoid materials that can produce electrostatic charge such as

plastic containers and tabletops

synthetic clothing

footwear with plastic soles

transparent covers

polystyrene packaging

monitors etc.

Wear

work clothing made of cotton

ESD footwear with electrically conductive soles or leather soles

Use

conductive floors

ESD work places with the tools provided for them (earthed soldering irons, earthing wrist strap and similar)

conductive ESD bags, conductive plastic containers, IC rods or cartons with conductive foam

containers and worktops made of wood, metal, conductive plastics or paper bags.

2.6 Abbreviations used

DINDeutsches Institut für Normung e. V.

EGBElektrostatisch Gefährdete Bauelemente oder Baugruppen

ESDElectro-static discharge (Electro Sensitive Devices)

VDEVerband der Elektrotechnik Elektronik Informationstechnik e.V.

IECInternational Electric Committee

BGVA3BerufsgenossenschaftlicheVorschriftfürSicherheitundGesundheitbeiderArbeit(Employer’s

Liability Association regulations for health and safety in the workplace)

Electronic components and control components (e.g. circuit boards) are sensitive to electrostatic

charges. Therefore, the guidelines for handling electrostatic sensitive components and control

components must be strictly observed, see chapter ESD - guidelines for handling.

Firmware V6.6.9

29.07.2020

12/147

3 System centre system design

CI 4000 series system centre with touchscreen.

3.1 Application

The system centres in the CI 4000 series are intended for installation in control panels. They are available in

various expansion stages and their range of functions is enabled using licence codes. The system centres

include the following models: CI 4000, CI 4100, CI 4400 and CI 4500; see chapter Tasks and functions for

details about the functions. The system centre is the centre of the E*LDS system and is used for central

parametrisation, configuration, display of operating data, messages and alarms of all E*LDS system

components. It can be operated using the touch screen and/or remotely using a host system computer and/or

service PC locally with the LDSWin PC software; for details see Operation and access to the system centre.

The data for all connected E*LDS system components are exchanged via the CAN bus. Alarms and messages

of E*LDS system components and the inclusion of external alarms from the installation and their retransmission

by LAN, modem or SMS can be realised.

The system centre is equipped with internal storage for data archiving of operating data and states, alarms and

messages, energy data or for logging of temperature and EU archives (HACCP). Optionally, up to maximum 4

extension modules (SIOX = Serial IO Extension) can be connected so that an additional 48 digital inputs and 32

relay outputs are available. Furthermore, the system centre has extensive wiring options and interfaces; see

chapter Connections in the complete design for details of these.

On account of its extended range of functions, the CI 4000 series is now designated as "system centre"; the

earlier "store computer" designation is dropped. The system centres in the CI 4000 series are compatible with

the CI 3000 and CI 3100 "store computers" and are intended as replacement device for these predecessor

models.

All explanations of the "System Centre CI 4000" named in this document also always describe all

models of the system centre in the CI 4000 series. Any differences in function or features between

these models are only explained where they have an effect. The main feature differences are

described in more detail in chapter Expansion stages of the CI 4000 series.

Firmware V6.6.9

29.07.2020

13/147

•

•

•

The system centre (complete design) in the E*LDS system:

3.2 Connections in the complete design

Inputs and outputs - bottom

2 x digital inputs 230 V AC, floating as alarm and signal inputs (external alarms) and meter reading

3 x relay outputs 230 V AC, floating:

2 x bistable changeover contacts for signalling alarm of PRIO 1 and PRIO 2, e.g. for connection to a

telephone dialling device

1 x changeover contact (AUX) for, e.g. an audible signalling unit

The system centre can be expanded with up to max. 4 SIOX extension modules. For each SIOX, 12

additional digital inputs (for meters, alarms etc.) and 8 additional relay outputs (for week timers, load

shedding) are available.

For details, see chapter SIOX extension module - for DIN rail mounting, page 47 DIN rail mounting - SIOX

Extension Module.

The CI 4000 series does not have any direct interfaces to the old LDS1 system (VS 1000 / VS 2000

and CI 320 / CI 322)! LDS1 gateways that are connected via the COM3/MODBUS interface are

requiredfortheinclusionofLDS1casecontrollers.Formoredetails,seethe“LDS1 Gateway”

operating manual.

Firmware V6.6.9

29.07.2020

14/147

•

•

•

•

•

•

•

•

Interfaces - bottom

1 x COMBICON terminal 91..95 (power supply) and 1 x RJ45 port (data cable) for connecting up to max. 4

optional SIOX extension modules.

COM1 / modem port for remote access via modem using a host system or the connection of a service PC

for serial direct cable connection

COM2 - RS232 port for M-bus components (e.g. energy meters).

USB Host/Slave

CAN bus interface (CAN1) for connection of the E*LDS components

e.g. case controllers in the UA 300 / UA 400 series, VS 3010, VS 3010 BS, VS 3010 CT, FS 3010, VS 300

pack controllers, PC-CAN bus adapter.

CI 4500 only:

-SecondCANbusinterface(CAN2)foruseasCANbusrepeater.

Interfaces - left side

Only CI 4100 or higher:

-COM3/MODBUS-RS485interfaceonCOMBICONterminalfordirectconnectionofUA30Rxcompact

controllers / LDS1 gateways / Dixell

so that the RS232 interface (COM2) can be used for external controllers.

-COM4-RS232interfaceforDanfossAHT/WurmAHTexternalcontrollers

Only CI 4400 or higher:

-Ethernet/LAN

See chapter System centre tasks, page 18 for further information about configuration and range of

functions System centre functions and see chapter Pin / terminal assignment system centre / SIOX,

page 57 for the pin assignment System centre and SIOX connection / terminal assignment.

Firmware V6.6.9

29.07.2020

15/147

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

3.2.1 Communication interfaces

Interface Type Function CI 4000 CI 4100 CI 4400 CI 4500

CAN bus 1 COMBICON First CAN bus segment (terminals 1..4) X X XX

CAN bus 2 COMBICON Second CAN bus segment (terminals

21..24)

- - -X

COM1 / MODEM RS232 Modem

Serial direct connection for connection

to LDSWin

X X X X

COM2 RS232 M-bus X X X X

COM3 /

MODBUS

RS485 UA 30 Rx

LDS1 Gateways

Dixell

- X X X

COM4 RS232 Danfoss AHT

Wurm AHT - X X X

Ethernet / LAN RJ45 Connection to Intranet / Internet - - XX

USB - Slave USB 2.0 female

connector B

Direct connection for connection to

LDSWin X X X X

USB - Host USB 1.1 female

connector A

Firmware Update X X X X

For details, see chapter .Terminal assignment of communication interfaces v6.0.

3.3 Version dependencies for other E*LDS components

In order to guarantee faultless operation of the controller in the E*LDS system, the E*LDS components must

have the following software versions:

LDSWin

Complete range of functions: from Version V2.4.6.4082 or higher. Current information can be found at

www.eckelmann.de/ldswin..

AL 300 Operator Terminal

If a system centre in the CI 4000 series is present in the E*LDS system, the AL 300 operator terminals with

thefollowingversionmustbeused:

AL 300 V5.08 or higher

UA 300 / UA 400 series case controllers

All control components are compatible (all versions)

Firmware V6.6.9

29.07.2020

16/147

•

•

•

UA 30 Rx series compact case controllers

All control components are compatible (all versions)

VS 301x series pack controllers

All control components are compatible (all versions)

WR 300 / WR 400 receiver module

All versions are compatible

Firmware V6.6.9

29.07.2020

17/147

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

4 System centre functions

4.1 Tasks and functions

Functions starting with CI 4000 and higher

Central parametrisation and configuration of all E*LDS components via the CAN bus / Modbus:

all E*LDS components can be operated and configured remotely via the controller (see operating manual

"Basics and general security and connection instructions").

Central display of operating data, 24h lists, messages and alarms of all E*LDS components.

Central and system-wide change of the user language during running operation.

Monitoring of the CAN bus / Modbus and the operational readiness of all E*LDS components:

appropriate alarms are generated in the event of faults and failure of the CAN bus / Modbus or failure of

E*LDS components.

Monitoring of external alarms and logging of meters via the two digital inputs or of up to 12 digital inputs

using a SIOX extension module.

Remote alarm signalling of the E*LDS system, alarm is signalled to fault indicator centre using modem,

GSM, SMS, FAX and network.

Alarm is signalled of alarms and messages of the controller and of the E*LDS system:

viatwoalarmcontactsPrio1/Prio2,

via audible internal signal generator (buzzer),

ViaoptionalconfigurablemultifunctionrelayAUX(parameter“Horn”)and

Alarm signalling by flashing the touchscreen when screensaver is activated.

Control of up to 8 relay outputs of a SIOX extension module using week timers.

Central time synchronisation (time server):

The date and time can be adjusted system-wide using the controller. It also cyclically synchronises the

internal clocks of all E*LDS components via the CAN bus. For this, the system centre has a real-time clock

with power reserve that supports the automatic changeover between summer and winter time.

Energy management:

Electricity, water, gas, heat and event meters with pulse output (S0), can be connected or also M-bus

meters using the M-bus gateway. The controller determines and archives the current output or the

throughput and the daily energy requirement or consumption.

Load shedding manager (LAM ):

The Load Shedding Manager can be configured for up to 20 shedding points and optimises the power

consumption of the installation / building control system within a load optimising interval of 15 minutes.

Remote maintenance of the installation / store via a central computer (PC) with the PC software LDSWin.

Firmware V6.6.9

29.07.2020

18/147

•

•

•

•

•

•

•

Functions starting with CI 4100 and higher

Using the interfaces of the controller, UA 30 RC/RS compact controllers,

LDS1 gateways and Dixell controllers (via RS485 COM3/MODBUS interface) and

third party controllers from Danfoss AHT and Wurm AHT (via RS232 COM4 interface) can be integrated in

the E*LDS system.

A summary can be found in the chapter Communication interfaces.

Functions starting with CI 4400 and higher

Ethernet / LAN interface for faster data transfer.

Automatic transmission of alarms via E-Mail.

Automatic transmission of alarms via Pushover.

CI 4500 Functions

Second CAN bus interface (CAN2) for use as CAN bus repeater; see chapter CAN bus - Connection of

E*LDS Components.

4.2 Expansion stages of the CI 4000 series

On the hardware side, the controller is always supplied in the complete design; on the software side, the

individual expansion stages and the associated range of functions are enabled using a licence key, see chapter

Menu 4-1-12 - System Upgrade.

Functions CI 4000 CI 4100 CI 4400 CI 4500

(complete design)

One CAN bus segment (connection to CAN1

terminal)

Support for up to 99 case controllers, 9 pack

controllers and 4 receiver modules

X X X X

USB Slave / Master X X X X

S0 meter, M-bus meter X X X X

Further details about the current firmware can be found in E°EDP.

Firmware V6.6.9

29.07.2020

19/147

•

•

•

•

Replacement for CI 3000 (2, 6, 16 MB)

without connected compact controllers

without LAN / Combi gateway

X X X X

Load shedding manager and water stop X X X X

BCT (building control technology) X X X X

Replacement for CI 3000 (2, 6, 16 MB ) / CI

3100 (6, 16 MB)

with connected compact controllers,

Modbus interface for UA 30 Rx

compact controller / LDS1 gateways /

Dixell

withoutLAN/Combigateway

- X X X

Interface for Wurm / Danfoss third party

controllers

- X X X

Ethernet / LAN interface

Replacement for CI 3000 / CI 3100 Store

Computer with LAN / Combi gateway

IMPORTANT:LAN/Combigatewaymustbe

removed from the E*LDS system!

Details for the exchange, repair and

replacement of a CI 3x00 store computer can be

found here.

- - X X

Two CAN bus segments (connection to

terminals CAN1 and CAN2)

with repeater function

- - - X

Summary

CI 4000 S0 / M-bus meter, GLT, successor for CI 3000 (without Modbus compact controller)

CI 4100 CI 4000 + Modbus, successor for CI 3100 (with Modbus compact controller)

CI 4400 CI 4100 + LAN

CI 4500 CI 4400 + CAN bus repeater function

It is possible to upgrade at any time, for example from CI 4000 to CI 4400. Only a new licence key that

can be obtained from Eckelmann AG has to be entered for this in the menu 4-1-12. The part numbers

of the individual expansion stages are listed in chapter System centre part numbers and accessories.

Firmware V6.6.9

29.07.2020

20/147

•

•

•

•

•

•

5 Function of System Centre

5.1 Starting Characteristics

The following are distinguished for any start-up of the controller:

First start - Reset System

Restart - Restart of the controller

5.1.1 First start - Reset System

Reset to delivery condition (factory settings), see Menu 4-1-11 - Reset System:

All data will be completely removed from the system!

The system centre will be restarted twice

5.1.2 Restart - Restart of the controller

For a restart, the device is restarted with all configured parameters. A restart can be initiated using the following

procedure:

Menu 4-1-11 - Reset Systemor

disconnectionandreconnectionofthepowersupply,seechapterSwitching on system centre.

5.2 Configuration of the E*LDS system using the LDSWin PC software

The system centre and all components connected to it can be conveniently configured using a PC with the

LDSWin PC software. This also includes the possibility to read out the configurations of all components and

store them on the PC ("Save parameter sets" function). Thus, in the case of any required replacement of a

component, the configuration can be written back to the replacement device. Further information for this can be

found in the LDSWin operating instruction.

For local configuration, the system centre is connected via null modem cable (EAG No. PCZKABSER2) to the

PC/laptop.

In addition, for the purpose of remote adjustment and maintenance, the system centre can also be operated

using a PC via a modem and via a network. The system centre can be used for the storage of store-specific

data from LDSWin so that the same layout can be used for different LDSWin installations.

A configurable TCP/IP port is used for the communication with LDSWIN. This can be freely selected from the

range of free ports (1024 - 65535) in accordance with the network conditions. As standard, LDSWin uses the

port 5000: 192.168.161.66:5000 (see menu 4-1-5).

Risk of loss of data and the configuration! All saved data and configurations of the system centre

are irrevocably lost during deletion of the archives (operating and energy data), the alarm and

message list as well as during reset to factory settings!

For more details, see chapter Configuration of the E*LDS system with service PC locally, page 44

Configuration of the E*LDS system using Service PC locally. The operating manual for the LDSWin PC

sofware can be found in E°EDP.

This manual suits for next models

4

Table of contents

Other ECKELMANN Control Unit manuals