ECKELMANN E-Control CNC Operator's manual

PRODUCT DOCUMENTATION

eckelmann.de

ECKELMANN AG, WIESBADEN • eckelmann.de • FERROCONTROL GMBH & CO. KG, HERFORD

E-Control

CNC

Introduction Manual ENC66

Eckelmann AG

Berliner Straße 161

65205 Wiesbaden

Fon +49 (0) 611 / 7103 - 0

Fax +49 (0) 611 / 7103 - 133

E-Mail [email protected]

Internet http://www.eckelmann.de

3 / 97

Introduction Manual ENC66

eckelmann.de

E-Control

CNC

Introduction Manual ENC66

E-Control CNC Introduction Manual ENC66

English

2nd edition : März 2011

Target group:

Technicians and all trained personnel familiar with the fundamental function of automa-

tion systems.

Content of this document:

Additionally to the CNC task the E·Control ENC66 controller can run a PLC program.

The manual is designed to generate a simple CNC program with the Eckelmann controller

E•ENC where particular previous knowledge of CNC programming is not required.

The manual supports you in creating your first CNC program and initiates you in the usage

of the PLC function as per IEC 61131-3 in connection with the CNC core.

Additionally the configuration of the controllers is explained for an effective commission-

ing.

Copyright protection:

All rights to any use whatever, utilisation, further development, forwarding and creation

of copies remain with the ECKELMANN AG company.

In particular, neither the contract partners of ECKELMANN AG nor other users have the

right to distribute or market the IT programs/program parts or modified or edited versions

without express written permission.

To some extent, names of products/goods or designations are protected for the respective

manufacturer (registered trademarks etc.); in any case, no guarantee is assumed for their

free availability/permission to use them.

The information provided in the description is given independently of any existing patent

protection or other third-party rights.

Errors and technical modifications are expressly reserved.

Release: Thomas Franzmann

Name in block letters

29.03.2011

Date

signed. Franzmann

Signature

4 / 97

Revision notification

Tabelle 1:

Tabelle 2:

Tabelle 3:

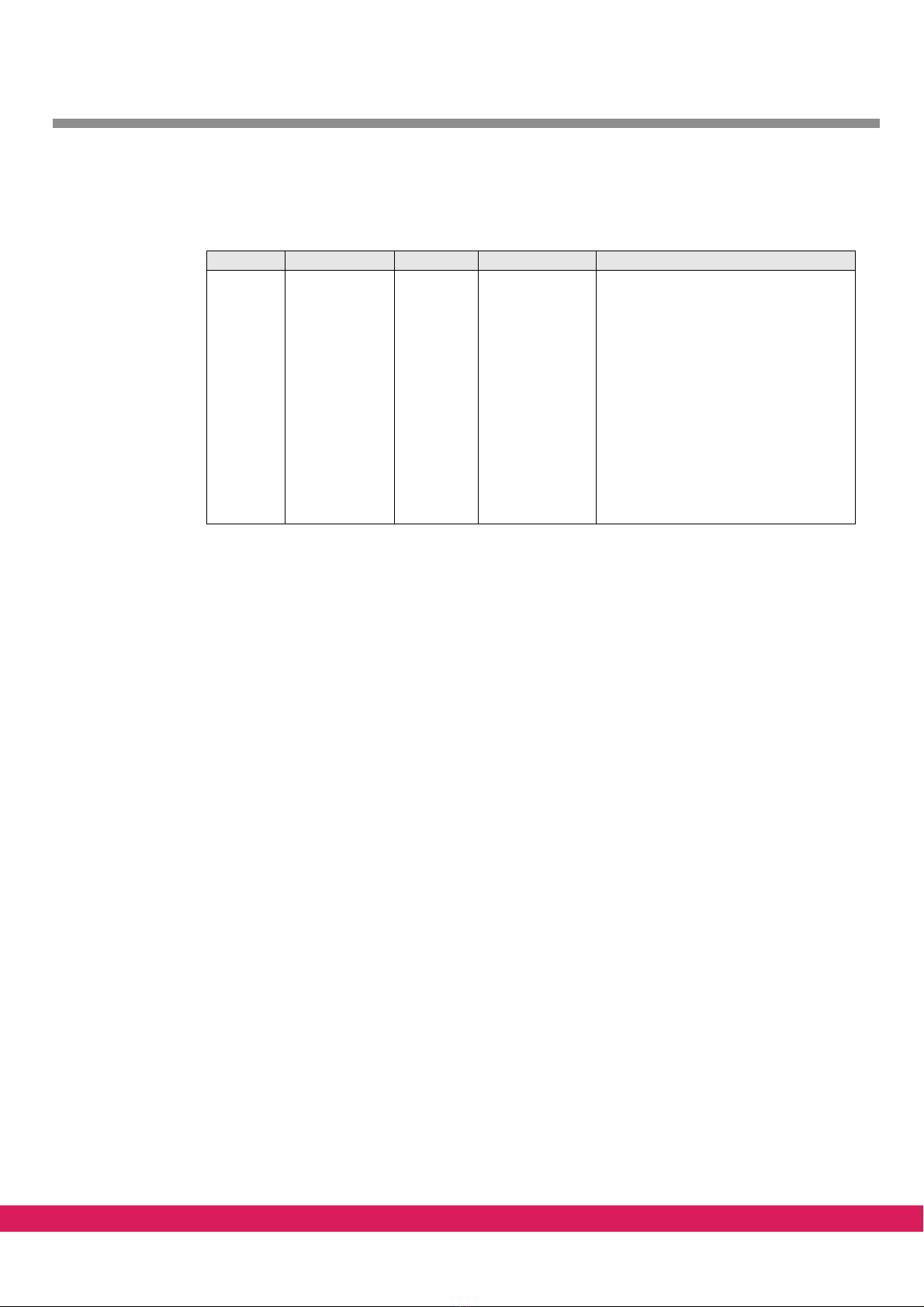

Version Chapter Date edited by Amendment

1 All 23.09.2010 Martin Kellner First release based on the introduc-

tion manual of the ENC55

21.4.6.229.03.2011 Martin Kellner- E108 and F703 added

- Data blocks corrected for diagnostic

address of the LBM modules

5 / 97

Introduction Manual ENC66

eckelmann.de

Table of Contents

1 Overview.............................................................................. 12

1.1 List of documents................................................................................................. 12

1.2 Controller family E-CONTROL CNC ..................................................................... 13

1.3 Variants „Stand-Alone“ and „With PC-HMI“..................................................... 14

1.4 Status information of the ExC66......................................................................... 15

1.4.1 Status information during booting .................................................................... 15

1.4.2 LEDs while booting .............................................................................................. 16

1.4.3 Status information during start of firmware ..................................................... 17

1.4.4 Status information in normal operation ............................................................ 18

1.4.5 The LEDs in normal operation............................................................................. 19

1.4.6 Error indication .................................................................................................... 20

1.4.6.1 Error indication during booting.......................................................................... 20

1.4.6.2 Error indication in normal operation ................................................................. 20

2 Connection and installation............................................... 22

2.1 Example of a structure......................................................................................... 22

2.2 Controller connection.......................................................................................... 22

2.3 Serial connection.................................................................................................. 24

2.4 Connection via Ethernet...................................................................................... 24

2.4.1 Connection via Ethernet (local connection) ....................................................... 25

2.4.2 Connection via Ethernet (network) .................................................................... 25

3 Monitor interface of the controller................................... 26

3.1 Running the terminal program........................................................................... 26

3.1.1 Configuration of the terminal program............................................................. 26

3.2 Calling of the monitor interface......................................................................... 28

3.3 Configuration of an Ethernet connection.......................................................... 30

3.4 Important monitor commands............................................................................ 32

3.5 Possible errors ...................................................................................................... 33

4 Setting of the IP address in the controller........................ 34

4.1 Setting of the IP address via the monitor interface (serial interface) .............. 34

4.2 Setting of the IP address via Ethernet (network or local) with NetConf.......... 35

4.2.1 Automatically display controllers in NetConf .................................................... 35

4.2.2 Change the IP address of a controller with NetConf......................................... 36

4.2.3 Configure gateway and subnet mask in NetConf.............................................. 37

4.2.4 Add a controller in NetConf manually ............................................................... 37

6 / 97

4.2.5 MAC address ........................................................................................................ 38

5 Update of the firmware via the boot monitor.................. 39

5.1 Access to the boot monitor................................................................................. 39

5.2 Check of the firmware version............................................................................ 40

5.2.1 Variant „with PC-HMI“........................................................................................ 40

5.2.2 Variant „Stand-Alone“ ........................................................................................ 40

5.3 Update of the firmware ...................................................................................... 40

5.4 Remove a firmware ............................................................................................. 42

5.5 Commands of the boot monitor......................................................................... 43

6 Parameterizing of the drives .............................................. 44

6.1 Parameterizing of the drives in detail................................................................ 44

6.2 Number of axes and CAN node addresses ......................................................... 44

6.3 Important machine constants ............................................................................. 45

6.4 Machine constants file......................................................................................... 48

6.5 Loading of a file with machine constants into the controller .......................... 49

6.6 Synchronized and gantry axes ............................................................................ 50

6.6.1 Example of synchronized axes at the CAN-Bus .................................................. 50

6.6.2 Example of synchronized axes with analog interface ....................................... 52

6.6.3 Example of a gantry axis with CAN-Bus ............................................................. 53

7 CNC programming as per DIN 66025.................................. 54

7.1 G-functions........................................................................................................... 54

7.2 M-functions .......................................................................................................... 56

8 StdHMI .................................................................................. 57

8.1 Installation StdHMI .............................................................................................. 57

8.2 Starting the StdHMI............................................................................................. 57

8.3 Modifying machine constants............................................................................. 58

8.4 Checking the drives ............................................................................................. 59

8.5 Individual manual checking of drives in jogging mode .................................... 60

8.6 Programming as per DIN 66025 .......................................................................... 60

8.6.1 The program editor ............................................................................................. 61

8.6.2 Editing the program ............................................................................................ 62

8.6.3 Saving the DIN program...................................................................................... 63

8.6.4 Loading a program into the controller .............................................................. 63

8.6.5 Starting of the program in the controller .......................................................... 64

7 / 97

Introduction Manual ENC66

eckelmann.de

8.6.6 Extending of the program for the lowering of the tool ................................... 65

8.7 Exiting of the program StdHMI........................................................................... 68

8.8 Changing the user language of the program StdHMI....................................... 68

8.9 Changing the colour setting of the graphical display ....................................... 68

9 Generating of a PLC program with ETOOLS PLC2 ............. 70

9.1 Programming – Software ETOOLS PLC/2 ............................................................ 70

9.2 Installation ETOOLS PLC/2 (CoDeSys) .................................................................. 70

9.3 Hardware.............................................................................................................. 70

9.4 Configuration of a controller in ETOOLS PLC/2 ................................................. 71

9.4.1 Calling of the program E-Tools PLC/2 ................................................................. 72

9.4.2 General instructions for the address mapping of IO modules .......................... 73

9.4.2.1 Limitations of FBM modules................................................................................ 73

9.4.2.2 General instructions for the PLC configuration with LBM modules ................. 73

9.4.3 PLC configuration ................................................................................................ 74

9.4.3.1 Add and configure LBM modules ....................................................................... 75

9.5 Task configuration ............................................................................................... 77

9.6 Changing of the language german / english ..................................................... 77

10 Sample PLC program........................................................... 79

10.1 Sample program CNC Test................................................................................... 79

10.2 Required libraries................................................................................................. 79

10.3 System variable and data block .......................................................................... 79

10.4 Task for the M-functions M14 and M15 ............................................................. 80

10.5 Calling of the program ........................................................................................ 81

10.6 Sequential function cart ...................................................................................... 81

10.7 Definition of inputs and outputs ........................................................................ 82

10.8 Function START_STOP.......................................................................................... 83

10.9 Function RELEASE_SIGNAL_HANDLER ................................................................ 83

10.10 Function M_FUNCTIONS ...................................................................................... 83

10.11 Loading of the program into the controller ...................................................... 85

10.11.1 Serial connection.................................................................................................. 85

10.11.2 Network connection ............................................................................................ 86

10.11.3 Loading of the program ...................................................................................... 87

10.11.4 Starting of the program in the controller.......................................................... 88

10.11.5 Stopping of the program in the controller ........................................................ 88

10.11.6 Reset of the data memory in the controller....................................................... 88

10.11.7 Permanent storage of the program in the controller (boot-project) ............... 88

10.11.8 Termination of communication with the controller.......................................... 89

8 / 97

11 Testing of the CNC and PLC program ................................. 90

11.1 Connection of the controller inputs ................................................................... 90

11.2 Loading and starting the PLC program .............................................................. 90

11.3 Loading and starting of the CNC program ........................................................ 90

11.4 Error messages of the CNC program .................................................................. 91

9 / 97

Introduction Manual ENC66

eckelmann.de

Conventions

General notes

A general note is composed of three parts:

1. The letter „i“

2. A blue bar with the word „Note“

3. The text of the note below the bar

Example:

x

Note

Please observe that the extended interface generates a bus load, which is higher by approx.

50 %.

10 / 97

Explanations regarding the safety instructions

Safety instructions and hazard warnings are composed of five parts:

1. An icon at the margin

2. A bar with the signal word, the colour of which depends on the danger level.

3. A short, clear description of the danger

4. A description of possible consequences

5. A list of measures for danger prevention

Example:

x

DANGER

High voltage in power supply unit

Severe injuries or death due to electric shock

• Pull off mains plug prior to open the housing

• Do not put objects in the venting slots during operation

The danger levels are described in the following table:

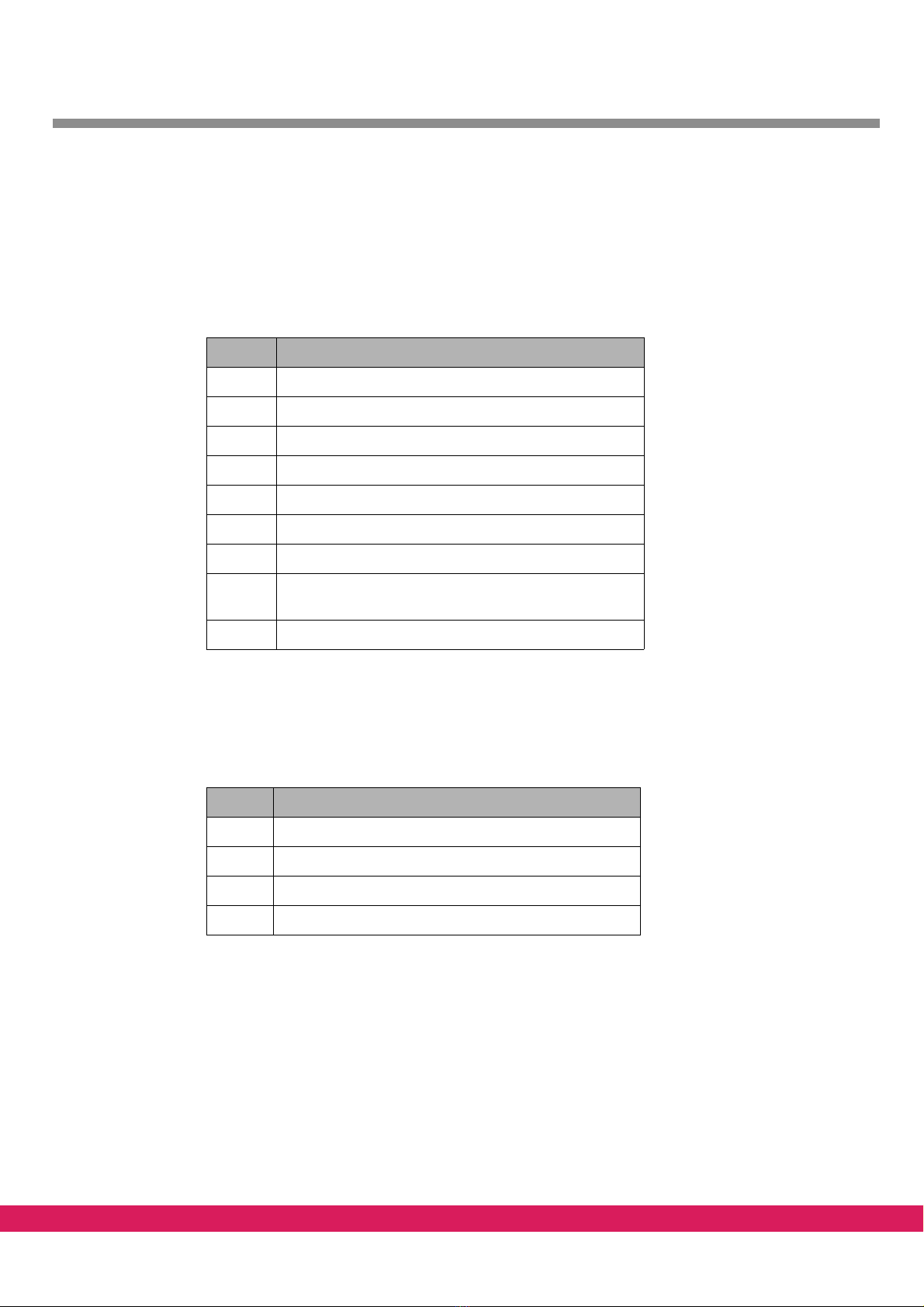

Tabelle 1:

Table 1: Warning levels

Marking bar Warning level

Severe consequential damage such as death or irreversible

injuries

Imminent hazardous situation if the precautions are not observed.

Severe consequential damage such as death or irreversible

injuries

Potentially hazardous situation if the precautions are not observed.

Slight injuries (reversible)

Potentially hazardous situation if the precautions are not observed.

Property damage

Devices may be damaged if the precautions are not observed.

DANGER

WARNING

CAUTION

NOTICE

11 / 97

Introduction Manual ENC66

eckelmann.de

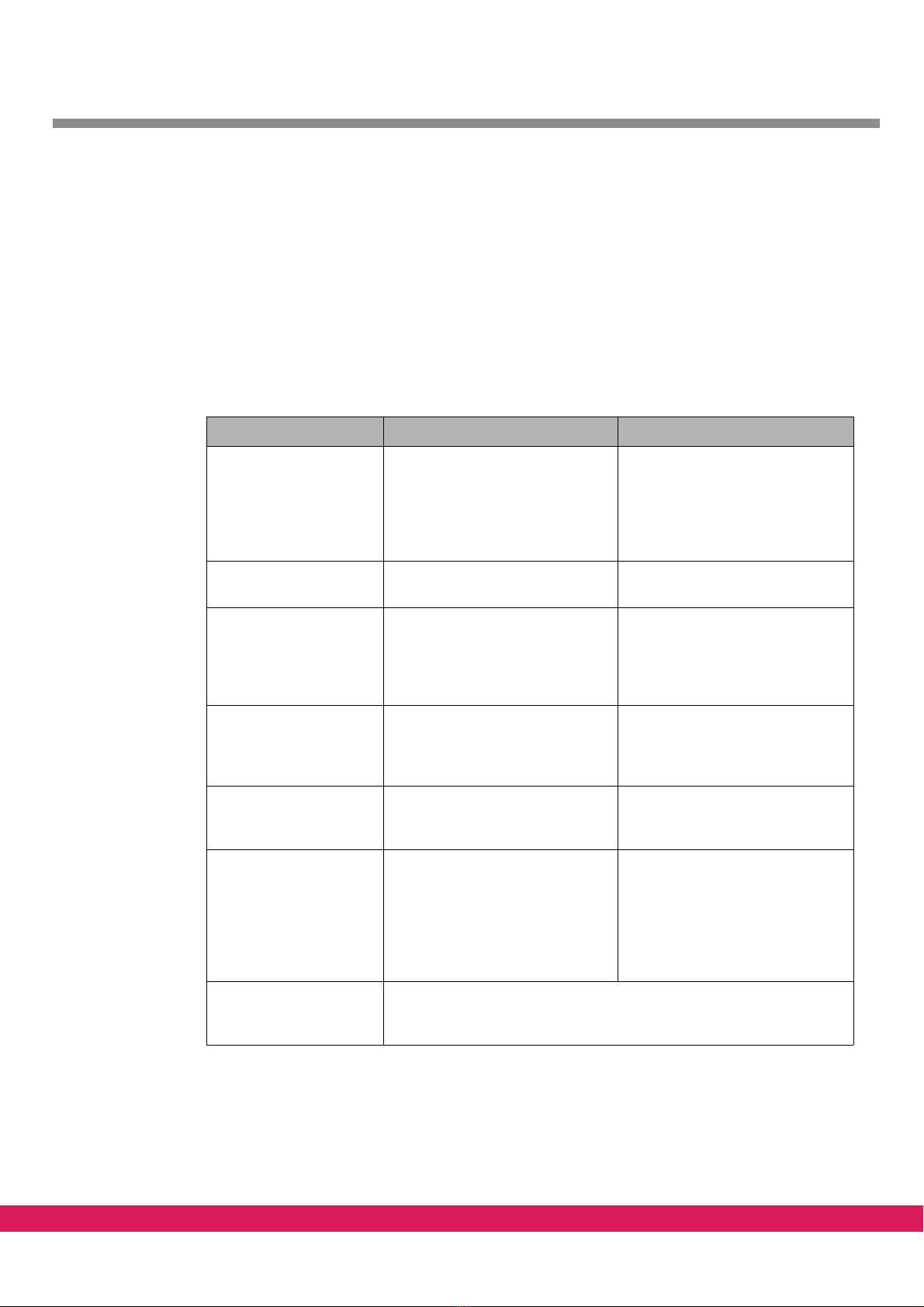

Warning signs

Tab el le 2 :

Table 2: Warning signs

Pictograph Warning Possible consequences

Warning of general

danger

Nonobservance of the warning may cause property

damage and/or personal injuries (in extreme cases,

most severe injuries or death).

Warning of dangerous

electric voltage

Nonobservance of the warning may cause death or

most severe injuries.

Warning of hot surfaces Nonobservance of the warning may cause burning

of the skin.

Warning of contusions Nonobservance of the warning may cause contu-

sions or bone fractures.

Warning of damage to

the electronics

Nonobservance of the warning may destroy elec-

tronic components in the system due to ESD (elec-

trostatic discharge), overload or wrong connection.

Warning of mechanical

damage to the machine

Nonobservance of the warning may damage or

even destroy machine parts.

12 / 97

1Overview

1.1 List of documents

The manual makes reference to other documents that include the respective details.

Tabelle 3:

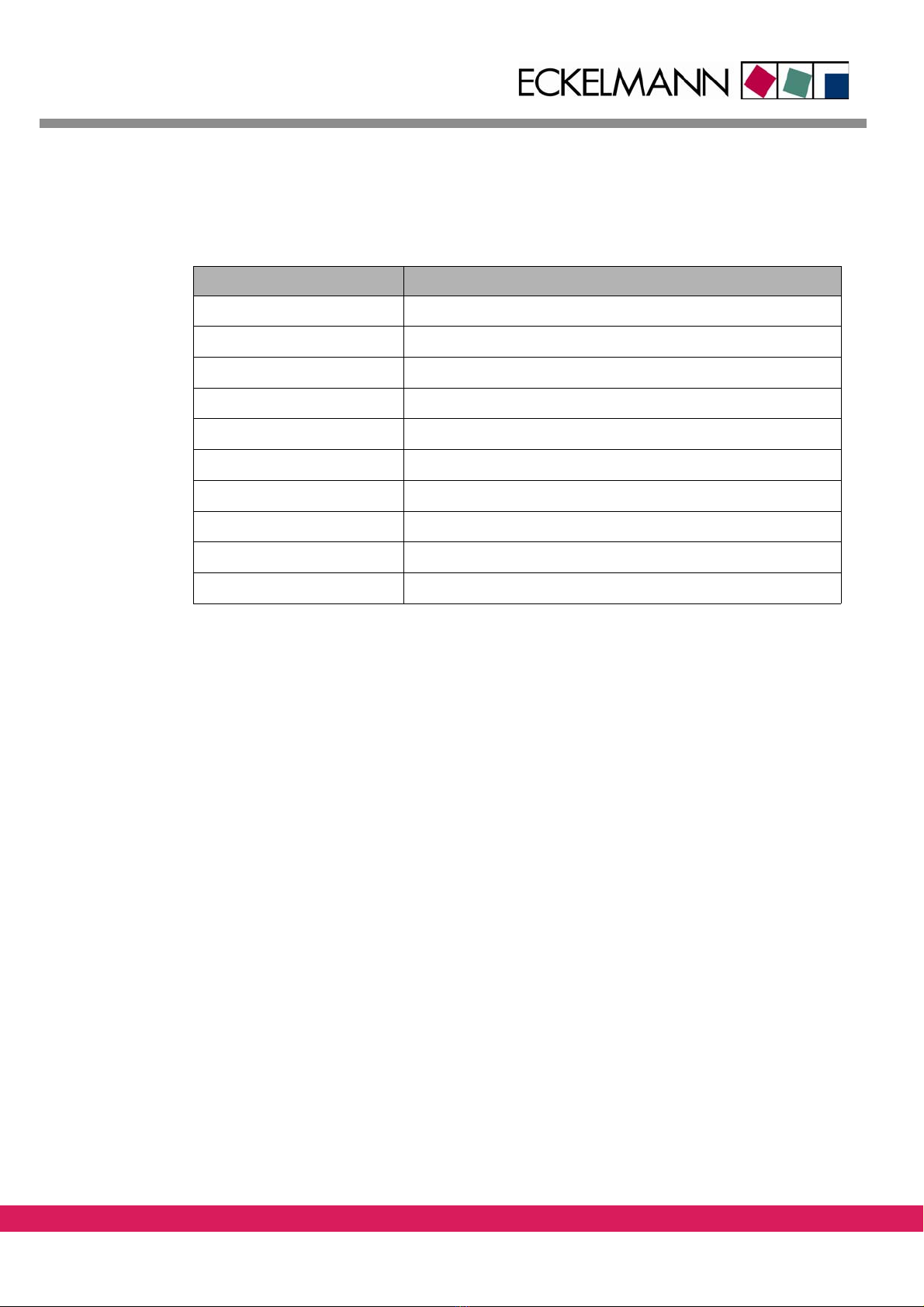

Table 3: List of documents

Manual

/1/ User manual PLC/2 for CNC

/2/ Installation manual Standard HMI

/3/ User manual Standard HMI

/4/ Communication protocols

/5/ different technical manuals for FBM modules Diverse

/6/ ECNC configuration manual

/7/ ECNC programming instruction manual

/8/ ECNC configurations instructions

(interface PLC<->NCR)

/9/ Technical manual for LBM modules

This document also makes reference to the following technical descriptions of the control-

lers.

Tabelle 4:

Table 4: List of technical descriptions

Manual

/A/ ExC66 Technical Description

/B/ ExC55 Technical Description

/C/ PNC55 Technical Description

/D/ CNC55 Technical Description

13 / 97

Introduction Manual ENC66

eckelmann.de

1.2 Controller family ECONTROL CNC

Abbildung 1:

The controller family E-Control CNC comprises the ENC66, ENC55,

PNC55 and CNC55 controllers.

This manual describes the ENC66 controller, that is designed for top

hat rail mounting.

The memory size and the number of interfaces depends on the or-

dered configuration.

The configuration code is an extension of the order number and is

part of the type label. The type label is on the bottom side of the

ENC66.

Figure 1: ENC66

The controller has the following features:

• Numerical controller (CNC) for 2 to 16 axes (depending on the ordered configura-

tion)

• CNC programming as per DIN 66025

• Integrated PLC function, programming as per IEC 61131-3

• 2 to 4 CAN busses (depending on the ordered configuration)

• Usage of local bus modules (LBM) for inputs and outputs and for analog CNC axes

• Connection of field bus modules for inputs and outputs

• Memory extension via SD card slot and USB

You can find more details in /A/.

14 / 97

1.3 Variants „Stand-Alone“ and „With PC-HMI“

On principle, the controllers can be operated in 2 different operating modes:

• The variant „Stand-Alone“ starts with the firmware immediately after the application of

the voltage

• The variant „With PC-HMI“ waits after the application of the voltage for the loading of a

firmware from a PC via the program StdHMI

The variant „With PC-HMI“ is the standard variant that is supplied. The table shows the two

variants in comparison:

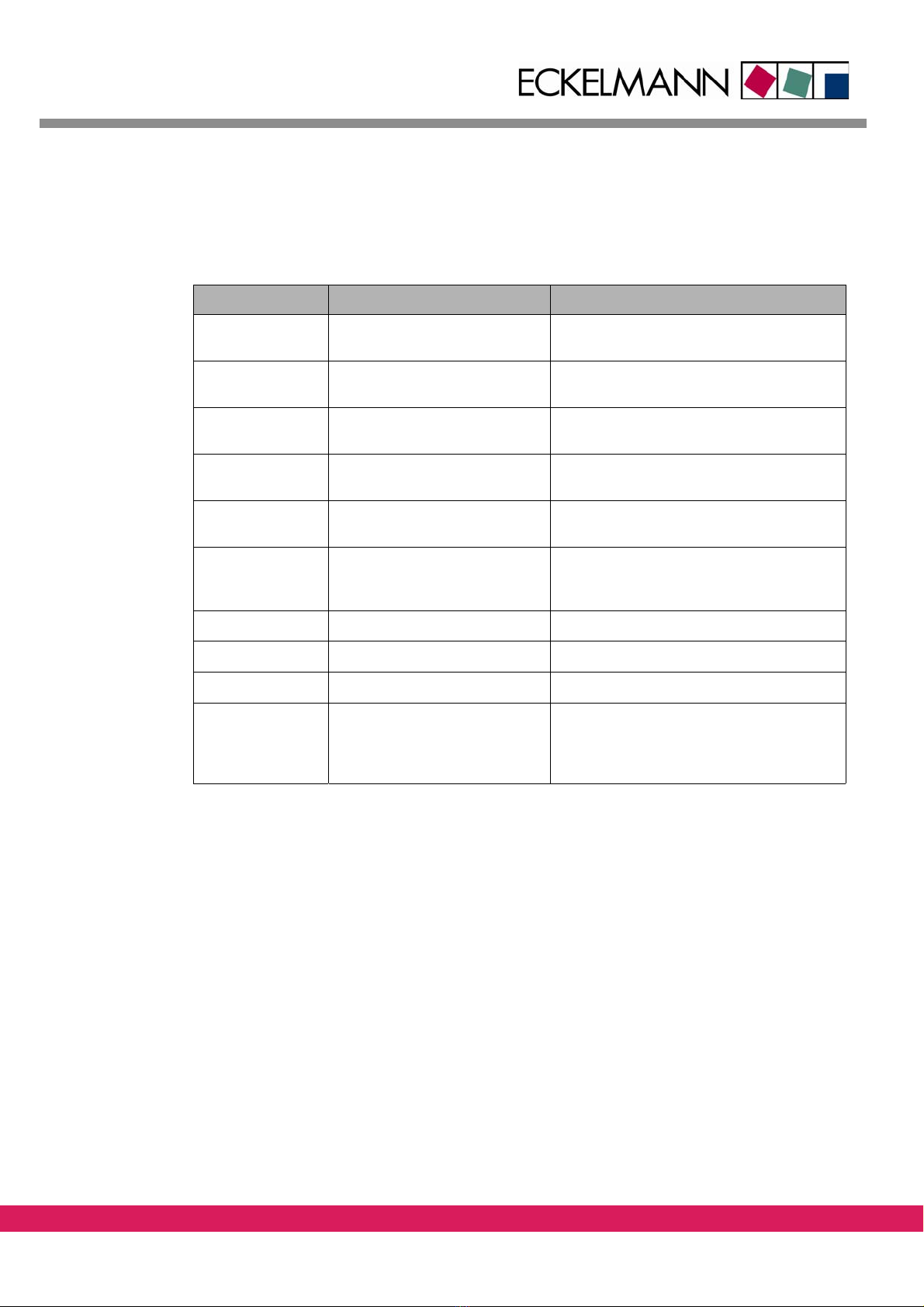

Tabelle 5:

Table 5: Operating modes PC-HMI and Standalone in comparison, ENC66

With PC-HMI Stand-Alone

Use The controller operates a

machine by means of coupling

with a PC with graphical user

interface, the PC is used for the

loading of programs and for the

operation of the controller

The controller operates a

machine without

further coupling with a PC

Firmware installed on

the controller

Bootloader Bootloader

NC-Firmware

Installation of the

firmware

No additional software is neces-

sary. The NC firmware is loaded

from the PC after the starting of

the StdHMI by means of the

bootloader.

The NC firmware is installed by

the bootloader into the control-

ler FPROM memory

Behaviour of the con-

troller after the appli-

cation of the voltage

Upon application of the voltage,

the controller waits for the load-

ing of the NC firmware via the PC

Upon application of the voltage,

the controller starts automati-

cally the bootloader and then

the NC firmware

7-segment indicator

after application of

the voltage

Two adjacent segments rotate in

clockwise direction

The 7-segment display works as

described in chapter 1.4

Starting of the NC

firmware

The NC firmware is available on

the PC and is loaded after the

starting of the graphical user

interface StdHMI from the PC

into the controller RAM by

means of the bootloader and is

started

The NC firmware is loaded from

the FPROM memory into the

RAM by means of the boot-

loader. Then the NC firmware is

executed in the RAM.

7-Segment indicator

after starting the NC

firmware

Each segments of the 7-segment indicator are assigned to a system

task. The brightness of the various segments corresponds to the com-

puting load of the single tasks in the system.

15 / 97

Introduction Manual ENC66

eckelmann.de

The following files are reserved for the firmware of the controllers:

Tab el le 6 :

Table 6: Firmware files

File Description Installation via bootloader

BOOT66.BIN Bootloader for installing the NC

firmware. It has netboot functionality to

reload the firmware via the StdHMI

ENC66.RSC NC firmware for the ENC66 x

Other filenames with the extension „.rsc“ and the name „boot*.bin“ must not be used.

1.4 Status information of the ExC66

Besides 3 status LED, a 7-segment indicator is available on the assembly which indicates the

current operating state and probable faults of the assembly, depending on the operating

state.

In current operation, the 7-segment indicator is used as status information. In case of a soft-

ware error, the occurring error is indicated in the form of a defined string of characters.

The green LED indicates the watchdog function and is lit if no malfunction occurs. The two

other LED are used to indicate the CAN1 state. In case of the 7-segment indication a distinc-

tion is made between booting and operation.

1.4.1 Status information during booting

At the beginning of booting, a memory test is made and the firmware is loaded. In this

phase, the following indications are made.

Tab el le 7 :

Table 7: 7-segment indicator, Status information during booting

7-segment indicator Meaning

0Hardware initialization

1RAM test

2Initialization terminated

3Loading of firmware from FROM to RAM

4Firmware loaded

5Firmware started

16 / 97

1.4.2 LEDs while booting

The single LED on the front panel indicate the following state and meaning during boot-

ing.

Tabelle 8:

Table 8: LEDs while booting, ENC66

LED Indication Meaning

WDOG Off Watchdog is not triggered in bootloader

CAN1/LED1 Off Not used

CAN1/LED2 Off Not used

CAN2/yellow Off Not used

CAN2/green Off Not used

RS232/green Off or flashing light RS232/TX state (indicates transmitting of data)

RS232/green Off or flashing light RS232/RX state (indicates receiving of data)

ETHERNET/yellow Flashing light Ethernet/ activity status

ETHERNET/green Off or on Ethernet/ connect status

CAN3/green Off Not used

CAN3/green Off Not used

CAN4/green Off Not used

CAN4/green Off Not used

17 / 97

Introduction Manual ENC66

eckelmann.de

1.4.3 Status information during start of firmware

The firmware is started after booting. The following indications are made in this phase.

Tab el le 9 :

Table 9: 7-segment indicator, Status information during start of the firmware, ENC66

7-segment indicator Meaning

0Initialization of processor

1Initialization of software

2Initialization of operating software

3Initialization of task and mailbox

4Initialization of I2C hardware

5Initialization of file system

6Initialization of local bus

7Hardware check

Flashing light of segment Normal state acc. to description in /A/

Continuous error number Error state acc. to tables in chapter 1.4.6.1

18 / 97

1.4.4 Status information in normal operation

After the start of the firmware, the controller changes to normal operation.

The single segments of the 7-segment indicator are assigned to a system task each. The

brightness of the various segments corresponds to the computing load of the single tasks

in the system.

The assignment is as follows:

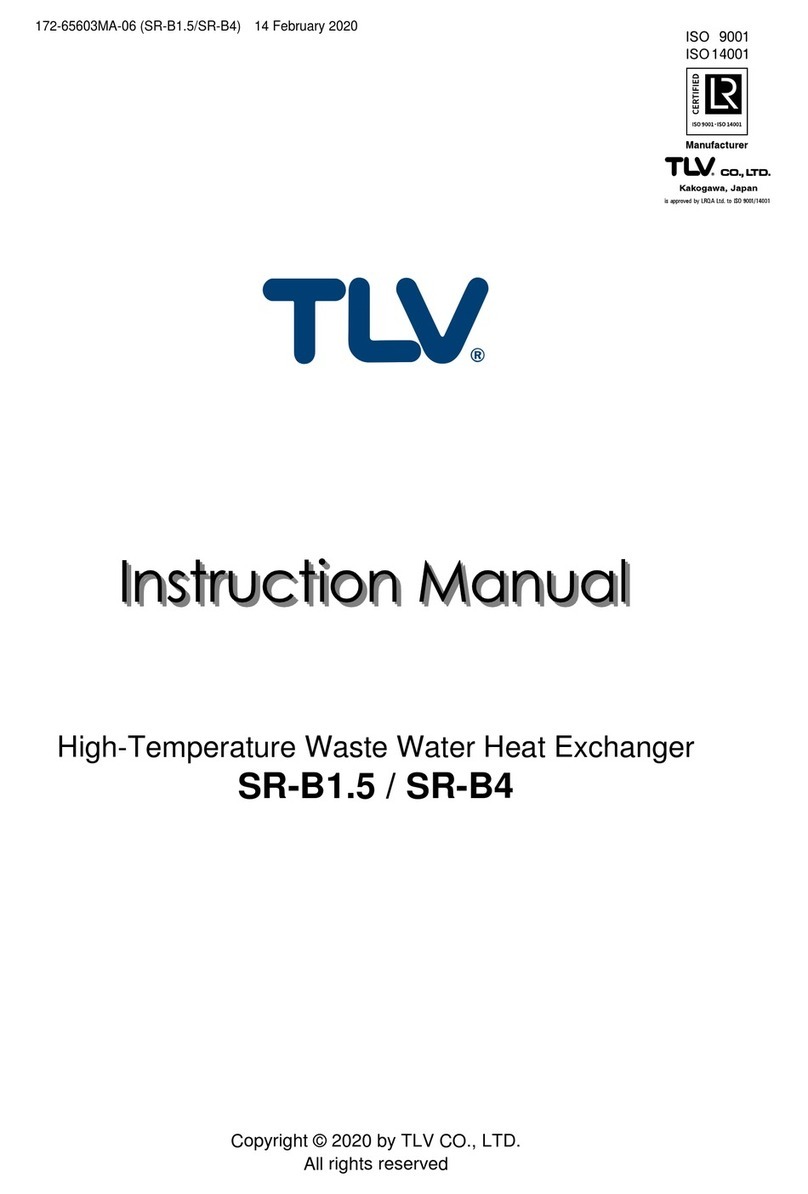

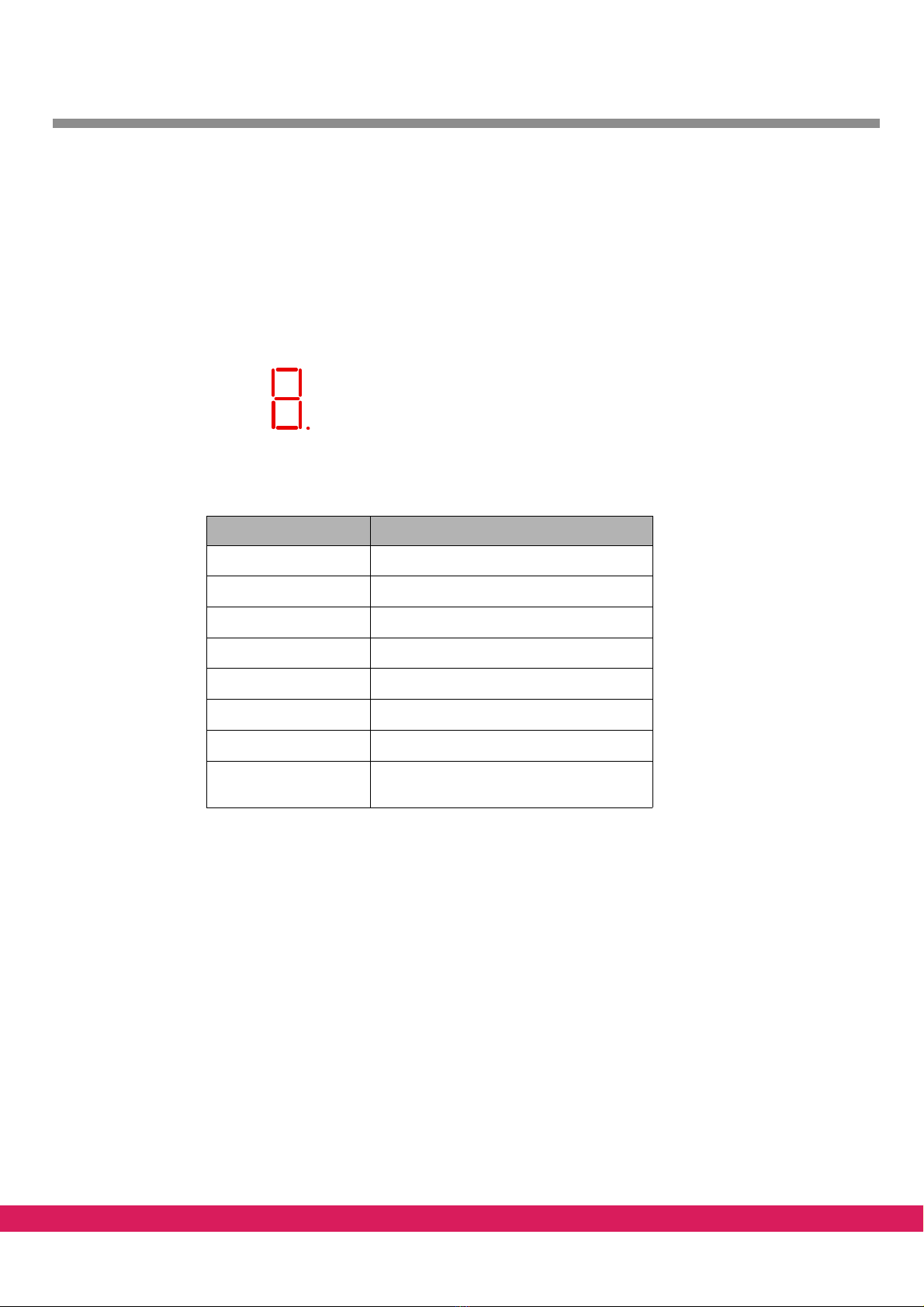

Abbildung 2:

a

b

c

d

e

fg

h

Figure 2: 7-Segment indicator

Tabelle 10:

Table 10: Status information in normal operation, ENC66

Segment Meaning

aPLC (PLC program)

bSRV (Services)

cAXE (fine interpolator)

dZST (central controller)

eINT (interpreter)

fPOS (interpolator)

gNET (Ethernet communication)

h (dot) Pulses in the rhythm of interpolator

(freq=1/MK_DELTAT [Hz])

19 / 97

Introduction Manual ENC66

eckelmann.de

1.4.5 The LEDs in normal operation

The state of the single LED in normal operation is described in the respective chapters of /

A/. The following table gives an overview:

Tab el le 1 1: .

Table 11: LEDs in normal operation, ENC66

LED Indication Meaning

WDOG On:

Off:

Watchdog ok

Error: Watchdog is de-energized

CAN1/LED1 Flashing light:

Flashing at 2 Hz:

RX-Status ok

RX-Error-Counter>13

CAN1/LED2 Flashing light:

Flashing at 2 Hz:

TX-Status ok

TX-Error-Counter>13

CAN2 to CAN4

yellow

Flashing light:

Flashing at 2 Hz:

TX-Status ok

TX-Error-Counter>13

CAN2 to CAN4

green

Flashing light:

Flashing at 2 Hz:

RX-Status ok

RX-Error-Counter>13

CAN2 to CAN4

green and yellow

synchronous

Synchronous flashing at 1 Hz:

Synchronous flashing at 0,5 Hz

State error passive

State bus-off

RS232/yellow Flashing light: Transmitting of data (TX-Status)

RS232/green Flashing light: Receiving of data (RX-Status)

ETHERNET/yellow Flashing light: signals data transfer via RX or TX

ETHERNET/green Off:

On:

no ethernet connection available

as soon as an ethernet connection is estab-

lished (result of the internal link integrity

test)

20 / 97

1.4.6 Error indication

1.4.6.1 Error indication during booting

Probable errors in the booting phase are signalled by the following indication pattern. The

indication shows the pattern sequentially with 2 characters/sec. The indication is made until

the controller is reset (exception: start of the boot monitor).

Tabelle 12:

Table 12: Error indication during booting, ENC66

7-segment indicator Meaning Start of boot

monitors

E01 RAM error

E02 Checksum error in boot loader (FPROM)

E05 unknown FPROM type

E06 Error during loading of firmware from FPROM x

E07 Error during start of firmware x

E88 Processor exception

A running light in the 7-segment indicator (two adjacent segments rotating in clockwise di-

rection) shows that the boot monitor is active.

The boot monitor is activated either by the user or by the boot loader, if the start of the

operating system has not been made successfully after E06 and E07.

1.4.6.2 Error indication in normal operation

Probable errors are signalled by the following indication pattern. The indication shows the

pattern sequentially with 2 characters/sec. The indication is made until the controller is re-

set.

Tabelle 13:

7-segment

indicator

Meaning

E104 ZST / I2C initialization failed

E105 ZST / EEPROM initialization failed

E106 ZST / RTC initialization failed

E107 UTI / Power failure of real-time clock, time invalid

E108 ZST / Identification of the ExC66-expansion card failed

F001 SYS / Incorrect segment at freemem()

F002 SYS / Invalid segment at freemem

F003 SYS / Invalid argument at PutMsg()

F004 SYS / Unexpected termination of a task

Table 13: Error indication in normal operation, ENC66

Table of contents