Important Information

The following information is a revised version of MYDATA

Service Bulletin 98015.

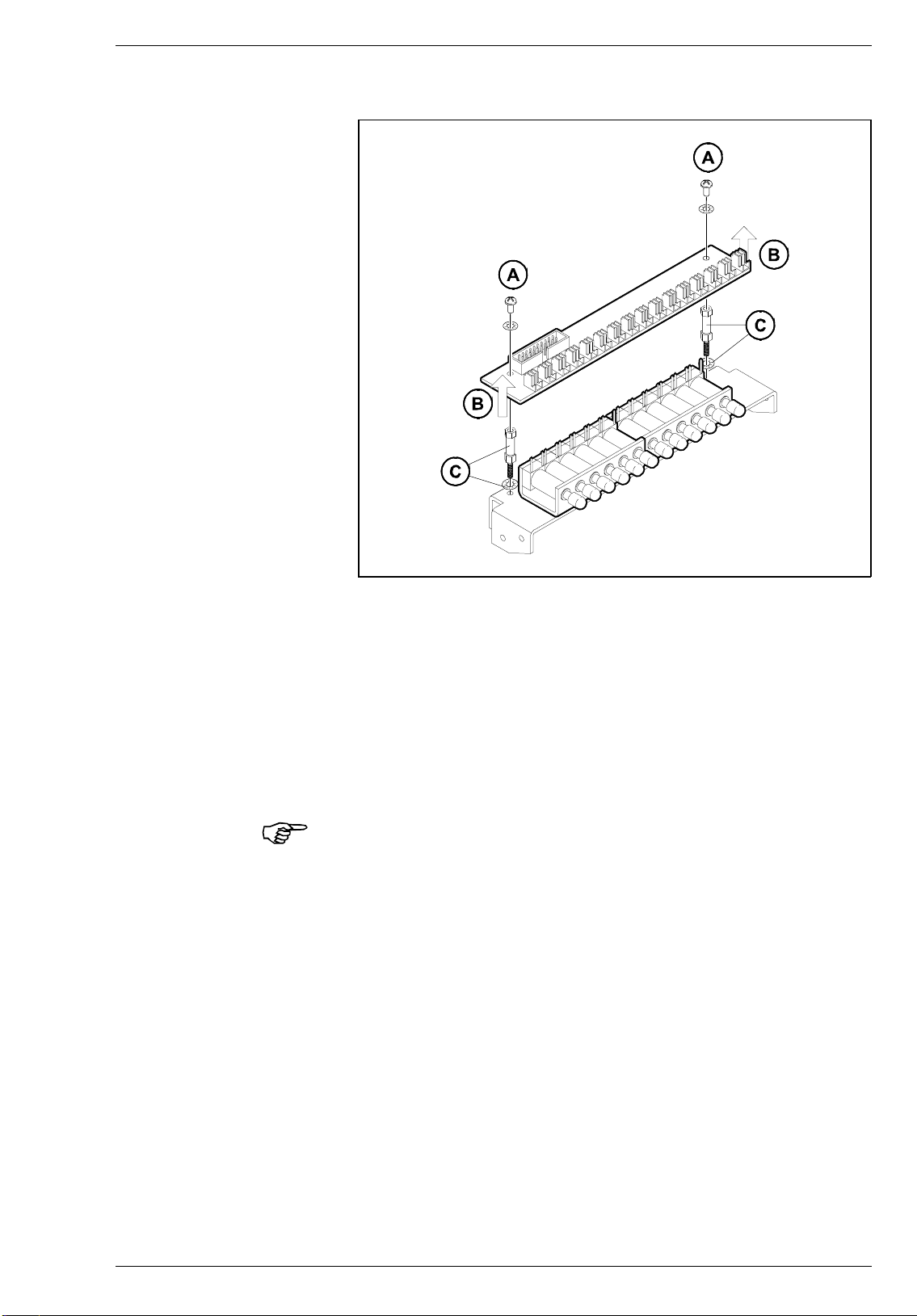

Feeder Wheels

The purpose of the TM8C upgrade is to reduce the feeder wheel

spacing, i.e. the thickness of the feeder wheels plus the feeder

wheel spacers.

This is achieved by changing to slightly thinner feeder wheel

spacers.

Thinner wheels There are, however, feeder wheels that are slightly thinner than

normal, and these wheels must not be further compensated by

being upgraded.

Upgrading such a magazine makes the pick position distance

between adjacent feeders to be less than 10mm, causing a high

reject rate if a HYDRA system is used. And, it can make the

entire feeder wheel pack to be too short, causing an inadequate

friction.

Which wheels are thinner? A batch of feeder wheels manufactured in the summer of 1997

are slightly thinner than normal.

These wheels are transparent and they are found in TM8C

magazines with the serial number most likely within the serial

number interval 14704 - 14724, but they might be found within

the larger serial number interval 14022 - 15298.

How to test the wheels? Before upgrading any TM8C magazines with the above serial

numbers, check the feeder wheel thickness as follows:

•Put the magazine with the old transparent spacers in the

machine.

•Using the positioning camera, measure the distance between

magazine feeder 1 and feeder 16. A piece of white tape on these

two feeders can be used to find a reference.

Normal wheels If the measured distance is more than 150.2mm, then the feeder

wheels are normal and the upgrade can be performed as described

on the following pages.

Thinner wheels If the measured distance is less than 150.2mm, then the feeder

wheels are thinner than normal and you can choose one of the

following two actions:

•Keep the present wheels and transparent spacers, provided the

distance is correct, see below. In this case, put an extra label

beside the Revision 1 label referring to Service Bulletin 98015.

The revision label is mentioned on page 16.

•Renew all the feeder wheels and all the feeder wheel spacers.

Correct distance The correct distance between feeder 1 and feeder 16 is from

149.7mm to 150.3mm, measured as described above.

0<'$7$DXWRPDWLRQ$% Magazine Upgrade Guide

Magazine Upgrade Guide P-014-0866-EN Rev. 2A 1999-06 2