Date May 23rd 2024 Current on the internet at www.maedler.de Page 3 from 4

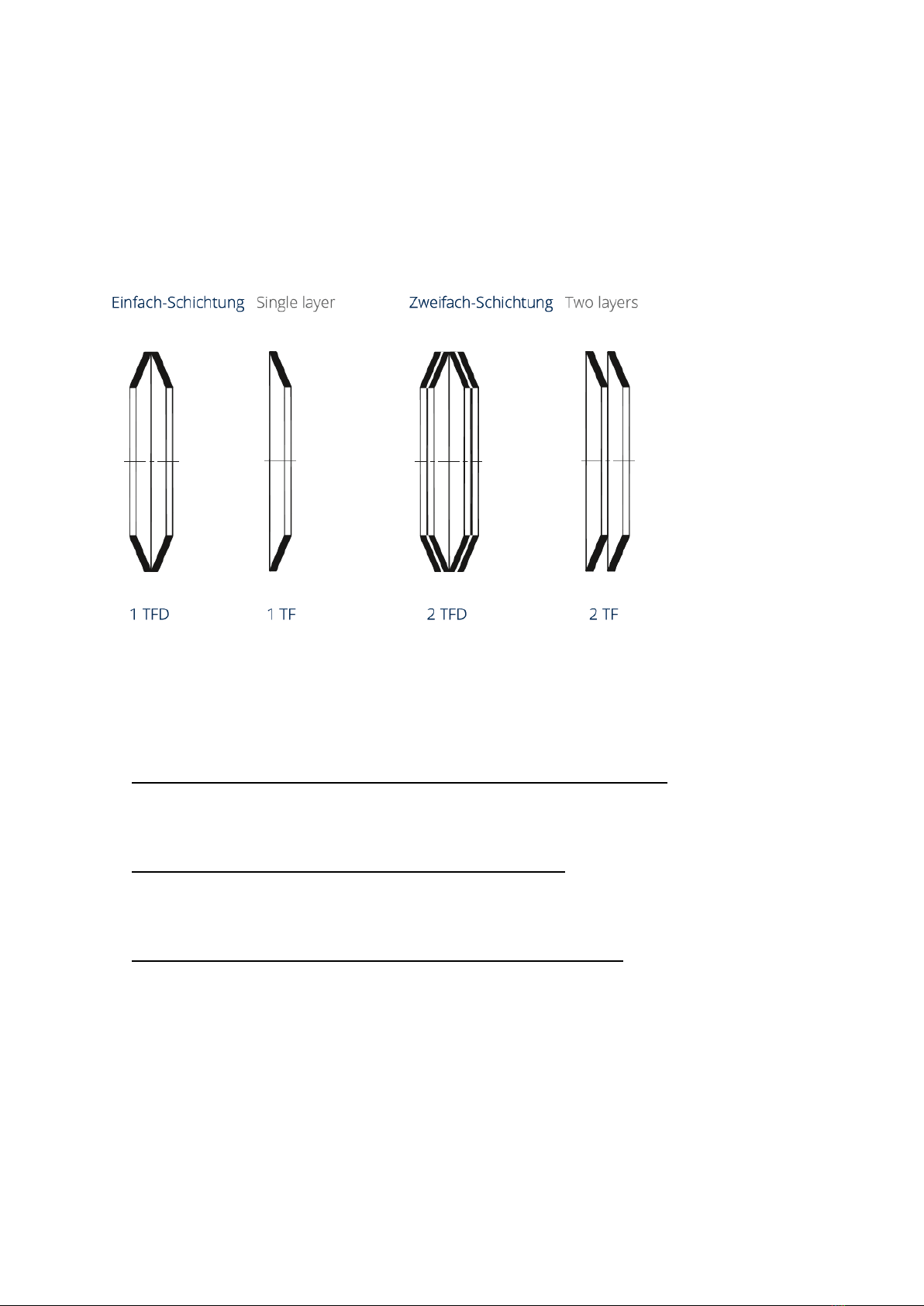

Springs, Quantity and Mounting Direction

At the various sizes, there are different numbers of springs:

Size 120-1: 2 springs Size 120-2: 4 springs

Size 180-1: 1 spring Size 180-2: 2 springs

Size 250-1: 1 spring Size 250-2: 2 springs

Size 350-1: 1 spring Size 350-2: 2 springs

Size 500-1: 1 spring Size 500-2: 2 springs

Size 700-1: 1 spring Size 700-2: 2 springs

120-1 180-1 up to 700-1 120-2 180-2 up to 700-2

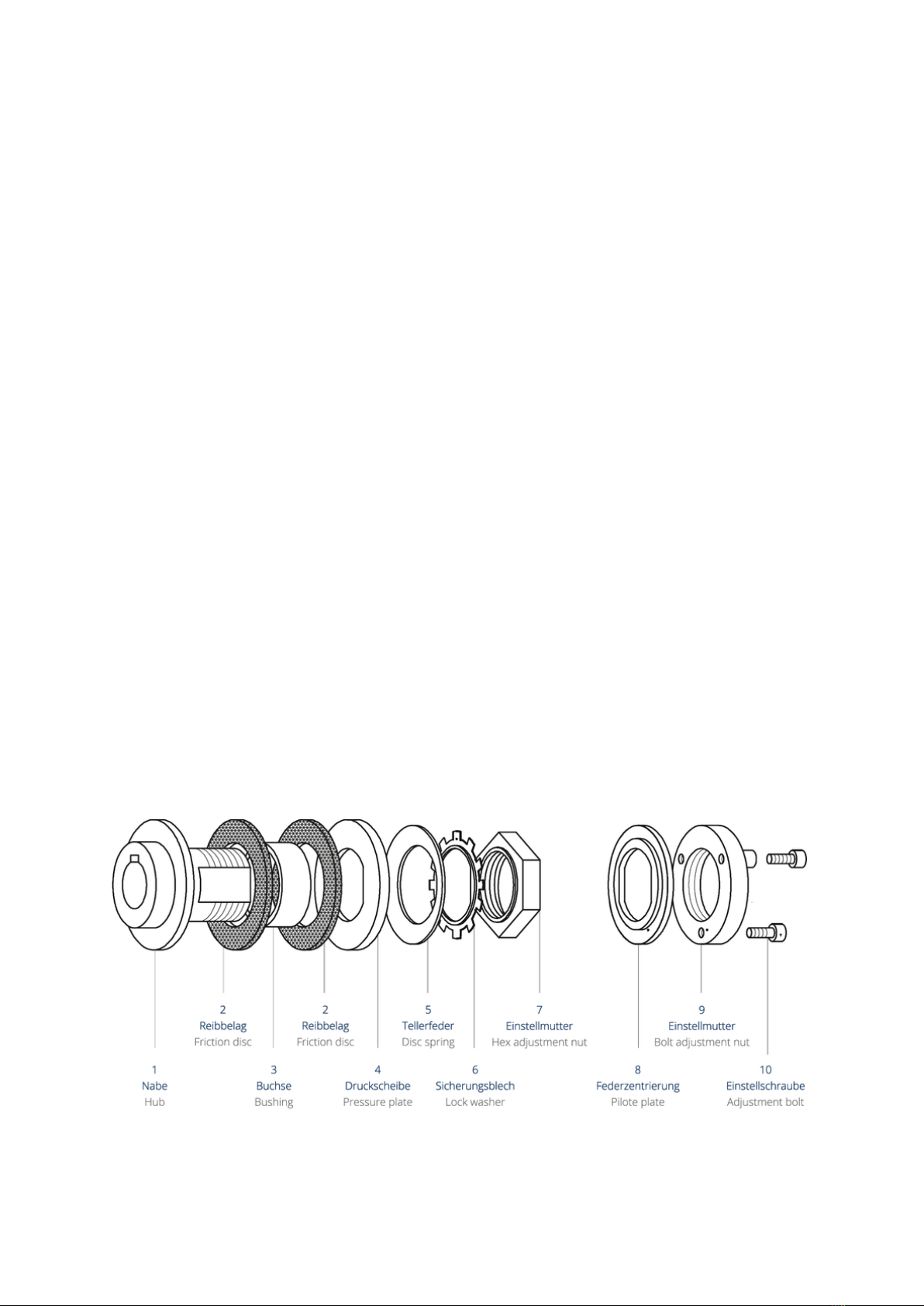

Torque Setting for Torque Limiters

- Types with round nut with clamp screw (product no. 612 000 00 - 612 006 00):

The spring must be pre-loaded by turning the adjustment nut (60°-steps, see table on page 4).

The disk spring must not be completely flattened. After adjusting, the clamp screw must be

tightened by hand.

- Types with hexagon nut (product no. 612 010 00 - 612 040 00):

The spring must be pre-loaded by turning the adjustment nut (60°-steps, see table on page 4).

The disk spring must not be completely flattened. After adjusting, a few flaps of the lockwasher

must be bent.

- Types with round nut with axial bolts (Art.-Nr. 612 050 00 - 612 080 00):

First screw back the three adjustment bolts, so that they don´t protrude. Then hand tightening the

nut. Screw the three adjustment bolts fully into the nut. The maximum torque has now been set.

When a lesser torque setting is desired, the three adjustment screws have to be turned back into

the nut to allow the nut to be turned counterclockwise in 60° increments in accordance with the

table on page 4). Then the three screws have to be screwed completely into the nut again.

Locking after Torque Setting

The sizes 120 and 180 have a round nut with clamp screw. After adjusting, the clamp screw must

be tightened by hand. The sizes 250 and 350 have a crowned lock washer. After adjusting,

several flats must be bent to the nut. The sizes 500 and 700 have not a lock washer, but

adjustment bolts. After adjusting, these bolts must be tightened:

Size 500, screws M8: 18 Nm.

Size 700, screws M10: 38 Nm.